High-efficiency environmental-friendly belt conveyor cleaning device

A technology of cleaning device and belt conveyor, applied in the direction of cleaning device, transportation and packaging, conveyor objects, etc., can solve the problems of increasing the wear of the conveyor belt, pulling the surface glue of the conveyor belt, tearing the rubber coating layer of the drum, etc., to improve the service life , strong penetration, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

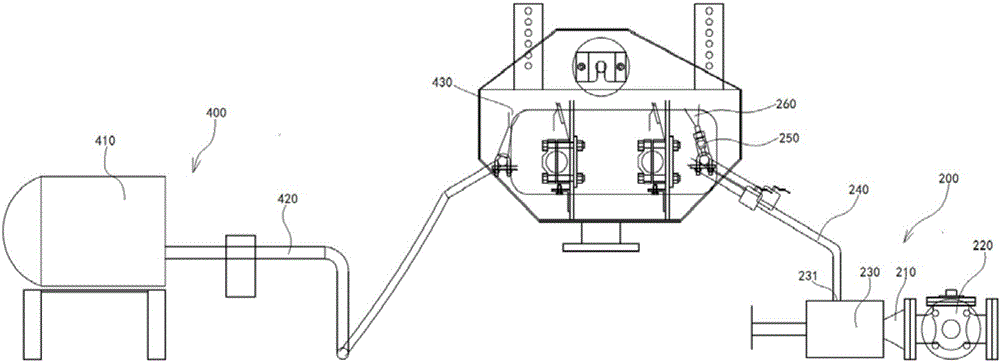

[0013] see figure 1 The shown a kind of efficient and environment-friendly belt conveyor cleaning device includes an ultrasonic cleaning device 200 arranged on the belt conveyor 100 for cleaning, and a sewage channel 300 arranged on the belt conveyor 100, which is cleaned by the ultrasonic cleaning device 200. The residue is discharged through the sewage channel 300.

[0014] The ultrasonic cleaning device 200 also includes a transducer 210 that converts electrical energy into mechanical energy, an ultrasonic generator 220 that generates high-frequency electrical signals, a storage tank 230 for storing cleaning fluid, a cleaning fluid ejection pipeline 240 and A working head 250 arranged at one end of the cleaning liquid ejection pipeline 240 is also provided with a cleaning liquid ejection port 260 on the working head 250, the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com