Construction method for forming waterproof grouting curtain on water-rich pore rock stratum by blasting

A technology of grouting curtain and construction method, which is applied in earthwork drilling, surveying, wellbore lining, etc., and can solve the problems of complex construction technology, long construction period, and high project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

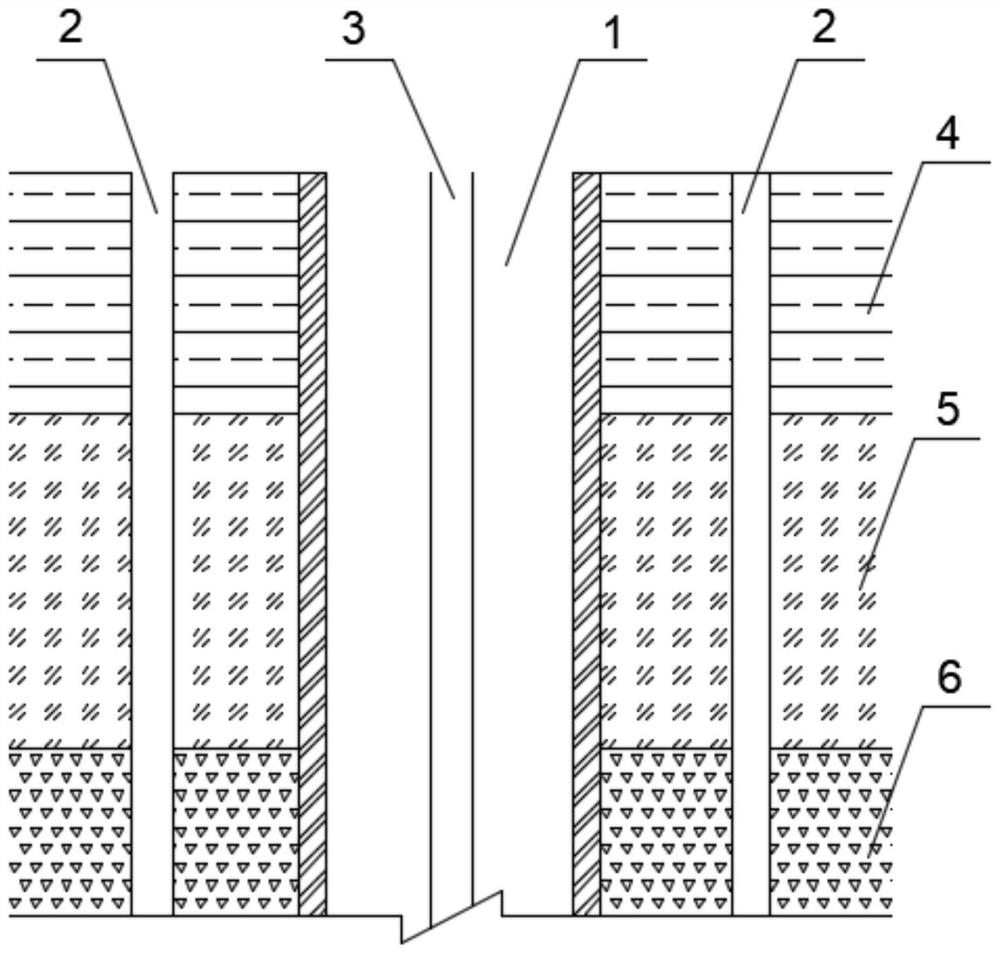

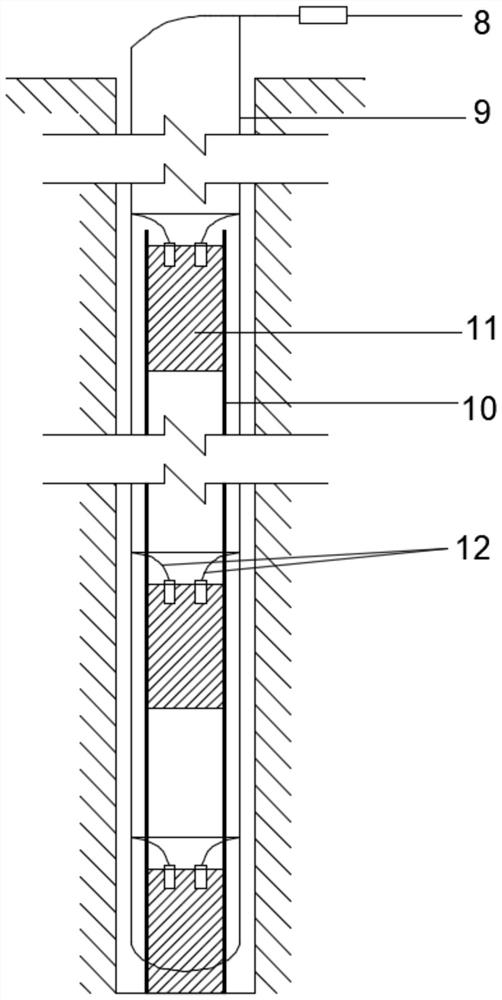

[0033] Such as figure 1 As shown, a construction method utilizing blasting to form a water-proof grouting curtain in a water-rich porous rock formation comprises the following steps:

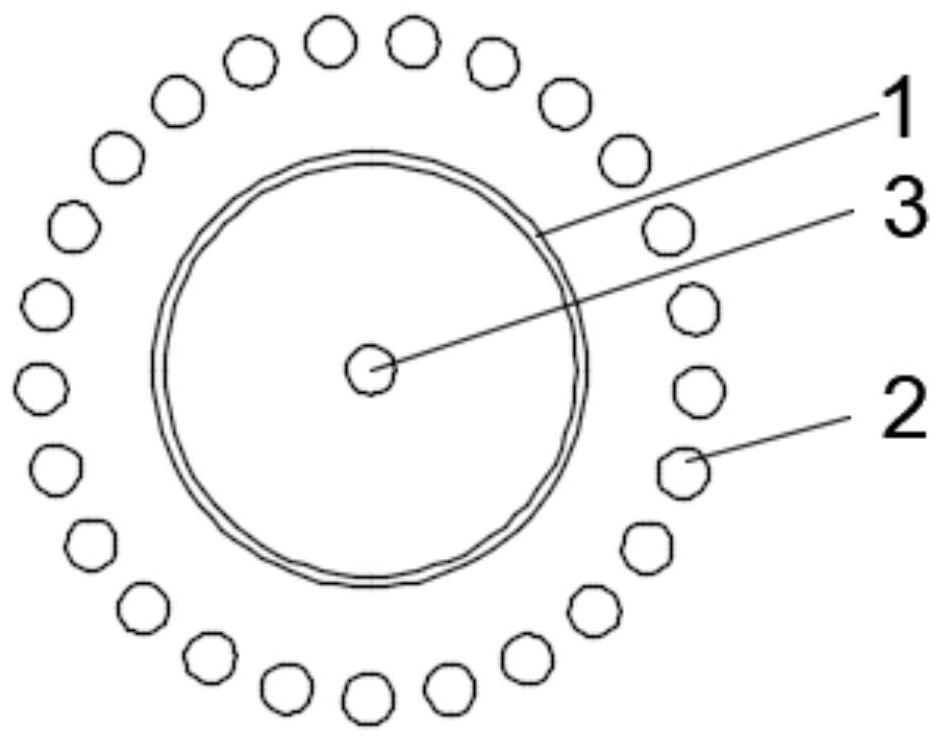

[0034] Step 1: If figure 2 As shown, taking the center of wellbore 1 as the center of the circle, a circle of blasting boreholes 2 is constructed on the periphery of the planned wellbore 1, and the distance between adjacent blasting boreholes 2 is 1.2m. Drilling rigs are used to drill vertically from the ground down until Through the water-rich porous rock formation 5 to reach the impermeable formation 6, the two sides of each blasting borehole 2 are respectively provided with grooves with a depth not greater than 10 cm through high-pressure water jets, and the grooves can form cracks between the blasting boreholes 2 Drill a pumping inspection hole 3 near the center of the well shaft to be constructed, and use a drilling rig to drill vertically from the ground until reaching the impermeable fo...

Embodiment 2

[0041] Such as Figure 4 As shown, a construction method utilizing blasting to form a water-proof grouting curtain in a water-rich porous rock formation comprises the following steps:

[0042] Step 1: If Figure 5 As shown, taking the center of wellbore 1 as the center, two circles of blasting boreholes 2 are constructed on the periphery of the planned wellbore. The distance between adjacent blasting boreholes 2 is 1.5m, and the distance between the first circle and the second circle is Drilling rigs are used to drill vertically from the ground downwards. The first round of blasting holes 2 passes through the first layer of water-rich porous rock layer 5 to the first layer of impermeable stratum 6. The second round of blasting holes 2 passes through the first layer of One layer of water-rich porous rock formation 5 and the second layer of water-rich porous rock formation 5 reach the second layer of impermeable formation 6, and the two sides of each blasting hole 2 are respect...

Embodiment 3

[0049] In addition to the above two embodiments, the water-proof grouting curtain construction method of the present invention is also applicable to other areas that require water-proof construction, such as tunnel excavation, coal mining and other fields. The drilling arrangement can be linear according to needs, such as Figure 6 shown. All the other construction steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com