Temperature adjusting device and water heater

A technology of temperature adjustment device and heat exchanger, which is applied in the directions of fluid heater, lighting and heating equipment, etc., can solve the problems of leakage of refrigerant or heat storage material, low heat exchange efficiency of heat storage part, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

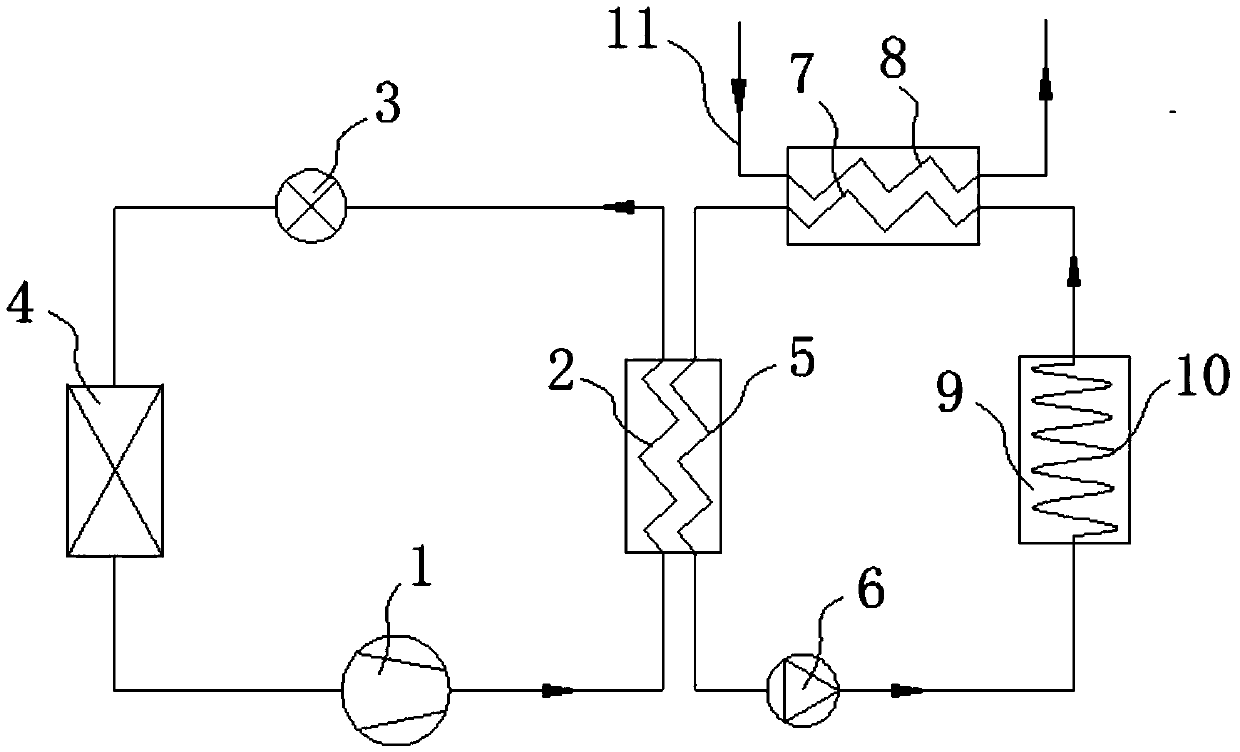

[0038] figure 1 A schematic diagram of the principle of the temperature regulating device of this embodiment is shown. Such as figure 1 As shown, the temperature regulating device of this embodiment includes a refrigerant circuit, and the refrigerant circuit includes a compressor 1 , a condenser 2 , a throttling component 3 and an evaporator 4 connected in sequence.

[0039] The refrigerant compressed by the compressor 1 condenses and releases heat in the condenser 2. The condensed refrigerant enters the evaporator 4 after being throttled and reduced by the throttling part 3. The refrigerant evaporates and absorbs heat in the evaporator 4 and then is compressed. The suction port of the machine 1 returns to the compressor 1 to be compressed again.

[0040] The temperature regulating device also includes a medium circuit, and the medium circuit includes a first heat exchanger 5 that exchanges heat with the condenser 2, an accumulator 9 that communicates with the outlet of the ...

Embodiment 2

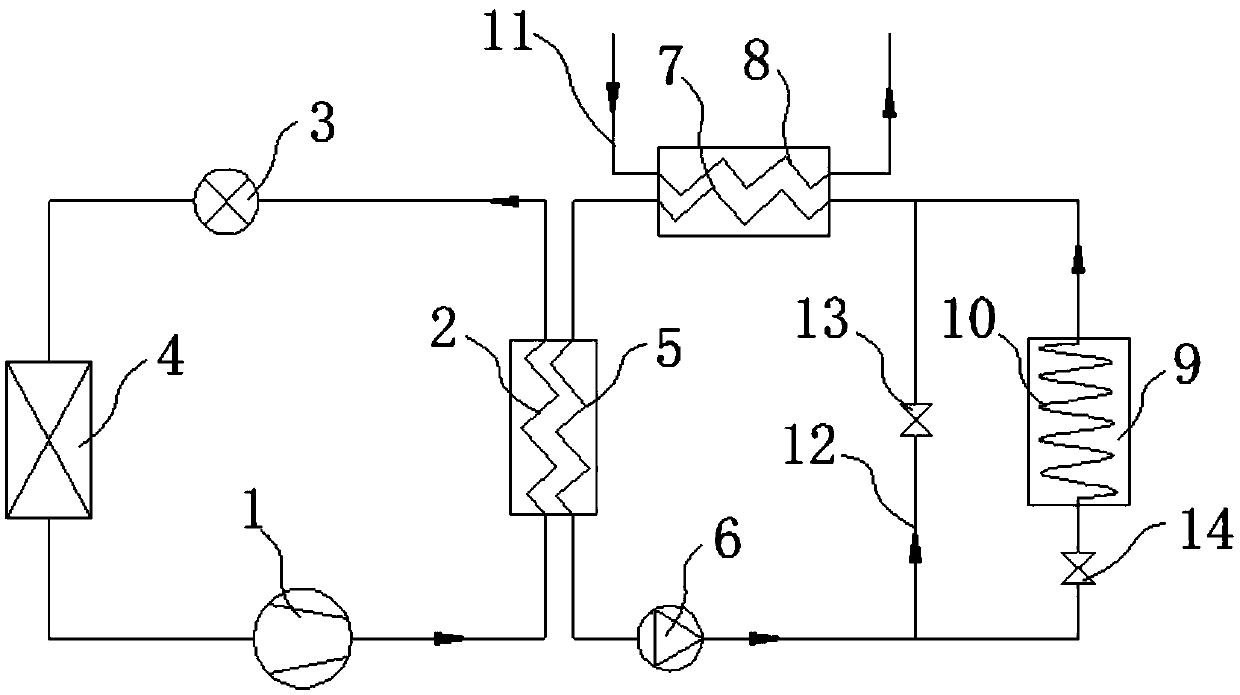

[0068] figure 2 A schematic diagram of the principle of the temperature regulating device of this embodiment is shown. Such as figure 2 As shown, the difference between this embodiment and Implementation 1 lies in:

[0069] The medium circuit comprises a first branch 12 and a second branch, wherein the energy store 9 is arranged in the second branch. The inlets of the first and second branches are both connected to the outlet of the first heat exchanger 5 , and the outlets of the first and second branches are both connected to the inlet of the second heat exchanger 7 .

[0070] The medium circuit also includes an inlet for controlling the communication of the second heat exchanger 7 with the first branch 12 and / or the accumulator 9 .

[0071] The control valve comprises a first valve 13 arranged in the first branch 12 and a second valve arranged in the second branch.

[0072] To sum up, the inlet of the second heat exchanger 7 in this embodiment can be selectively commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com