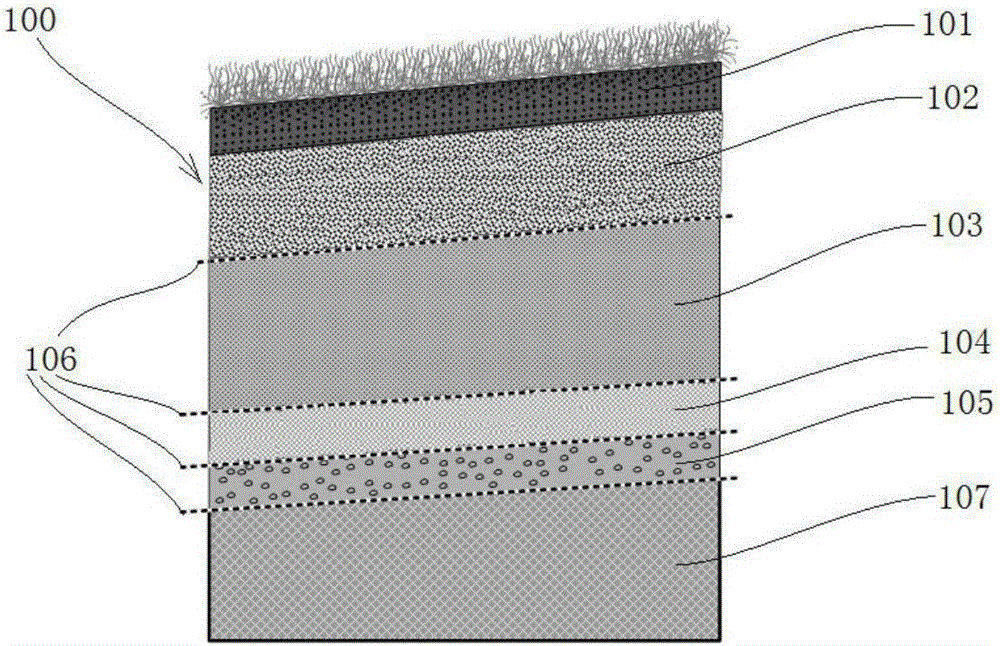

Final covering layer for semi-aerobic landfill

An end-field coverage and quasi-aerobic technology, applied in the direction of smoke removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as abnormal operation, high cost, and reduced strength of landfills, so as to prevent rainwater from entering, Good air permeability, the effect of promoting methane oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The CH of different covering materials and seeding ratio of embodiment 1 4 oxidation rate

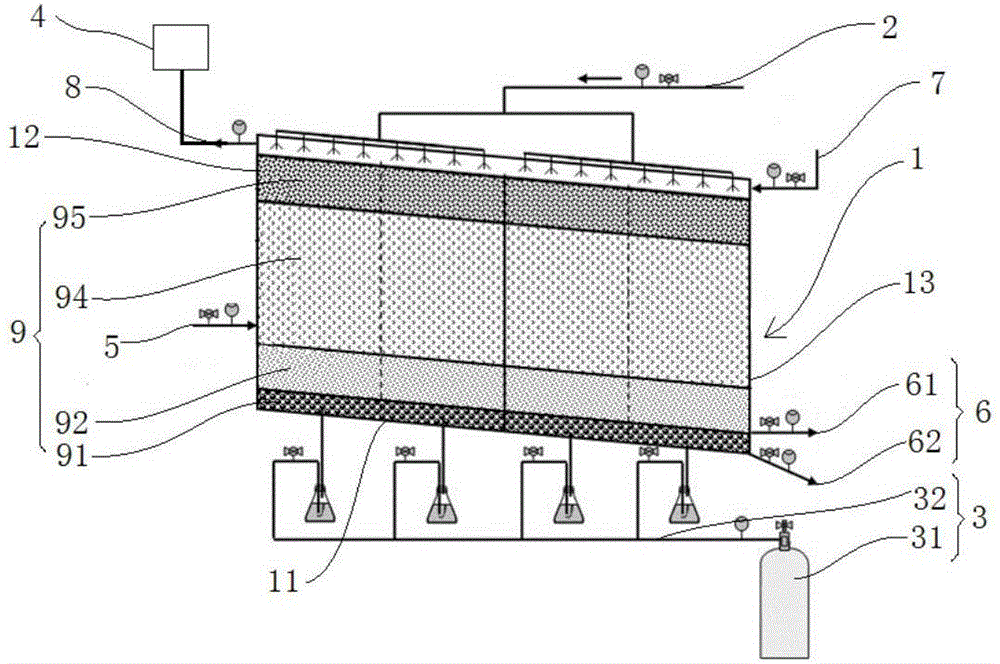

[0067] The overlay methane oxidation simulation device is used, and its schematic diagram is shown in figure 2 As shown, the simulation device includes a closed box, a precipitation system, a methane gas input system, a methane gas detection system, a water inlet, a water outlet, an air inlet and an air outlet. The bottom surface of the closed box includes the first side and the second On the second side opposite to one side, the first side is inclined to the second side, the side wall connected to the first side is the high side 12, and the side wall connected to the second side is the low side 13, laying in the box parallel to Covering layer 9 on the bottom surface of the box body. The covering layers are successively from bottom to top a fine sand layer 91 , a sandy clay layer 92 , a geotextile layer, a loamy sand layer 94 and a biological covering layer 95 . A water inlet...

Embodiment 2

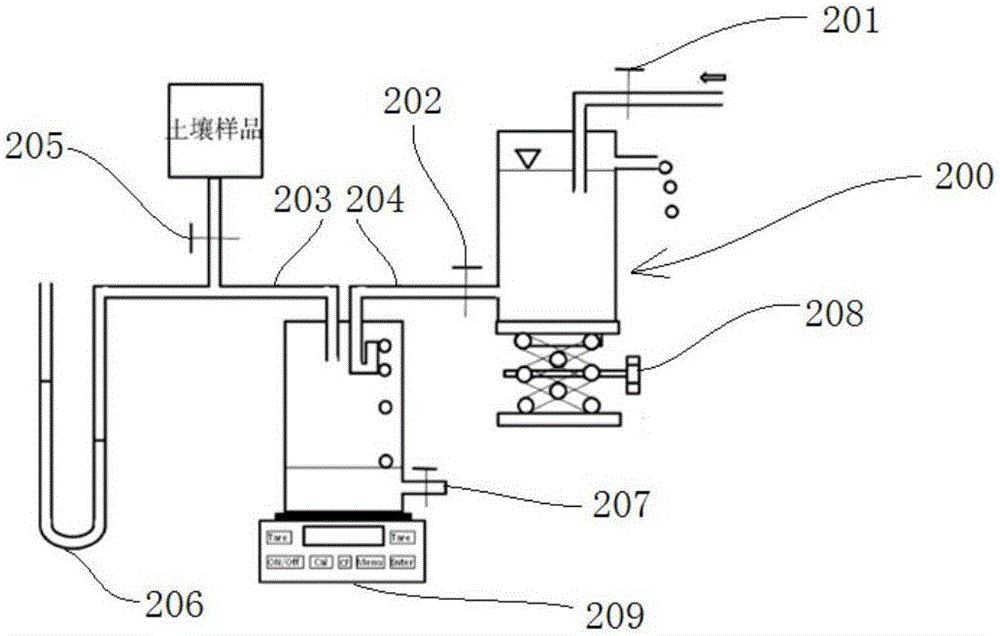

[0075] The gas conduction performance of embodiment 2 final covering layer

[0076] The method of "a simple method for measuring soil air permeability and its application ("Soil", 2014, 46(4):766-768)" proposed by Bi Lidong et al. (2014).

[0077] (1) Measuring principle

[0078] According to Darcy's law, soil air permeability Q is proportional to soil ventilation area S, air pressure difference ΔP, and time Δt, and inversely proportional to soil thickness h and air viscosity coefficient μ, namely:

[0079] Q = K S · Δ P · Δ t h · μ - - - ( 1 )

[0080] In the formula: K is the soil air permeability rate; Q is the soil air permeability; S is the soil air ventilation area; Δ...

Embodiment 3

[0091] Example 3 Overlay drainage performance test

[0092] The simulated equipment in Example 1 is used to study the influence of rainfall intensity on the drainage performance of the covering layer after the selected covering layer structure. The drainage performance experiment of aquifer and capillary barrier layer was carried out under the same conditions by changing the rainfall intensity:

[0093] The specific experimental conditions are: drainage layer, permeability coefficient is 1×10 -4 ~1×10 -3 m / s, thickness 30cm; capillary barrier layer, permeability coefficient 1×10 -6 ~5×10 -6 m / s, thickness is 50cm; aquifer, permeability coefficient is 1×10 -4 ~1×10 - 3 m / s and a thickness of 30cm.

[0094] This study uses the SEEP / W module in GeoStudio software for simulation.

[0095] The simulated slope of the model is 1:3, and the simulated rainfall infiltration intensity is 1×10 -8 , 1×10 -7 , 1×10 -6 , 1×10 -5 , 1×10 -4 , 1×10 -3 , 1×10 -2 and 1×10 -1 m / s. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com