Circulating water anti-freezing system for solar heat collector

A technology of solar collector and antifreeze system, applied in solar thermal power generation, solar thermal device, heating device, etc., can solve the problems of high operating energy consumption and cost, low heat exchange efficiency, etc. High efficiency and smooth water return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

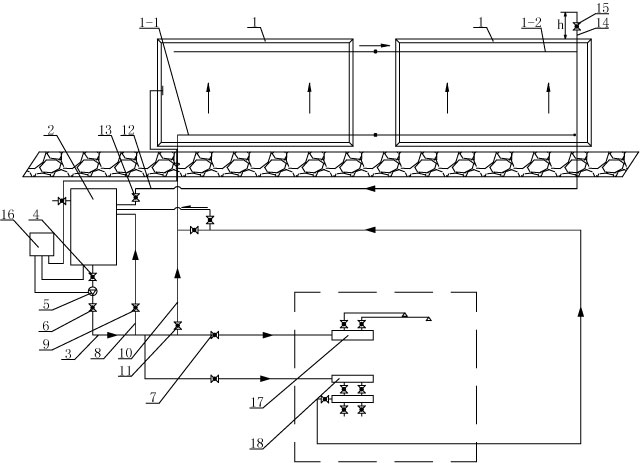

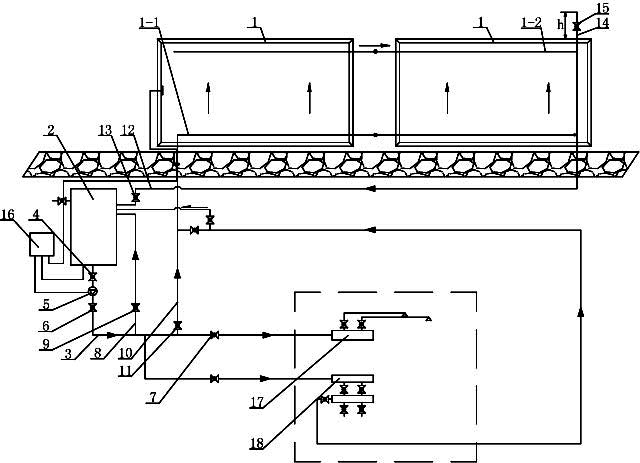

[0007] Specific implementation mode 1: Combination figure 1 To illustrate this embodiment, this embodiment includes the heat preservation water tank 2, the first pipeline 3, the first valve 4, the circulating pump 5, the second valve 6, the third valve 7, the second pipeline 8, the fourth valve 9, and the The third pipeline 10, the fifth valve 11, the fourth pipeline 12, the sixth valve 13, the exhaust air pipe 14, the exhaust air valve 15, the automatic temperature difference controller 16 of the circulating pump, and at least one plate solar collector 1. The input end of a pipeline 3 is connected to the water outlet of the heat preservation water tank 2, the output end of the first pipeline 3 is connected to the domestic water device 16 or the heating device 17, the first valve 4, the circulating pump 5, the second valve 6 and the The three valves 7 are sequentially arranged on the first pipeline 3 from the input end to the output end of the first pipeline 3, the input end of...

specific Embodiment approach 2

[0008] Specific implementation manner two: combination figure 1 Describing this embodiment, the angle between the plate-type solar heat collector 1 of this embodiment and the horizontal plane is 10 degrees to 90 degrees. This design can ensure that the water in the plate-type solar collector 1 can return to the water tank by gravity. The other components and connection relationships are the same as in the first embodiment.

[0009] The working principle of the present invention: the exhaust and intake valve 15 is normally open. When the circulating pump 5 is working, the first valve 4 and the second valve 6 are both open. When the exhaust and intake valve 15 overflows, adjust the sixth valve 13 , So that the water in the plate-type solar heat collector 1 quickly flows into the heat preservation water tank 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com