Construction method for rapidly conducting impervious curtain grouting in karst pipeline leakage area

A technology of anti-seepage curtain and construction method, which is applied in the direction of infrastructure engineering, construction, etc., which can solve the problems of poor construction quality and progress, large engineering volume, and high cost, and achieve the effects of small engineering volume, less consumable materials, and short working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

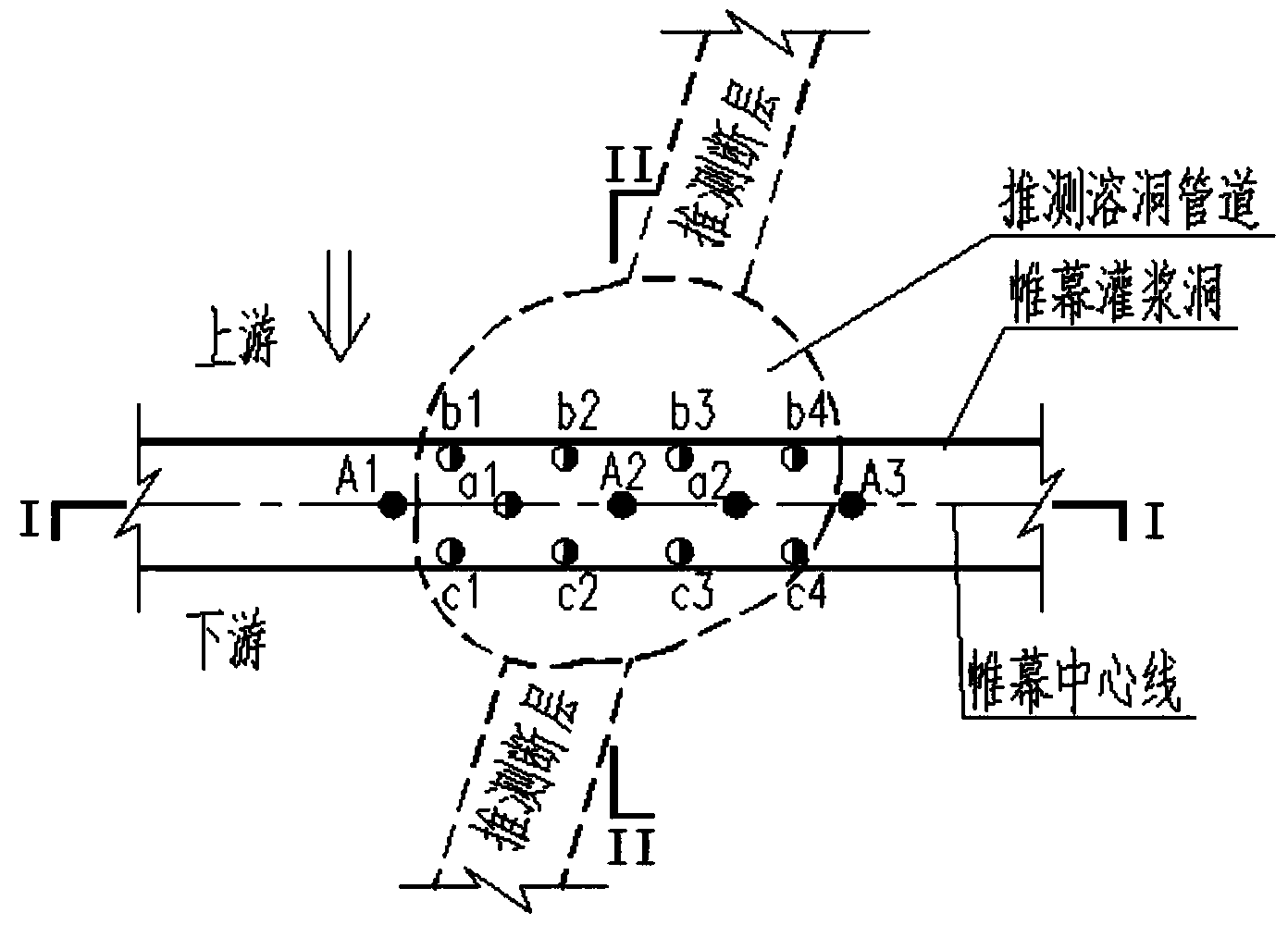

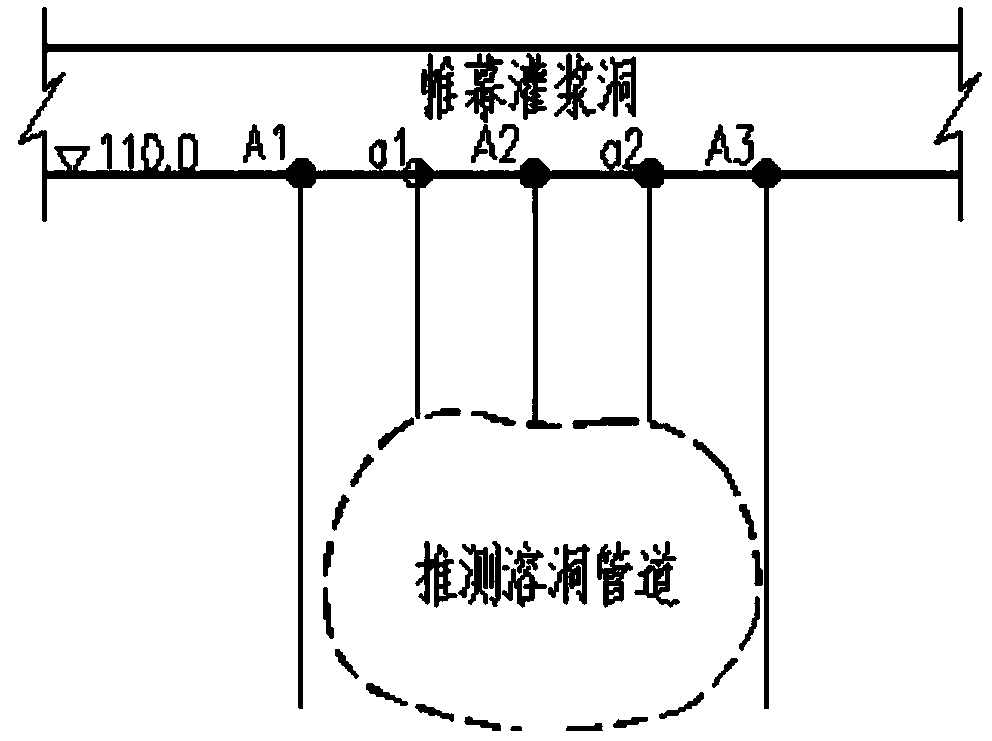

[0027] Firstly, drill conventional grouting hole A1, grouting hole A2 and grouting hole A3, the diameter of which is 75mm. According to the phenomenon, it can be preliminarily inferred that this area is a section where karst pipelines are developed; then, according to the original design hole spacing, the intensified hole a1 and the intensified hole a2 are arranged, and the hole diameter is 75mm. Hole B (b1, b2, b3, and b4) and a row of detection holes C (c1, c2, c3, and c4), the same aperture diameter is 75mm and the detection hole B and detection hole C are both oblique holes of 5°, arranged in the same direction In order to tilt outward based on the vertical direction, the main function is to detect the distribution range of the upstream and downstream directions of the karst pipeline and the grouting axis, and then determine the grouting implementation method according to the implementation effect of the detection hole; if the karst pipeline around the grouting hole is dist...

Embodiment 2

[0029] Firstly, drill conventional grouting hole A1, grouting hole A2 and grouting hole A3, the diameter of which is 75mm. According to the phenomenon, it can be preliminarily inferred that this area is a section where karst pipelines are developed; then, according to the original design hole spacing, the intensified hole a1 and the intensified hole a2 are arranged, and the hole diameter is 75mm. Detection holes B (b1, b2, b3, and b4) and a row of detection holes C (c1, c2, c3, and c4), with the same aperture diameter of 75mm and 7° oblique holes for detection holes B and C, are arranged to face They are all inclined outwards based on the vertical direction. The main function is to detect the distribution range of the upstream and downstream directions of the karst pipeline and the grouting axis, and then determine the grouting implementation method according to the implementation effect of the detection hole; In the coverage area of detection hole B and detection hole C, it...

Embodiment 3

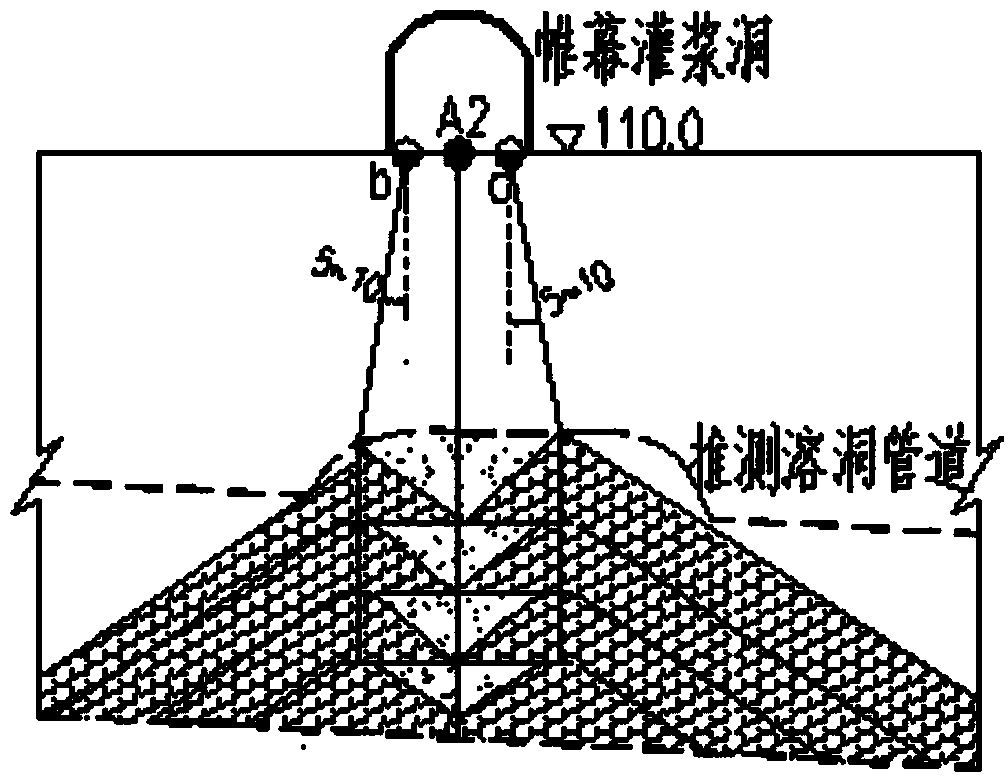

[0031] Firstly, drill conventional grouting hole A1, grouting hole A2 and grouting hole A3, the diameter of which is 75mm. According to the phenomenon, it can be preliminarily inferred that this area is a section where karst pipelines are developed; then, according to the original design hole spacing, the intensified hole a1 and the intensified hole a2 are arranged, and the hole diameter is 75mm. Detection holes B (b1, b2, b3, and b4) and a row of detection holes C (c1, c2, c3, and c4), with the same aperture diameter of 75mm and 10° oblique holes for detection holes B and C, are arranged to face They are all inclined outwards based on the vertical direction. The main function is to detect the distribution range of the upstream and downstream directions of the karst pipeline and the grouting axis, and then determine the grouting implementation method according to the implementation effect of the detection hole; In the coverage area of detection hole B and detection hole C, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com