Grouting pipe for miscellaneous fill stratum and construction method

A construction method and technology of grouting pipes, which are applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of grouting on the ground, failure to reach the reinforced soil layer, and large unevenness of particles, so as to achieve the purpose of reinforcing miscellaneous filling The effect of soil layer, improvement of reinforcement effect, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

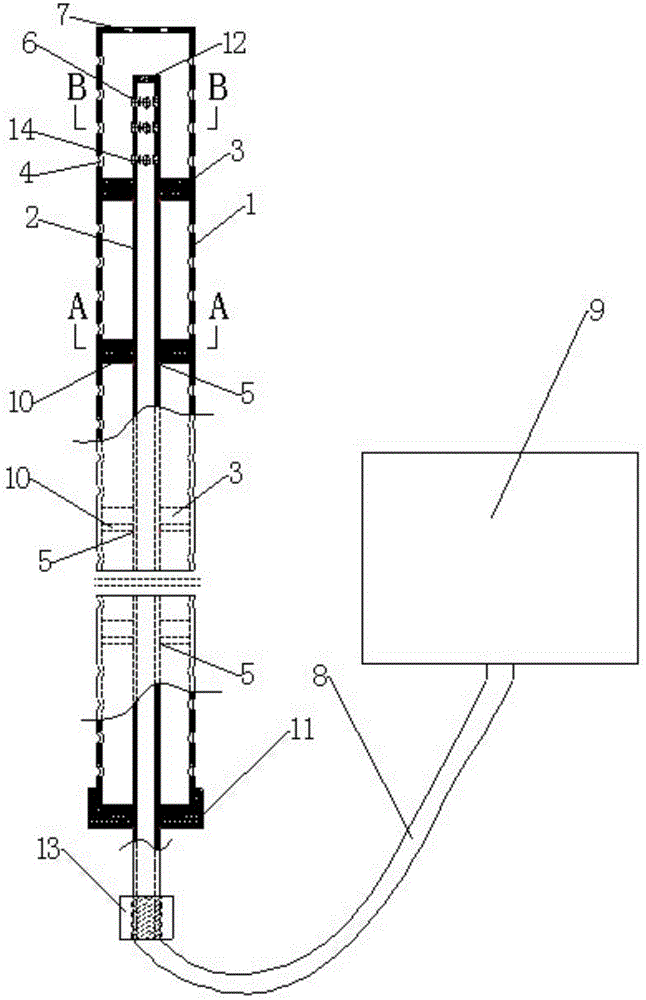

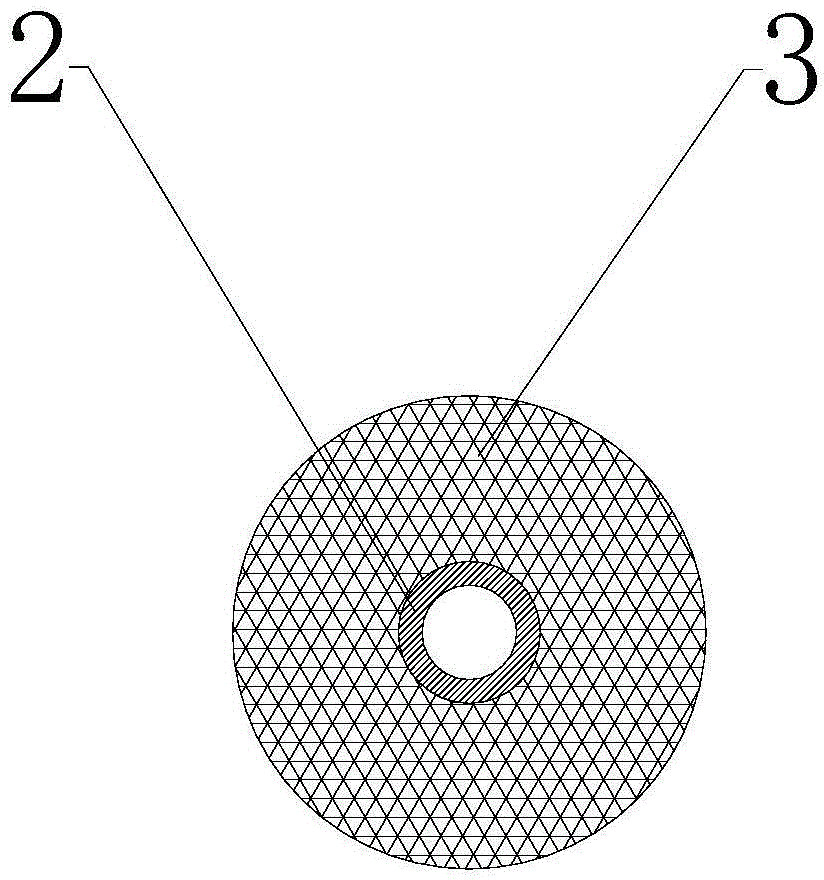

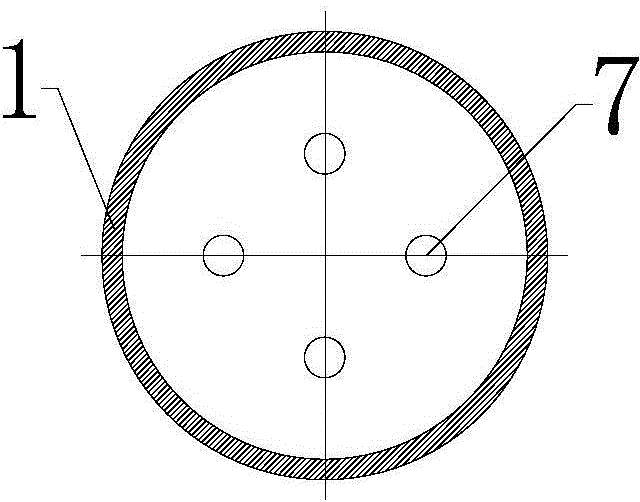

[0026] Such as figure 1 As shown, the grouting pipe used for miscellaneous fill soil formations is mainly composed of an external grouting pipe 1, an internal grouting pipe 2, a grout stopper 3, a grout blocking piece 6, a section separation ring 10 and a sealing plug 11. The inner grouting pipe 2 extends into the outer grouting pipe 1, the surface of the outer grouting pipe 1 is evenly opened with a number of grouting holes 4, and the top is opened with a top grouting hole 7, the inner grouting pipe 2. The upper spacer sleeve is equipped with a section partition ring 10 that divides the interior of the external grouting pipe 1 into multiple sections. Each section partition ring 10 is provided with a grout stopper 3. The grout stopper 3 is Elastic rubber stopper, the elastic rubber stopper is bonded on the section separating ring 10 by a strong adhesive, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com