Pavement structure with low cost, environmental friendliness and long service life

A pavement structure and long-life technology, which is applied to roads, roads, and on-site coagulation pavements, etc., can solve the problems of high cost and single function of long-life pavement structures, achieve low cost, and improve driving comfort and safety Sexuality and the effect of extending the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

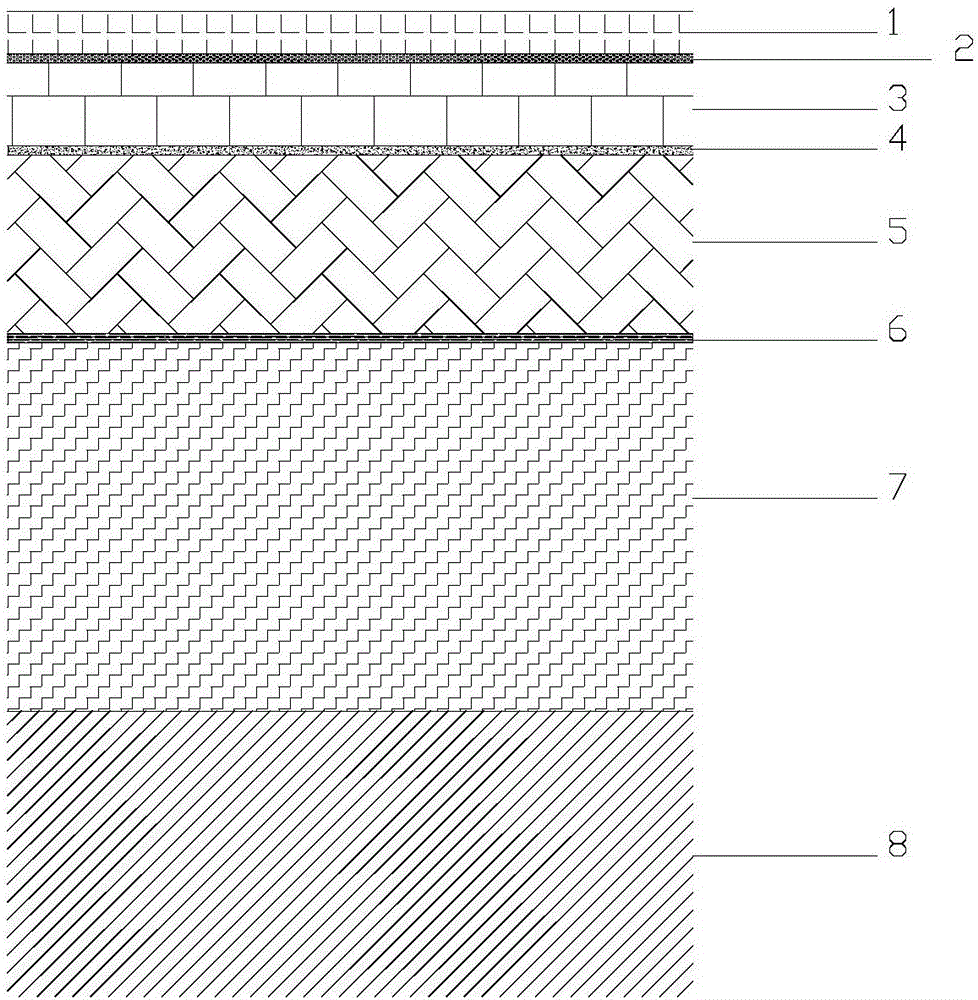

[0017] see figure 1 , the surface layer 1 adopts a thin OGFC-10 layer with a thickness of 3 cm; the upper seal layer 2 adopts a rubber asphalt fiber synchronous gravel seal layer with a thickness of 5-10 mm; Powder modified asphalt limestone SMA-20 mixture; sticky layer 4 adopts SBR modified emulsified asphalt; lower layer 5 adopts ATB-30 ordinary mixture with a thickness of 12cm; lower seal layer 6 adopts rubber asphalt fiber with a thickness of 10-20mm to be crushed synchronously Stone seal layer; semi-rigid base layer 7 adopts low-dose cement-stabilized crushed stone mixture with a thickness of 36cm; graded crushed stone base layer 8 has a thickness of 20cm.

[0018] During construction, first pave the 20cm graded crushed stone subbase 8 sequentially on the top of the road bed, pave 36cm low dose cement stabilized crushed stone semi-rigid base 7 on the graded crushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com