Rock-socketed single pile foundation of offshore wind turbines in batholith seabed and construction method thereof

A technology for offshore wind turbines and single-pile foundations, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., and can solve problems such as uneven drilling rock surfaces, stress concentration in rock-socketed sections of steel pipe piles, and many uncontrollable factors. Achieve the effect of solving key technical problems, reducing stress concentration problems, and reducing basic investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

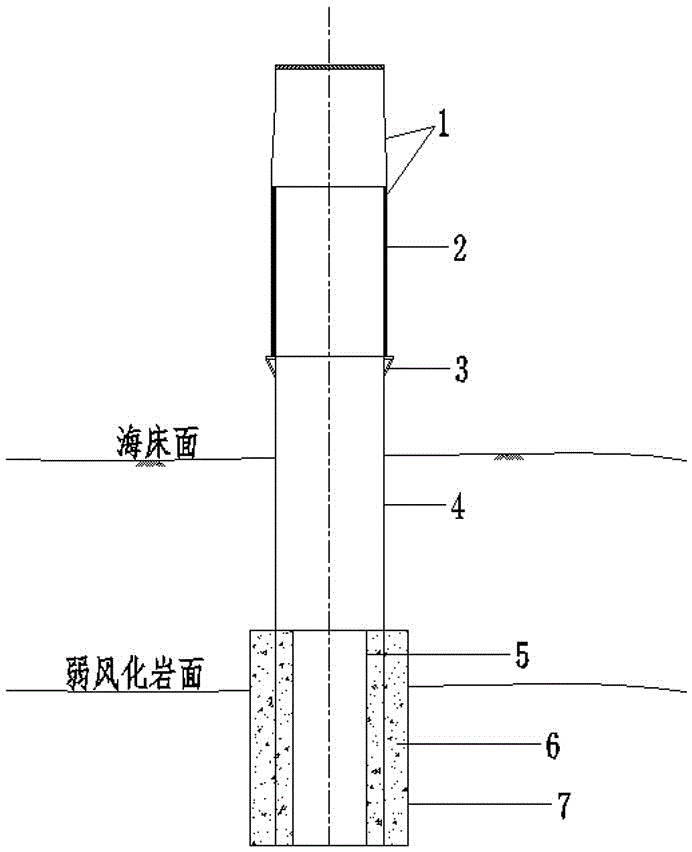

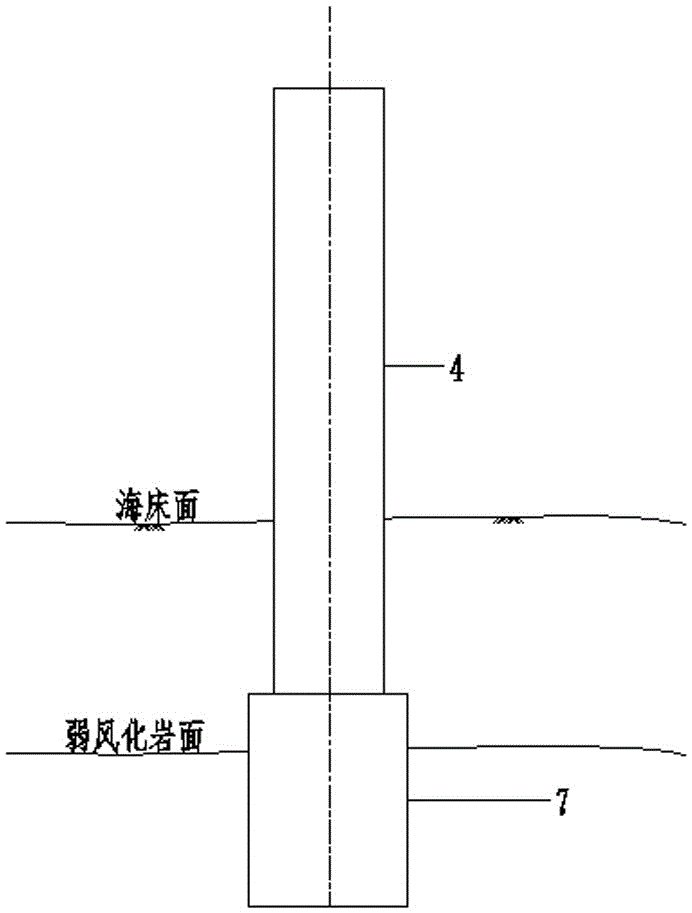

[0018] Such as figure 1 As shown, a rock-socketed seabed offshore fan rock-socketed single pile foundation includes a steel pipe pile 4 inserted into a weakly weathered rock base, and an annular groove 7 located at the periphery of the lower end of the steel pipe pile 4 is opened in the rock foundation. The inner casing of the lower end of the pile is provided with an inner casing 5, and there is a gap between the inner casing 5 and the inner wall of the steel pipe pile 4, and the initial setting The high-strength grouting body 6 with a time of not less than 8 hours, the high-strength grouting body 6 ensures that the outer wall of the steel pipe pile is closely combined with the rock mass. By adding a thin-walled inner casing inside the lower end of the single pile foundation, and performing reliable grouting at the pile end, the single The pile foundation can be closely combined with the surrounding bedrock, and can be reliably embedded in the weakly weathered rock base; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com