Dynamic gap type screw press

A screw press, dynamic gap technology, applied in the field of presses, can solve the problems of unreasonable blade structure, difficult processing, low strength, etc., and achieve the effect of no need for frequent maintenance, long service life and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

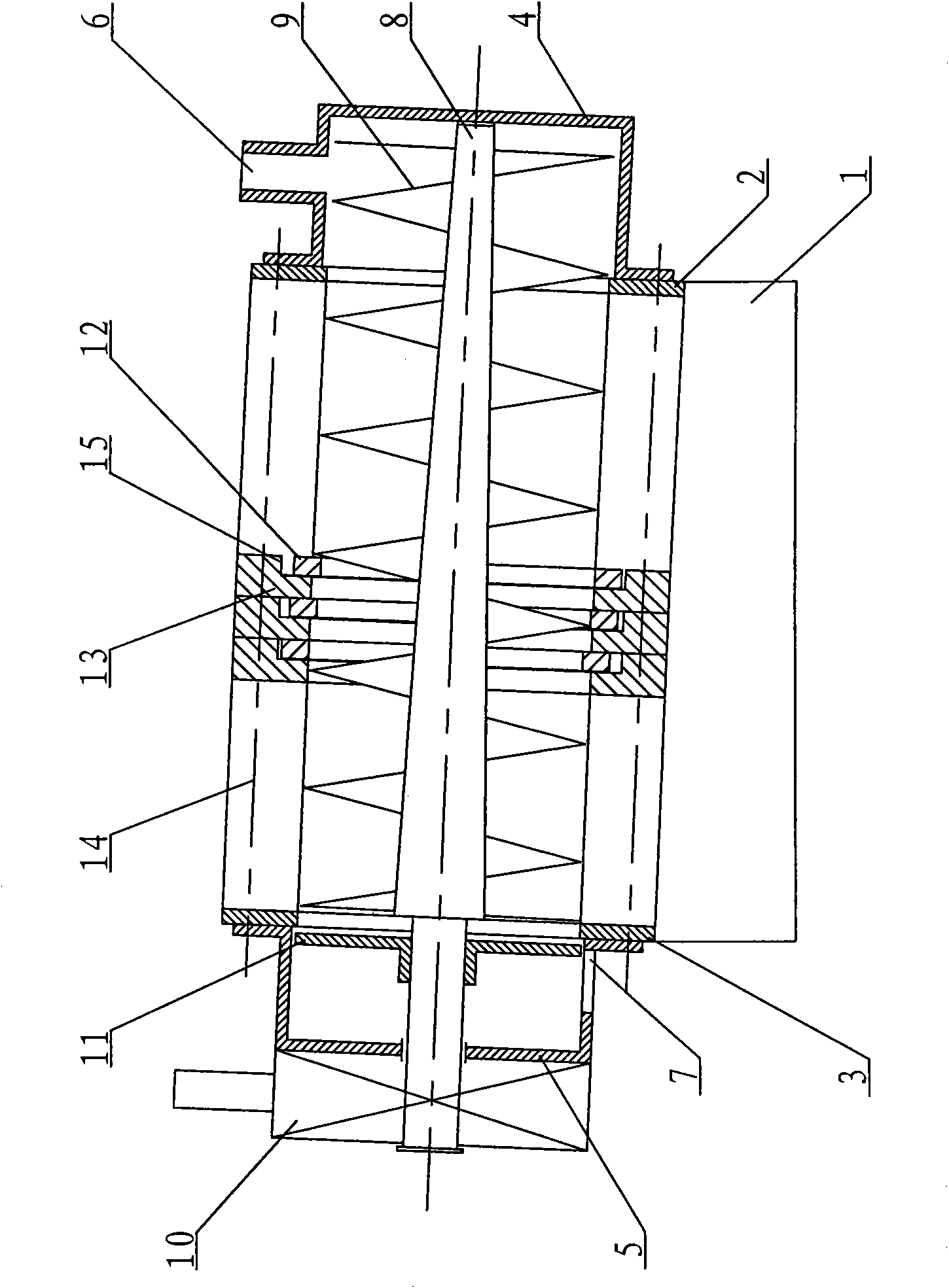

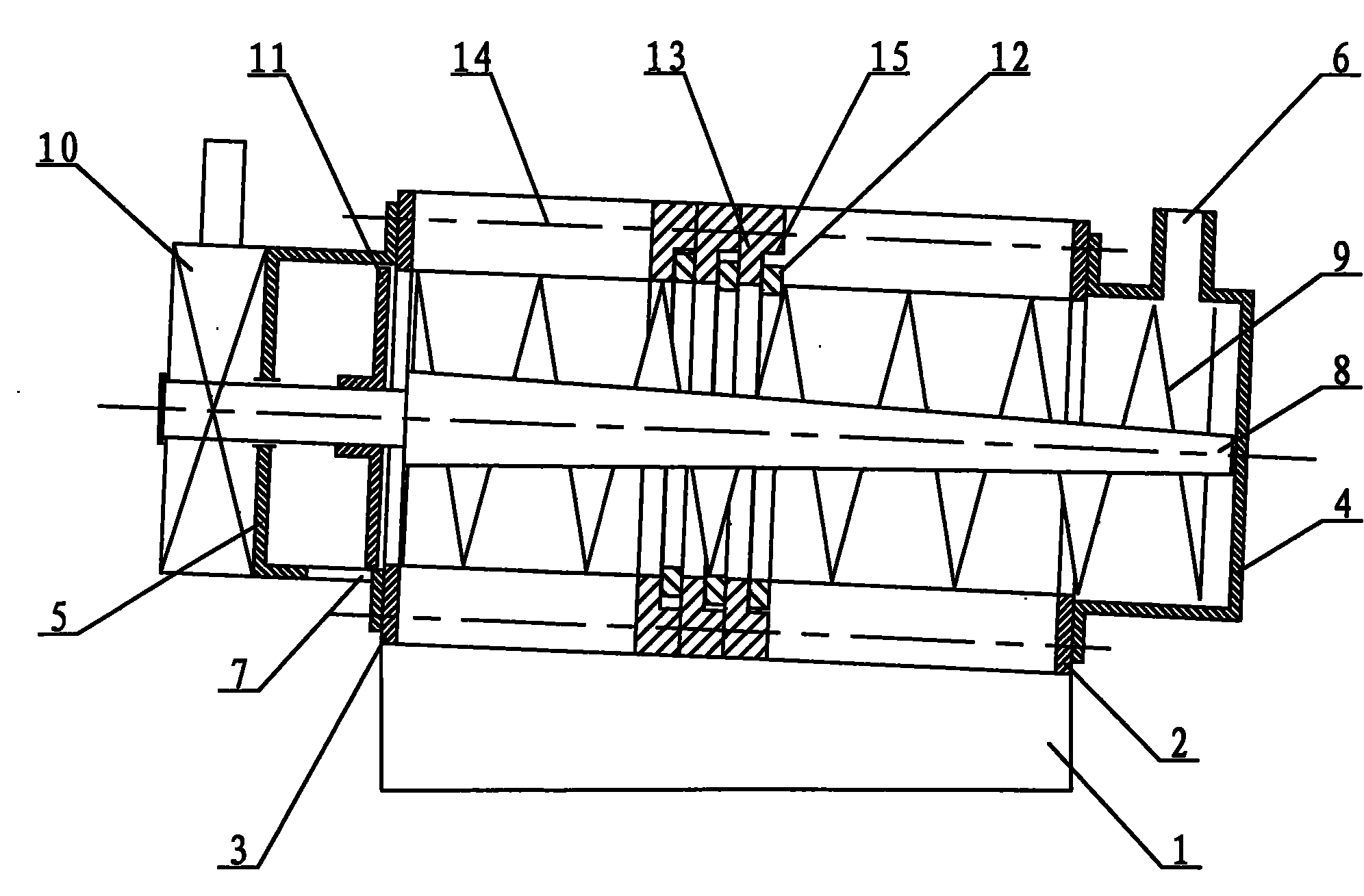

[0014] figure 1 As shown, the dynamic gap screw press mainly includes machine base 1, front and rear support plates 2 and 3, front and rear flange sleeves 4 and 5, tapered shaft 8, blade 9, gear motor 10, pressure regulating flange 11. Moving film 12 and static film 13. The front and rear support plates 2 and 3 are respectively supported by the front and rear ends of the machine base 1, and the front and rear flange covers 4 and 5 are respectively connected to the outer end surfaces of the front and rear support plates 2 and 3, and the front flange cover 4 upper end is provided with an inlet The feed port 6, the lower end of the rear flange sleeve 5 is provided with a discharge port 7; a screw auger composed of a tapered shaft 8 and blades 9 runs through the front and rear support plates 2, 3 and the two ends of the screw auger are respectively support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com