Chemical grouting material for reinforcing loose and broken bedrock

A chemical grouting material and grouting material technology, applied in the application, household appliances, other household appliances and other directions, can solve the problems of a large number of harmful gases, spontaneous combustion of consolidated bodies, detonation of gas, etc., to reduce prices, increase flash point, The effect of lowering the polymerization temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

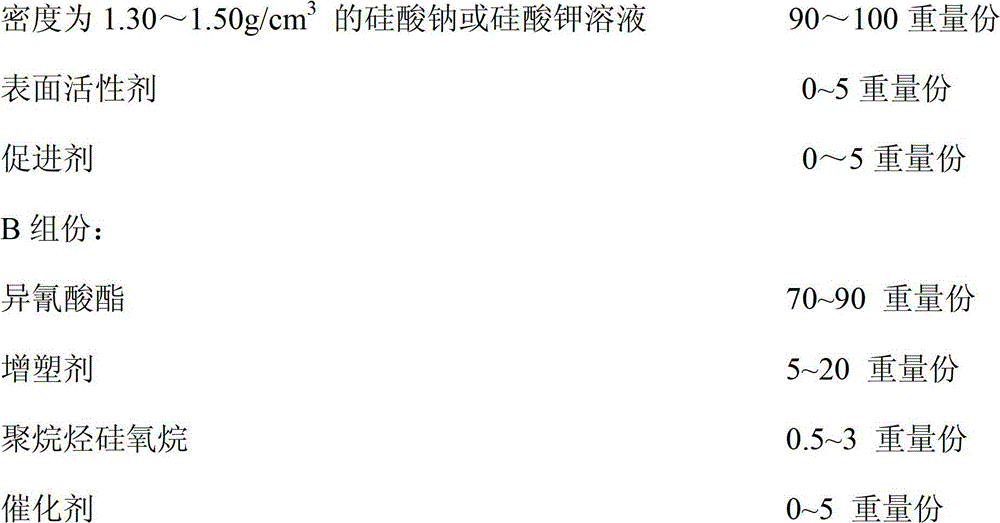

[0033] Embodiment 1. In this embodiment, the chemical grouting material is composed of two components A and B, and the raw material formulas are as follows:

[0034] A component:

[0035] Sodium silicate solution (Na 2 O nSiO 2 , modulus n=2.8, density d=1.37) 99 parts by weight

[0036] Polysorbate (Tween-80) 1 part by weight

[0037] B component:

[0038]

[0039] Stir components A and B separately, and mix and stir evenly according to component A / component B=1 / 1 (volume ratio) when using.

[0040] The product technical indicators obtained according to this implementation are as follows:

[0041] performance

Embodiment 2

[0042] Embodiment 2, the proportioning of the raw material of this example is

[0043] A component:

[0044] Sodium silicate solution (Na 2 O nSiO 2 , modulus n=2.5, density d=1.48) 99 parts by weight

[0045] Alkylphenol polyoxyethylene ether (OP-10) 1 part by weight

[0046] B component:

[0047]

[0048] Stir components A and B separately, and mix and stir evenly according to component A / component B=1 / 1 (volume ratio) when using.

[0049] The product technical indicators obtained according to this implementation are as follows:

[0050] performance

Embodiment 3

[0051] Embodiment 3, the proportioning of the raw material of this example is

[0052] A component:

[0053] Potassium silicate solution (K 2 O nSiO 2 , modulus n=2.8, density d=1.43) 96 parts by weight

[0054] Sodium dodecylbenzenesulfonate 2 parts by weight

[0055] Triethanolamine 2 parts by weight

[0056] B component:

[0057]

[0058]

[0059] Stir components A and B separately, and mix and stir evenly according to component A / component B=1 / 1 (volume ratio) when using.

[0060]The technical index of the product that above embodiment obtains is as follows:

[0061] performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com