Vertical shaft wall structure in bad stratum and construction device and method

A wall structure, poor technology, applied in shaft equipment, borehole/well components, sinking, etc., can solve the problems of layered backfill homogeneous soil, long construction period, difficult large-scale excavation, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

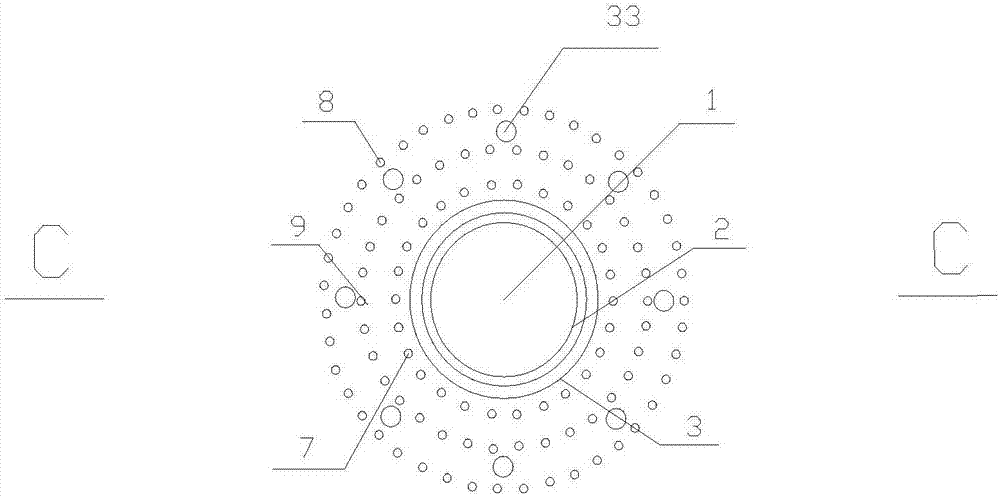

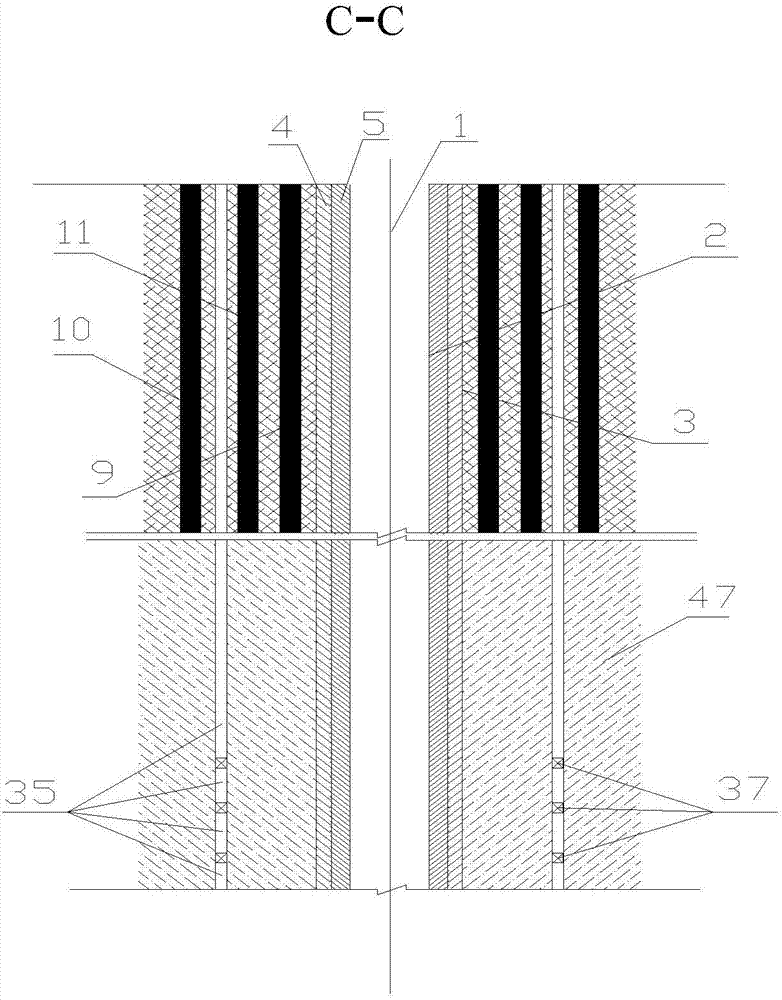

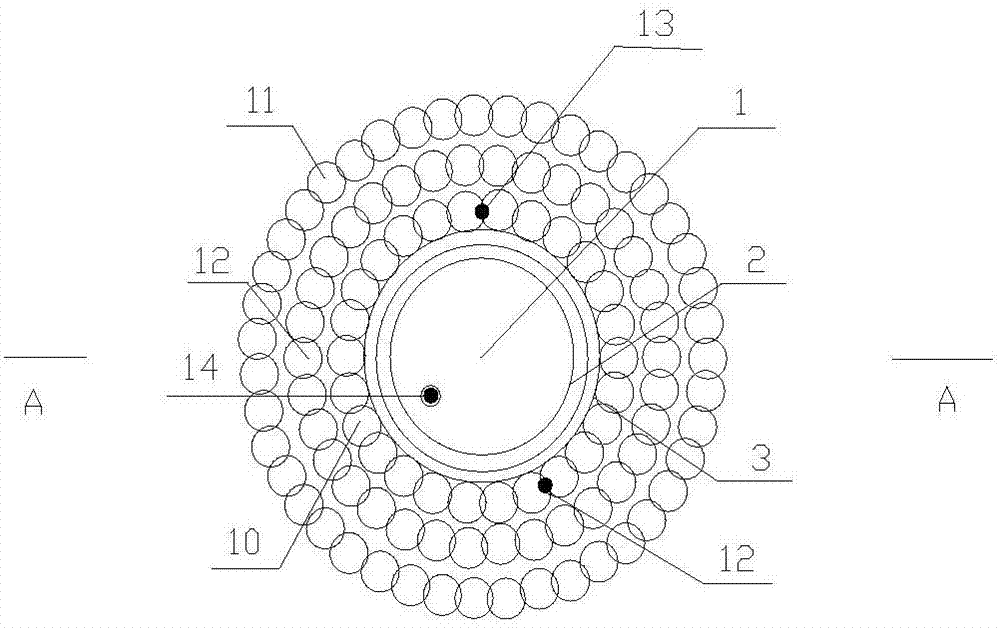

[0068] Depend on figure 1 , figure 2 , Figure 5 , Figure 6 , Figure 9It can be seen from the figure that a shaft wall structure in unfavorable formations includes the wellbore set in unfavorable formations, the wall structure of the high-spray curtain pile set in the neck section of the upper part of the shaft, and the positioning and targeting set in the bedrock section. The grouting well wall structure and the well wall, the upper and lower well walls are concentric and have the same diameter, and are closely connected into one; the well wall structure of the high-spray curtain pile at the neck section of the vertical well, the rock formation is excavated in the barren diameter line 3 of the wellbore, and the wellbore The shaft wall shall be poured between the clear diameter line 2 and the poor diameter line of the shaft, with the center of the shaft 1.1 as the center (not marked in the figure), and at least three ring-shaped high-spray curtain walls closed at the end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com