Energy-saving and environment-friendly solar reactor for hydrogen production by methanol reforming

A reforming reaction, energy saving and environmental protection technology, applied in the direction of hydrogen, energy input, hydrogen/synthesis gas production, etc., can solve the problem of low solar energy utilization rate, environmental pollution, waste heat recovery, optical optimization and enhanced support tail gas treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

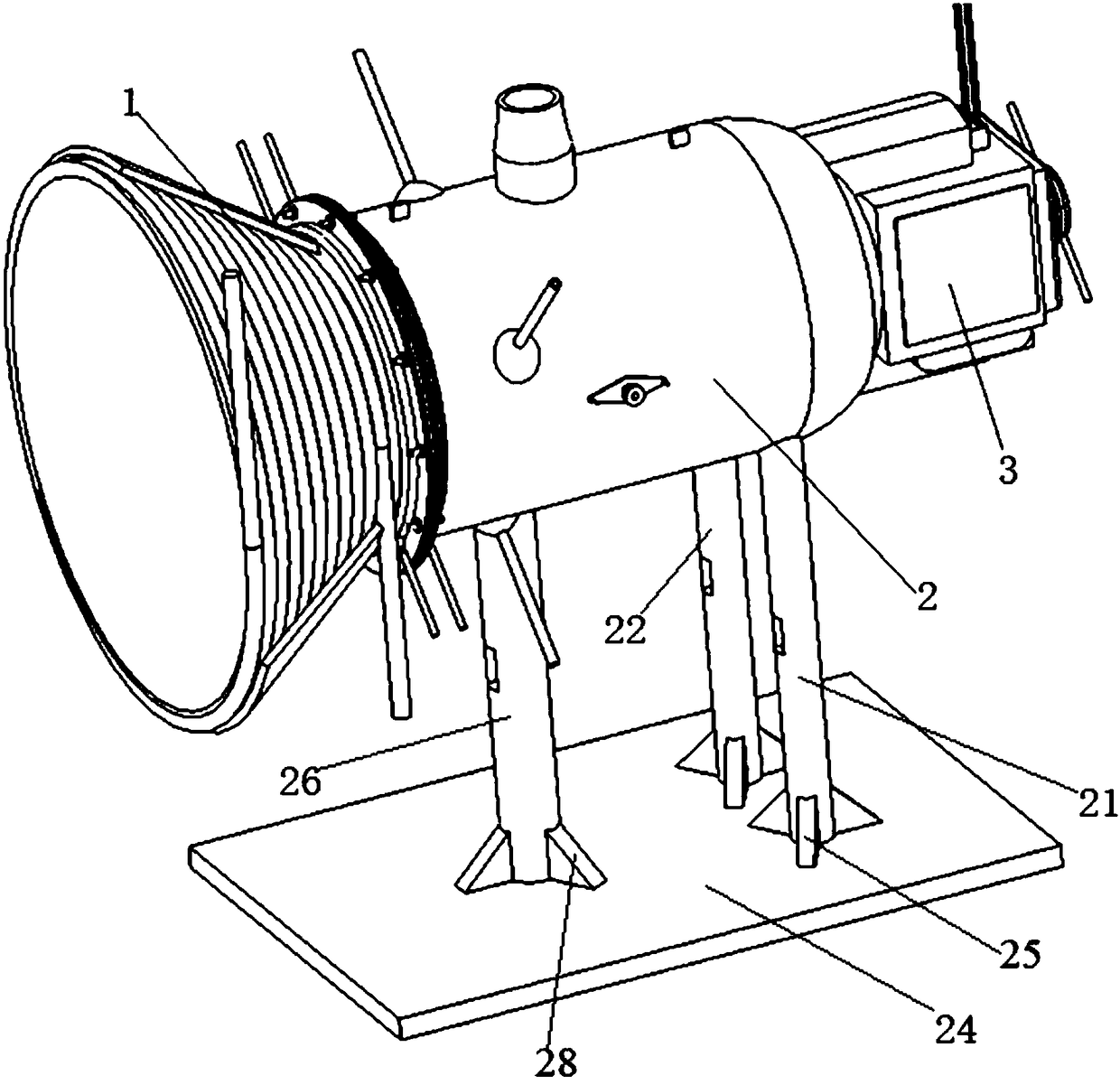

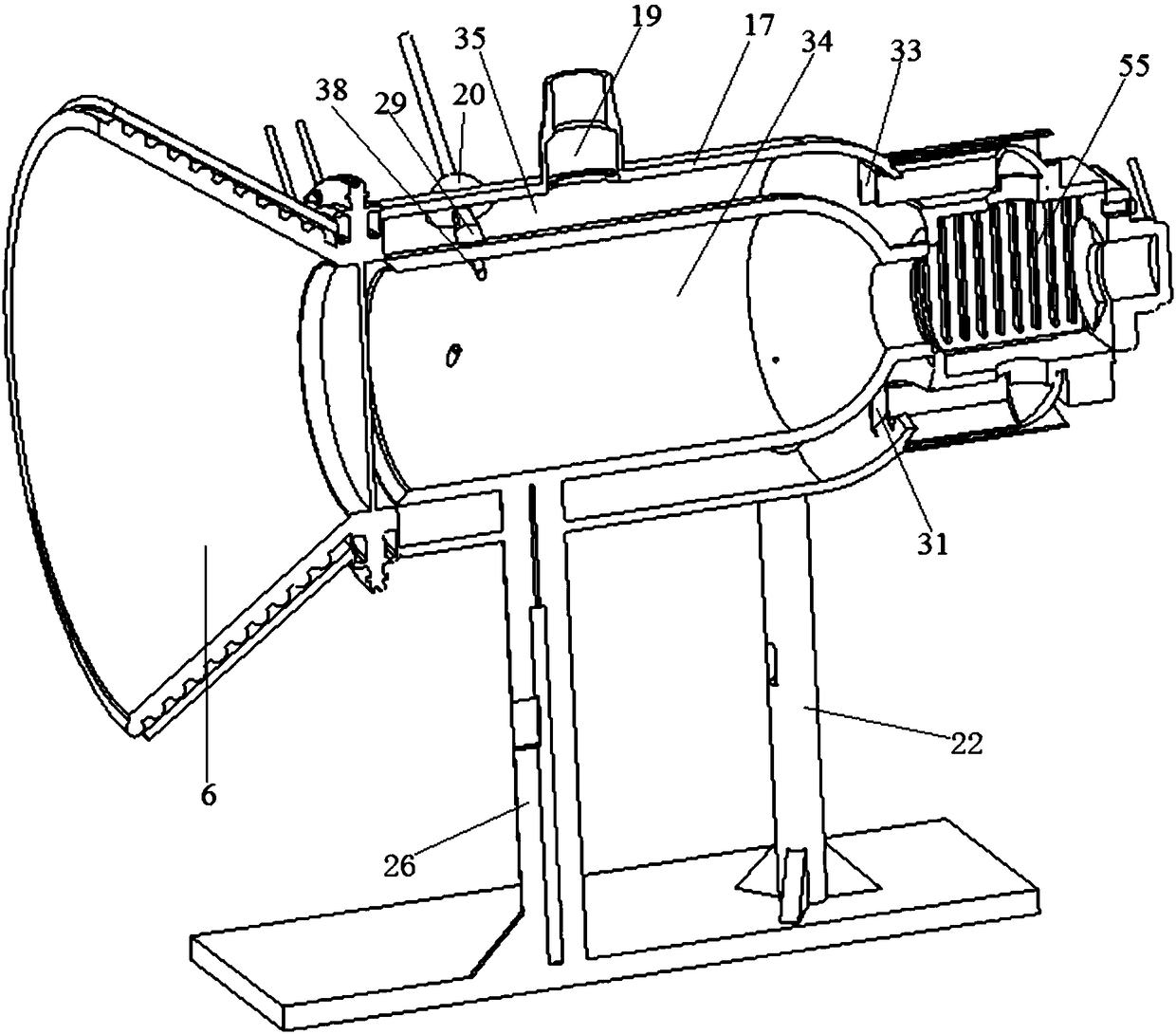

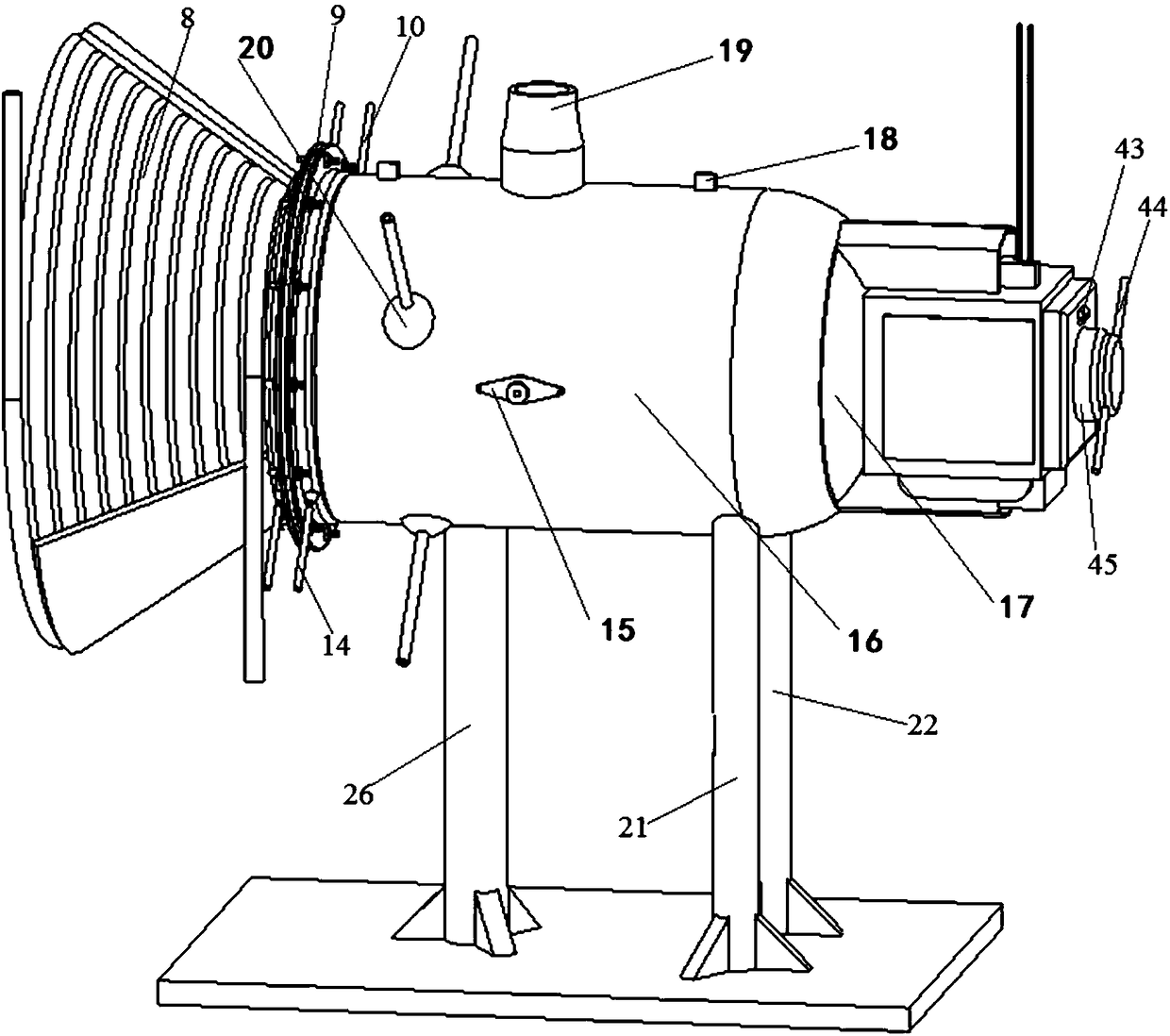

[0059] Embodiment 1: as Figure 1-12 As shown, an energy-saving and environment-friendly solar methanol reforming hydrogen production reactor includes a solar light receiving system 1, a methanol reforming reaction system 2, an exhaust dust removal treatment system 3, a support base 24, a solar light receiving system 1, a methanol reforming system The whole reaction system 2 and the tail gas dust removal treatment system 3 are fixedly arranged on the support base 24 in turn, and the sunlight receiving system 1, the methanol reforming reaction system 2, and the tail gas dust removal treatment system 3 are located on the same horizontal plane and communicate with each other;

[0060] Sunlight receiving system 1 includes ceramic fiber thermal insulation cotton 4, circular quartz glass lens 5, trumpet-shaped titanium alloy light collecting cover 6, refractory ceramic coating 7, titanium alloy spiral elbow 8, titanium alloy double-channel annular sink connector 9. The water inlet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com