Dual-channel counter-directional joint control single-flow valve

A dual-channel, single-flow valve technology, used in wellbore/well valve devices, wellbore/well components, earth-moving drilling and production, etc., can solve problems such as damage and fracture of double-layer coiled tubing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

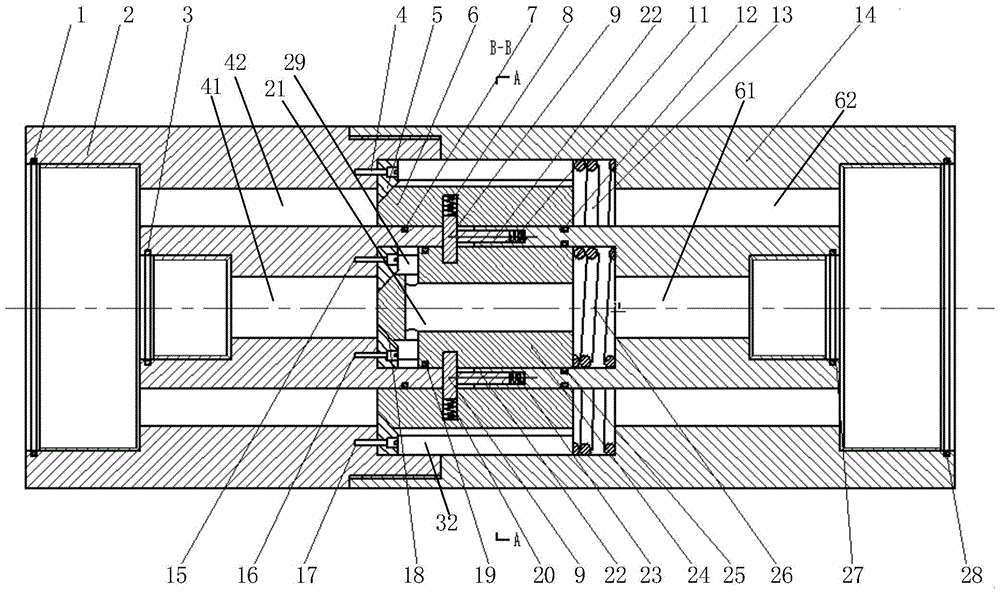

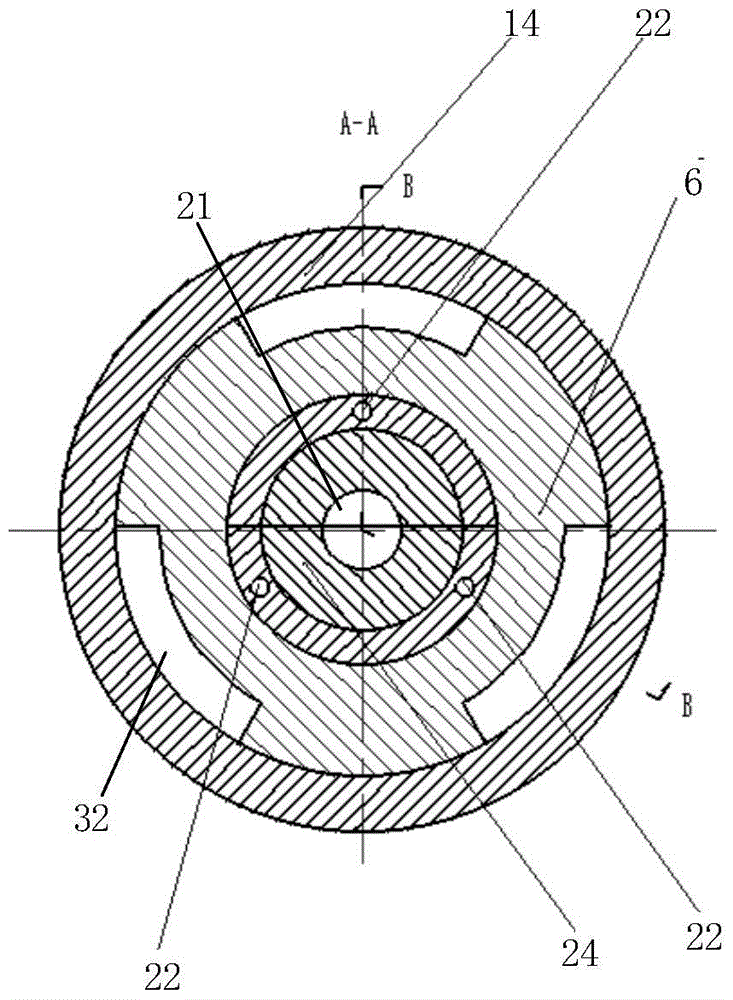

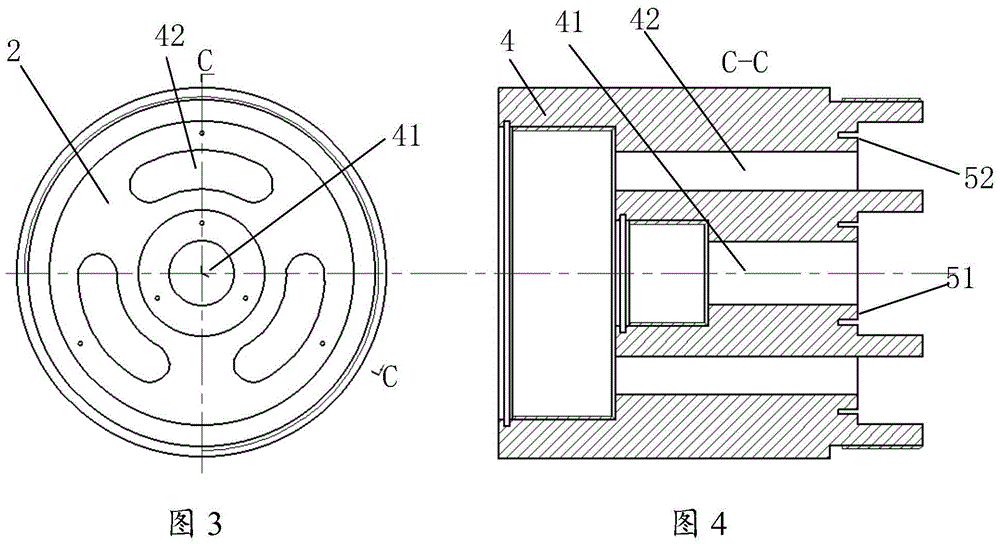

[0044] Such as figure 1 As shown in Figure 4, the left valve body 2 is a cylindrical structure, the inner wall at one end is finish-turned to connect the double-layer female ports of the inner and outer coiled tubing bodies, and the outer wall at the other end is finish-turned to connect to the right valve body 14 pins. A cylindrical through hole with a diameter smaller than the threaded thread of the inner layer is drilled and milled at the center of the left valve body 2, namely the first left through hole 41, which is used for the injection and discharge of the liquid in the inner coiled tubing. Three oblong cross-section through holes with an angle of 120° are respectively drilled and milled at a certain distance from the outer edge of the first left through hole 41, i.e. the second left through hole 42 (wherein the number in this embodiment is Three, or two or four, etc.), used for injection and discharge of liquid in the outer coiled tubing.

[0045] Such as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com