Pressure reducing device with temperature recovery function

A technology of decompression device and recovery function, applied in the direction of fluid pressure converter, mechanical equipment, etc., can solve the problems of energy waste, inability to compensate for unstable speed, etc., and achieve the effect of wide decompression range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

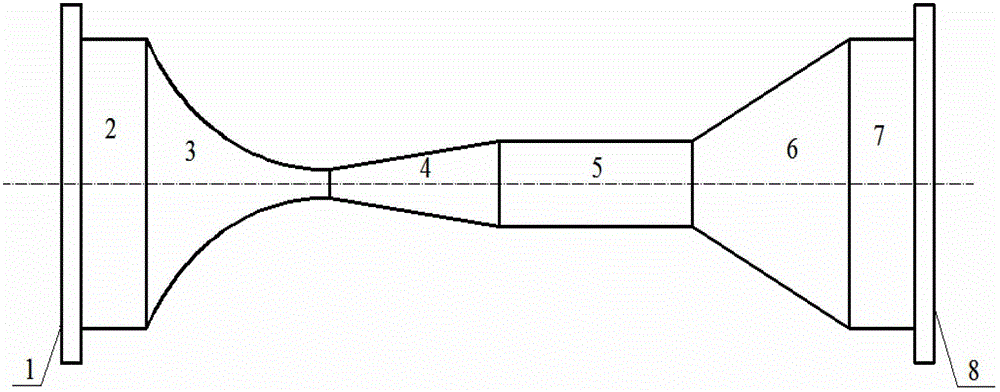

[0018] Below in conjunction with accompanying drawing the present invention is further described, and the present invention device comprises inlet flange 1, inlet straight pipe section 2, Rafael nozzle tapering section 3, Rafael nozzle expanding section 4, straight pipe section 5, diffuser section 6. Outlet straight pipe section 7. Outlet flange 8.

[0019] The device is connected to the main line of high-pressure fluid through the inlet flange 1 and outlet flange 8. At the same time, in order to prevent the fluid flowing into and out of the device from excessive turbulence, a certain length of smoothing is required at the inlet and outlet according to the flow rate. Straight section. The high-pressure compressible fluid first passes through the inlet straight pipe section and enters the tapering section 4. According to thermodynamic principles, at this stage, the fluid will accelerate, cool down, and depressurize, and reach a critical state at the throat. The fluid that has r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com