Clamping device for cavitation water jet surface strengthening treatment test

A clamping device and surface strengthening technology, which are applied in the field of clamping devices for cavitation water jet surface strengthening treatment experiments, and can solve the problems of lack of test fixtures for through-pipe structures and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

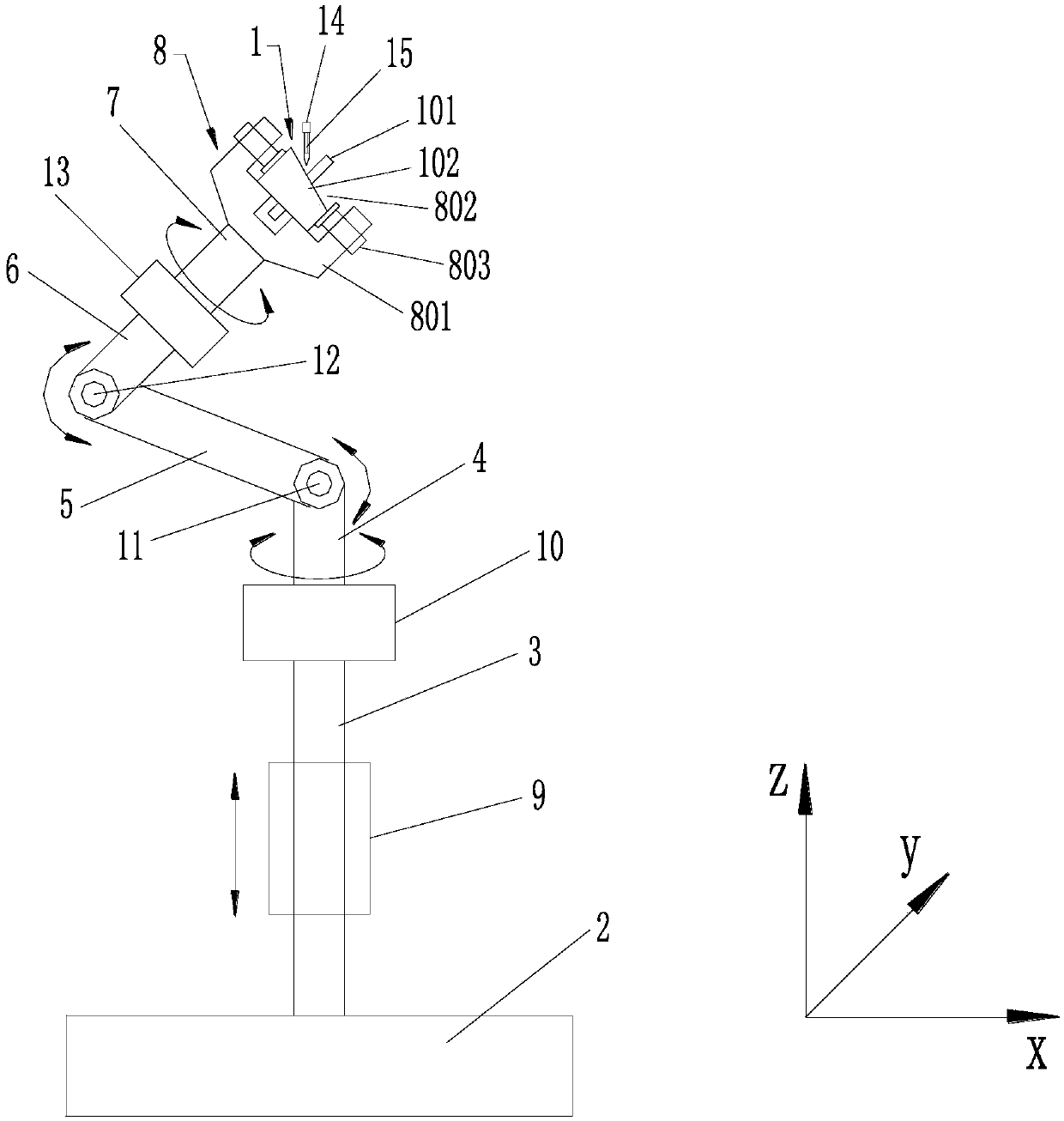

[0021] Such as figure 1 As shown, the present invention discloses a clamping device for a cavitation water jet surface strengthening treatment test, which is suitable for a test piece 1 with a penetrating structure of a nuclear power plant pressure vessel. The clamping device of the present invention includes a horizontal console 2 that can move along the XY plane (that is, the horizontal console 2 can control the displacement of the X-axis and the Y-axis on the horizontal plane), a second horizontal console that extends along the Z-axis and can be lifted along the Z-axis. A shaft 3, a second shaft 4 that is arranged above the first shaft 3 and can rotate along its own axis, a third shaft 5 that can rotate relative to the second shaft 4 in the XZ plane, and a third shaft that can rotate relative to the third shaft in the XZ plane The fourth shaft 6 tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com