Stage construction method for perpendicular anti-seepage structure of toe boards of concrete faced rockfill dam

A face rockfill dam and construction method technology, which is applied in the direction of dams, barrages, water conservancy projects, etc., can solve the problems affecting the construction of the cushion face plate and the long construction period of the anti-seepage wall, and achieve the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

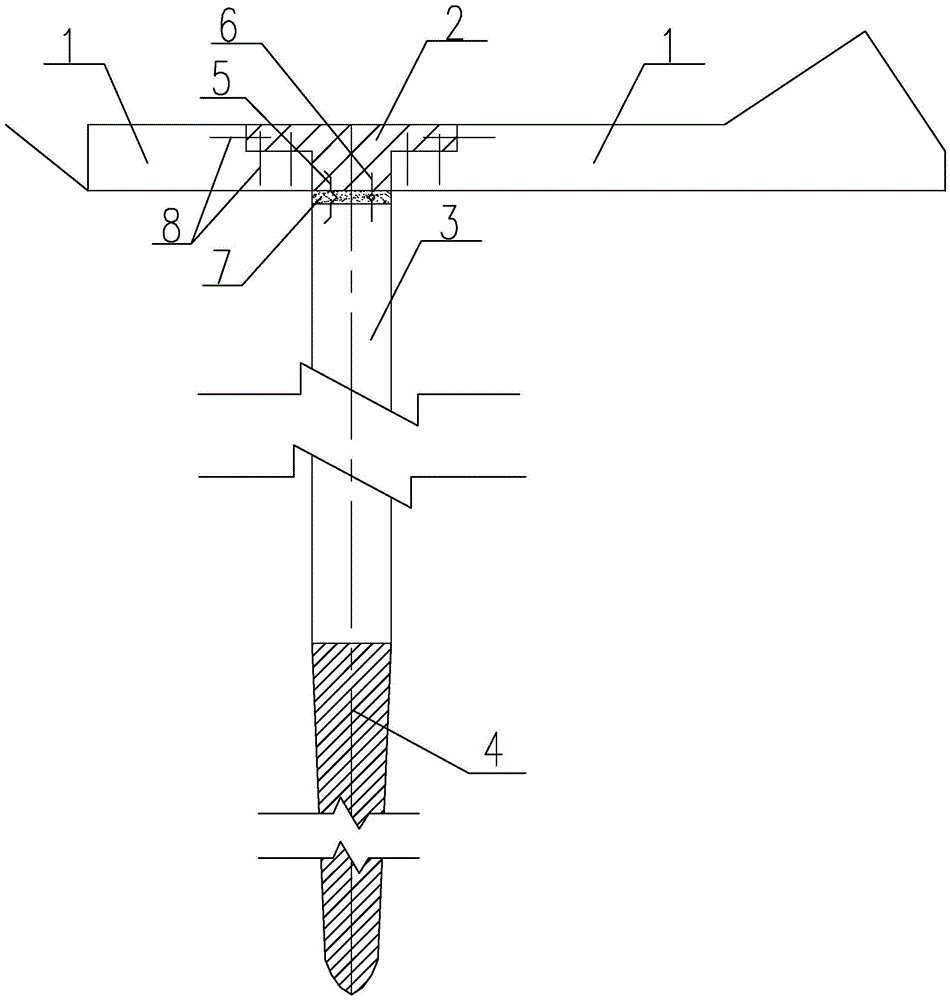

[0019] Such as figure 1 As shown, this embodiment is a staged construction method for the vertical anti-seepage structure of the toe slab of a face rockfill dam. On the strongly weathered rock foundation (such as soft rock), it includes the first-stage plinth 1, the second-stage plinth 2, the concrete anti-seepage wall 3 and the grouting curtain 4. The characteristic of this example is that the construction of the first-stage toe board 1 is carried out on the upstream and downstream of the concrete cut-off wall 3 first, and a T-shaped cut-off wall slot is reserved in the middle of the first-stage toe-board 1, and a pre-slotted hole is prepared at the slot position. Leave inserting ribs 8 (including horizontal and vertical inserting bars); then carry out the construction of the concrete cut-off wall 3, which is poured in groove sections, and the length of each groove section is 6-8m. The cut-off wall is generally embedded in strong weathering The bottom of the bedrock (or 1m d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com