Local foundation settlement reinforcement method for steel storage tank ring wall foundation

A technology for steel storage tanks and foundations, which is applied in the field of local subsidence and reinforcement of steel storage tank ring wall foundations, can solve problems such as weak lateral constraints and difficult control of grouting volume, and achieve reduced horizontal lateral deformation and good technical effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

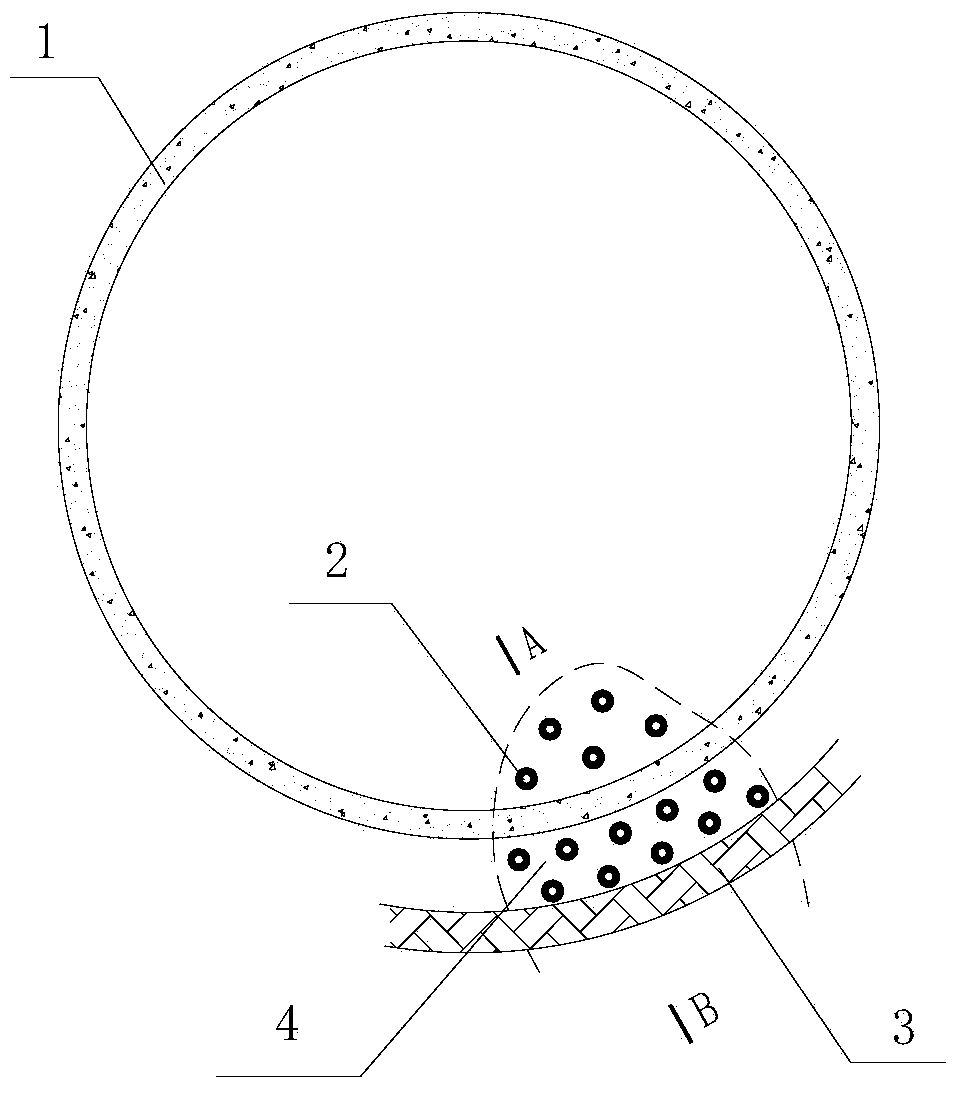

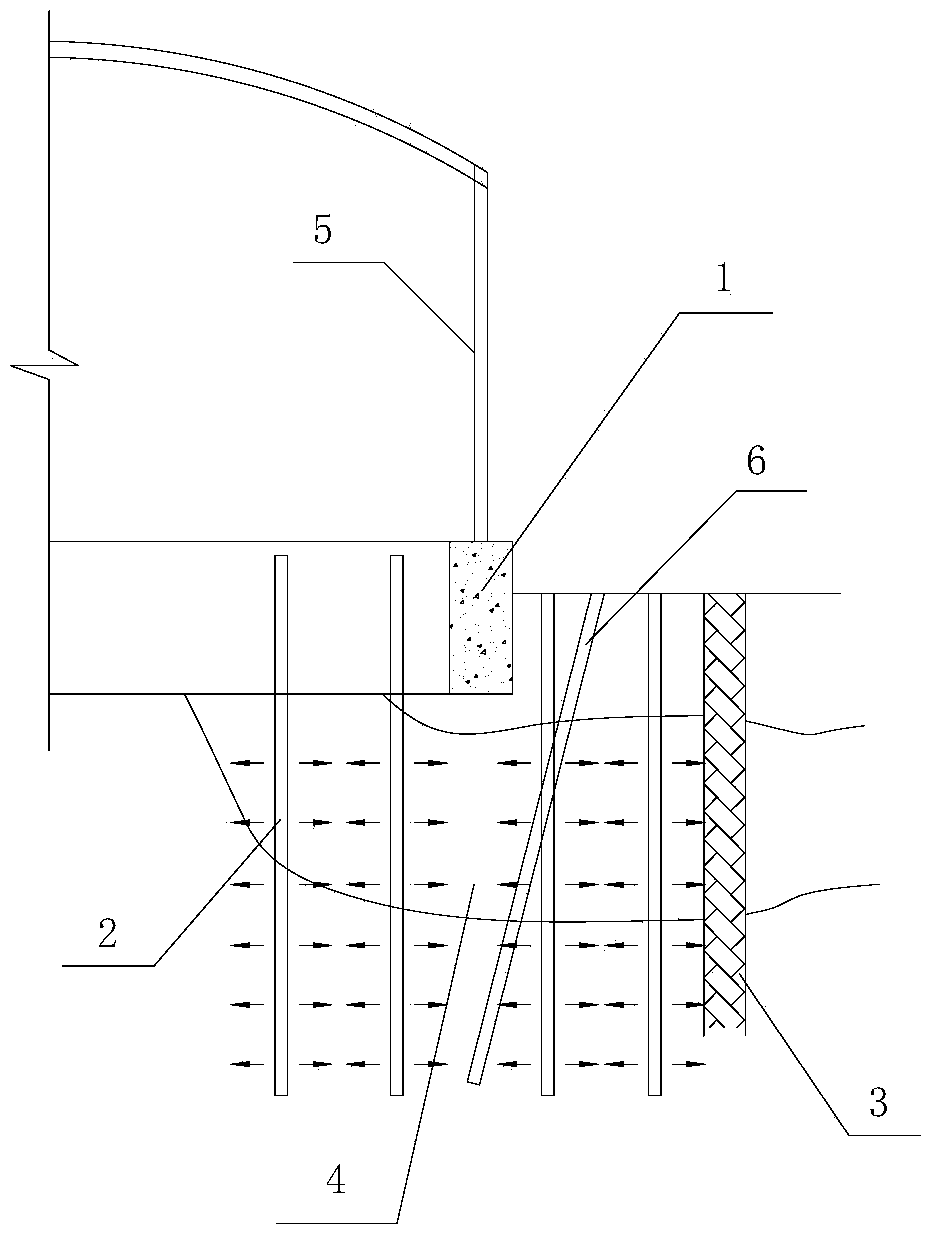

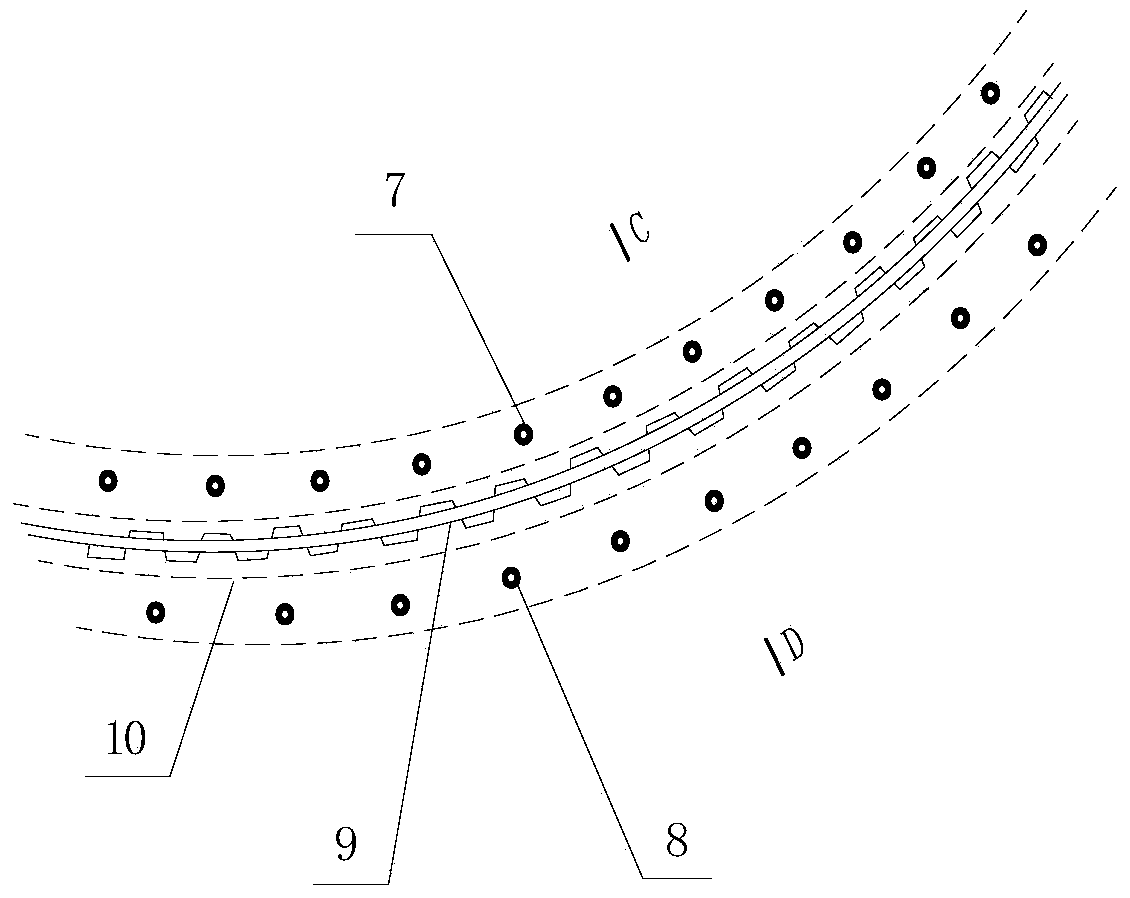

[0023] Local subsidence occurred in the foundation of a steel storage tank. The subsidence soil is mainly highly compressible, plastic-flow-plastic cohesive soil and silty cohesive soil. The location of the occurrence is under the tank ring wall foundation. Firstly, the scope and depth of the subsidence area were determined, and then the grouting curtain was artificially slotted 3m outside the ring wall foundation. The grouting curtain consisted of a bamboo raft and two rows of grouting holes, and the length of the grouting curtain was partially The subsidence area is extended by 1.0m. The bamboo raft is made of multiple bamboo boards that are overlapped and connected with each other. The depth of the bamboo board is 3m, and the distance between the grouting holes is 1000mm. It is 1500mm. Grouting in the grouting hole, the grouting material is mainly cement mortar with low slump, after forming the grouting curtain, adopt the conventional compaction grouting process to carry ou...

Embodiment 2

[0025] Local subsidence occurred in the foundation of a steel storage tank. The subsidence soil is mainly highly compressible, plastic-flow-plastic cohesive soil and silty cohesive soil. The location of the occurrence is under the tank ring wall foundation. Firstly, the scope and depth of the subsidence area are determined, and then the grouting curtain is artificially slotted 2.5m away from the outer side of the ring wall foundation. The grouting curtain consists of two polypropylene geogrids and four rows of grouting holes spaced apart from each other. . The length of the grouting curtain is 1.2m outside the local subsidence area, the depth of the polypropylene geogrid is 3m, the distance between the grouting holes is 750mm, and the distance between two rows of grouting holes is 1000mm. Grouting in the grouting hole, the grouting material is mainly cement mortar with low slump, after forming the grouting curtain, adopt the conventional compaction grouting process to carry ou...

Embodiment 3

[0027]Local subsidence occurred in the foundation of a steel storage tank. The subsidence soil is mainly highly compressible, plastic-flow-plastic cohesive soil and silty cohesive soil. The location of the occurrence is under the tank ring wall foundation. Firstly, the scope and depth of the subsidence area were determined, and then a grouting curtain was artificially slotted 4m outside the ring wall foundation. The grouting curtain consisted of two bamboo rafts and four rows of grouting holes, spaced apart from each other. The length of the grouting curtain is 0.8m outside the local subsidence area, the depth of the bamboo raft is 3m, the distance between the grouting holes is 1500mm, and the distance between two rows of grouting holes is 2000mm. Grouting in the grouting hole, the grouting material is mainly cement mortar with low slump, after forming the grouting curtain, adopt the conventional compaction grouting process to carry out compaction grouting in the local subsiden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com