Production method of corrosion-resistant steel rails

A production method and rail technology, applied in the direction of metal material coating process, etc., can solve the problems of rust pits, fractures, affecting the safety of line operation, etc., and achieve the effect of excellent corrosion resistance and good corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

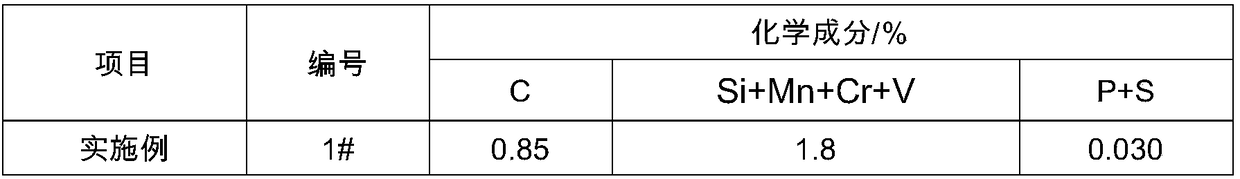

[0019] The following rail chemical compositions are selected for the embodiments and the corresponding comparative examples in this example.

[0020] Table 1 Example Rail Chemical Composition / %

[0021]

[0022] The comparative example in the present invention adopts the same chemical composition, heating, rolling and on-line heat treatment process as the embodiment.

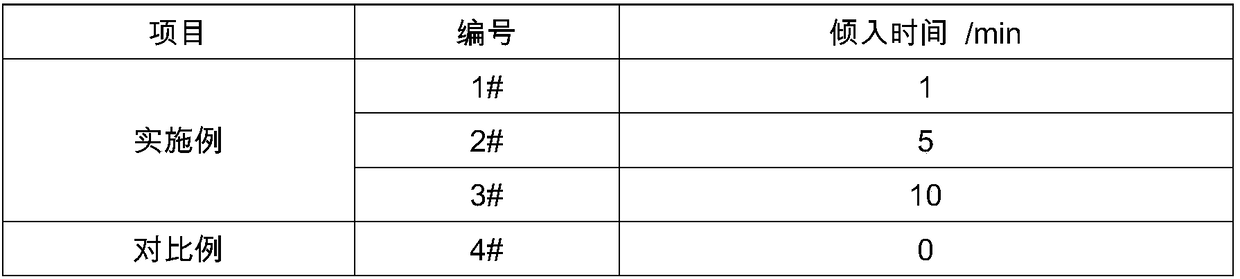

[0023] Adopt the method in the claim to put the steel rail into the passivation solution, wherein 1# to 3# are different treatment times, and 4# is the comparative example without carburizing treatment. Subsequently, 4 samples were produced by the same heating, rolling and online heat treatment process.

[0024] Table 2 embodiment and comparative example rail pouring time

[0025]

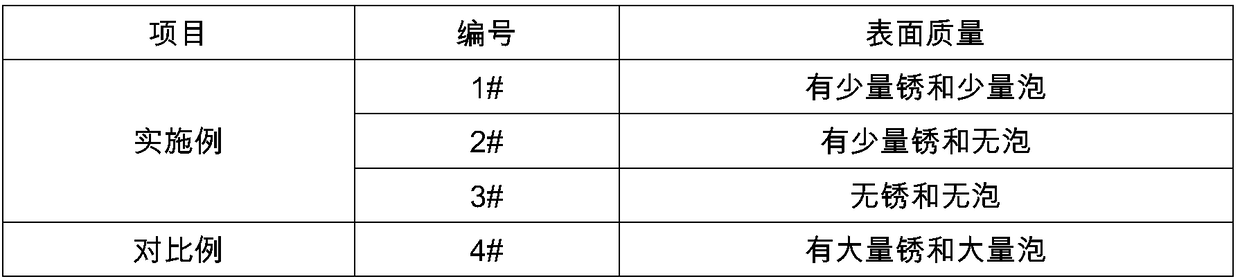

[0026] Put the 4 rail samples into the salt spray test chamber, prevent them for 500h, and observe the surface quality, as shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com