Water-bearing layer segmented grouting curtain water-holding mining method

A technique of grouting curtain and segmental grouting, which is applied in ground mining, earth square drilling, underground mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

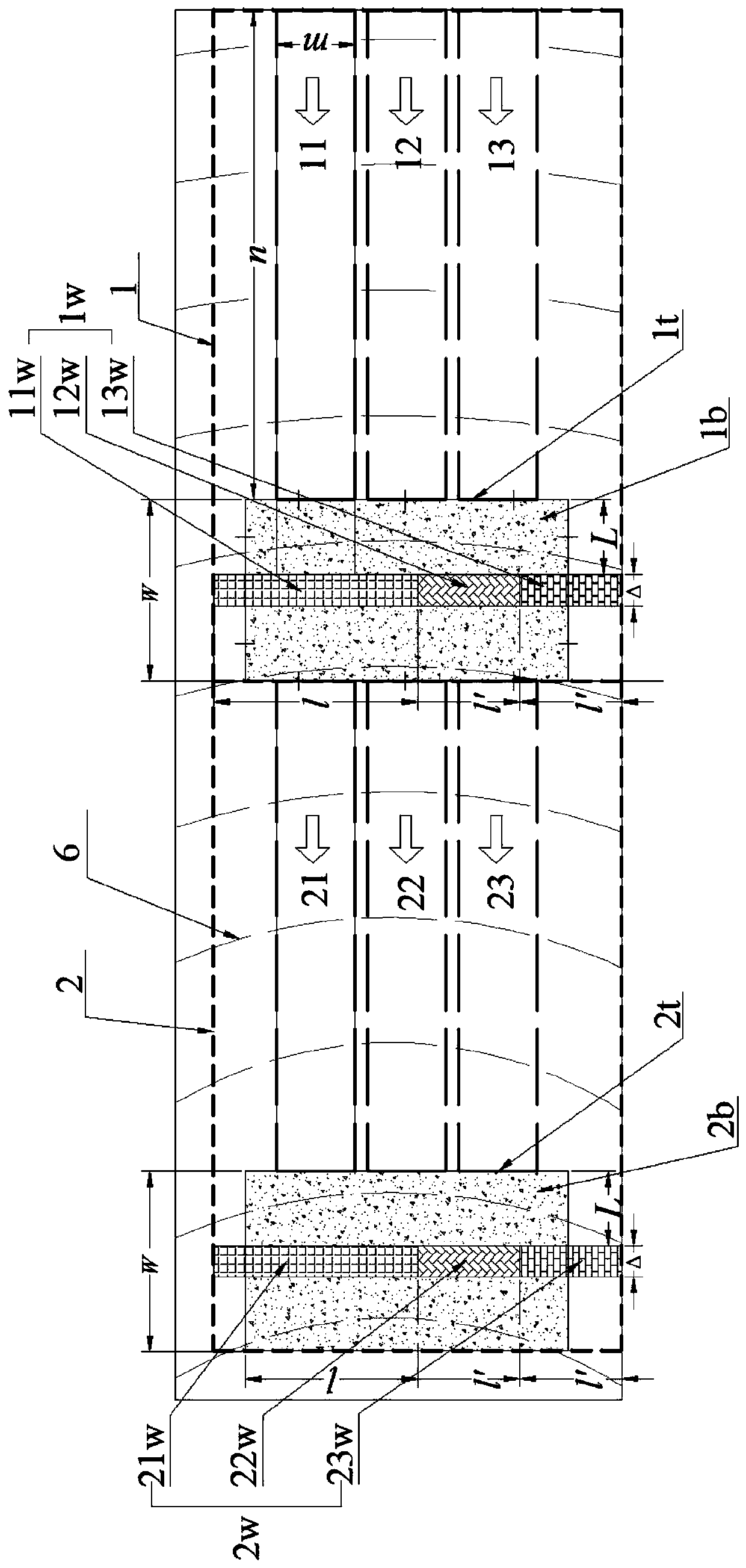

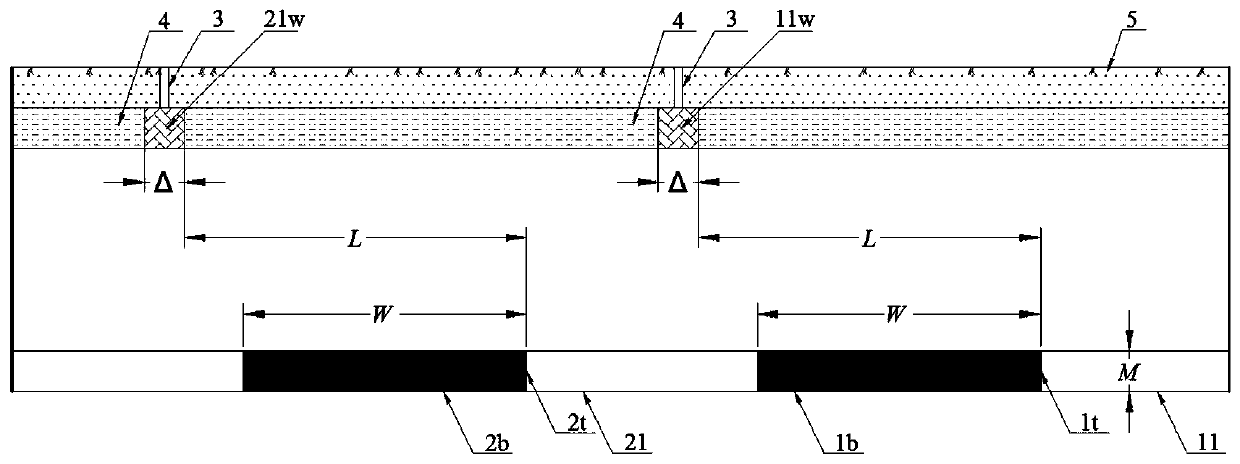

[0071] as attached figure 1 and 2 As shown, the advancing length of the working face of a certain mine is n=1800m, the length of the working face is m=150m, and the thickness of the mineable coal seam is M=10m. Such as figure 2 As shown, the distance between the roof of the working face and the aquifer is H=160m, the thickness of the aquifer is h=10m, and the water pressure q=1MPa. The width of the protection coal pillar is W=60m, and the rock formation movement angle δ=70°.

[0072] Step 1: Arrange the grouting curtain 11w of the first working face of the first mining area on the side of the aquifer 4 away from the edge of the mining area. The grouting material is cement-water glass slurry, the water-cement ratio of cement is 0.8:1, and the water The Baume degree of the glass is 40°Bé, water glass: cement = 1:1, and the shear strength of the curtain is τ = 0.6MPa. curtain length The 1t distance from the stop production line of the first mining area is L≥Hcotδ=61.9m, an...

Embodiment 2

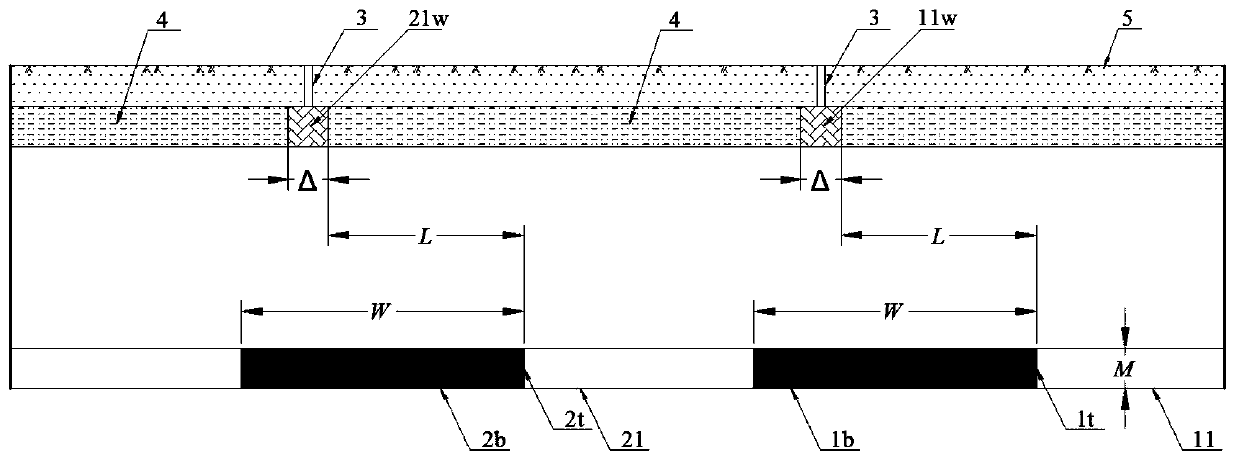

[0077] as attached figure 1 and 3 As shown, the advancing length of the working face of a certain mine is n=900m, the length of the working face is m=150m, and the thickness of the mineable coal seam is M=1m. Such as figure 1 As shown, the distance between the roof of the working face and the aquifer is H=100m, the thickness of the aquifer is h=5m, and the water pressure q=0.5MPa. The width of the coal pillar is W=60m, and the rock formation movement angle δ=70°.

[0078] Step 1: Arrange the grouting curtain 11w of the first working face of the first mining area on the side of the aquifer 4 away from the edge of the mining area. The grouting material is cement-water glass slurry, the water-cement ratio of cement is 0.8:1, and the water The Baume degree of the glass is 40°Bé, water glass: cement = 1:1, and the shear strength of the curtain is τ = 0.6MPa. Grouting Curtain Length The 1t distance from the stop production line of the first mining area is L≥Hcotδ=36.4m, and th...

Embodiment 3

[0084] as attached figure 1 and 4 As shown, the advancing length of the working face of a certain mine is n=1350m, the length of the working face is m=200m, and the thickness of the mineable coal seam is M=6m. Such as figure 1 As shown, the distance between the roof of the working face and the aquifer is H=30m, the thickness of the aquifer is h=9m, and the water pressure q=0.1MPa. The width of the protection coal pillar is W=60m, and the rock formation movement angle δ=70°.

[0085] Step 1: Arrange the grouting curtain 11w of the first working face of the first mining area on the side of the aquifer 4 away from the edge of the mining area. The grouting material is cement-water glass slurry, the water-cement ratio of cement is 0.8:1, and the water The Baume degree of the glass is 40°Bé, water glass: cement = 1:1, and the shear strength of the curtain is τ = 0.6MPa. Grouting Curtain Length The 1t distance from the stop production line of the first mining area is L≥Hcotδ=10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com