Impact testing device of protecting board of automobile seat

A technique for impact testing, automotive seating, used in impact testing, measuring devices, testing of machine/structural components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

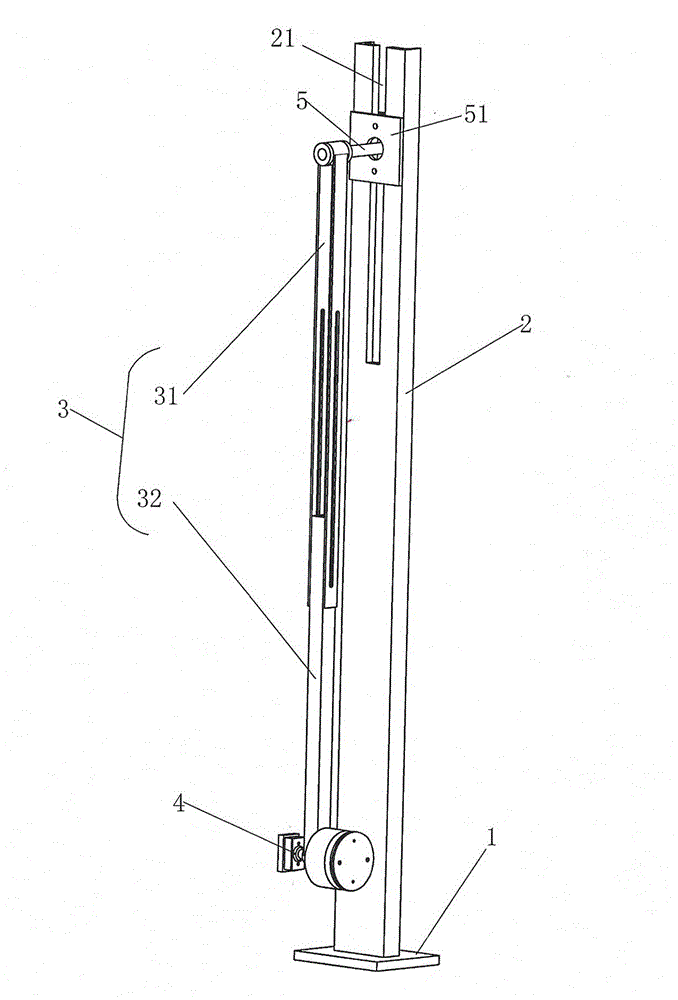

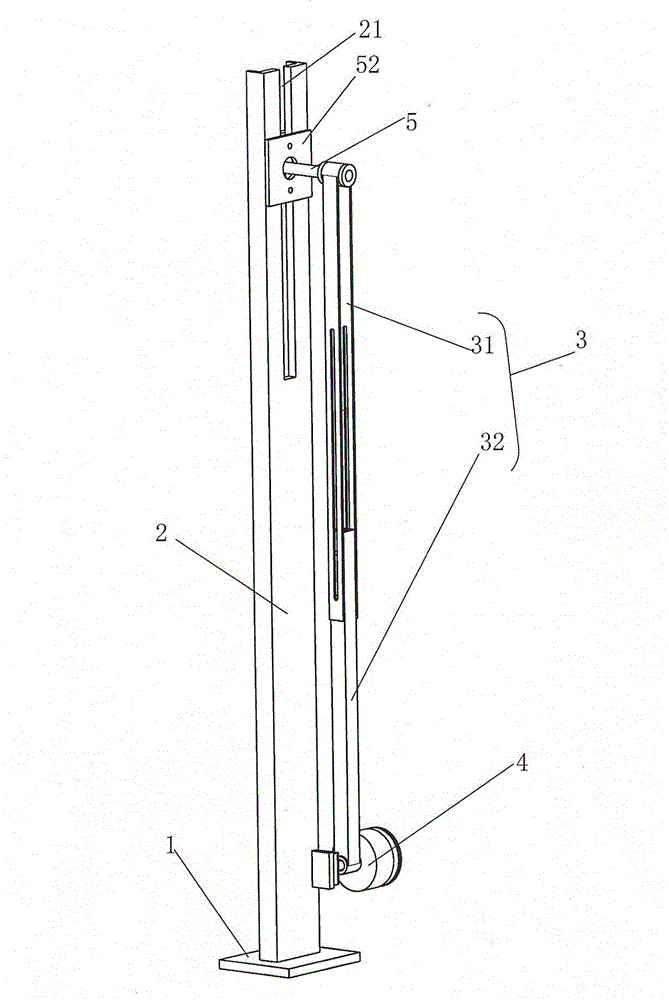

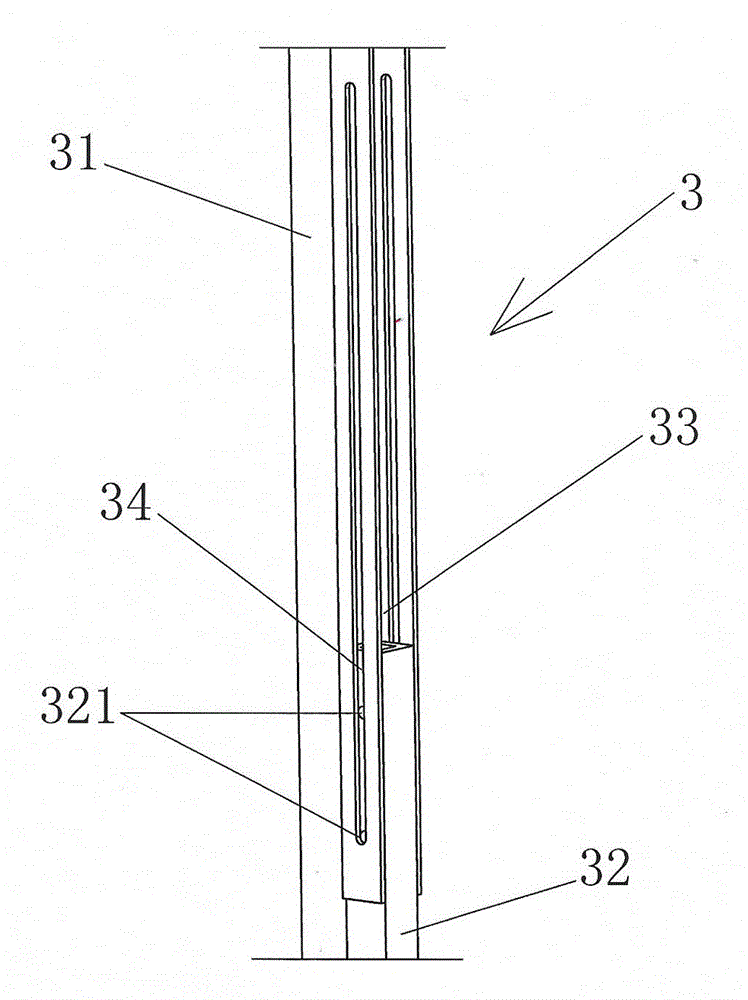

[0019] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, this embodiment is composed of a test bench 1, a column 2, a pendulum 3 and a pendulum 4, the column 2 is fixed on the test bench 1, the upper end of the pendulum 3 is hinged to the upper part of the column 2 through a shaft 5, and the pendulum 4 is fixed on the lower end of the column 2; the pendulum 4 is composed of a hammer body 41, a counterweight 42, a stiffness adjustment mechanism 43 and a punch mechanism 44, and the stiffness adjustment mechanism 43 is composed of a piston rod 431, a spring 432 and a matching The center of the hammer body 41 is provided with a stepped hole 411, the spring 432 is located at the rear end of the stepped hole 411, the piston rod 431 is located at the front end of the stepped hole 411, and the front part of the counterweight 42 is screwed to the bottom of the stepped hole 411. The rear end; the punch mechanism 44 is made of a ball head rod 441 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com