Preparation method of trench with anti-seepage function

A trench and function technology, applied in the sewer system, building, water supply device and other directions, can solve the problems of poor corrosion resistance and durability, prone to cracks, high water seepage at the base of the original trench, and achieve easy construction, prolong service life, The effect of easy construction and post-maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for preparing a trench with an anti-seepage function, comprising the following steps:

[0052] 1) Before construction, first determine the excavation line according to the drawings and the site conditions, and carry out excavation construction according to the excavation line, remove the soil layer, clean up the floating dust, silt, and sundries on the surface of the U-shaped foundation trench, tamp the bottom, and do a good job of waterproofing Drainage measures, keep the foundation groove dry, and leave a certain slope on both side walls to prevent collapse during vibration.

[0053] 2) After the groove is qualified, lay a composite soil layer with a thickness of 250mm at the bottom of the foundation groove. The above-mentioned composite soil layer is composed of clay, lime and fine sand, and its weight ratio is 1:2.5:5; the water content is controlled at 15%. The above-mentioned lime is slaked lime, and the particle size shall not be greater than 5mm; the p...

Embodiment 2

[0060] In this embodiment, epoxy mortar is also laid in the trench structure for anti-corrosion treatment, so the preparation method of the trench with anti-seepage function specifically includes the following steps:

[0061] 1) Before construction, first determine the excavation line according to the drawings and the site conditions, and carry out excavation construction according to the excavation line, remove the soil layer, clean up the floating dust, silt, and sundries on the surface of the U-shaped foundation trench, tamp the bottom, and do a good job of waterproofing Drainage measures, keep the foundation groove dry, and leave a certain slope on both side walls to prevent collapse during vibration.

[0062] 2) After the groove is qualified, lay a composite soil layer with a thickness of 200mm at the bottom of the foundation groove. The above-mentioned composite soil layer is composed of clay, lime and fine sand, and its weight ratio is 1:2:4; the moisture content is con...

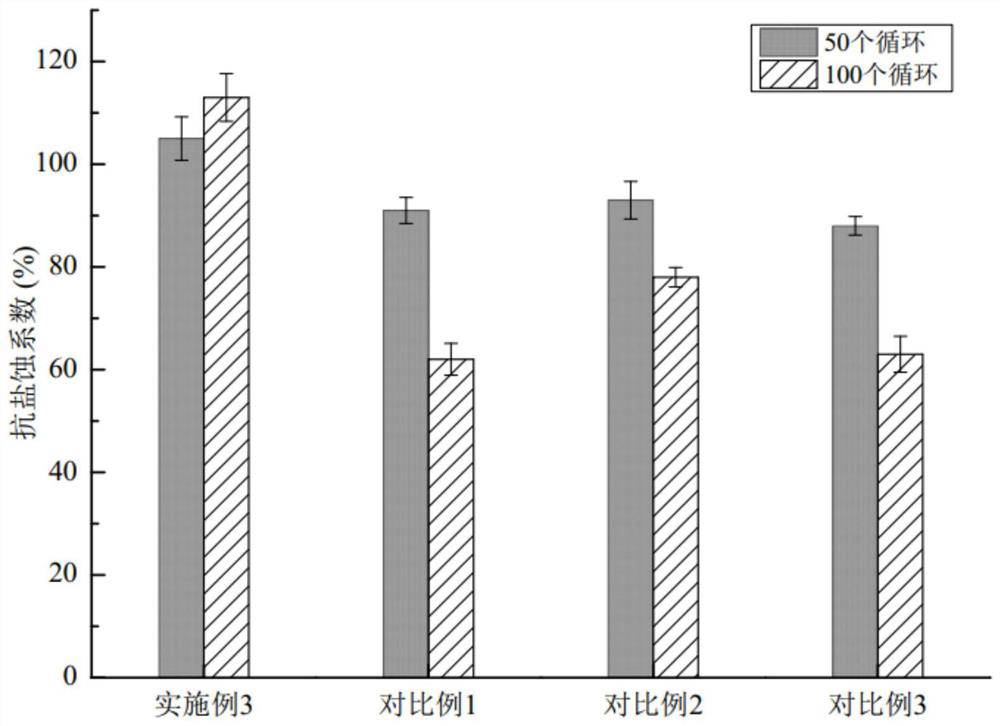

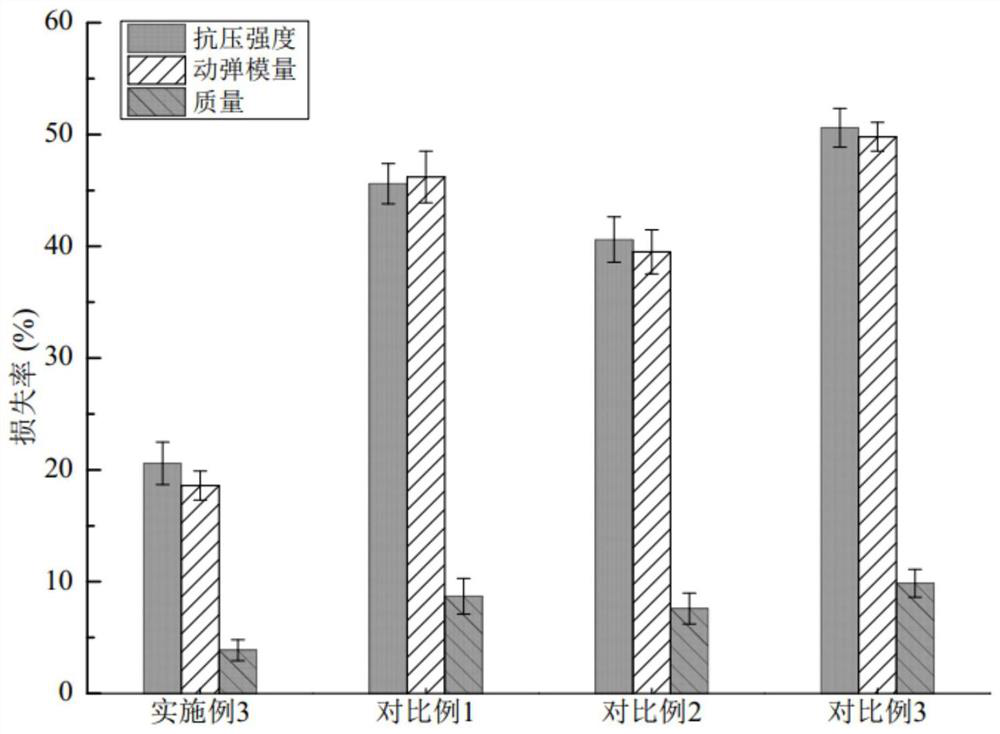

Embodiment 3

[0071] In this embodiment, the difference between the preparation method of the trench with anti-seepage function and embodiment 2 lies in the following steps:

[0072] Step 2) After the groove is qualified, lay a composite soil layer with a thickness of 250mm at the bottom of the foundation groove. The above-mentioned composite soil layer is composed of clay, lime and fine sand, and its weight ratio is 1:3:6; the moisture content is controlled at 17%.

[0073] Step 3) Lay a polyethylene geomembrane with a thickness of 0.8 mm on the composite soil layer as an anti-seepage membrane for anti-seepage treatment, and lay the bottom and side walls of the trench at the same time.

[0074] Step 4) Lay a lime-soil cushion with a thickness of 90 mm on the anti-seepage membrane, and ensure that the compaction coefficient is ≥ 0.97. The above-mentioned lime-soil cushion layer adopts notoginseng lime-soil, and the water content is controlled at 22%.

[0075] Step 5) first take 1050 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com