Construction method for grouting curtain combined with steel reinforced concrete guard ring

A technology of reinforced concrete and grouting curtain, which is applied in soil protection, infrastructure engineering, construction and other directions, can solve the problems of high construction cost, large amount of steel used for steel pipe curtain piles, and many construction equipment, etc., and achieves low cost and saving. Cost, good anti-seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

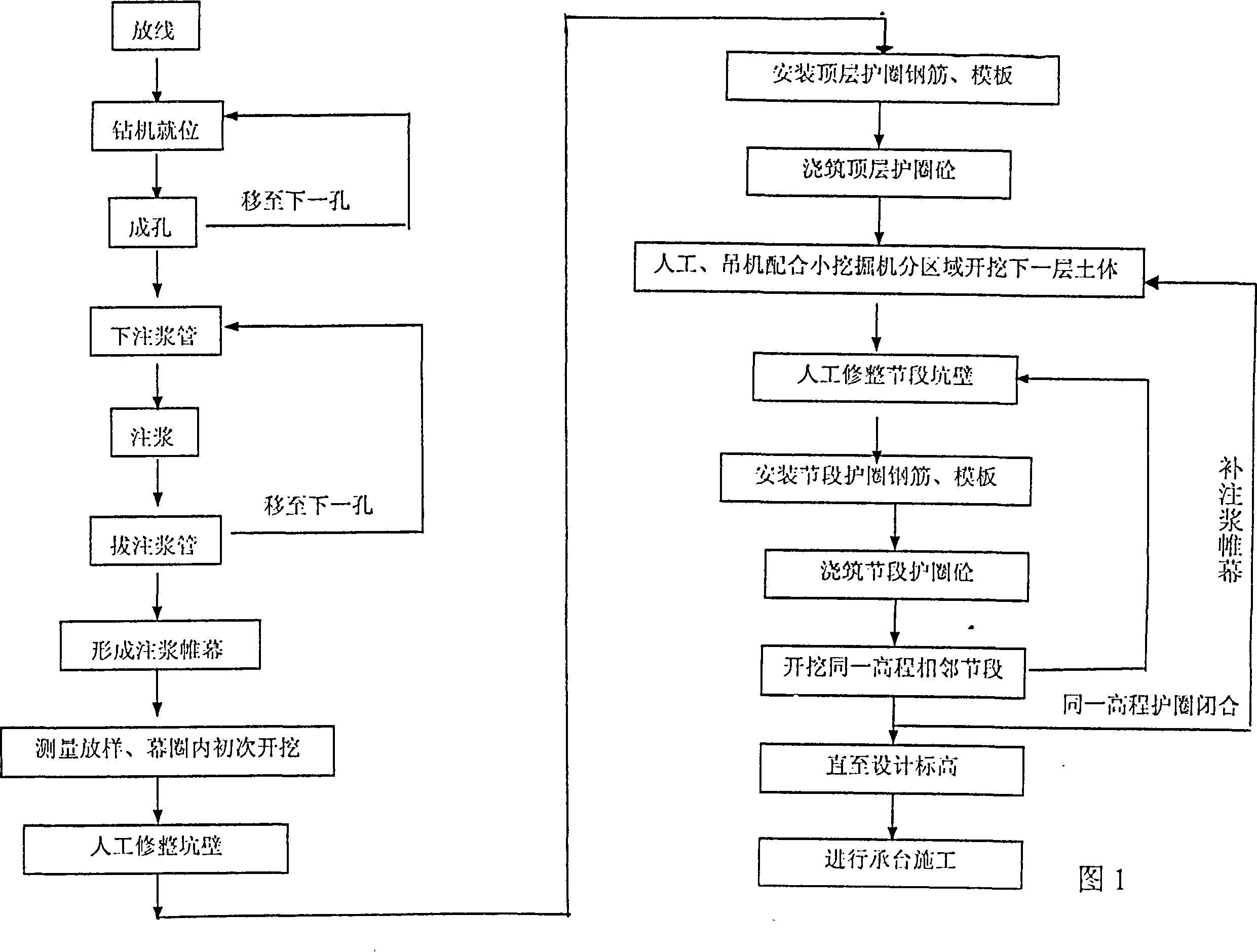

[0013] Referring to attached drawing 1, the grouting curtain construction method: first use the engineering drilling rig and the grouting machine to carry out the grouting curtain construction, consolidate the soil around the cofferdam to meet the requirements of water stop and partial wall consolidation, and wait for the bored pile construction to be completed 1. After the strength of the curtain cement slurry meets the requirements, carry out excavation and support in stages until the bottom of the pit. Then make a concrete cushion, install the cap reinforcement and formwork, and pour the cap concrete.

[0014] In the construction method of grouting flow operation, the drilling and grouting are divided into two groups, the front one forms the hole, the back one group grouting, and the two groups work in parallel.

[0015] Layout of grouting holes: The curtain adopts two rows of grouting holes, the diameter of the inner row is 25.68m, the diameter of the outer row is 27.2m, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com