Hollow planting brick and vertical greening structure

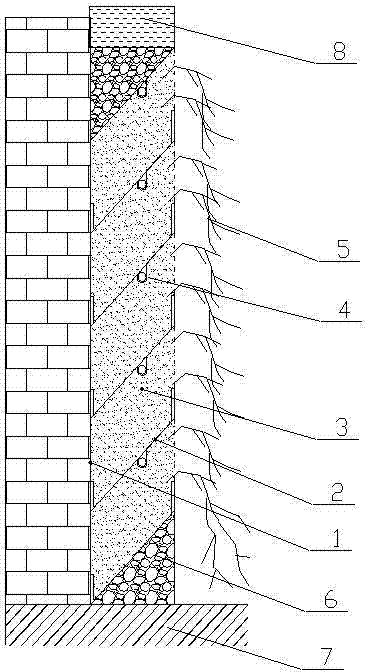

A technology for vertical greening and planting bricks, which is applied to underwater structures, infrastructure projects, building components, etc., can solve the problems of easy collapse, unsafe service life and high cost of plant bags, and achieves a wide range of plant selection and use. The effect of long service life and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples. For the convenience of description, the "upper" and "lower" referred to below are consistent with the upper and lower directions of the drawings themselves, but they do not limit the structure of the present invention.

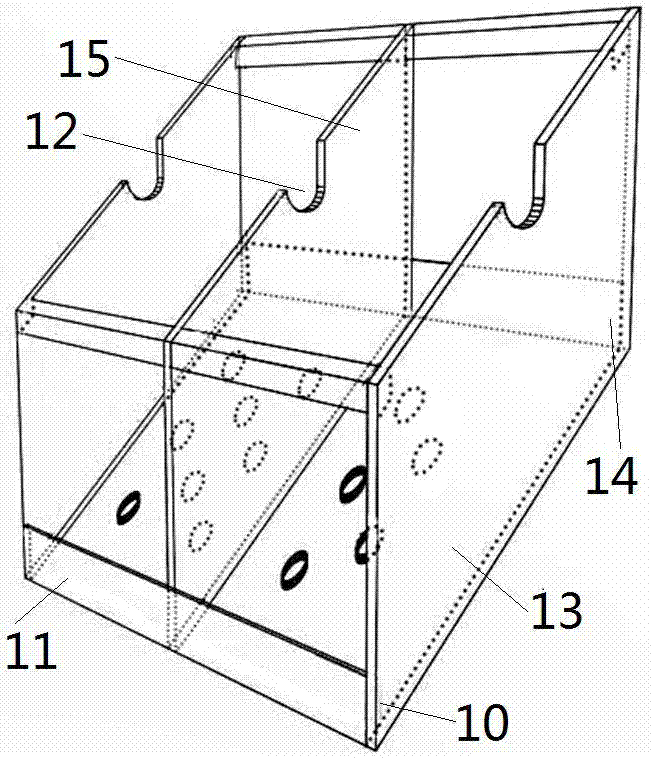

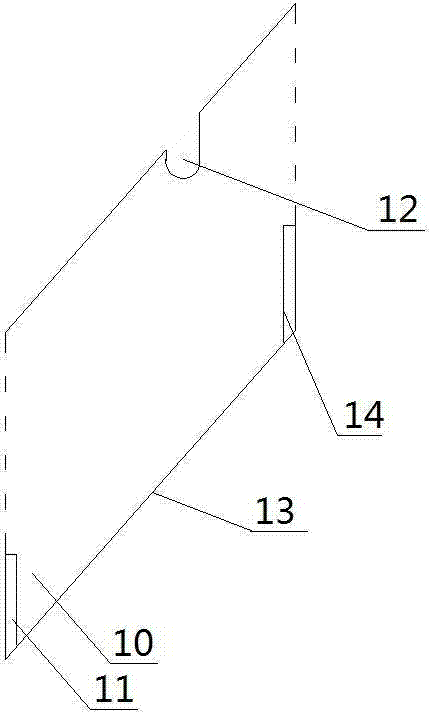

[0033] Such as figure 1 and figure 2 As shown, a hollow planting brick, the overall skeleton of the brick body is a rectangular prism whose upper, lower, left and right end faces are rectangular, and the front and rear end faces are parallelograms; the upper end face of the brick body is a hollow design; The right end face of the brick body is provided with a right rib 14 which is not completely sealed; the front end face and the rear end face of the brick body are provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com