High-activity nanoscale tricalcium phosphate production reaction kettle and using method thereof

A tricalcium phosphate, nano-scale technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of low production efficiency and low degree of integration, so as to improve output and production efficiency, improve reaction accuracy, The effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

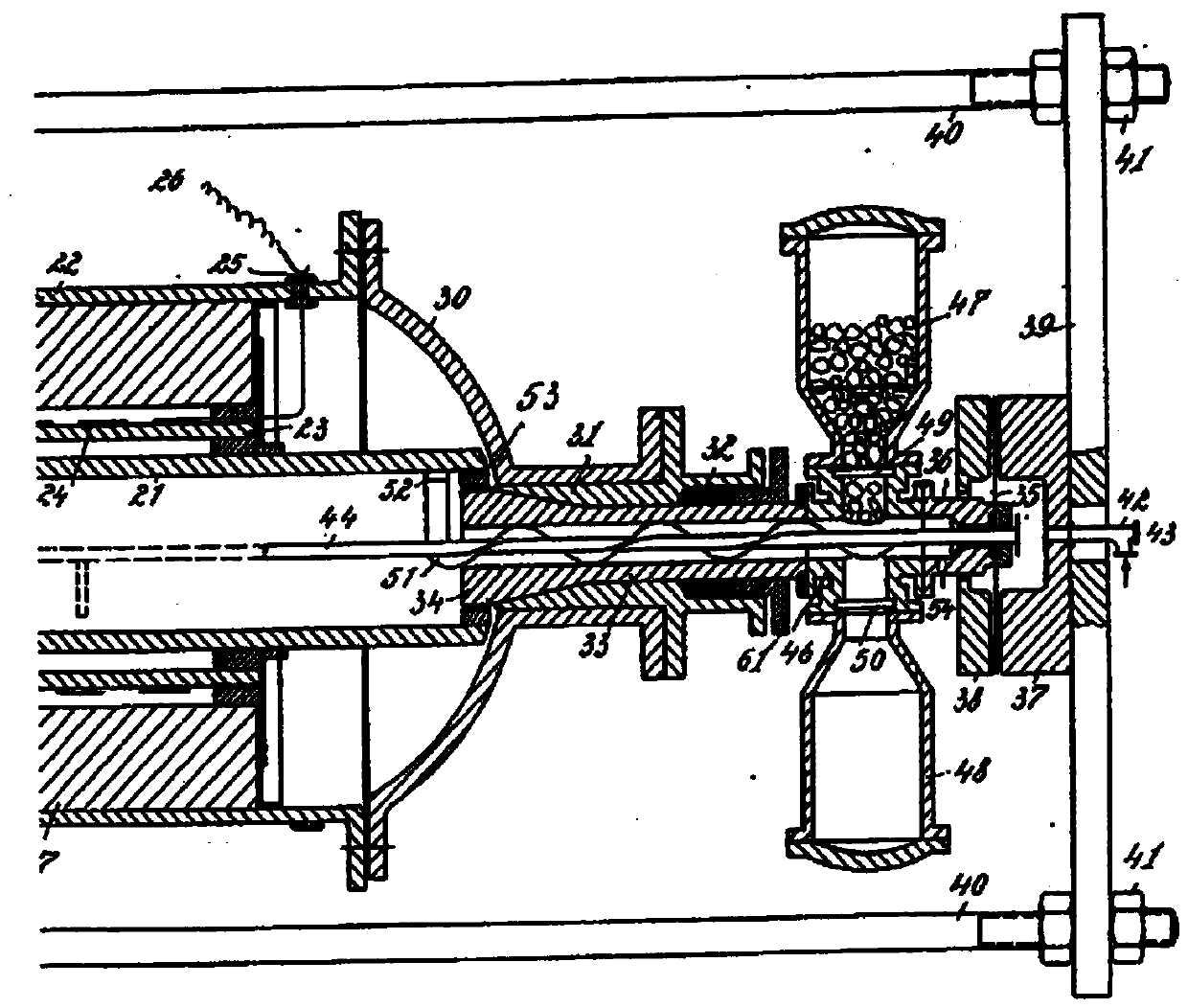

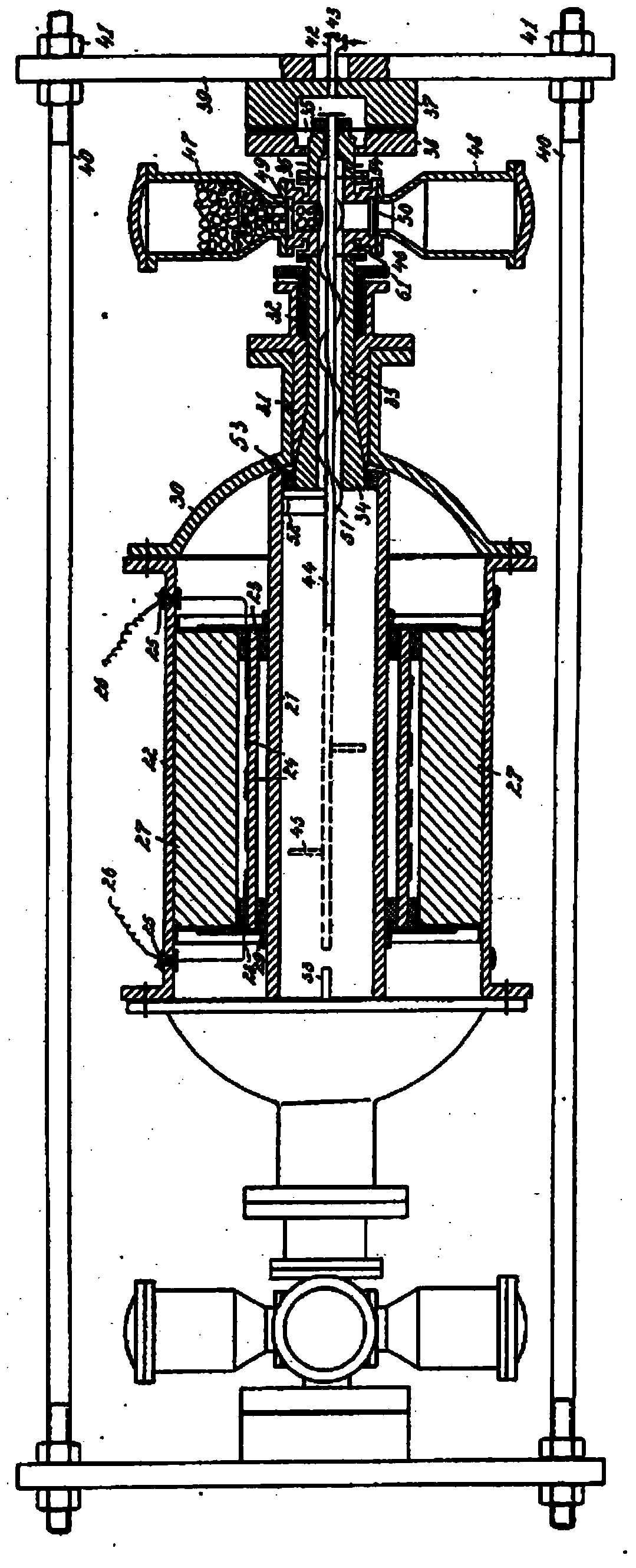

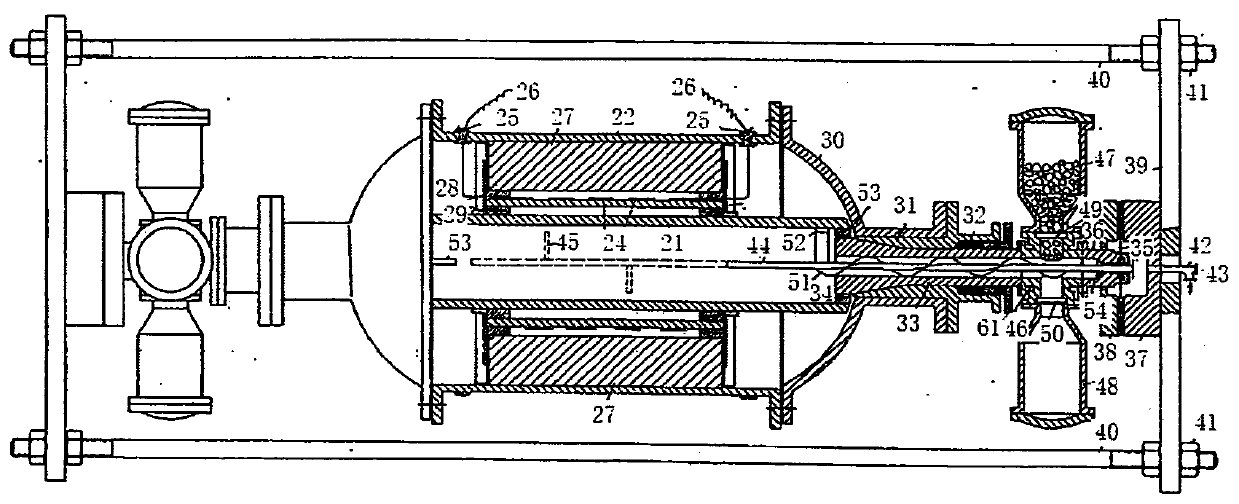

[0041] refer to Figure 1-3 , a high-activity nano-scale tricalcium phosphate production reactor, including a support plate, a support profile and a frame part composed of connectors, a first reaction vessel, a second reaction vessel, and a third reaction vessel; it is characterized in that the first There are two reaction containers; The fixing part is sequentially connected with a second fixing part and a connecting sleeve; the connecting sleeve is a hollow tubular structure, and a first channel and a second channel are symmetrically opened on its side wall, and the discharge ports of the first reaction vessel and the second reaction vessel are respectively It is docked with the first and second channels; the bottom of the first and second reaction vessels is also provided with an openable and closable bottom cover, which is used for filling in the preparation process; the first channel and the second channel are provided with useful The control switch for the opening and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com