A Low Disturbance Leveling Machine for Foundation Pit

A low-disturbance, leveling machine technology, applied in the direction of earth movers/shovels, construction, etc., can solve the problems of unevenness, easy disturbance, slow manual excavation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

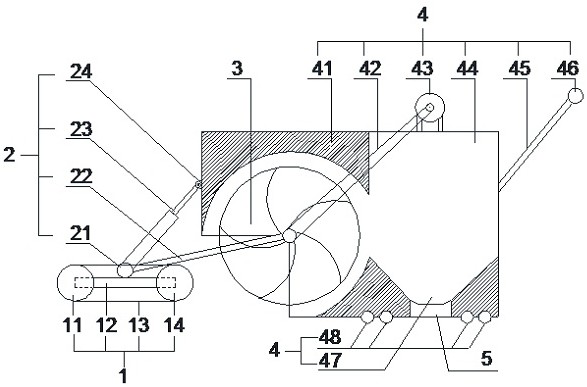

[0032] see Figure 1-Figure 9, a low-disturbance foundation pit leveling machine, including a two-wheel crawler vehicle 1, a traction system 2, a soil cutting wheel 3, a soil storage box 4, and a soil accumulation transmission device 5, characterized in that: the two-wheel crawler vehicle 1 is connected to the soil storage box 4 through the traction system 2, the soil cutting wheel 3 is installed at the front lower part of the soil storage box 4, and the soil accumulation transmission device 5 is installed at the rear lower part; Electric drive, providing forward traction; two-wheel crawler vehicle 1 is universally connected to traction system 2; the traction force of two-wheel crawler vehicle 1 is transmitted to soil storage box 4 through traction system 2, driving soil storage box 4 forward; traction system 2 Connect the central point of the front end of the soil storage box 4; the shape of the hollowed out front half of the soil storage box 4 is 3 / 4 sector, and the 1 / 4 gap ...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

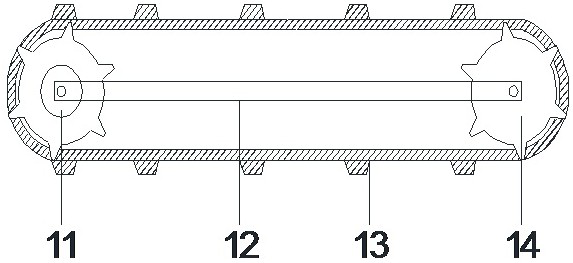

[0035] 2. The two-wheeled tracked vehicle 1 is a two-wheeled independent power tracked vehicle, comprising a front active track wheel 11, a tracked vehicle beam 12, a track 13 and a rear driven track wheel 14; the front active track wheel 11 is an electric drive wheel, and the rear The driven track wheel 14 has no power, and the speed of the left and right driving wheels is controlled to be different so that it can turn freely; the tracked vehicle beam 12 is a bridge connecting the left and right track wheels, and the middle part is welded with a universal rotating slipknot 21, which is used to transmit traction and change direction The crawler belt 13 is a part directly in contact with the ground, because the crawler belt is flatter than the common tire, and the ground contact part is always on the same level, so the soil layer contacted by the crawler belt 13 and the soil ...

Embodiment 3

[0041] Such as Figure 1-9 As shown, the embodiment provides a low-disturbance foundation pit leveling machine, which includes a two-wheel crawler vehicle 1 , a traction system 2 , a soil cutting wheel 3 , a soil storage box 4 and a soil accumulation conveying device 5 .

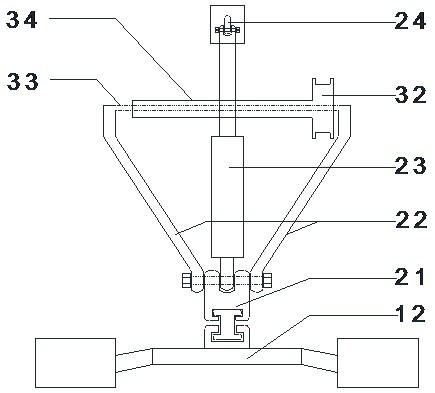

[0042] The two-wheeled crawler vehicle 1 is driven by electricity and provides forward traction for the whole device. The two-wheeled crawler vehicle 1 is connected to the traction system 2 through the universal conversion slipknot 21; the traction force of the two-wheeled crawler vehicle 1 is transmitted to the soil storage box through the traction system 2 4. Drive the soil storage box 4 forward; the traction system 2 uses two drawbars 22 to connect the two ends of the central fixed shaft 33, and the hydraulic telescopic rod 23 is connected to the central point of the front end of the soil storage box 4; the front half of the soil storage box 4 is the front box body 41, the shape of the hollowed out inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com