Multi-stage compressed air silencer and application

A technology of compressed air and muffler, which is applied in the direction of non-variable pumps, machines/engines, and components of pumping devices for elastic fluids, etc. It can solve the problems of not having drainage functions, etc., and achieves simple structure and easy installation , the effect of solving the noise problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

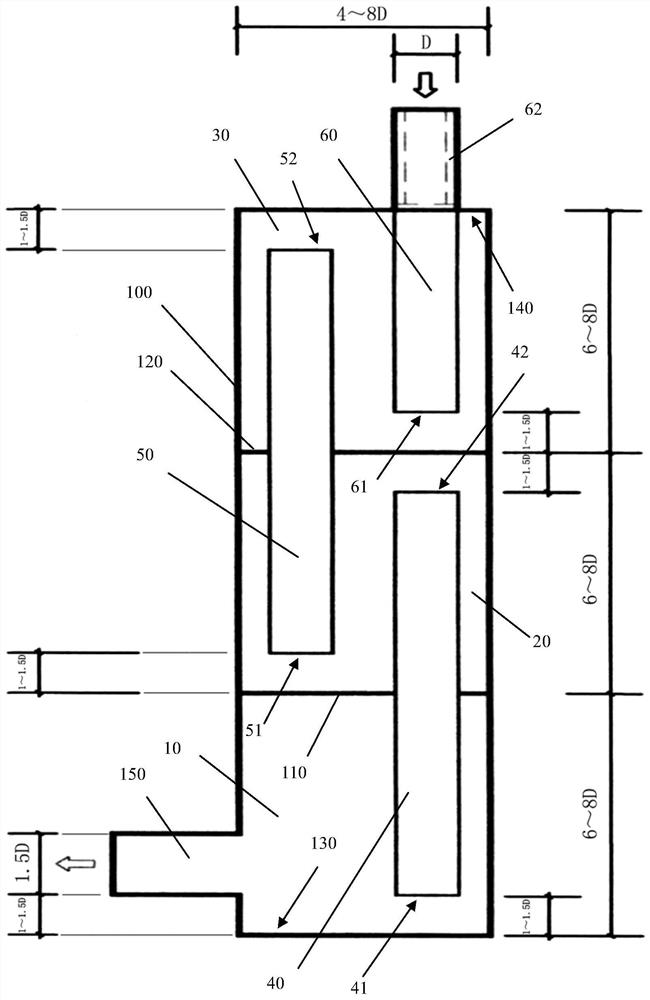

Image

Examples

Embodiment 1

[0050] In an air compressor station of a certain factory, on the drainage pipes of the primary and secondary coolers of the centrifugal air compressor, according to the drainage method and pipe diameter of the air compressor equipment unit, install the muffler at the end of the pipe, and according to the On-site conditions, set the direction of the exhaust outlet. The noise of the exhaust in the area is reduced to 39 decibels.

Embodiment 2

[0052] After the muffler is installed on the drainage pipe at the lowest point of the compressed air conveying pipe in a factory, the whistling sound in the factory building is controlled, which reduces the harm of noise to operators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com