Patents

Literature

73results about How to "Low cracking pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

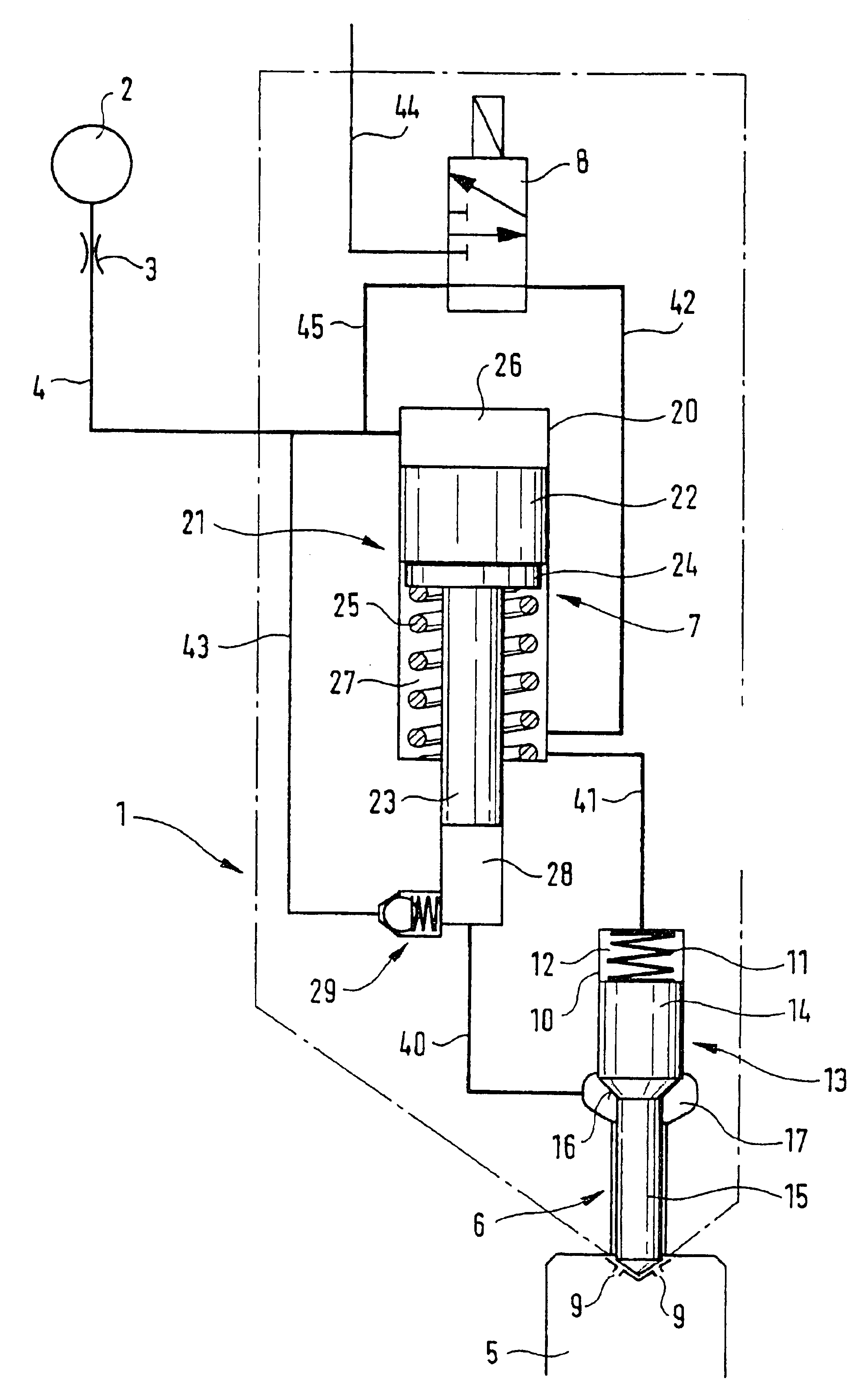

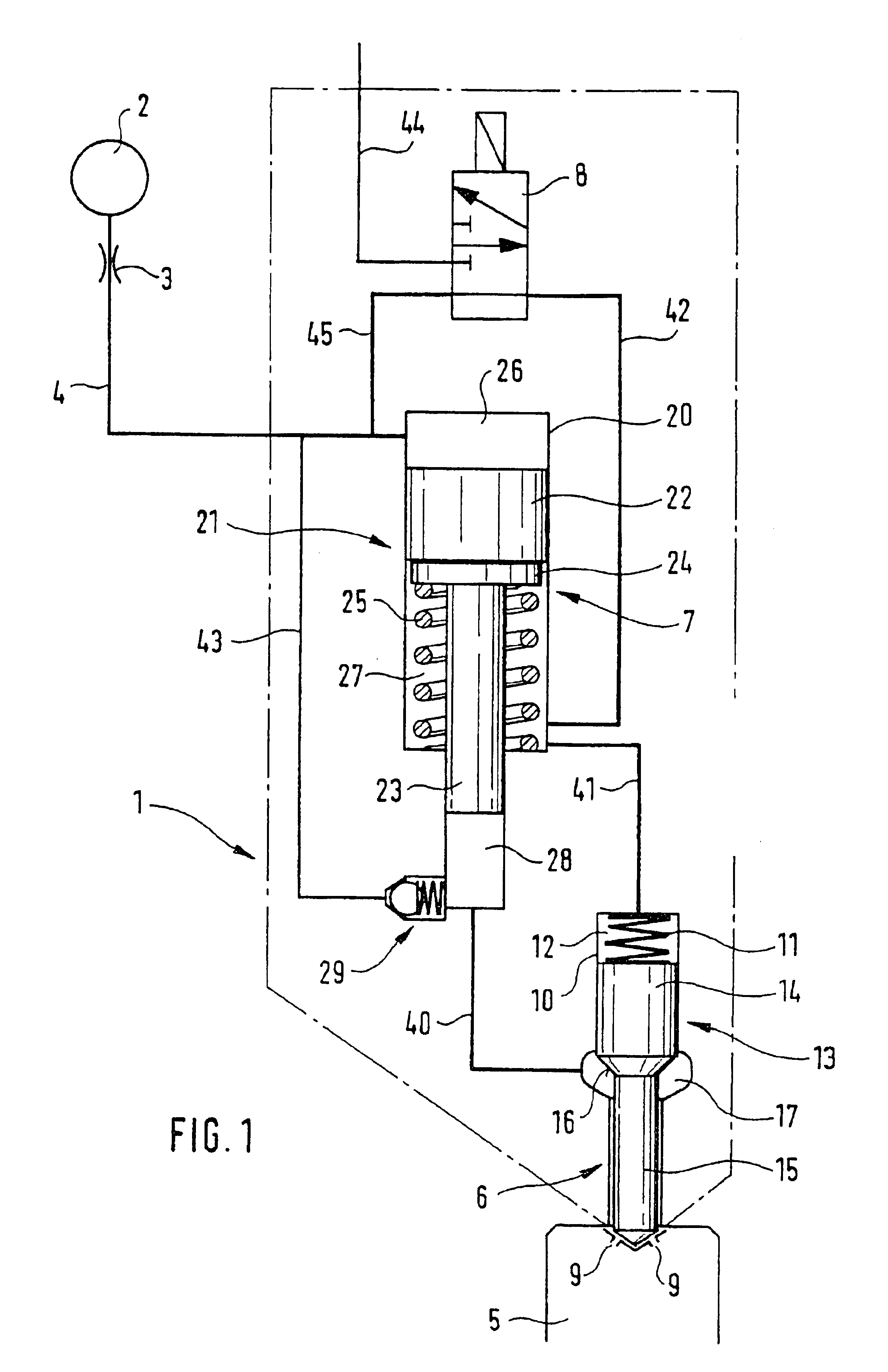

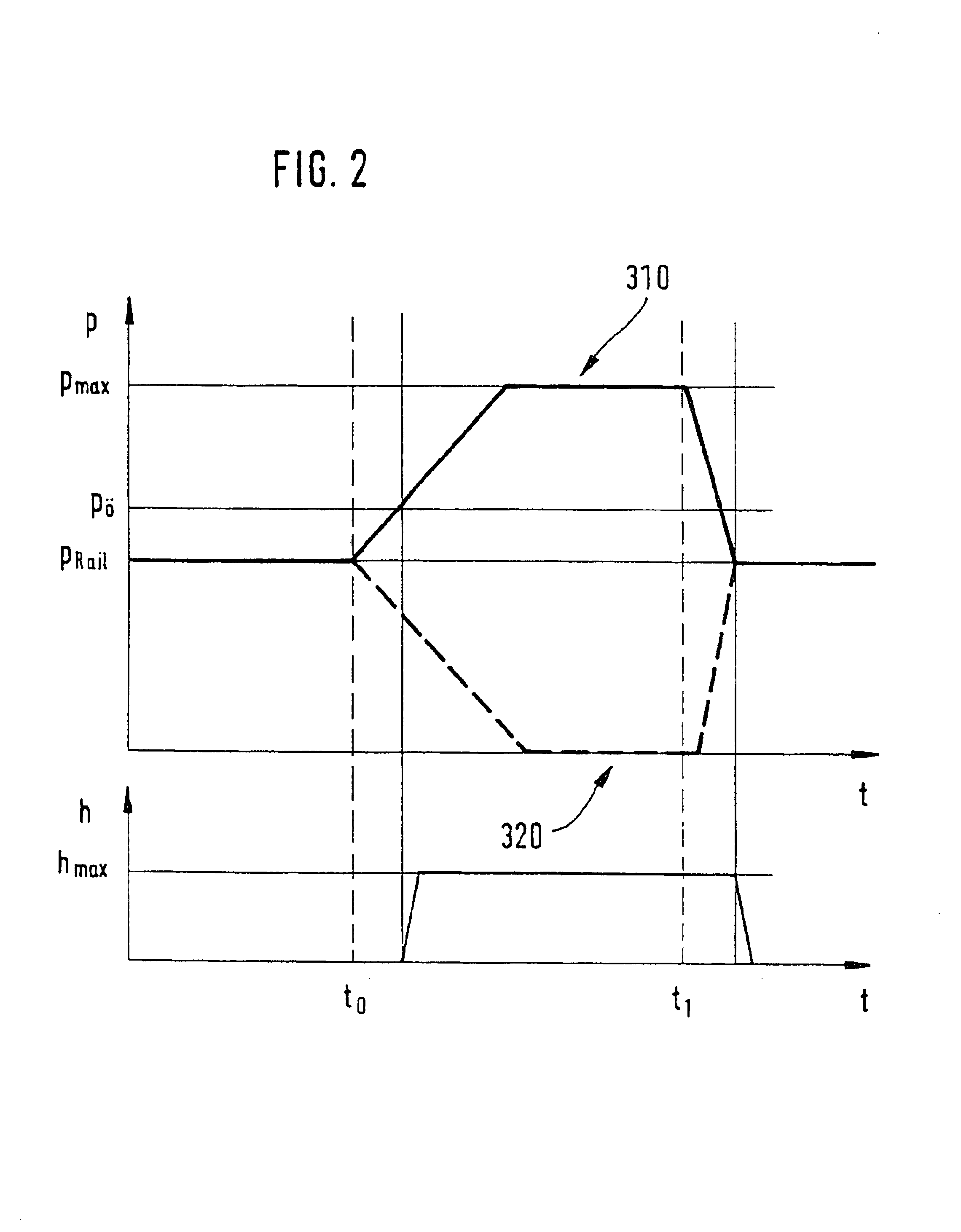

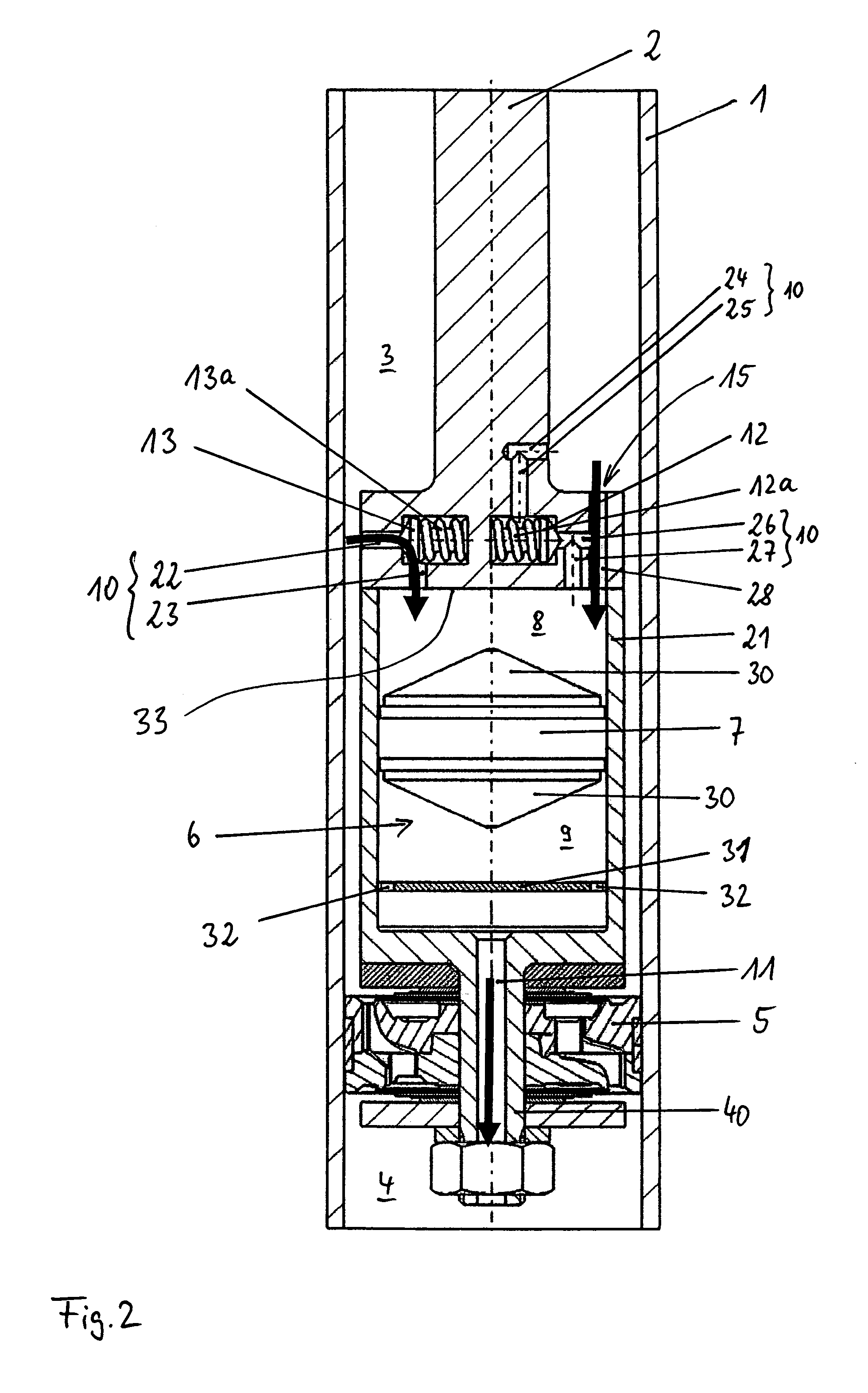

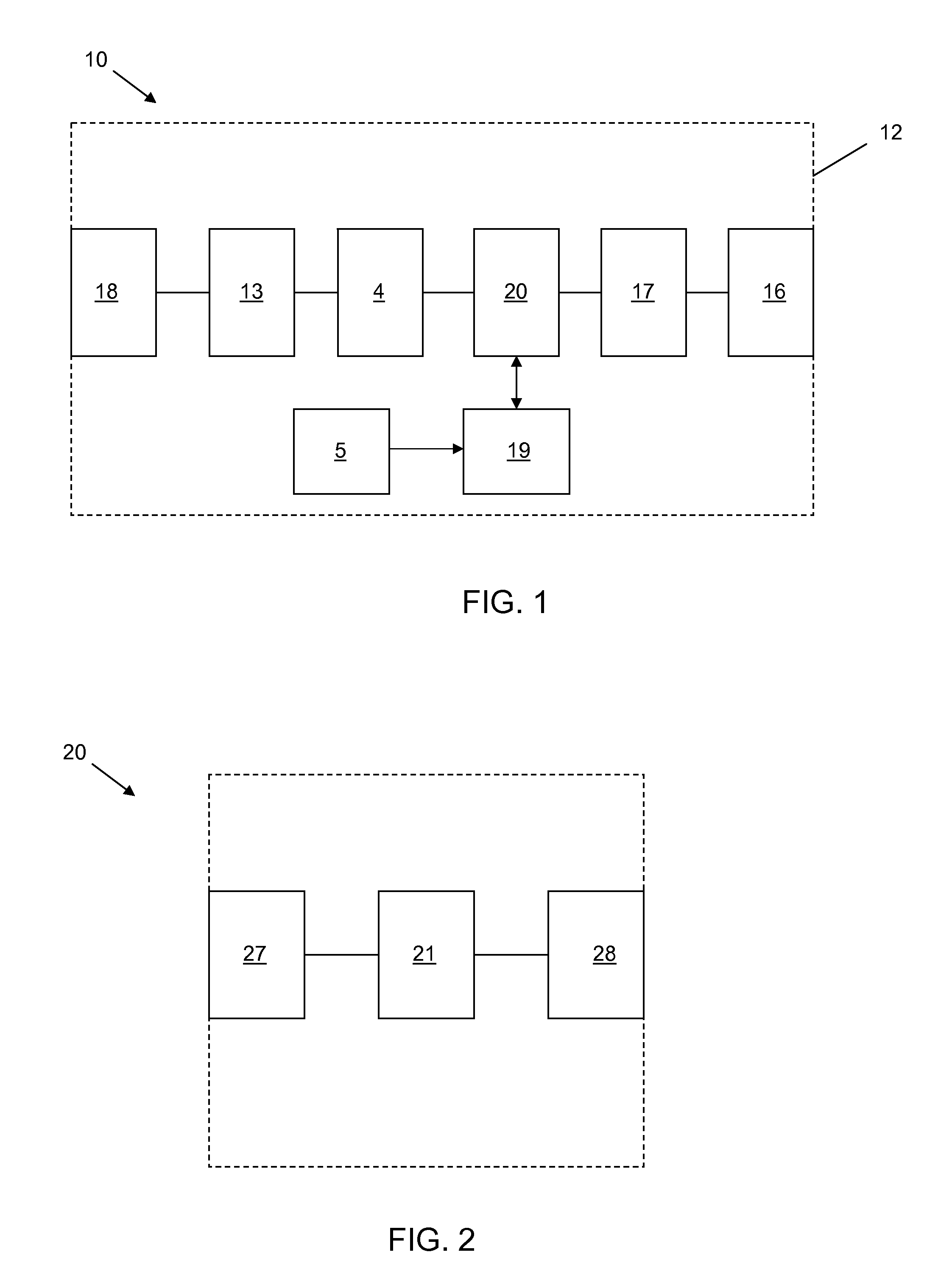

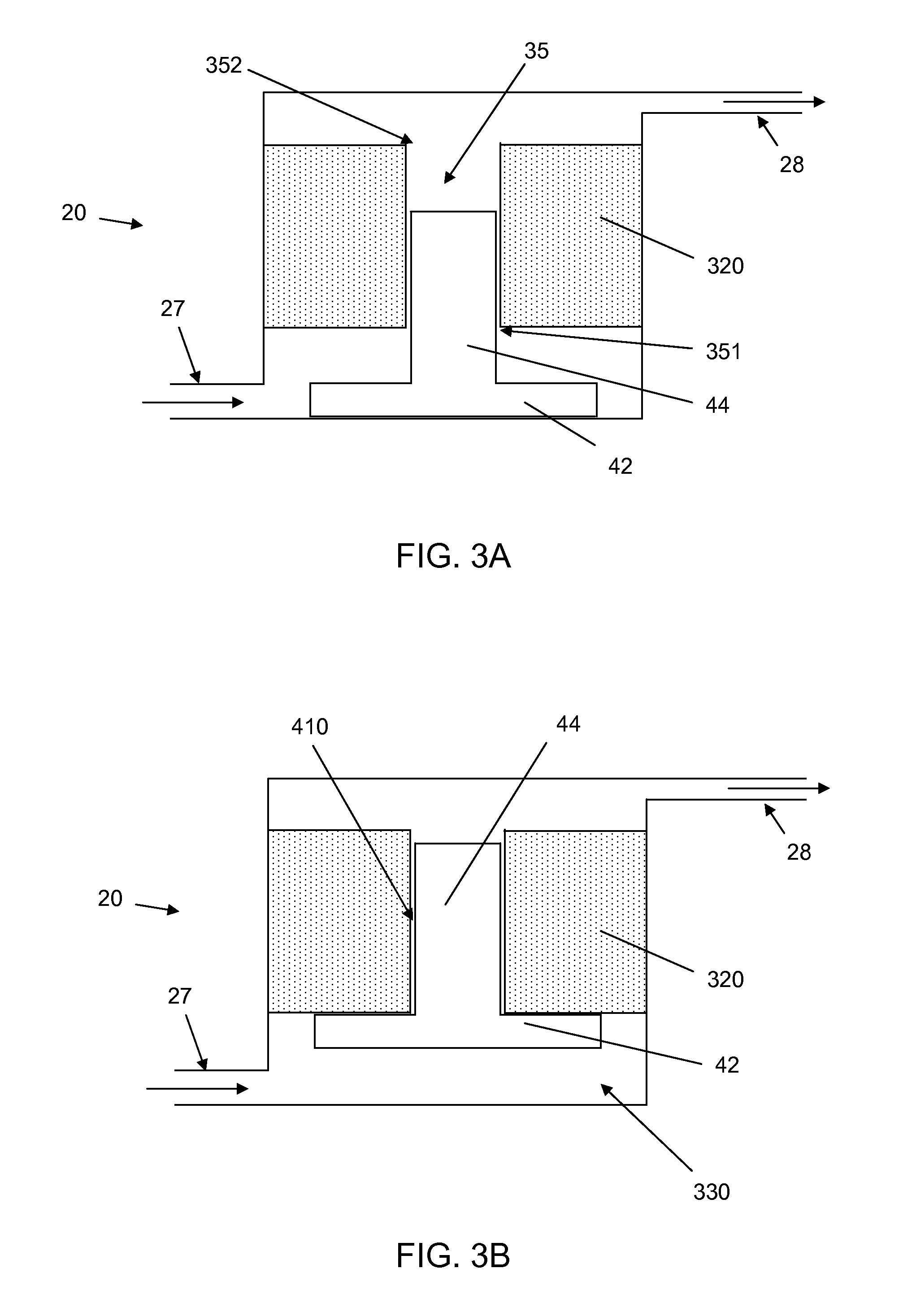

Fuel injection device

InactiveUS6880527B2Low pressure boosting ratioHighly dynamic pressure buildupFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesCombustionEngineering

A fuel injection system for internal combustion engines includes an injector supplied from a high-pressure fuel source and with a pressure booster device, in which the closing piston can be acted upon by fuel pressure to attain a force exerted on the closing piston in the closing direction, and in which the closing pressure chamber and the return chamber of the pressure booster device are formed by a common closing pressure return chamber, and all the portions of the closing pressure return chamber communicate with one another permanently for exchanging fuel, so that despite a low pressure boost by the pressure booster device, a relatively low injection opening pressure is attainable.

Owner:ROBERT BOSCH GMBH

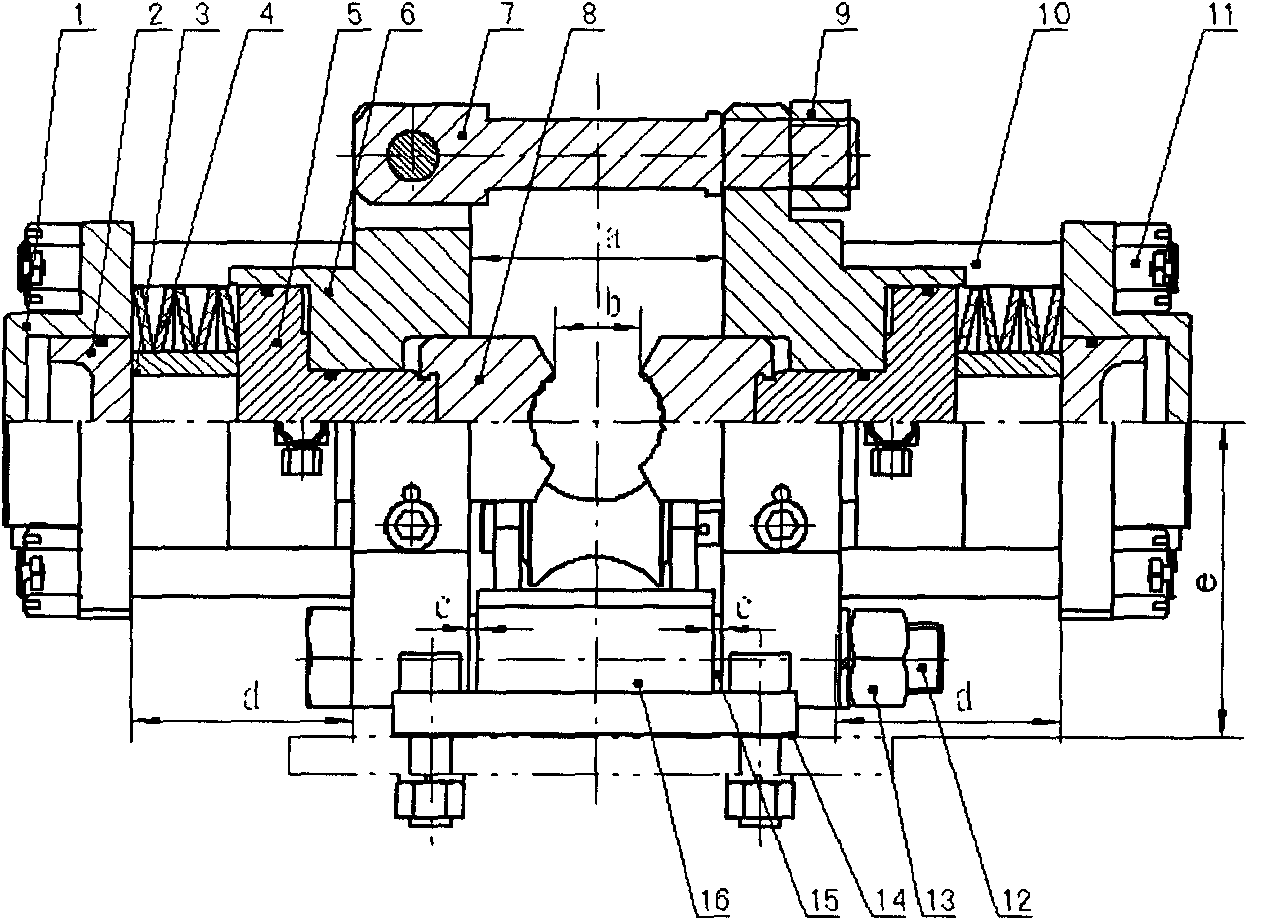

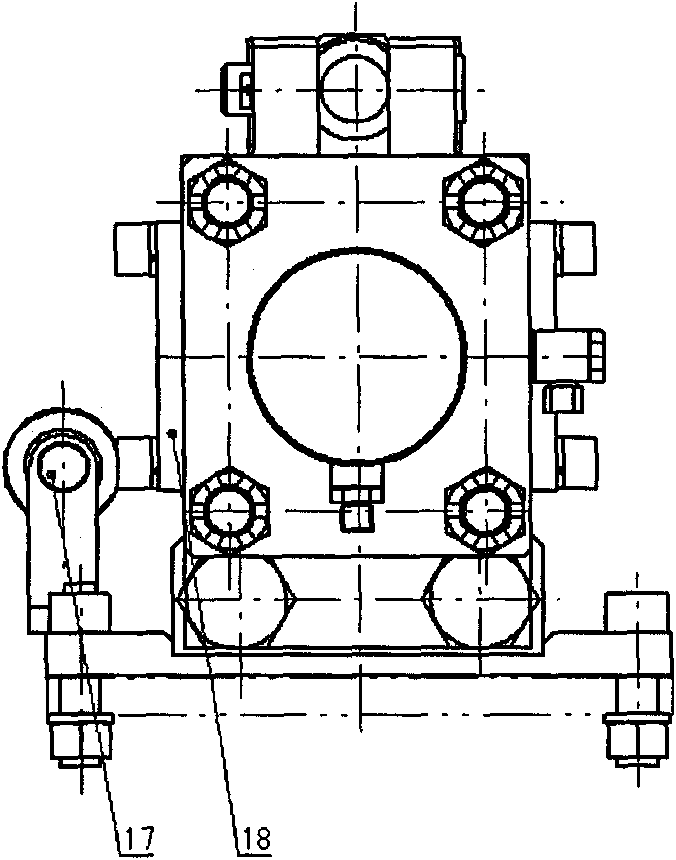

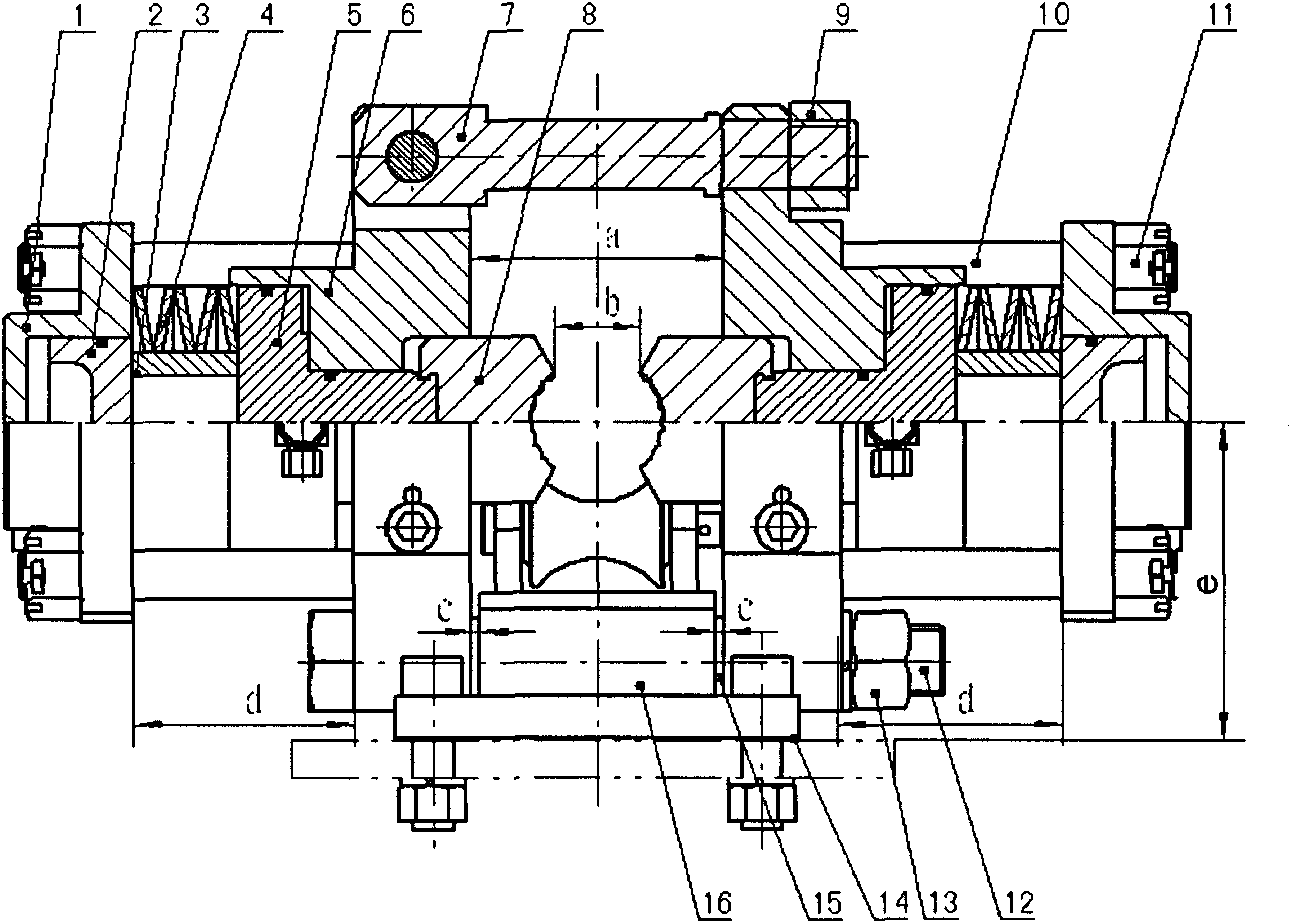

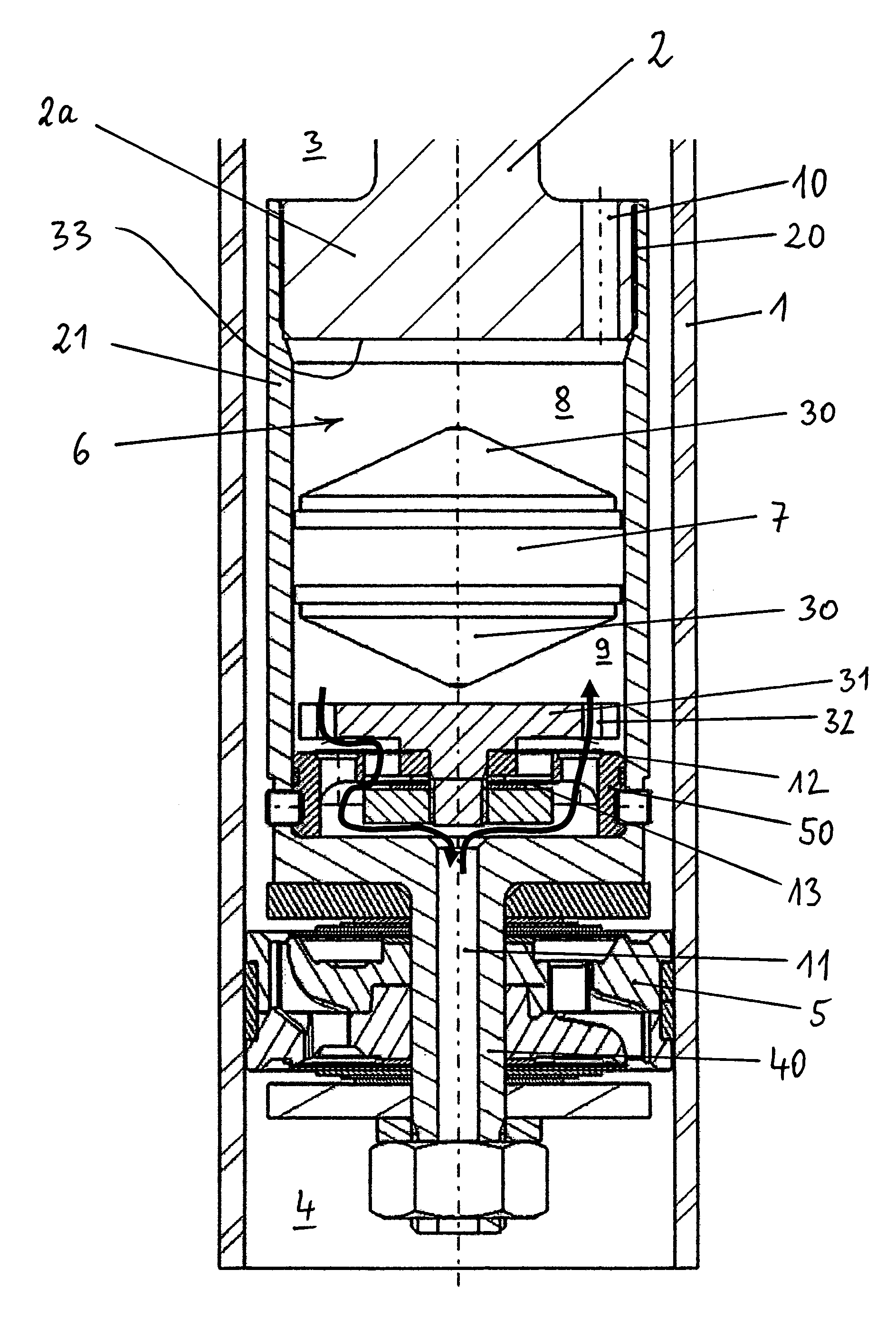

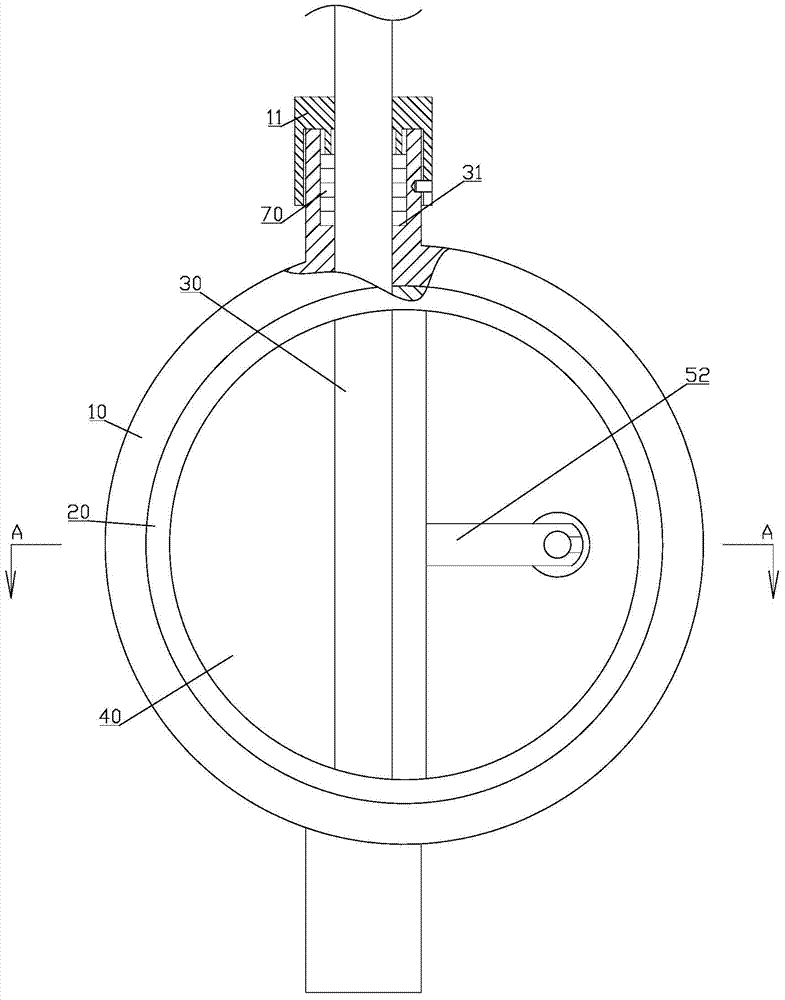

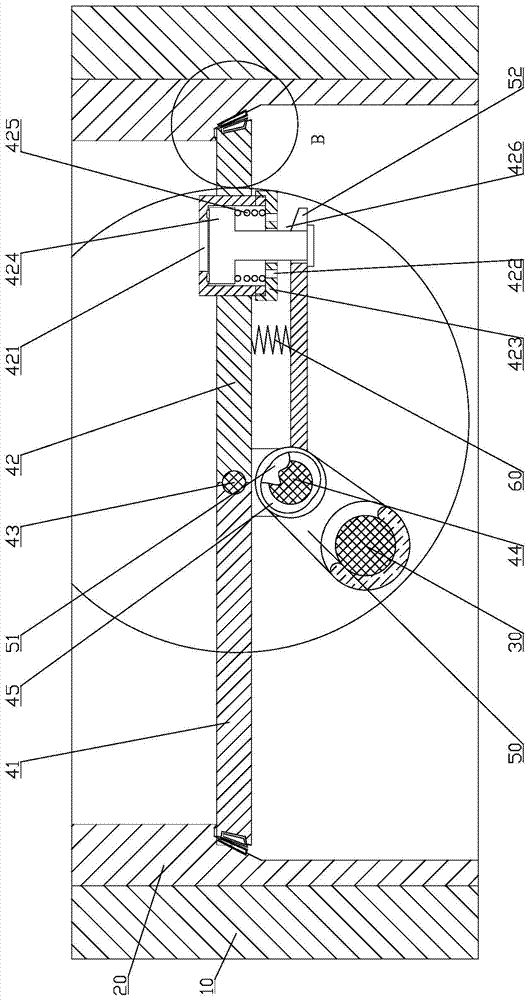

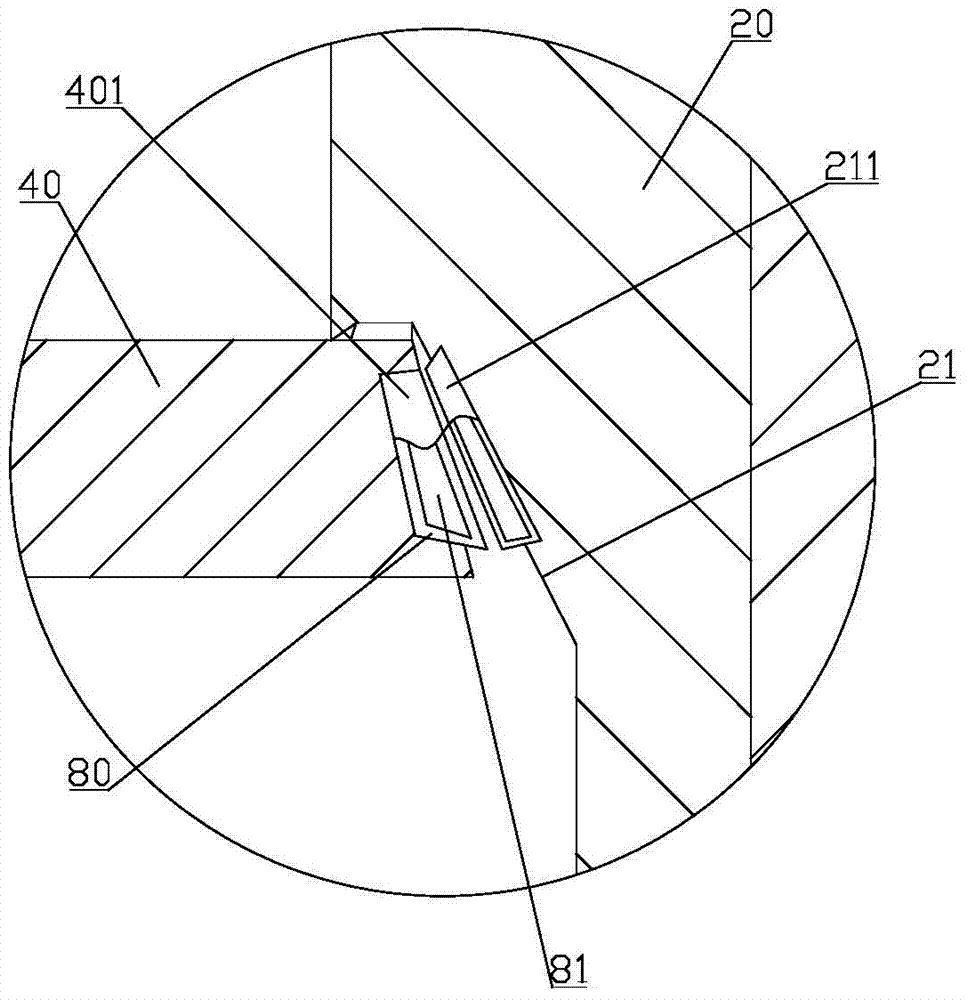

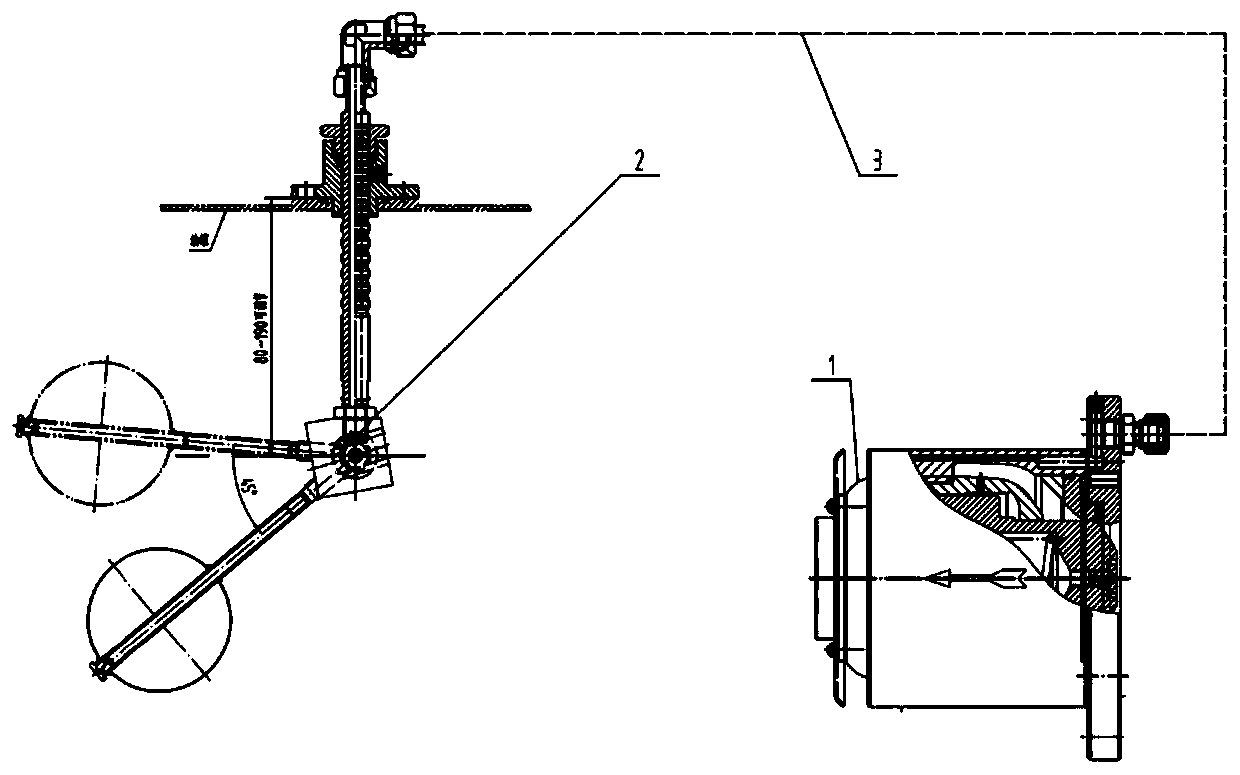

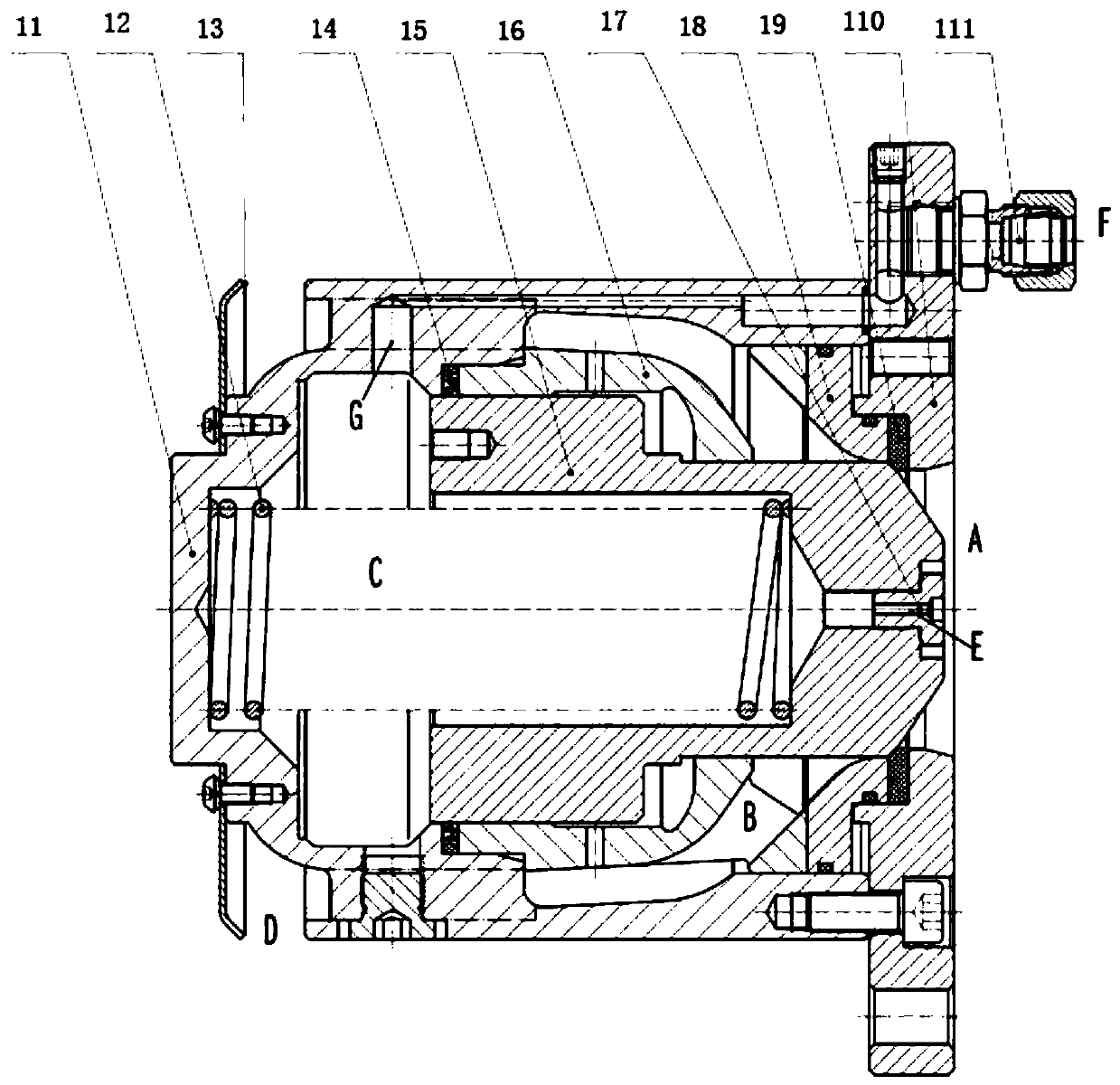

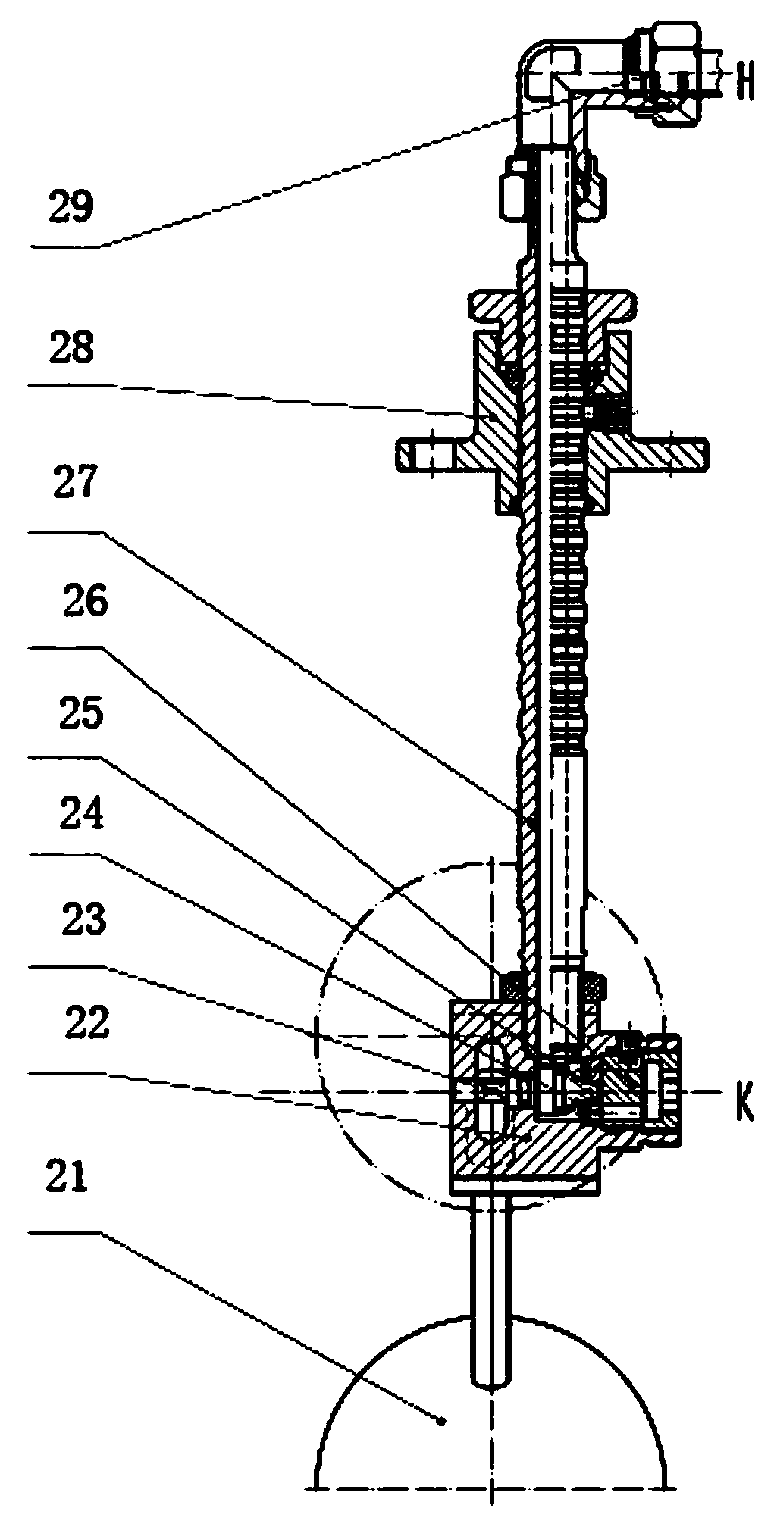

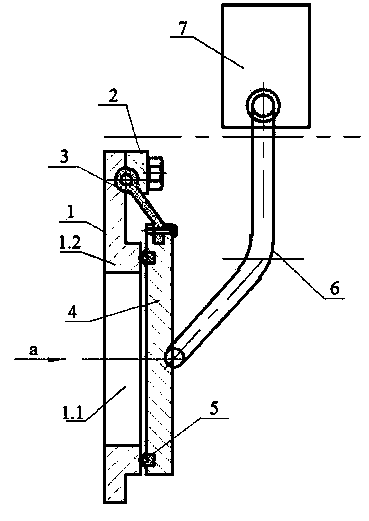

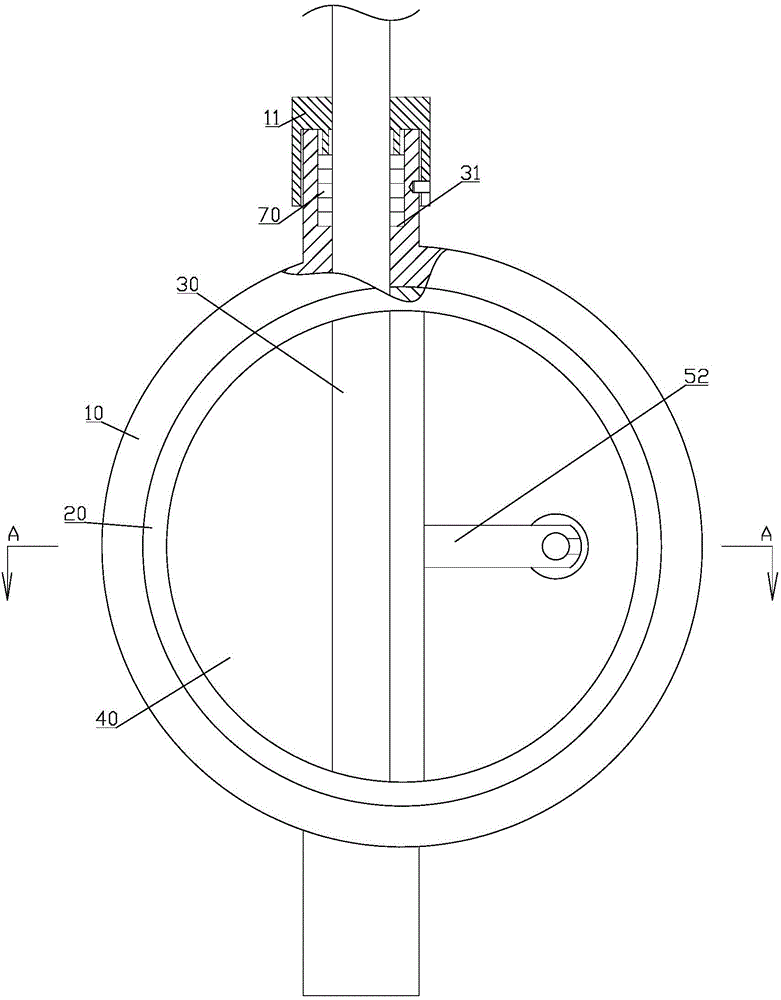

Open-top composite clamp holder

ActiveCN101775965AConducive to decentralizationLarge openingEarth drilling toolsDrilling rodsMaster cylinderEngineering

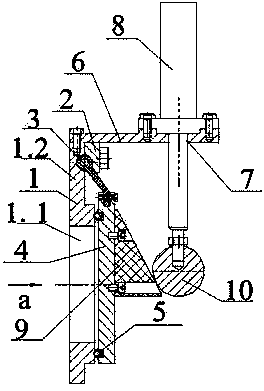

The invention discloses an open-top composite clamp holder. An all-hydraulic power head type drilling machine is usually provided with a clamp holder which is mainly used for clamping drilling rigs in holes and preventing the drilling rigs in holes from sliding and can be matched with a power head to automatically disassemble a drill pipe. The invention adopts open-top both-side symmetric arrangement, and two master cylinders are symmetrically arranged on two ends of the center of the clamp holder; a master cylinder piston is arranged in each master cylinder, and a slave cylinder piston is arranged in a slave cylinder; a slip is arranged in the master cylinder; a disc spring is connected with the master cylinder piston which is connected with the slip; a shore is arranged between the slave cylinder piston and the master cylinder piston; the lower ends of two master cylinders are connected with the sleeve, and the upper ends are provided with upper draw bars; the sleeve is arranged on a base and is connected by a base draw bar and a nut. The invention has big opening amount, low starting pressure and simple structure, can automatically center, is conveniently to let pass a thick-diameter drill rig and can clamp the drill rigs during sudden power cut.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

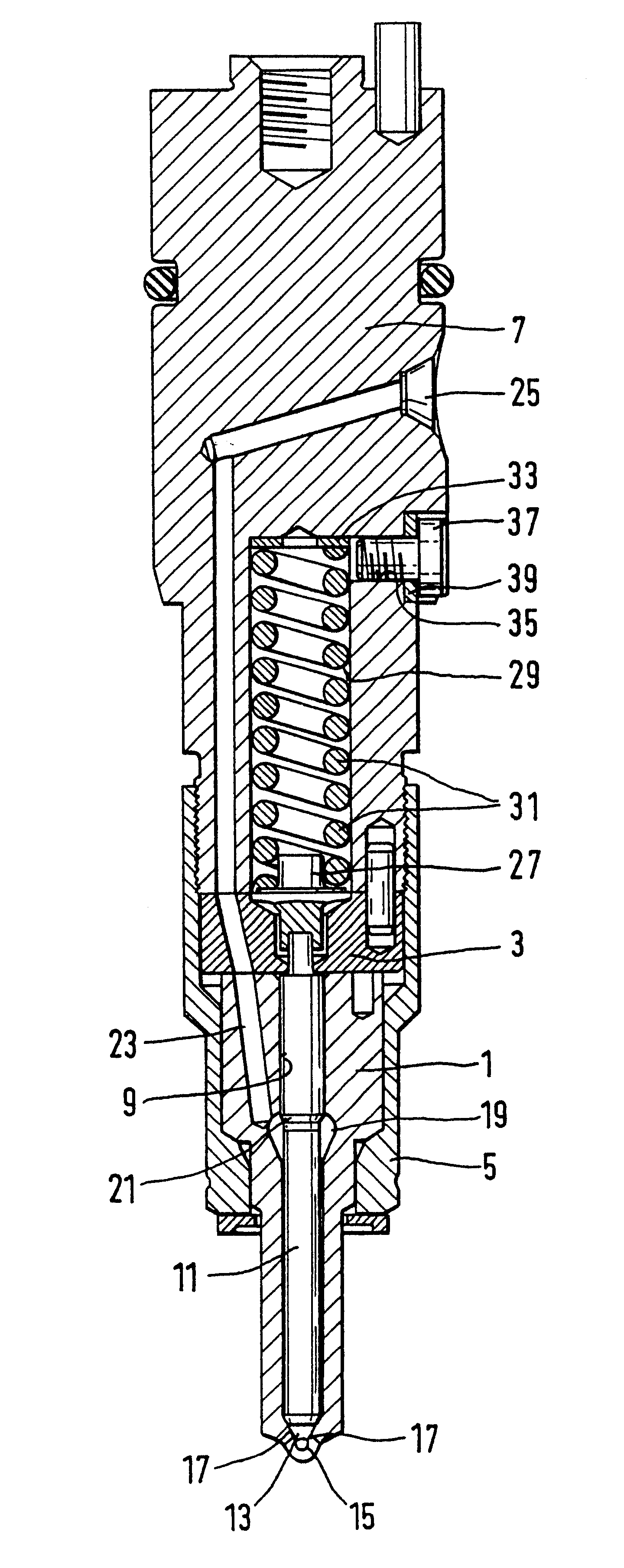

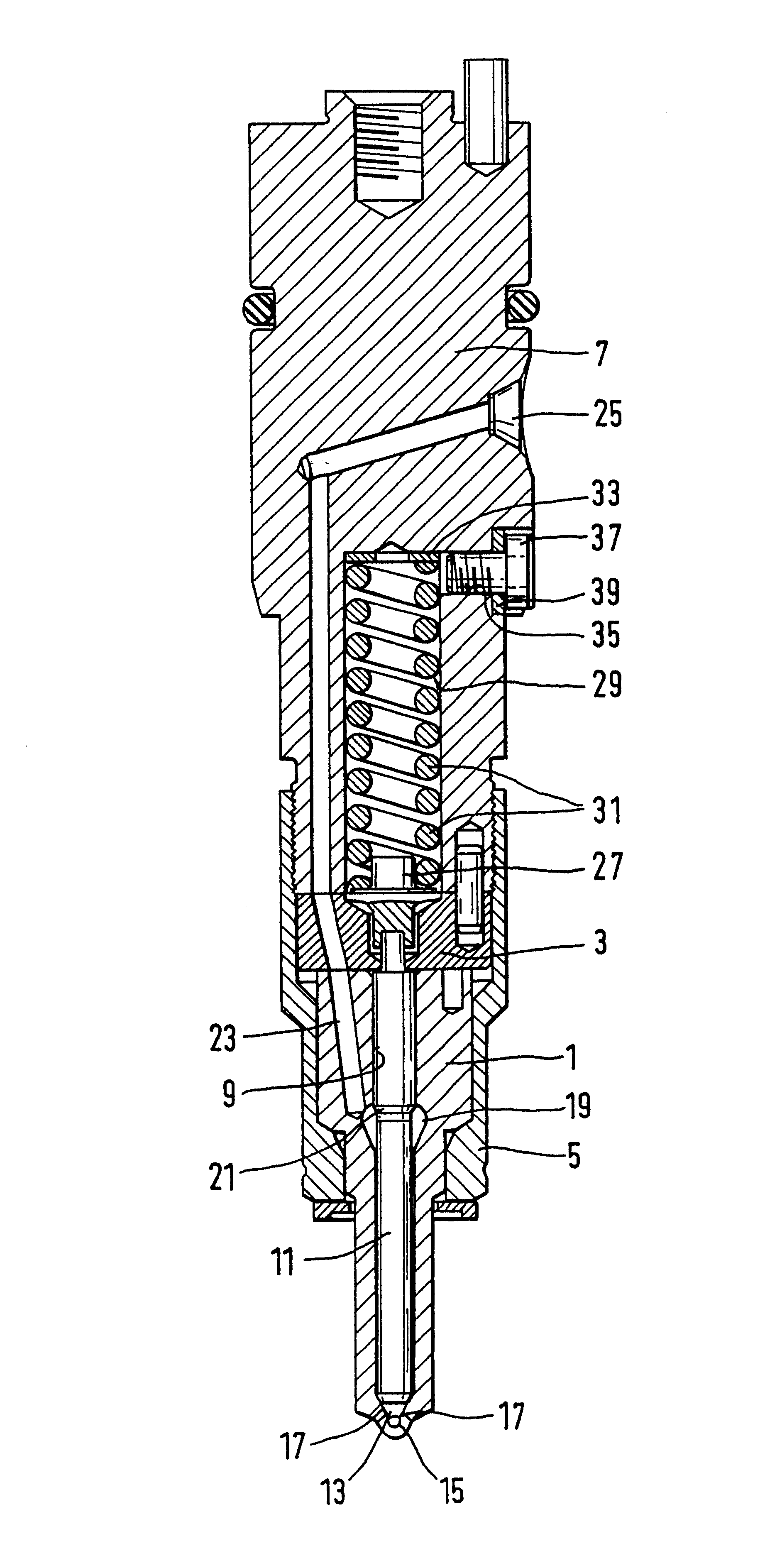

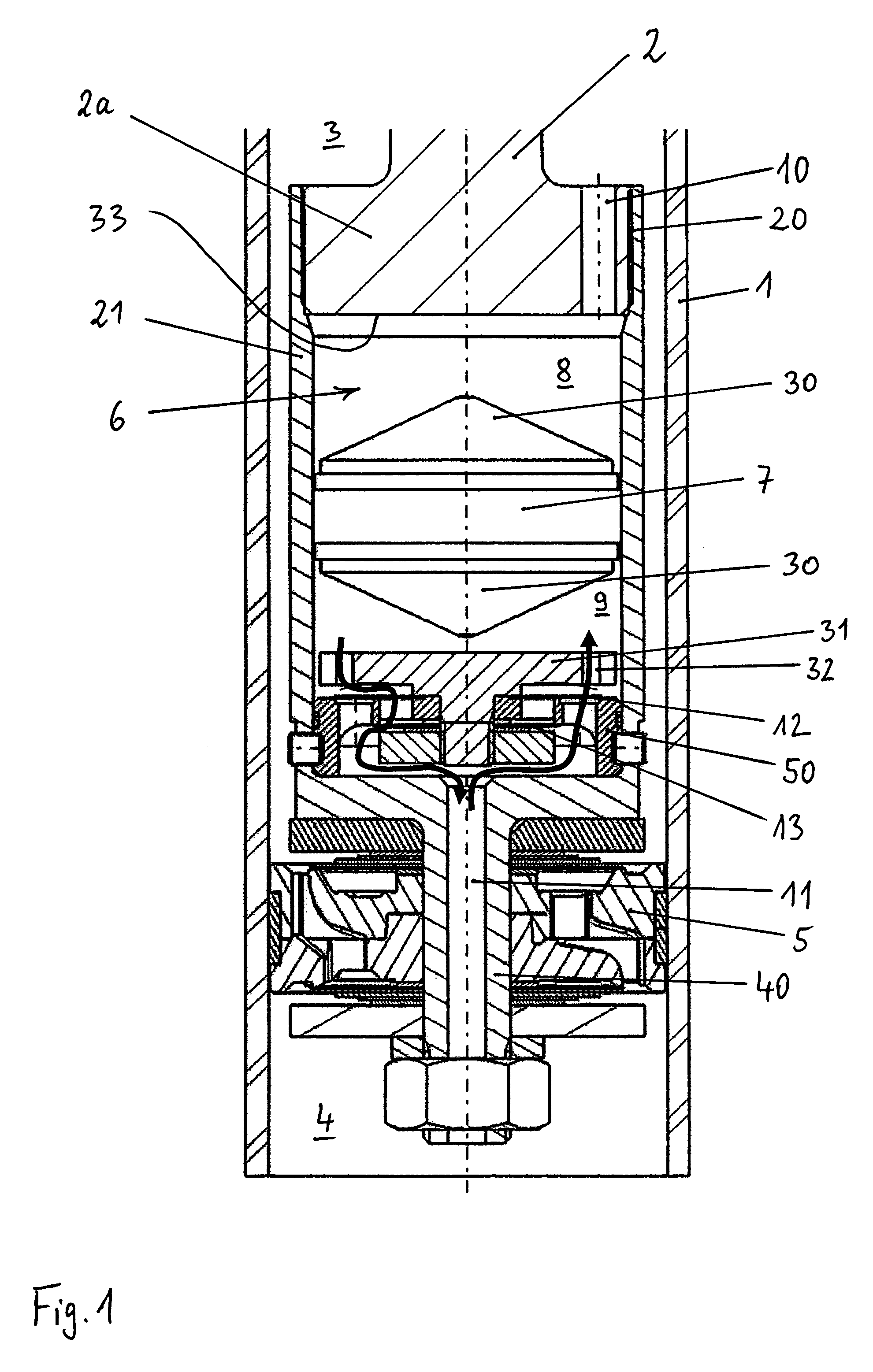

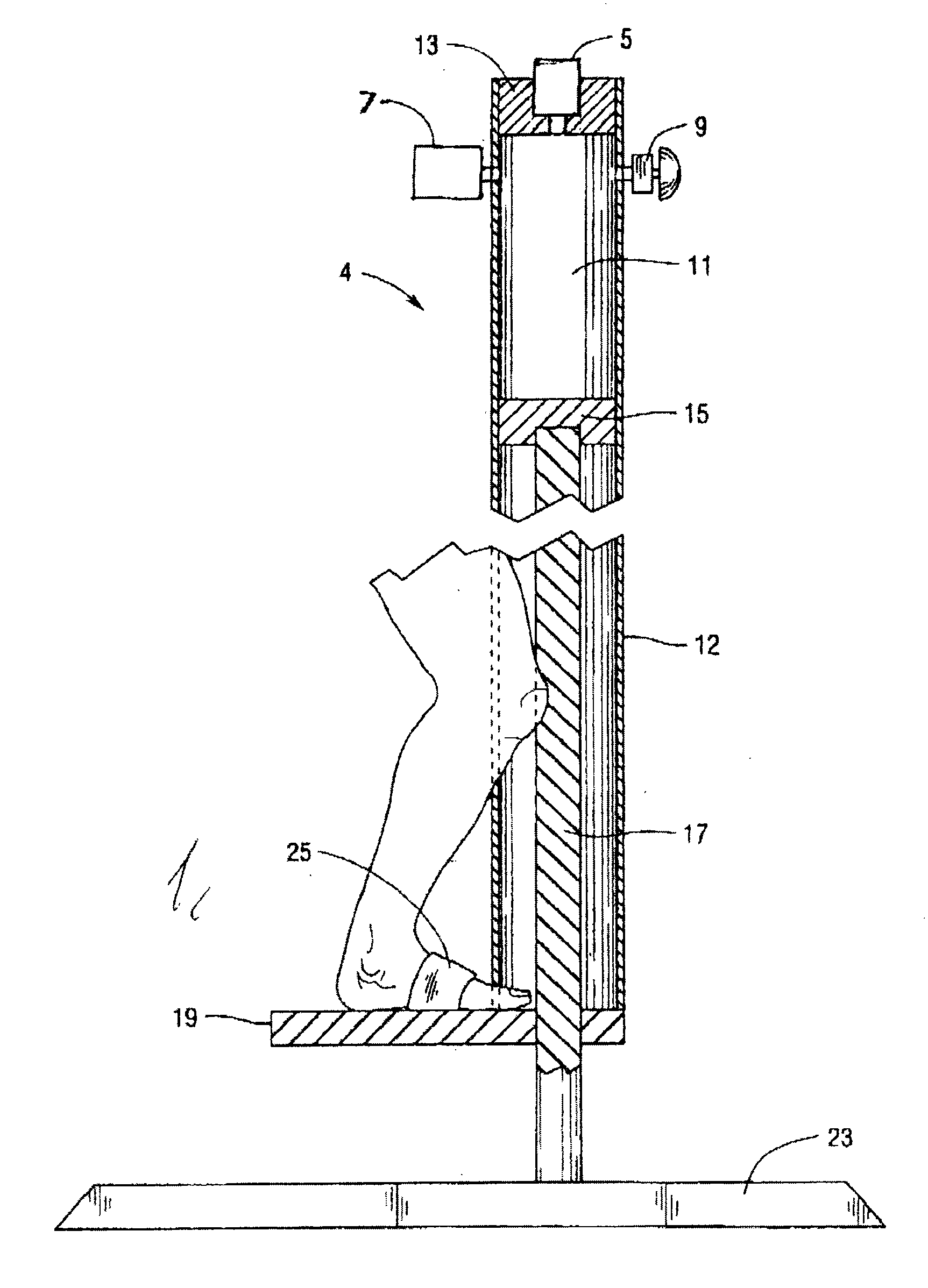

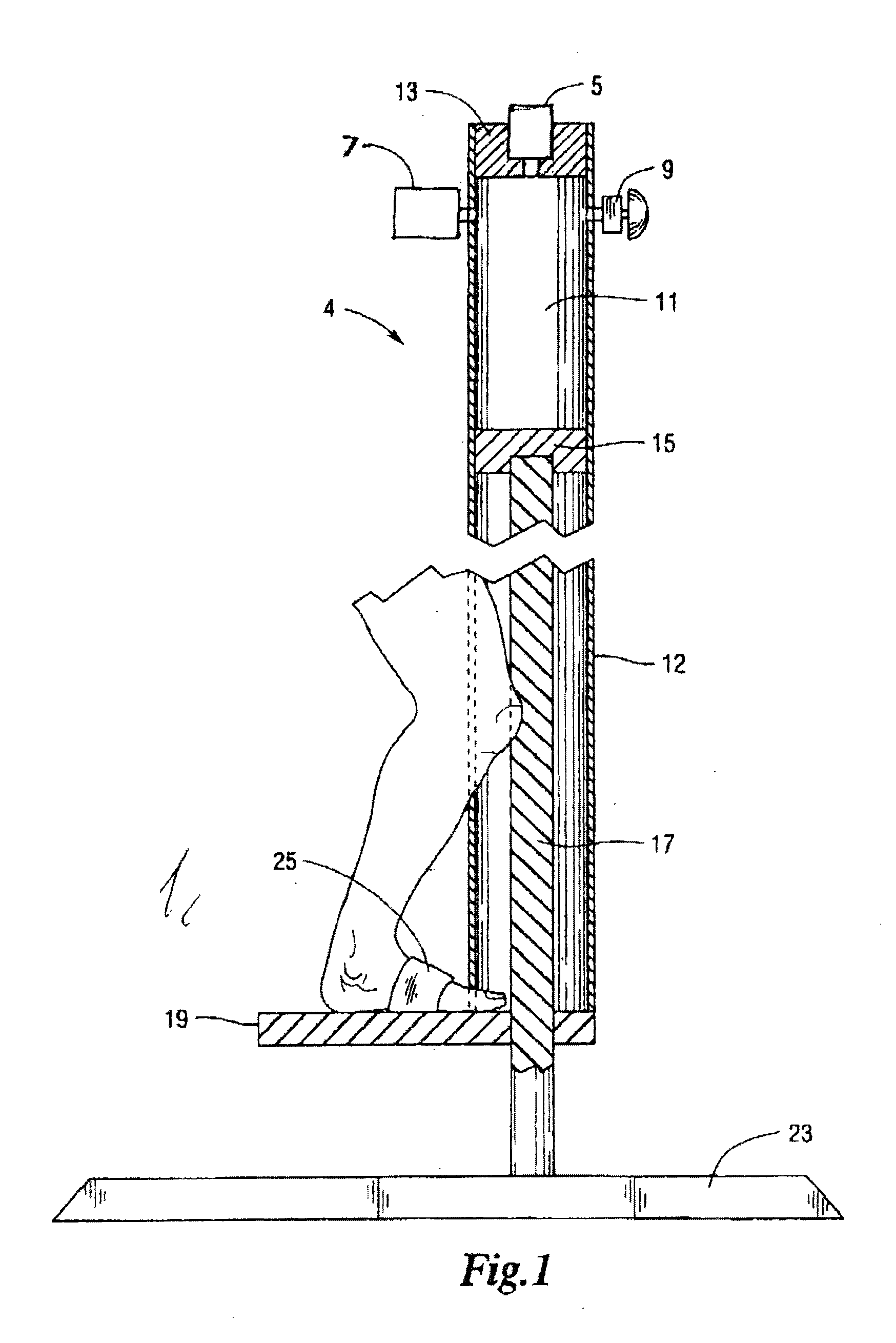

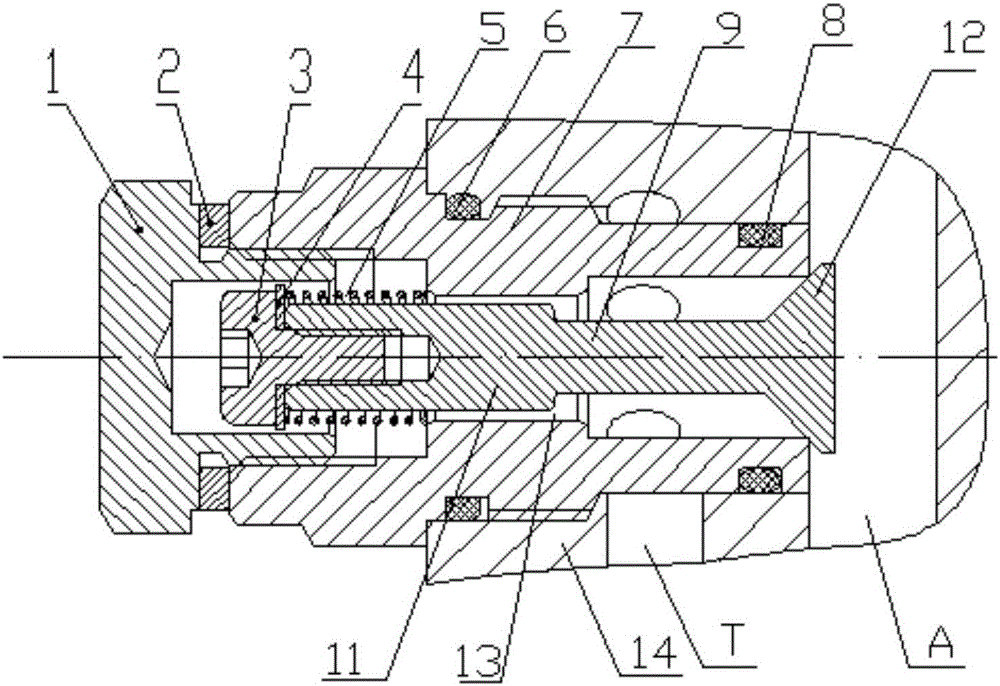

Fuel injection valve for internal combustion engines

InactiveUS6269795B1Quick closeReduce combustion noiseMachines/enginesFuel injecting pumpsCombustion chamberEngineering

A fuel injection valve for internal combustion engines, having a valve member that is axially displaceable in a valve body and that with a sealing face cooperates, to control an injection opening, with a valve seat face on the valve body. An end of the valve member remote from the combustion chamber is urged in the closing direction by a valve spring disposed in a spring chamber. The valve member has a pressure shoulder acting in the opening direction, which protrudes into a pressure chamber that is filled with high fuel pressure. Via a throttle gap, the spring chamber communicates with the pressure chamber and is sealed off from a fuel return system, so that during the opening stroke motion of the valve member the spring chamber acts as a hydraulic damper.

Owner:ROBERT BOSCH GMBH

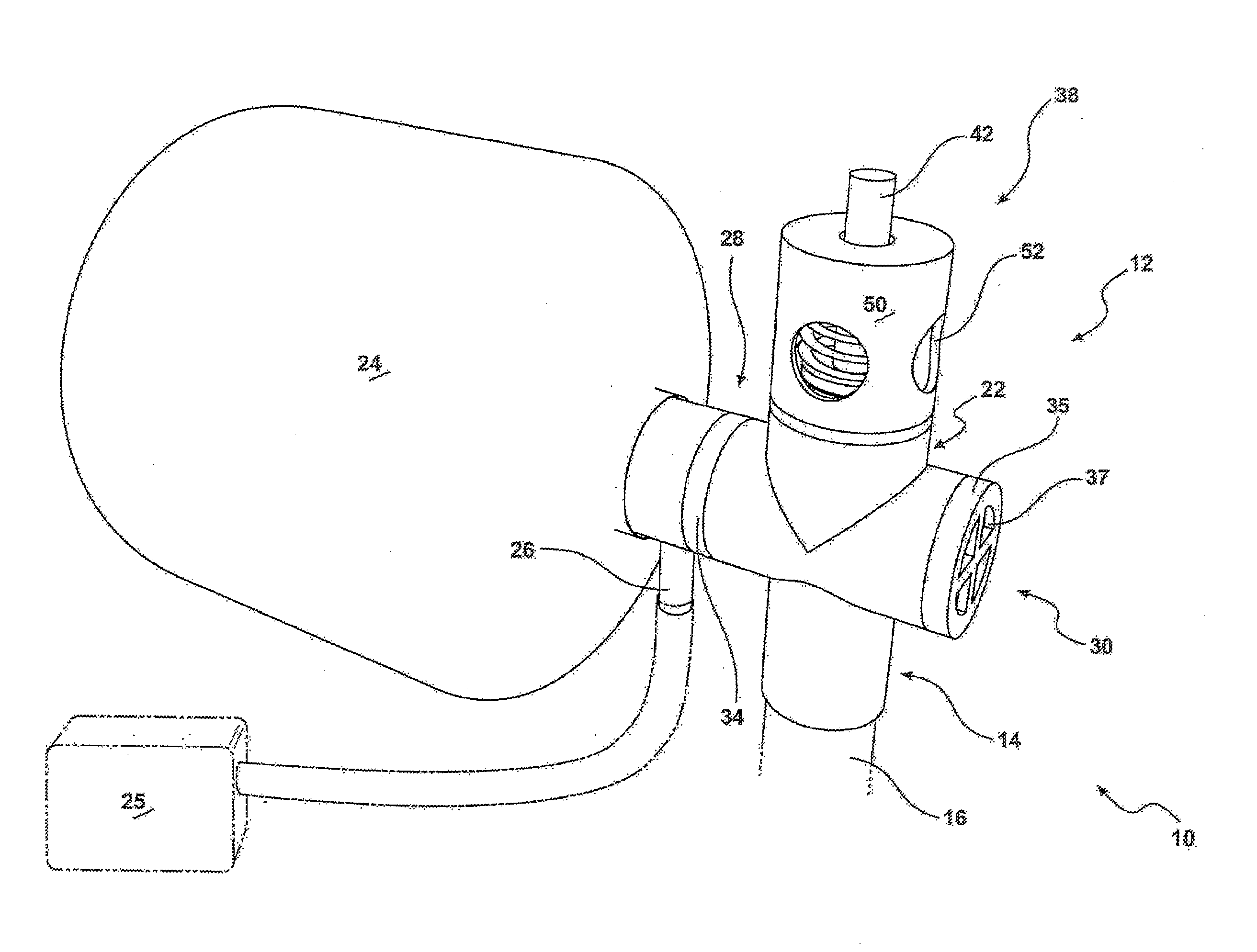

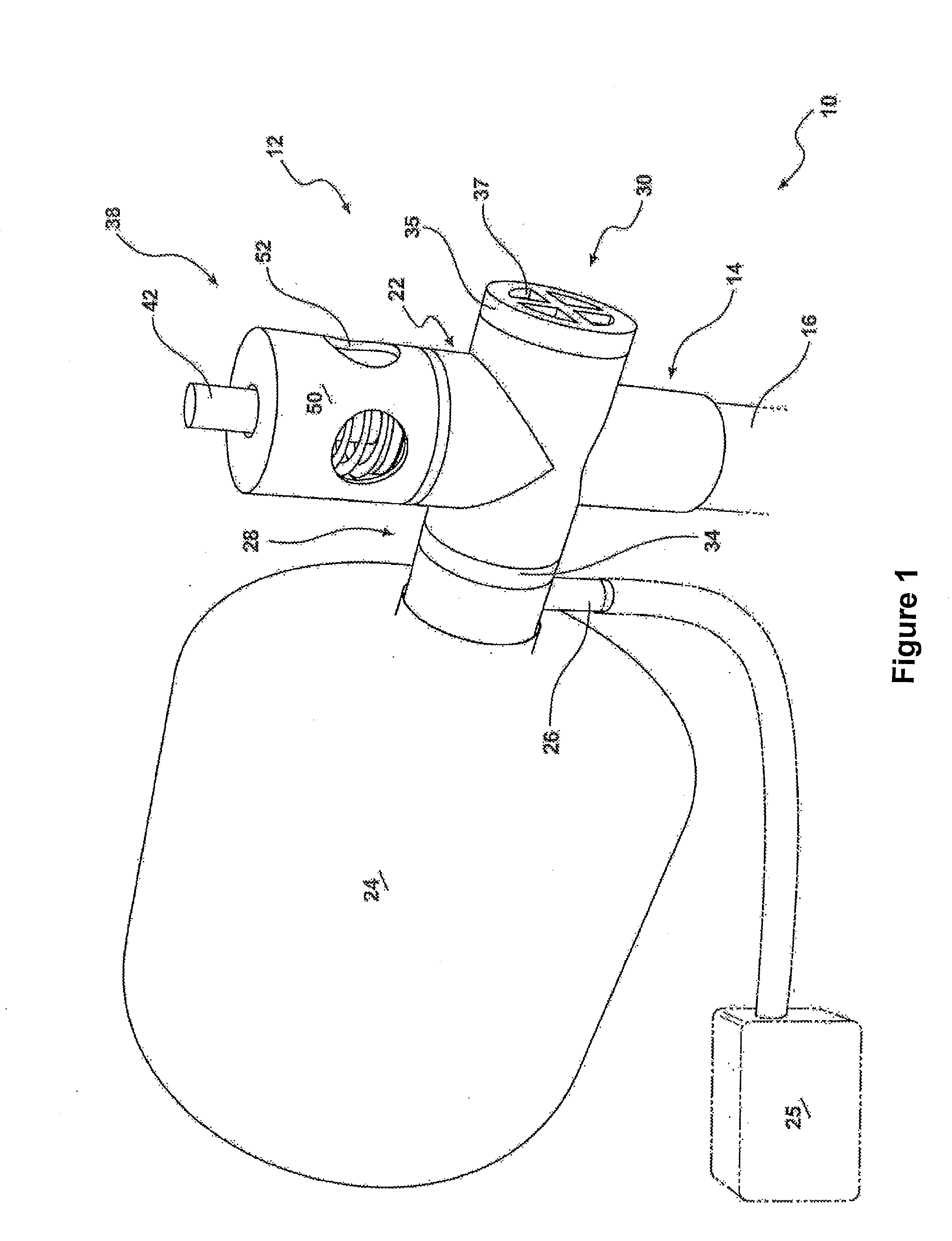

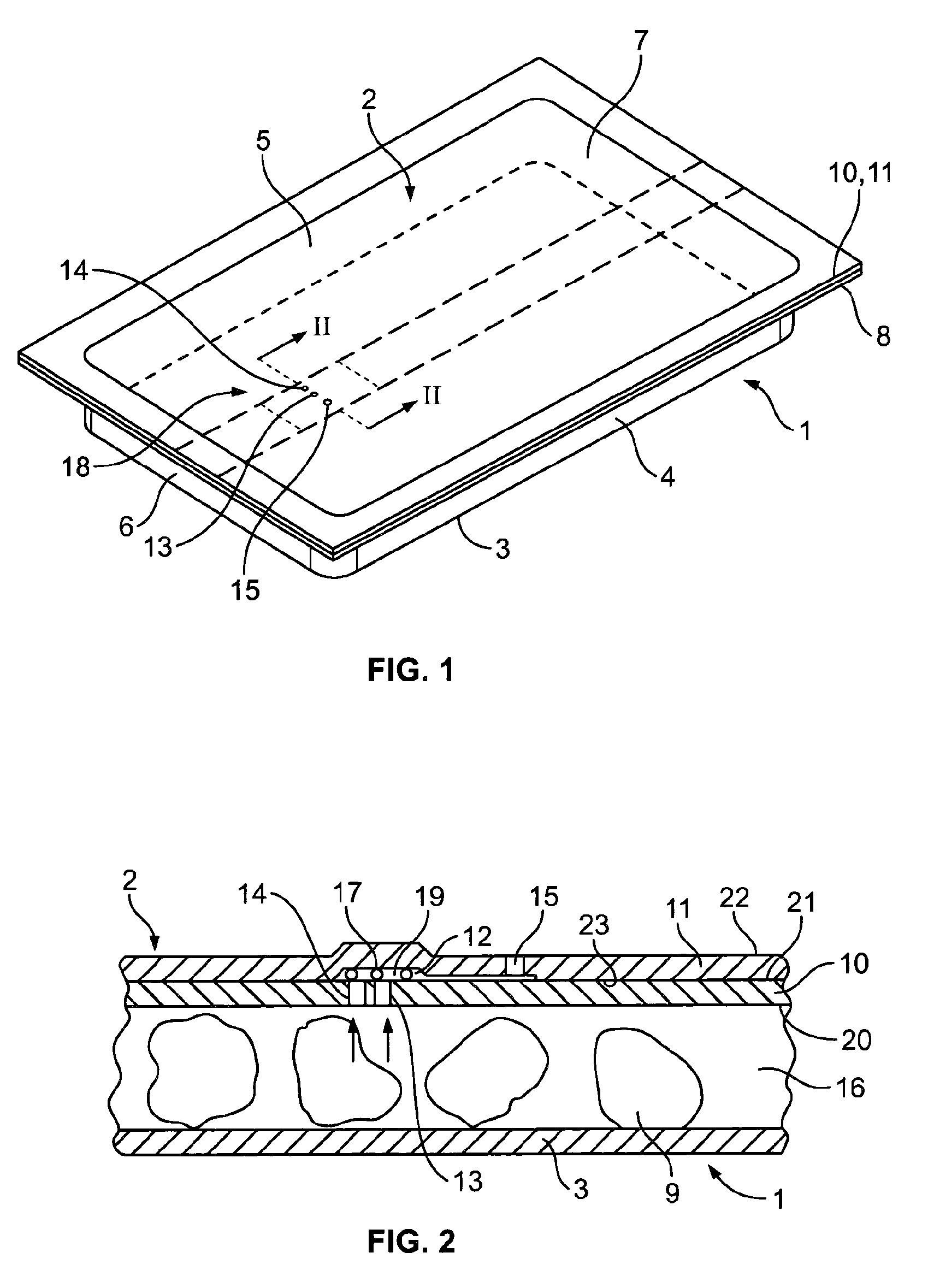

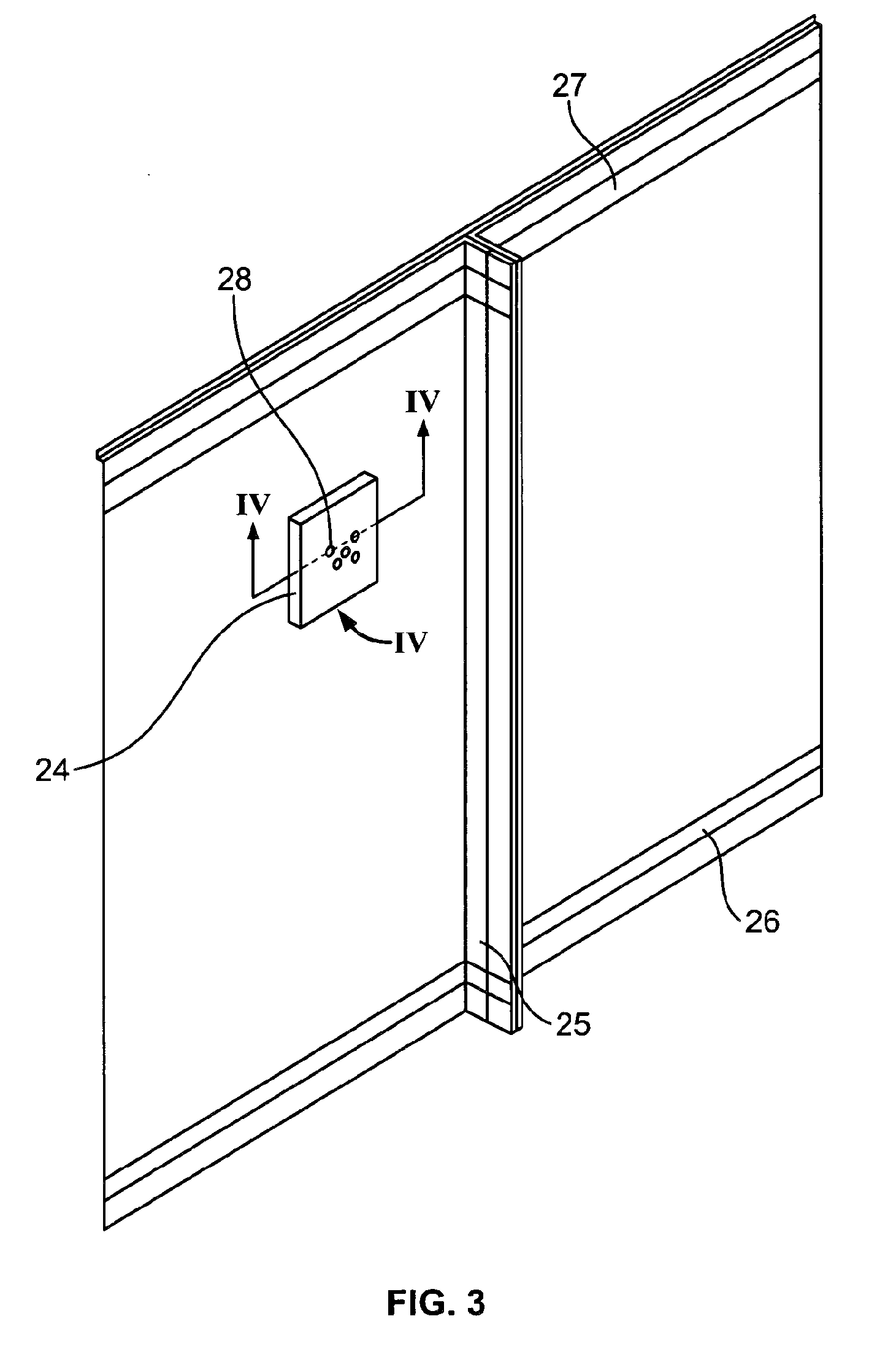

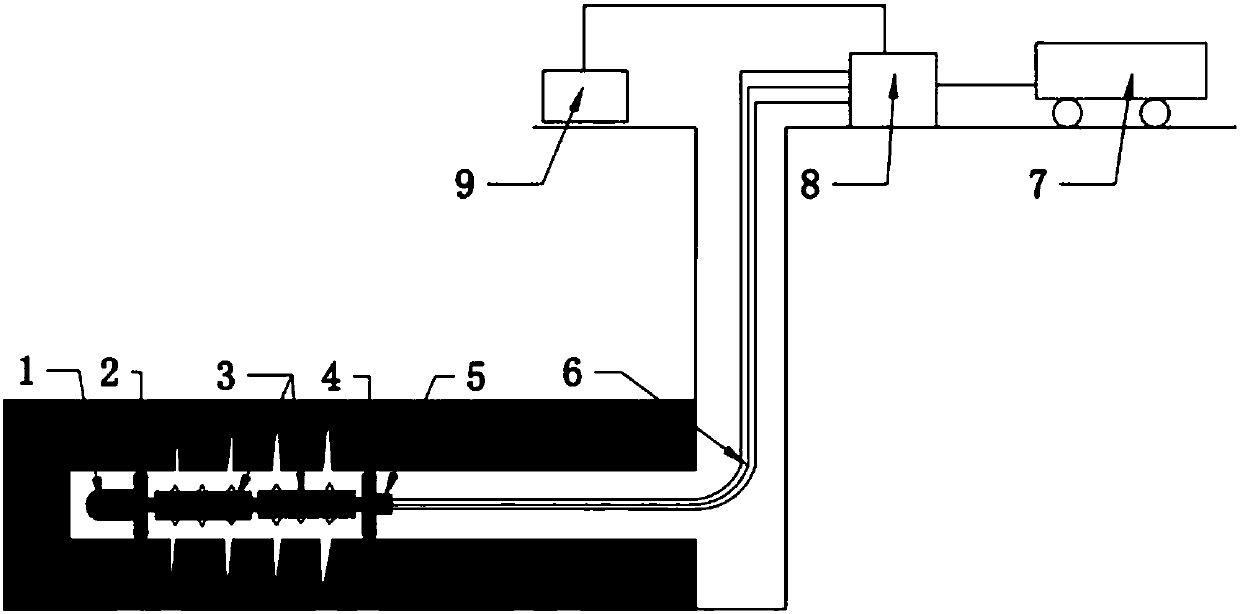

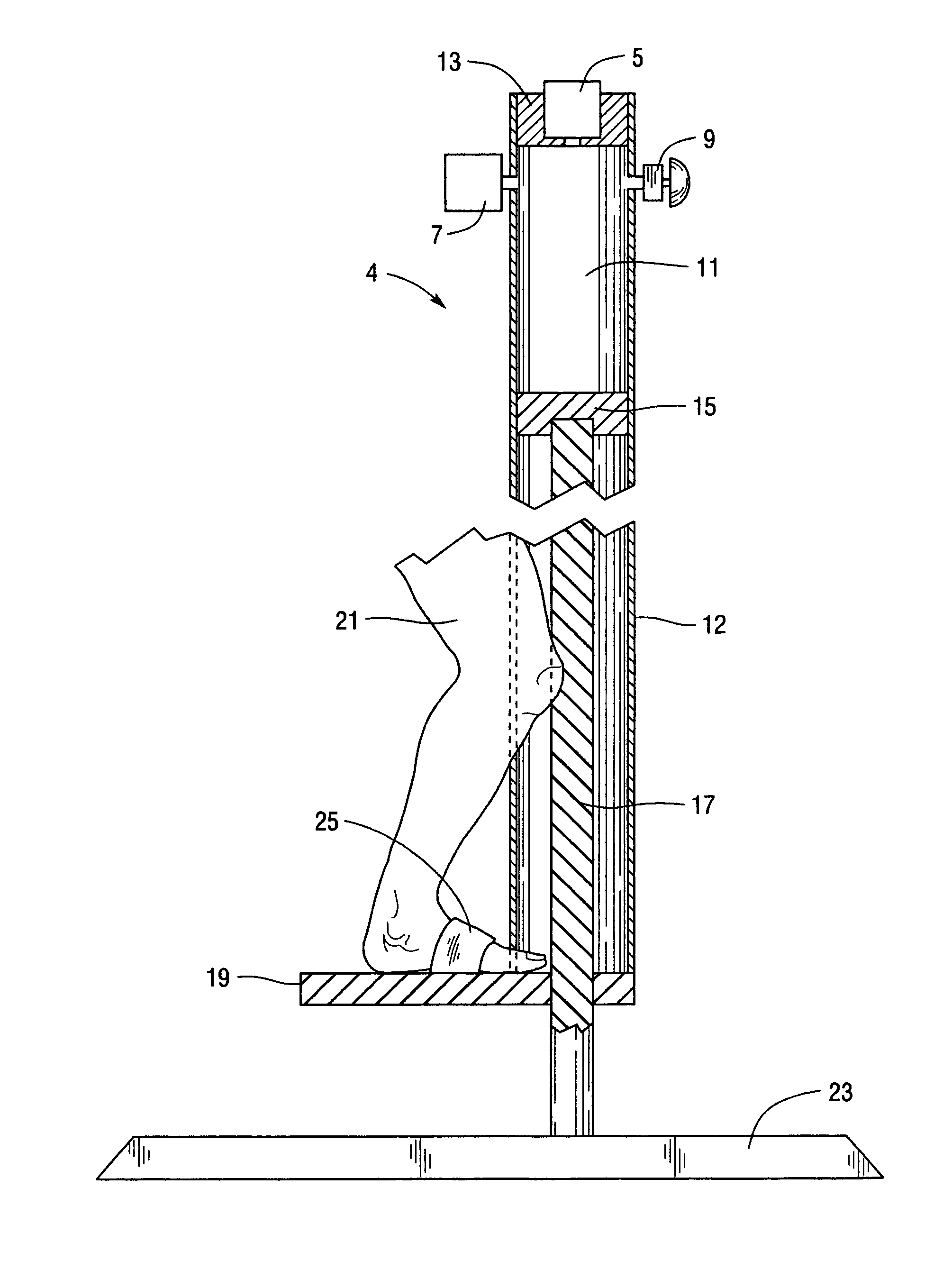

Improved oxygenating apparatus

InactiveUS20160256661A1Dissipate quicklyAvoid injuryTracheal tubesRespiratory masksReservoir bagExpiratory valve

A disposable oxygenation apparatus used to apply an oxygen enriched, positive pressure to a patient's airway where a respiratory device is in situ or is to be used, to decrease the incidence of desaturation and with an LMA in situ to assist in maintaining the patient's vocal cords open during recovery after anaesthesia. The apparatus includes a passageway or passageways extending therethrough, an expiratory valve or valves located in or adjacent an outlet for controlling the passage of expired air from said patient during expiration, a primary inspiratory valve located in or adjacent a primary inlet, for controlling oxygen or oxygen rich air flowing through the passageway or passageways from a collapsible reservoir bag, and a secondary inspiratory valve located in or adjacent a secondary inlet for controlling entry of ambient air in from an exterior of the apparatus during inspiration when the collapsible reservoir bad has been substantially emptied.

Owner:INNOVGAS PTY LTD

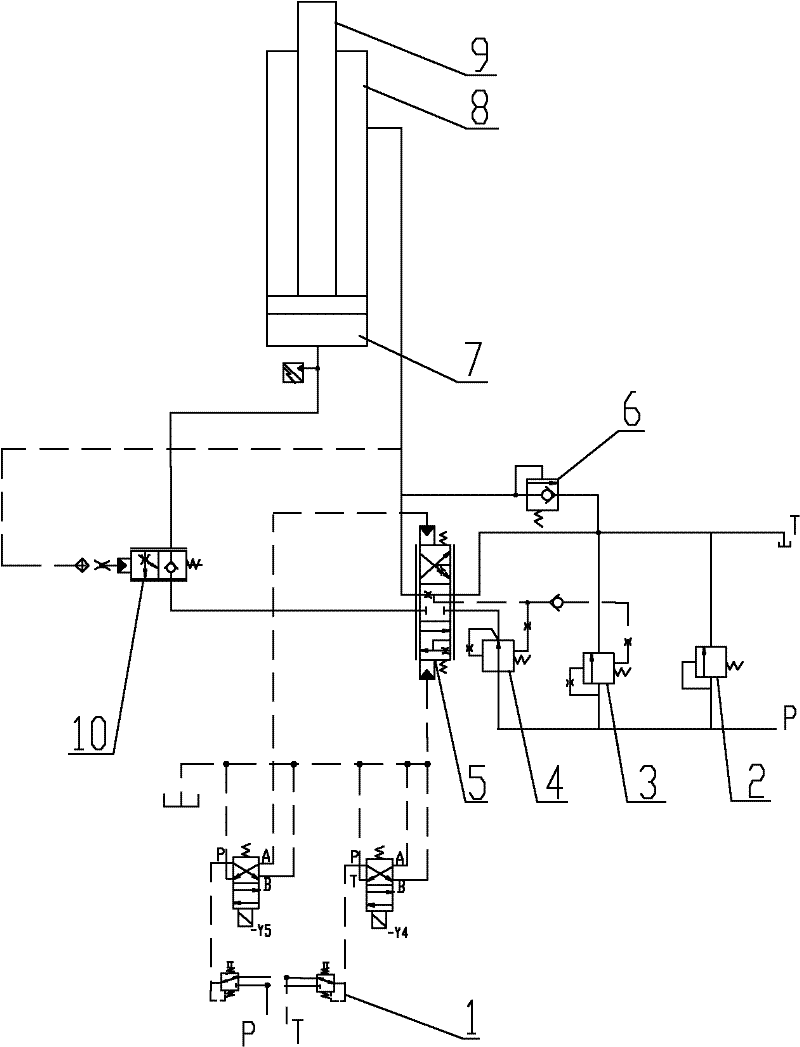

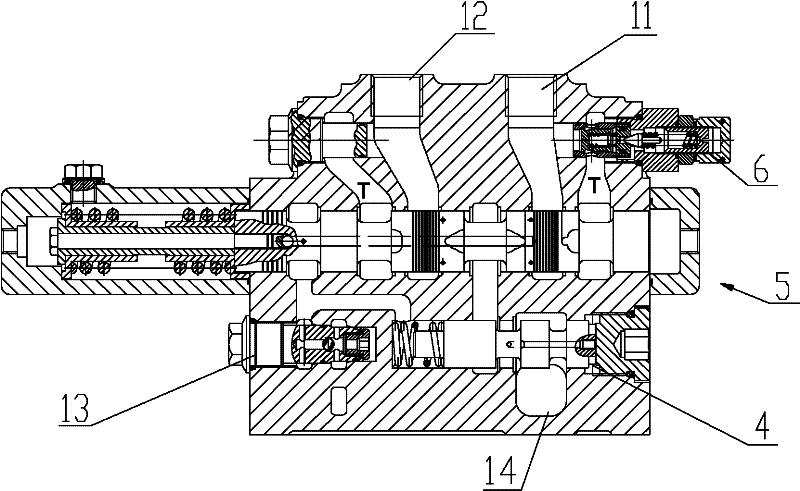

Crane luffing control valve and crane luffing hydraulic system

ActiveCN102398866AStable pressureEliminate jitterServomotor componentsCranesControl valvesPetroleum engineering

The invention discloses a crane luffing control valve, comprising a valve body and a valve core. The valve body is provided with an oil inlet, a first oil outlet, a second oil outlet and an oil return opening. One end of the valve core seals the second oil outlet shoulder and is equipped with a first groove for connecting the oil inlet and the second oil outlet; the other end of the valve core is equipped with a second groove for connecting the second oil outlet and the oil return opening; at least one of the second groove and the first groove has an axial spacing less than a width of an under cut groove of the second oil outlet. The control valve can substantially enhance jiggle characteristic of the crane during luffing and eliminate jitter phenomenon of a handle in a micro opening. The invention also discloses a crane luffing hydraulic system equipped with the crane luffing control valve.

Owner:XUZHOU HEAVY MASCH CO LTD

Gas generator

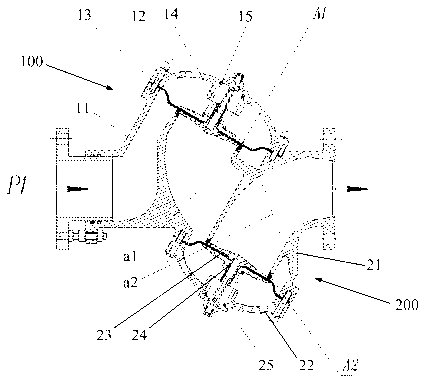

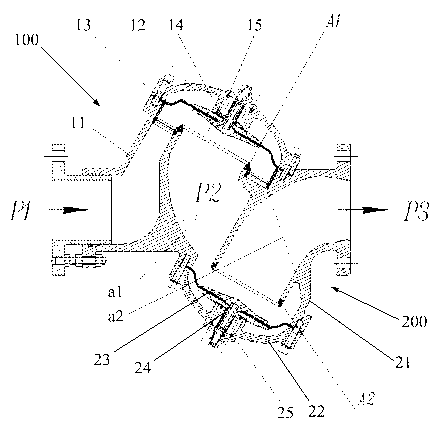

ActiveUS7240916B2Easy to manufactureLow cracking pressurePedestrian/occupant safety arrangementDeodrantsEngineeringVarying thickness

A gas generator includes a housing, which has outflow openings for outflowing gas, and at least one destructible insulation foil which in a non-activated state of the gas generator closes at least one of the outflow opening so as to be moisture-tight. The insulation foil has a varying thickness. The varying thickness is provided by at least one thermally insulating foil layer with a varying thickness, which lies over a base layer.

Owner:TRW AIRBAG SYST

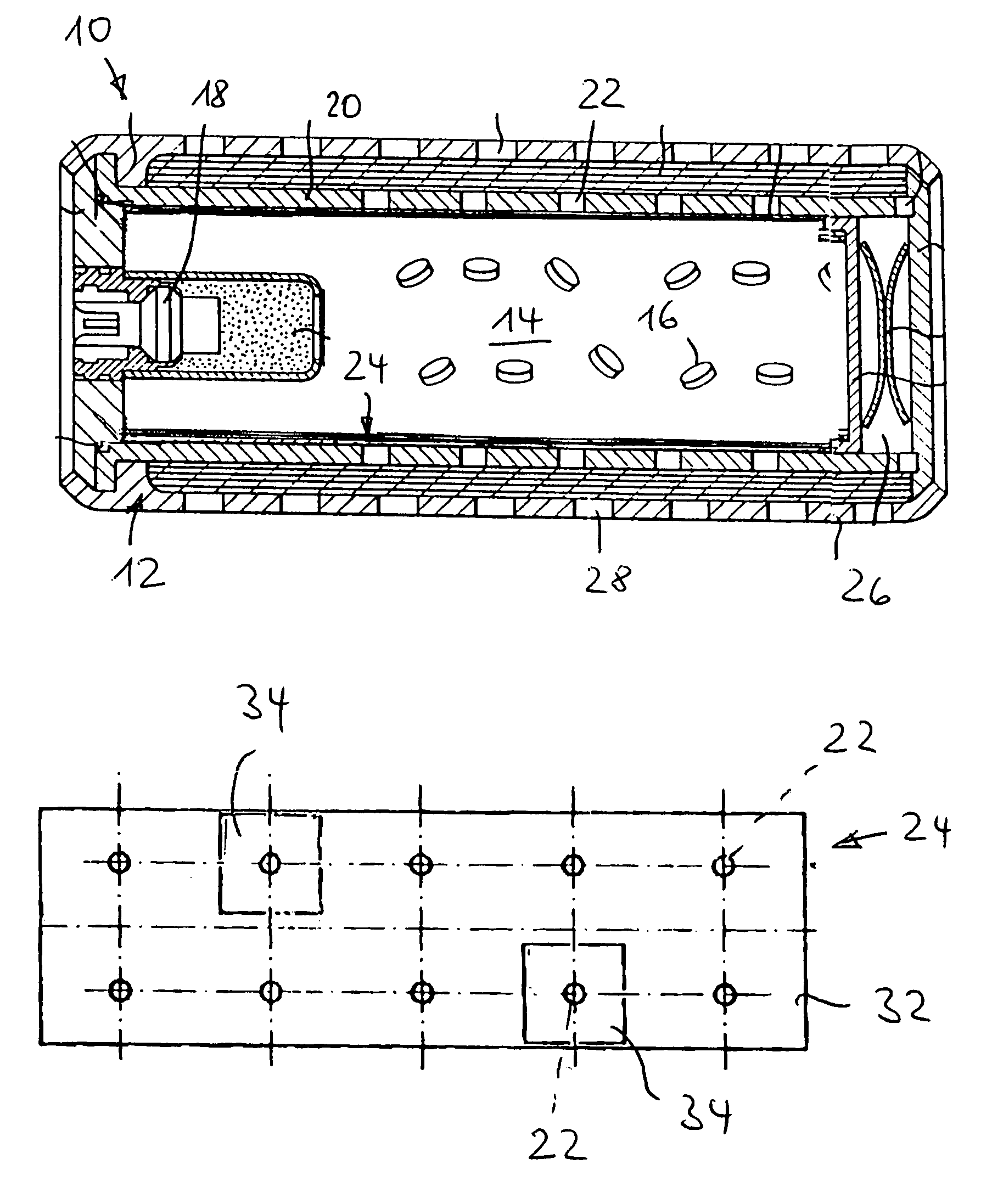

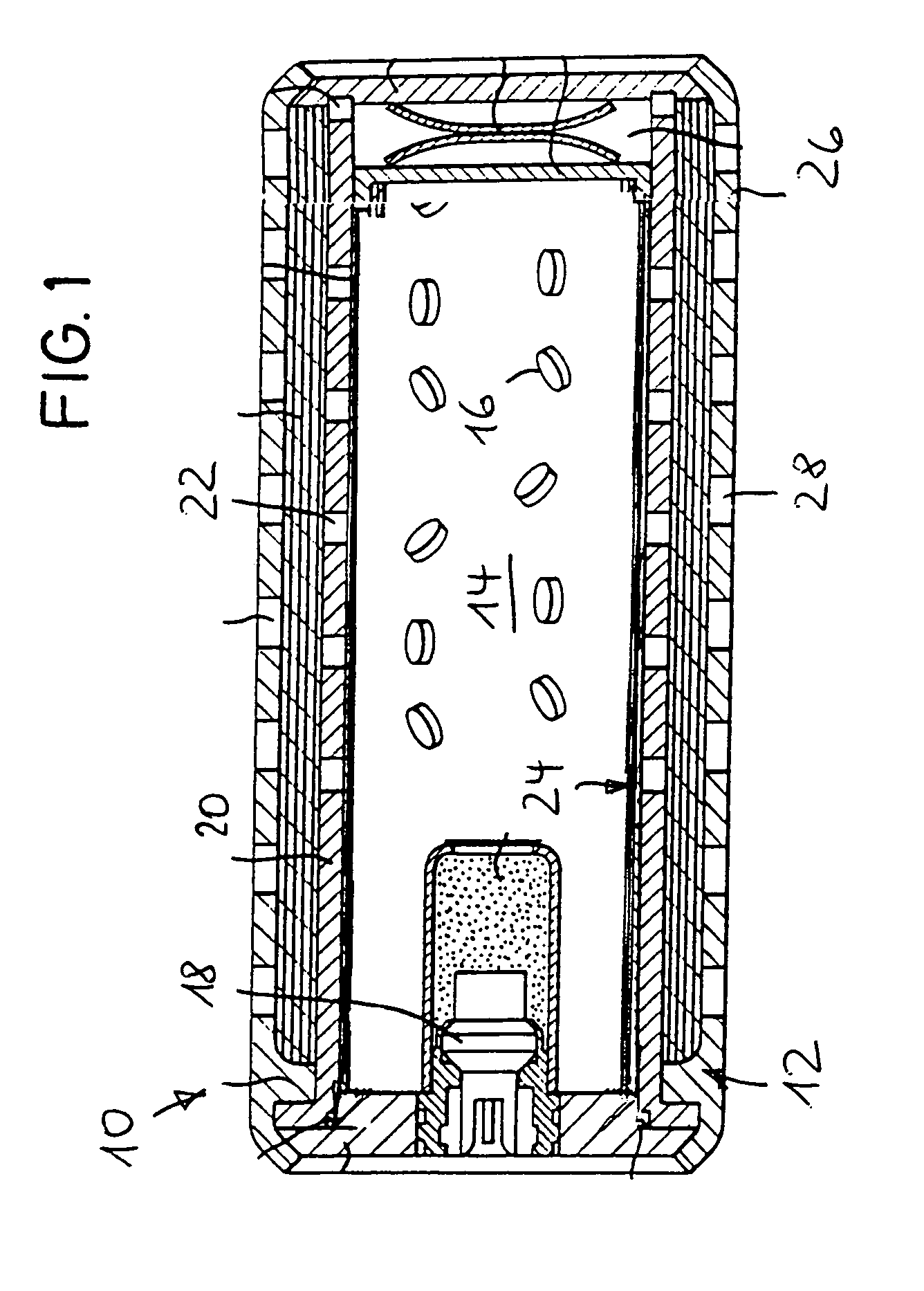

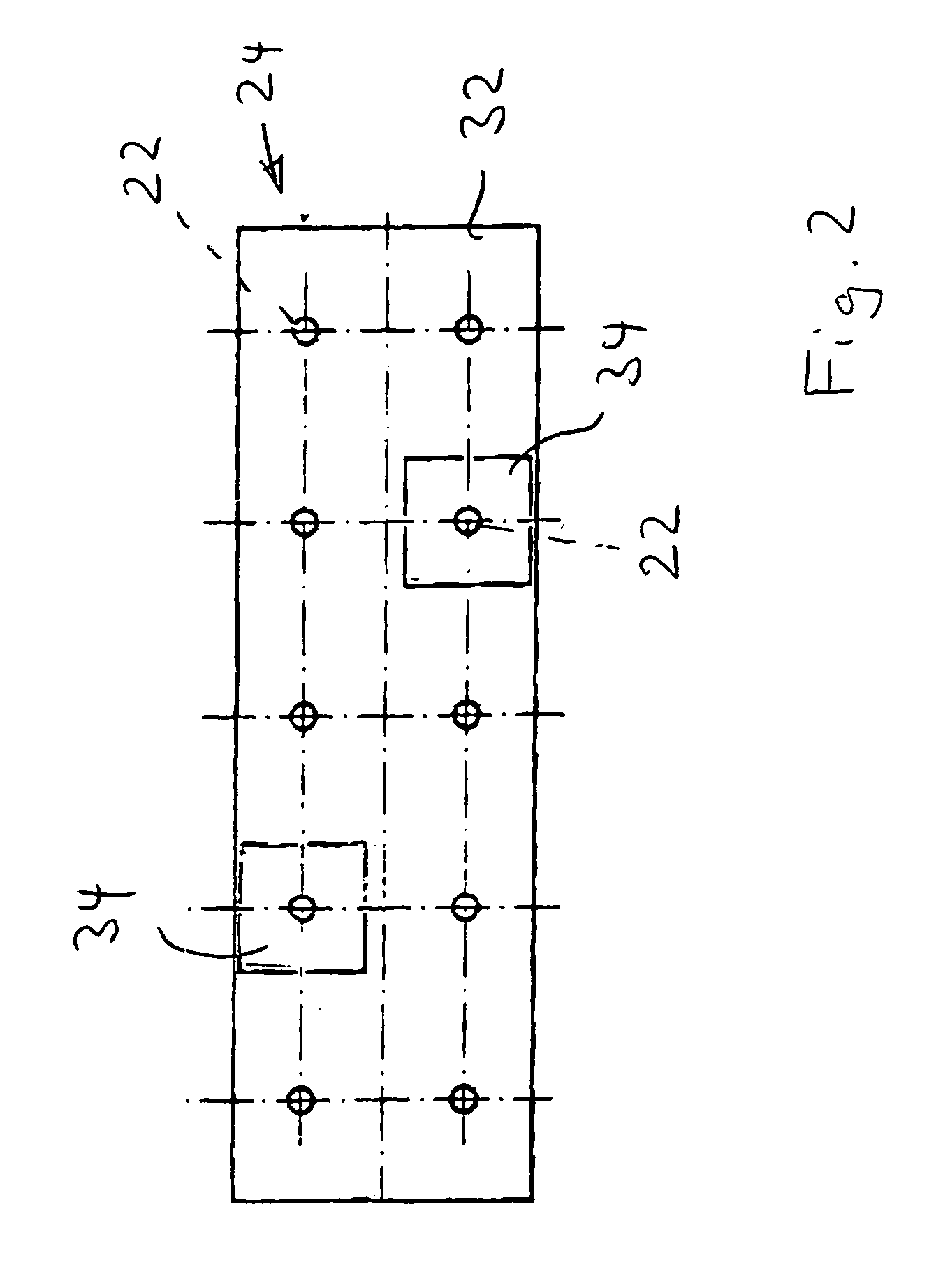

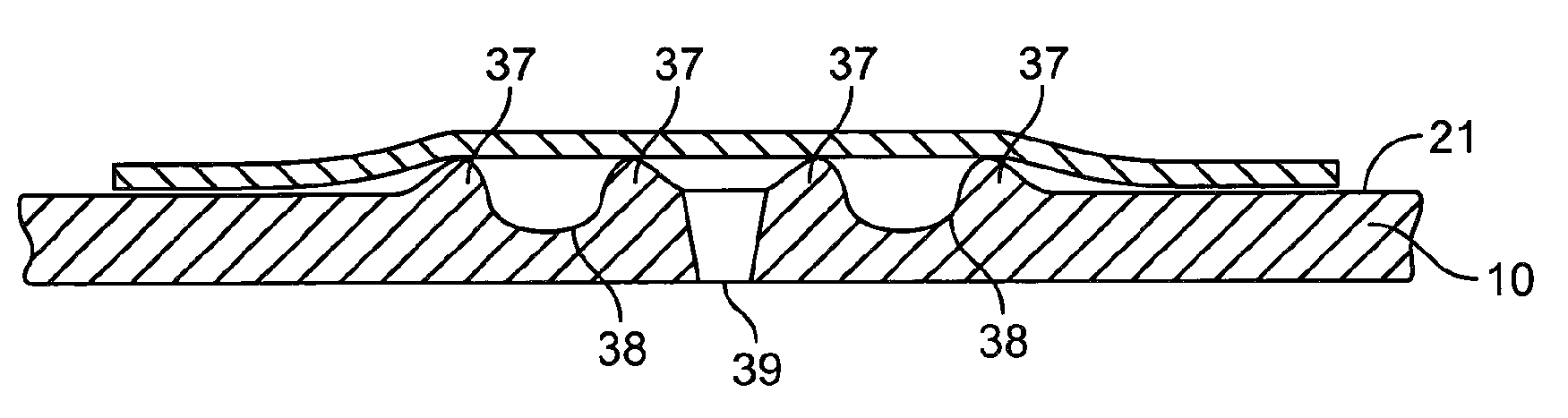

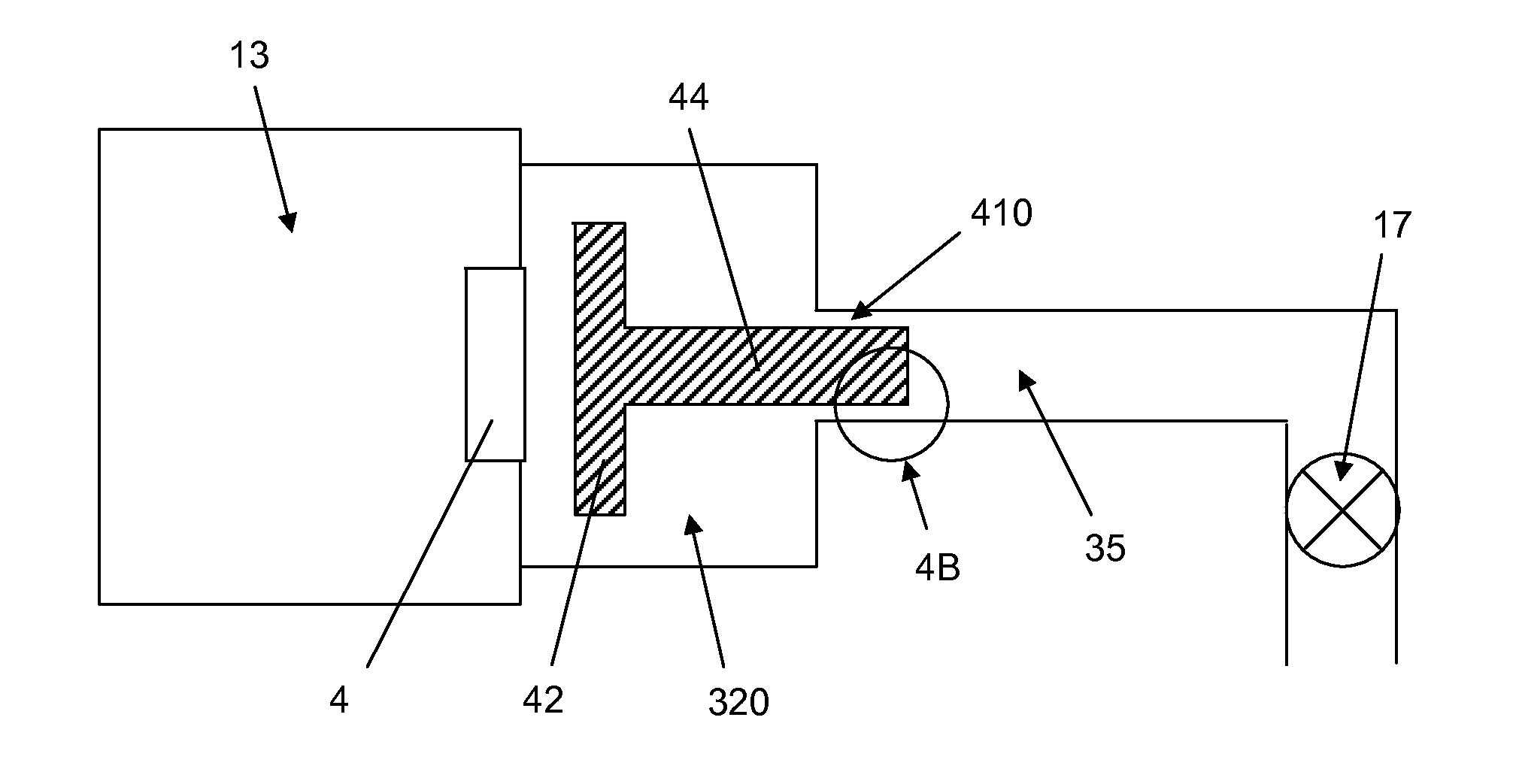

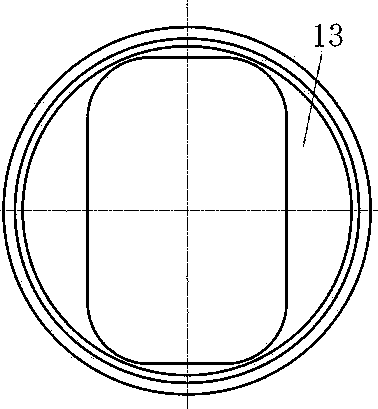

Packaging material with integrated pressure relief valve

ActiveUS20120196060A1Avoid connectionPrevent penetrationSynthetic resin layered productsSausage casingsTensile testingRelief valve

A packaging material for forming at least a part of a package for a product releasing gasses comprises a one-way pressure relief valve (18) including a first inner film (10), being provided with at least one inlet opening (13,14) therethrough, and a second outer film (11) covering the at least one inlet opening (13, 14) and being bonded to the first inner film (10) to form a channel portion (12) between the inner and the outer film. The channel portion (12) communicates with the surroundings of the package through at least one outlet opening (15) spaced apart from the at least one inlet opening (13, 14). The pressure relief valve (18) further comprises a liquid (19) provided in the channel portion (12) and solid spacer means (17) provided in the channel portion (12) proximate to the at least one inlet opening (13, 14). The outer film (11) is a soft film having such a flexibility or elasticity that in a tensile test a force of less than 5 N is needed for elongating a test piece thereof having a width of 15 mm by 5%.

Owner:AMCOR FLEXIBLES TRANSPAC B V B A

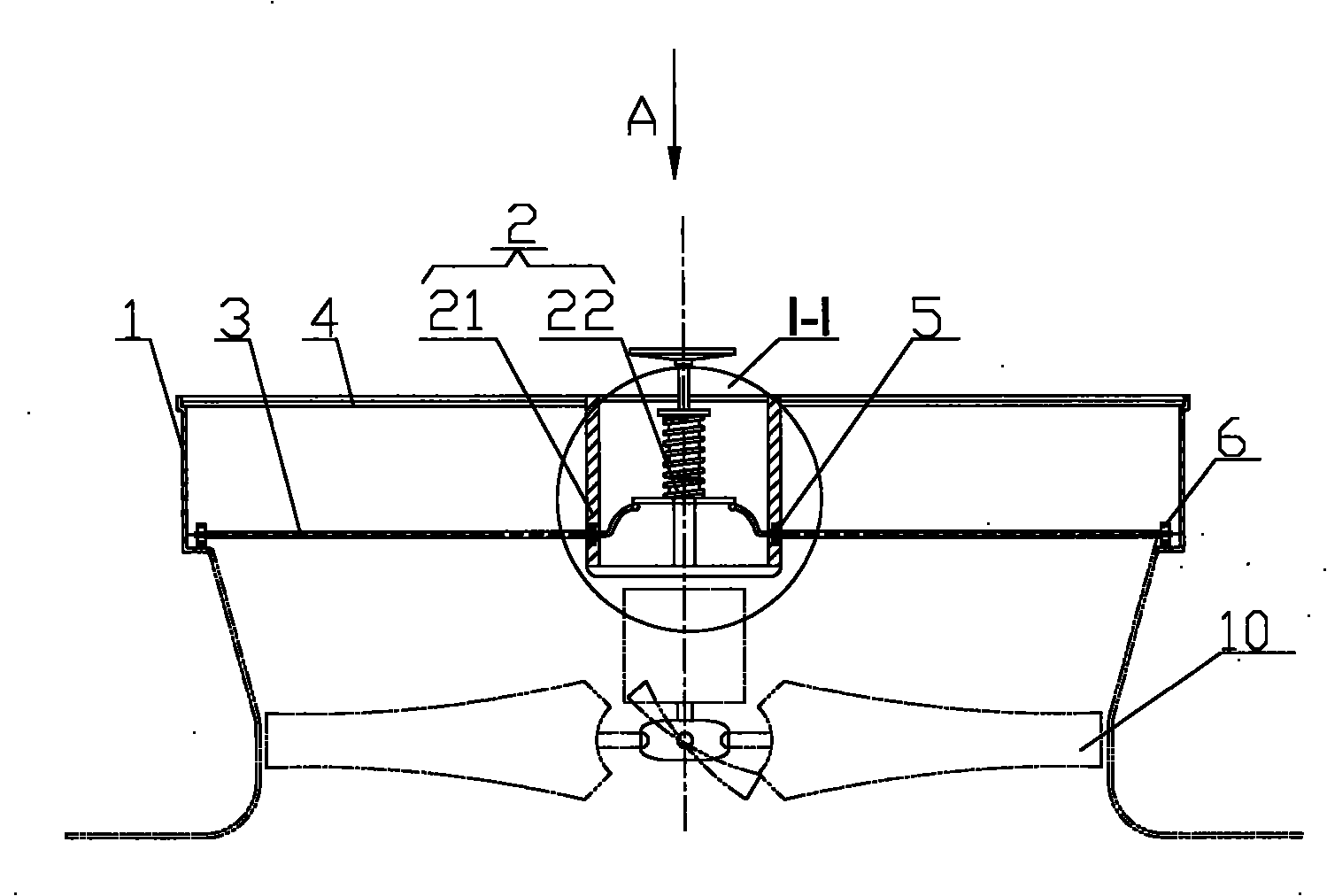

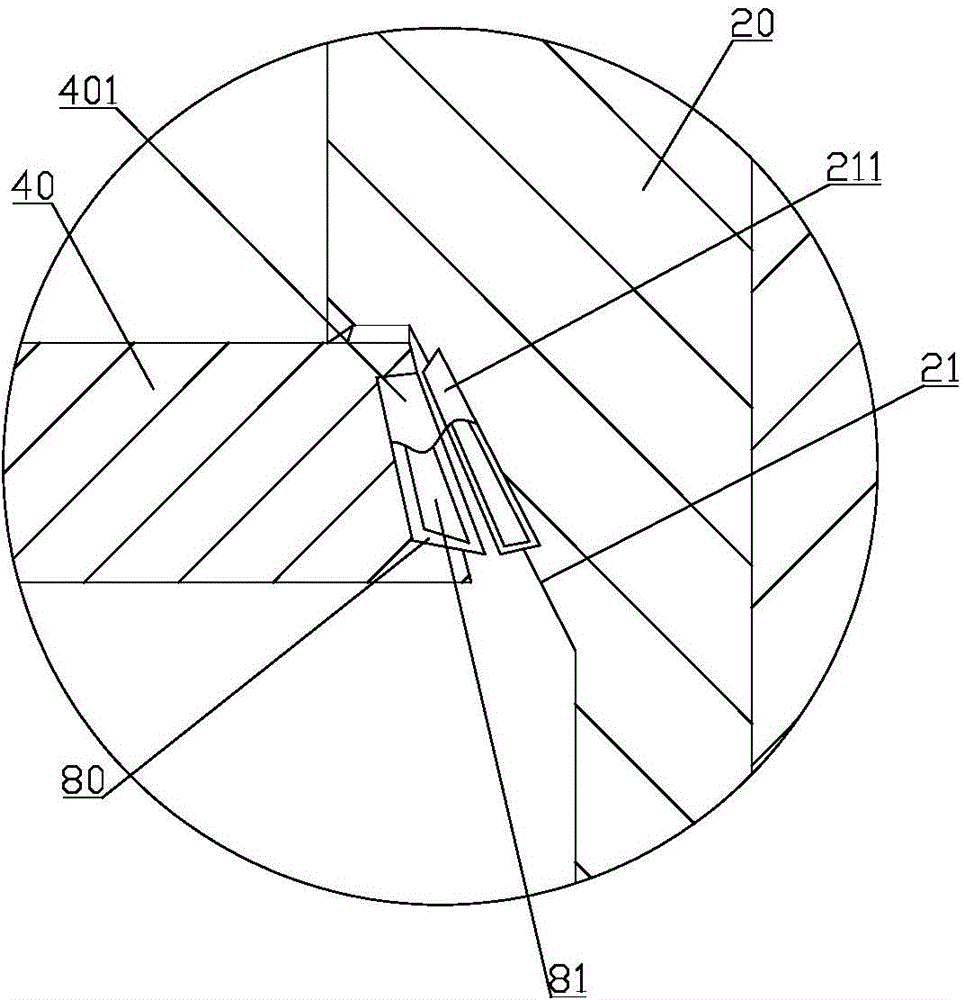

Axial flow fan and air valve thereof as well as cooling tower and air cooler

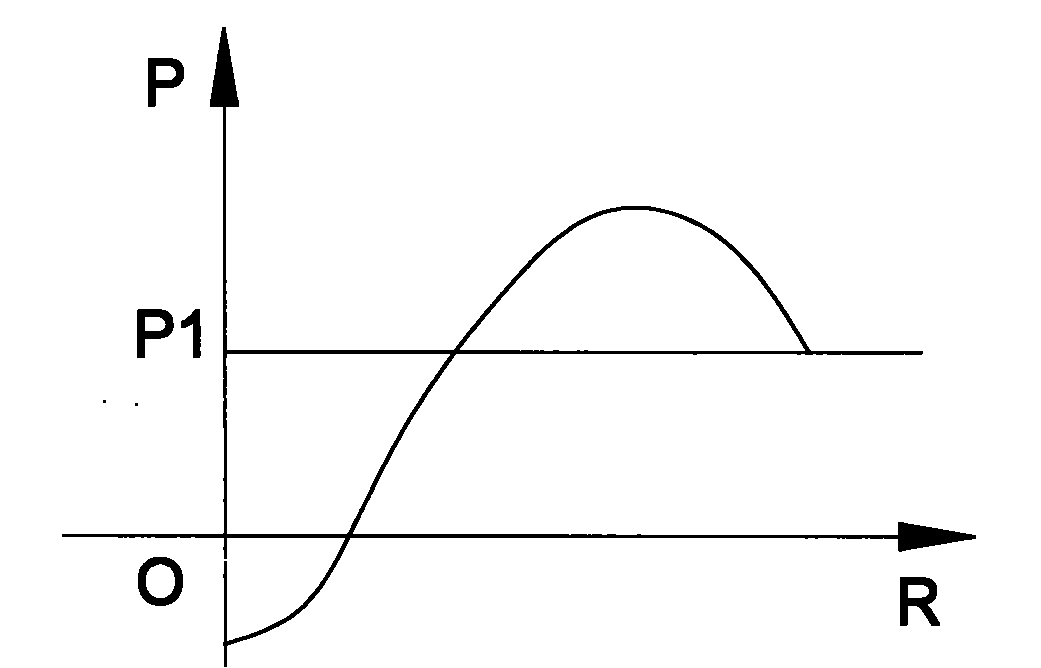

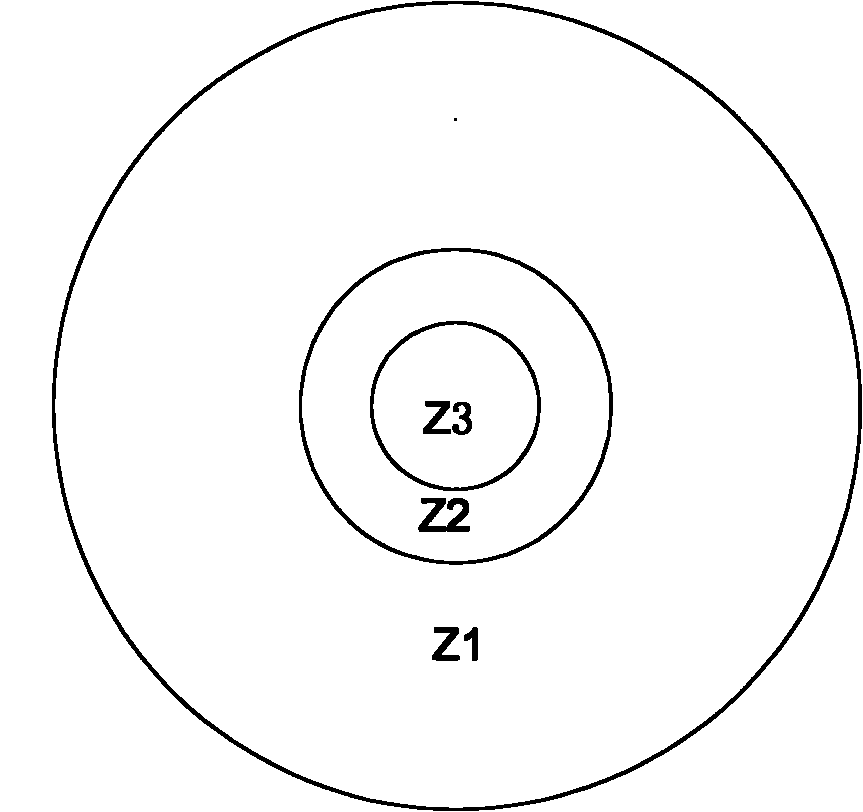

ActiveCN101832297AImprove performanceLow cracking pressurePump componentsPumpsCooling towerPositive pressure

The invention discloses an air valve for an axial flow fan, the axial flow fan with the air valve and a cooling tower or an air cooler with the axial flow fan. The disclosed air valve for the axial flow fan comprises a valve body and a plurality of blades, wherein each blade comprises a blade shaft and a main blade; the inner edges of the main blades are fixed with the blade shafts; the valve body comprises an outer barrel and a central seat which are relatively fixed, and the central seat is arranged in the outer barrel; the outer end and the inner end of the blade shaft are respectively and rotatably arranged on the outer barrel and the central seat; and the plurality of blades are radially distributed on the periphery of the central seat. In the disclosed air valve for the axial flow fan, the blades can be matched with the pressure distribution of an air outlet of the axial flow fan, the blade arrangement area corresponds to a positive pressure air exhaust area of the air outlet, and the opening degree of each blade can be better matched with the pressure of the area to reduce the air exhaust resistance of the air outlet so as to reduce the vibration of the blades, lower the noise and the opening pressure of the air valve and improve the working reliability of the air valve.

Owner:SHANGHAI ACEC REFRIGERATION TECH CO LTD

Vibration damper having an amplitude-selective damping device

ActiveUS7721856B2Comfortable damping adjustmentParticularly sensitive response behaviour of the amplitude-selective damping deviceSpringsShock absorbersEngineeringCheck valve

A vibration damper having a sensitive response behavior at very low amplitudes comprises a separating piston being disposed inside a bypass so as to move axially freely. The separating piston divides the bypass into two chambers mutually sealed from one another. Two valves are disposed in the bypass. The first valve acts in a compression stage as a pressure limiting valve and as a non return valve in an extension stage. The second valve acts as a pressure limiting valve in the extension stage and as a non return valve in the compression stage.

Owner:THYSSENKRUPP BILSTEIN

Device and method for leading liquid nitrogen to barefoot well

The invention discloses a device and method for leading liquid nitrogen to a barefoot well. The device includes a liquid nitrogen storage tank, a sealing liquid storage tank, a supercharging conveyingdevice, a conveying pipeline, a back sealing device, a liquid nitrogen spray gun and a front sealing device; the liquid nitrogen storage tank and the sealing liquid storage tank are connected to thesupercharging conveying device; the supercharging conveying device is connected to the back sealing device through the conveying pipeline; a liquid nitrogen inlet of the liquid nitrogen spray gun anda sealing liquid inlet of the front sealing device are connected to a liquid nitrogen outlet and a sealing liquid outlet of the back sealing device respectively; and the front sealing device seals theother end of the liquid nitrogen spray gun. The beneficial effects of the invention are that the device is simple in structure and is easy to operate and use; (2) reservoir pollution can be avoided through liquid nitrogen perforation; and (3) reservoir rocks are soaked in the liquid nitrogen to form more fracture nets, and then the fracturing effect can be improved.

Owner:XI'AN PETROLEUM UNIVERSITY

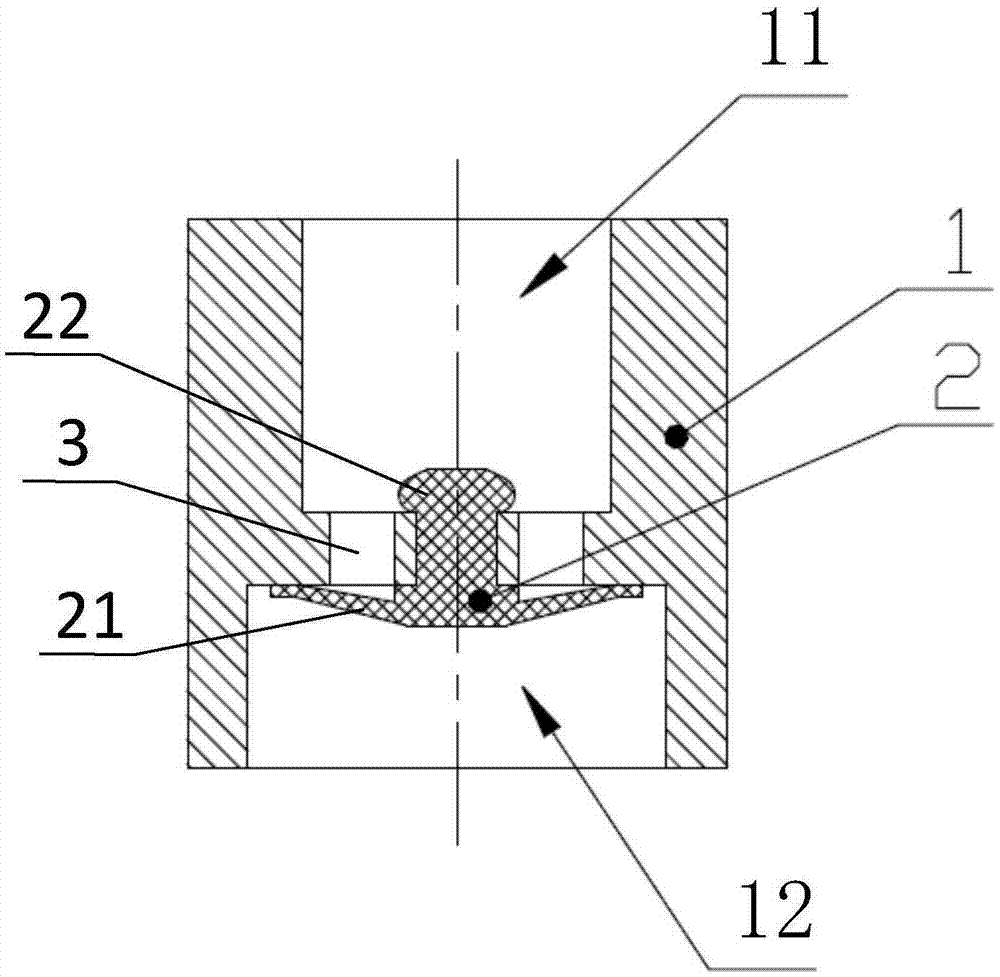

Diaphragm check valve

The invention discloses a diaphragm check valve. The check valve comprises a valve body (1), the valve body (1) comprises a gas inlet (11) and a gas outlet (12), and a plurality of small holes communicated with each other are formed in the position between the gas inlet (11) and the gas outlet (12); the valve body (1) further comprises an elastic diaphragm (2), the elastic diaphragm (2) is fixed on the valve body (1), and the elastic diaphragm (2) covers the plurality of small holes (3) at the air outlet side to seal the plurality of small holes. The diaphragm check valve is simple in overall structure, convenient to install, small in opening pressure, and good in sealing performance and can be mounted at any angles.

Owner:BEIJING AEONMED

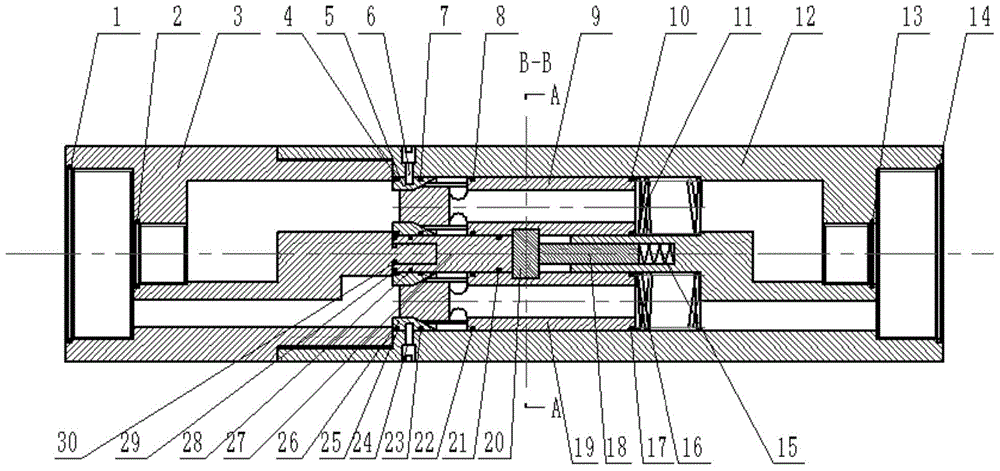

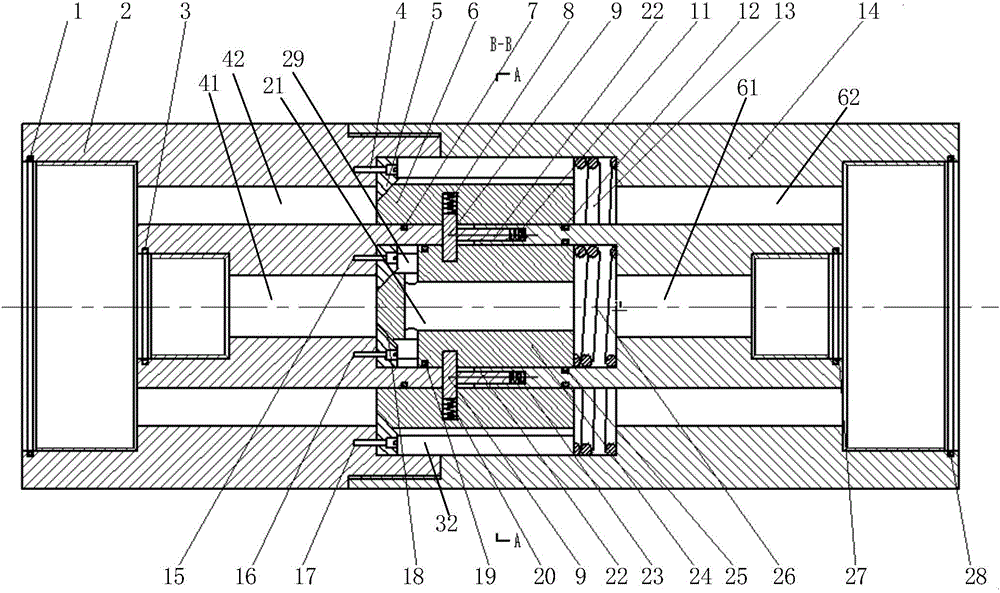

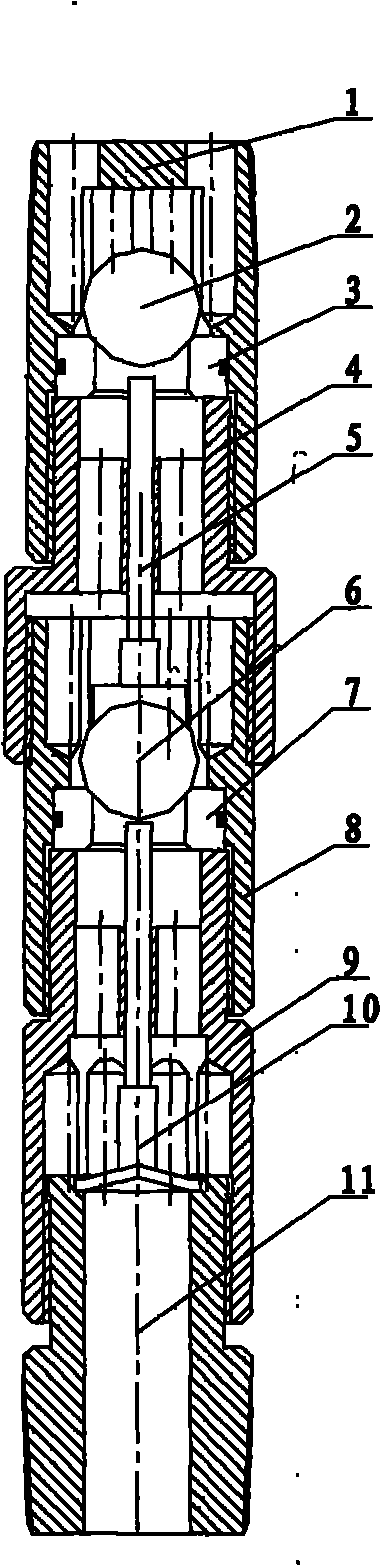

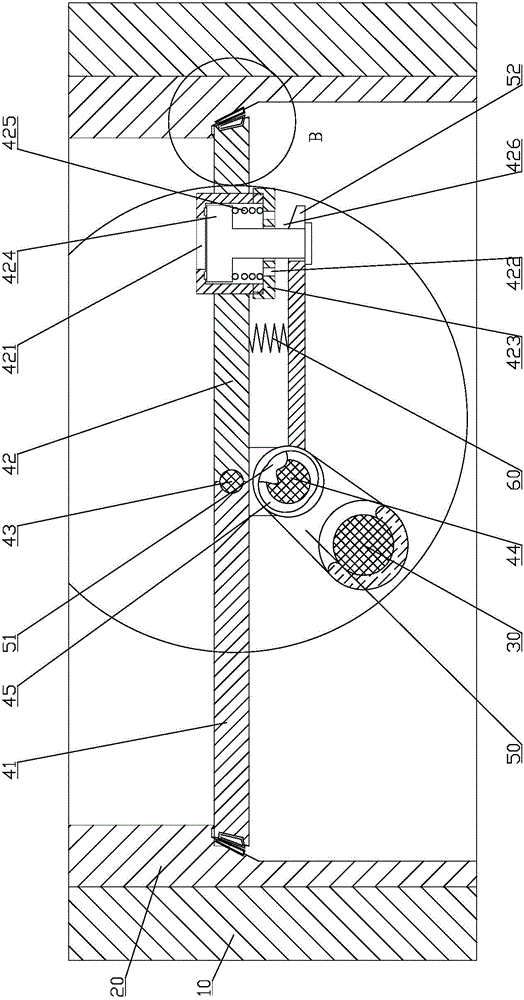

Plunger-type double-passage different-direction synchronous joint control check valve for double-layer continuous oil pipe

ActiveCN104806200AEffectively closedPrevent returnConstructionsWell/borehole valve arrangementsPistonCheck valve

The invention discloses a plunger-type double-passage different-direction synchronous joint control check valve for a double-layer continuous oil pipe, which is arranged between the double-layer oil pipe pipelines. The plunger-type double-passage different-direction synchronous joint control check valve comprises a left valve body, a right valve body, an inner passage piston, an inner passage piston seat, an outer passage piston, an outer passage piston seat, a long pin, a crossing plunger, a slide block, an inner passage piston return spring, an outer passage piston return spring and a slide block return spring. According to the plunger-type double-passage different-direction synchronous joint control check valve, the parts such as the piston, the return spring, the movable slide block and the like are simultaneously and additionally installed in the inner layer and the outer layer of continuous oil pipe passages, a different-direction synchronous joint control design scheme is adopted, a double-passage different-direction joint control check valve device is formed, so that when accidents happen, the passages of the inner and the outer continuous oil pipes are effectively sealed, the return of the well liquid is prevented, and the blowout is prevented.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

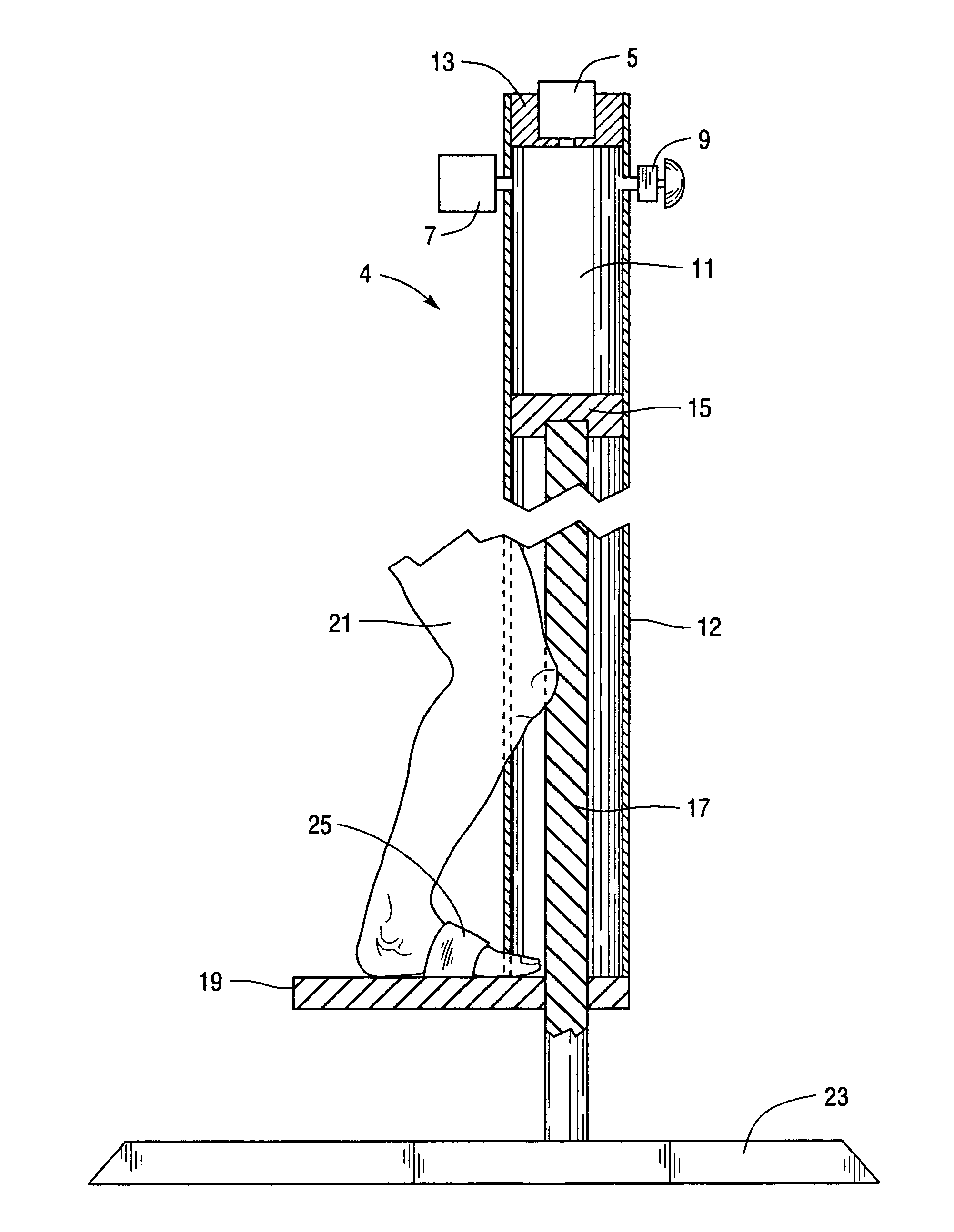

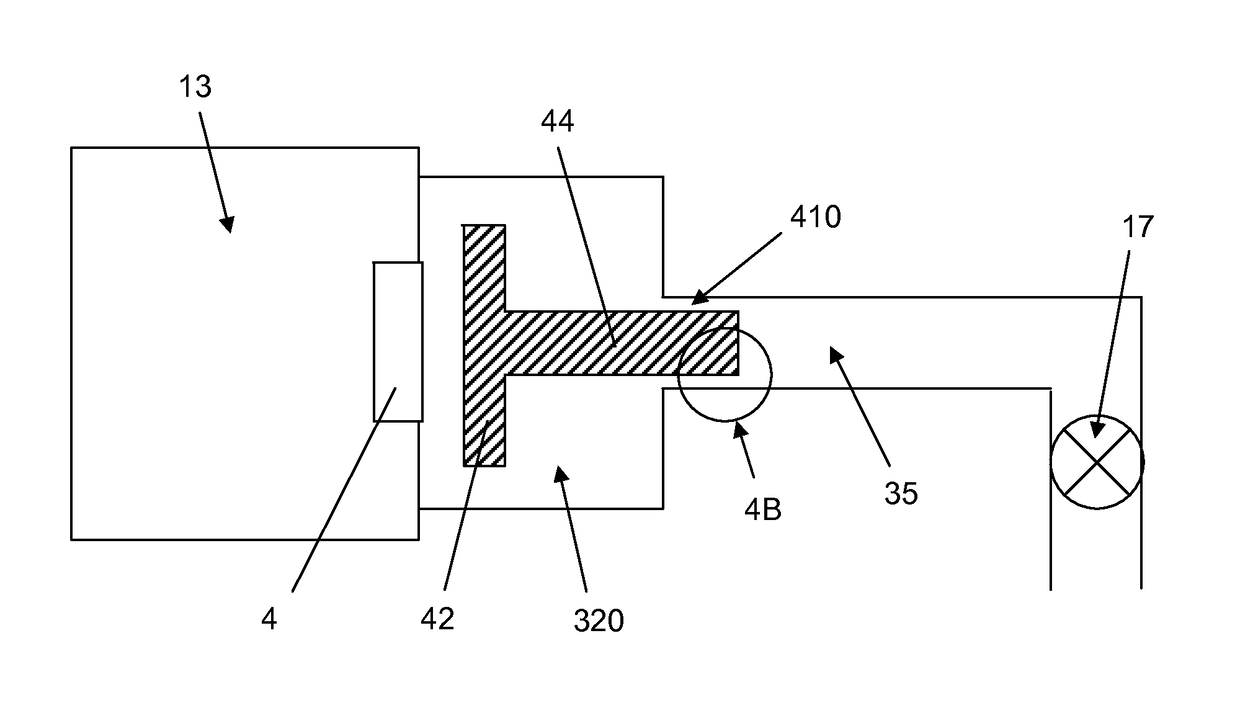

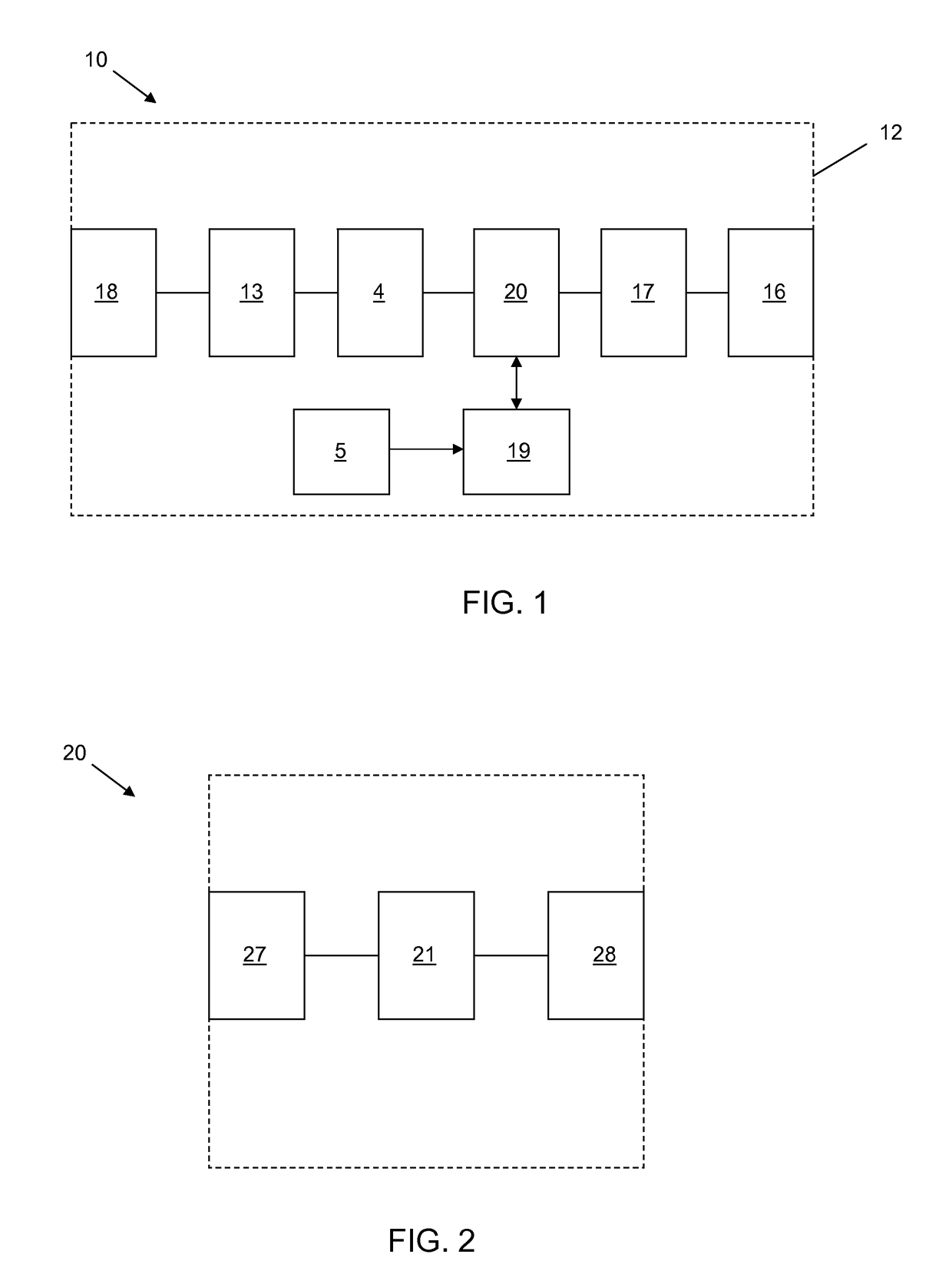

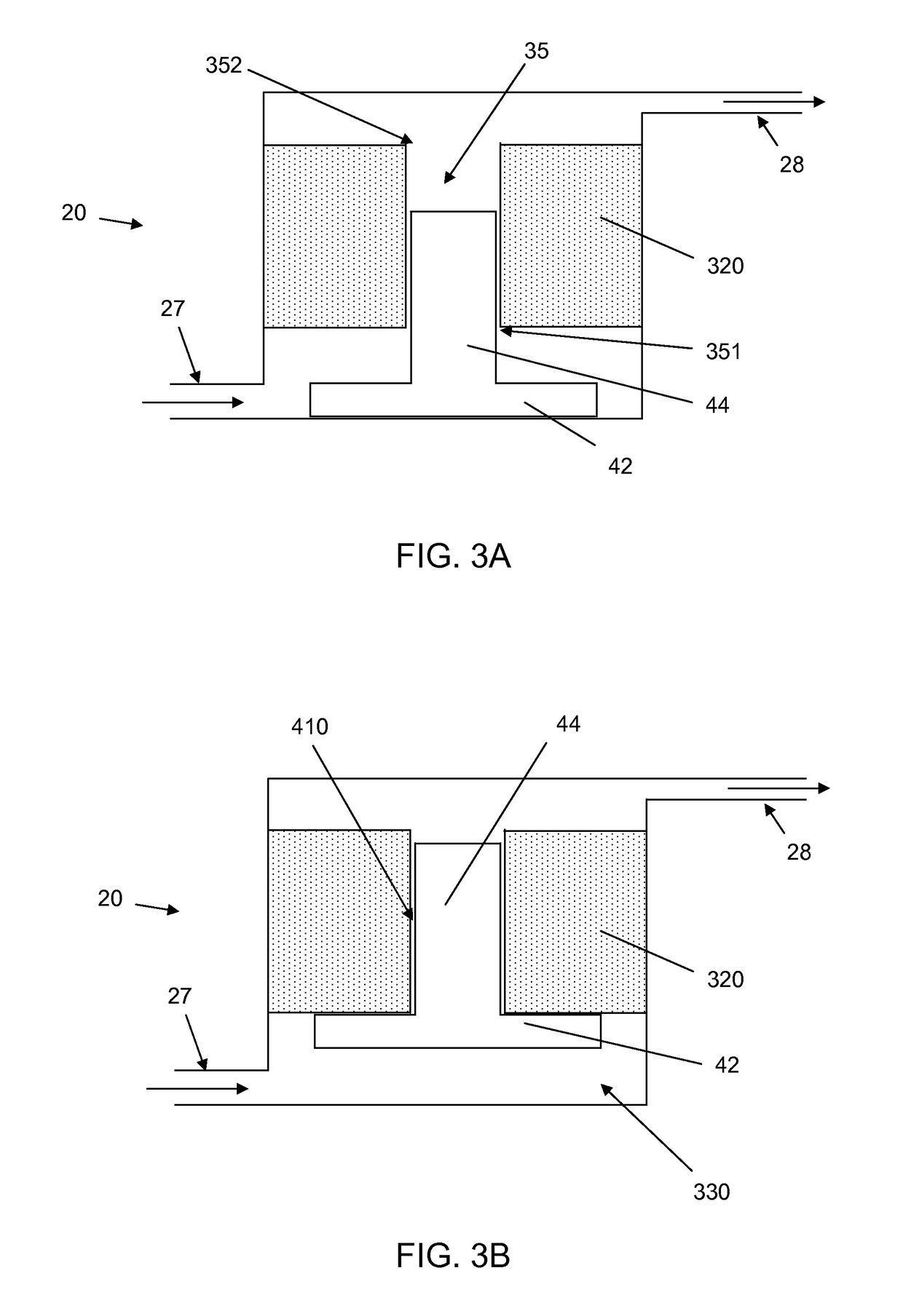

Air tolerant implantable piston pump

ActiveUS20100152714A1Reduce energy consumptionLow cracking pressurePositive displacement pump componentsFiltering accessoriesInlet channelEngineering

An implantable infusion device includes a reservoir for housing an infusion medium and a drive mechanism having an inlet chamber, a piston and a piston channel. The inlet chamber is in fluid communication with the reservoir. The piston channel is in fluid communication with the inlet chamber, and has a distal end and a proximal end, the proximal end being closer to the inlet channel than the distal end. The piston is axially moveable within the piston channel to drive infusion medium out of the distal end of the piston channel. The clearance between the piston and the channel is sufficiently small to prevent undissolved gas in the inlet chamber from passing through the clearance. The inlet chamber may be sufficiently large to allow undissolved gas to accumulate without adversely affecting the performance of the infusion device.

Owner:MEDTRONIC INC

Butterfly valve

The invention discloses a butterfly valve. The butterfly valve comprises a valve body, a valve base, a valve rod and a valve flap. According to the butterfly valve, the improvement is performed on the following performances: 1, the valve flap is divided into two parts, a pressure release hole is formed in the valve flap, so that the valve flap releases pressure before rotating wholly and opens in steps during opening, thus the butterfly valve is small in opening pressure and labor-saving; 2, due to the introduction of a titanium material and a fluorine plastic layer, so that the corrosion resistance of the butterfly valve is greatly improved; 3, due to the adoption of a dustproof ring, so that the dustproof performance of the butterfly valve is improved; and 4, due to the adoption of a sealing tape, the sealing performance of the butterfly valve is improved. Through the manner, the butterfly valve is excellent in comprehensive performance.

Owner:NINGBO TIANJILONG INTELLIGENT CONTROL TECH

Built-in bottom filling anti-overflow control device for canned oil tank

ActiveCN110406832AImprove reliabilityHigh explosion-proof gradeLarge containersEngineeringPilot valve

The invention provides a built-in bottom filling anti-overflow control device for a canned oil tank. The built-in bottom filling anti-overflow control device comprises a hydraulic control main valve,a floater guide valve and a connecting pipe, wherein the hydraulic control main valve is arranged in an inlet pipeline oil tank at the bottom of the oil tank, the floater guide valve is arranged at the top of the oil tank, the floater guide valve communicates with the hydraulic control main valve through a connecting pipe, and the liquid control main valve realizes opening and closing of the valvethrough the inlet and outlet pressure difference; when the liquid level is lower than the set height, the floater guide valve is opened, and the hydraulic control main valve is automatically opened under the pressure difference effect; when the liquid level reaches the set height, the floater floats to enable the floater pilot valve to be closed, and the hydraulic control main valve is automatically closed, namely, the hydraulic control main valve realizes pilot control through the floater pilot valve, and when the oil in the oil tank reaches the set volume height, the floater pilot valve isclosed, so that the hydraulic control main valve is controlled to be closed to prevent the oil tank from overflowing.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA +1

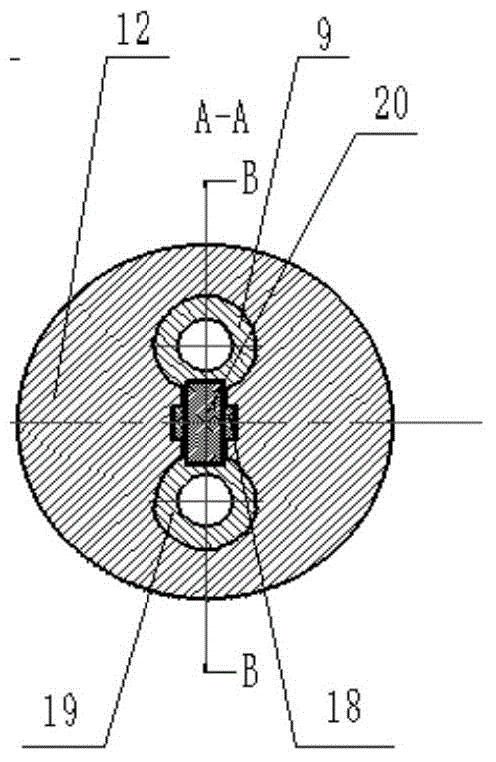

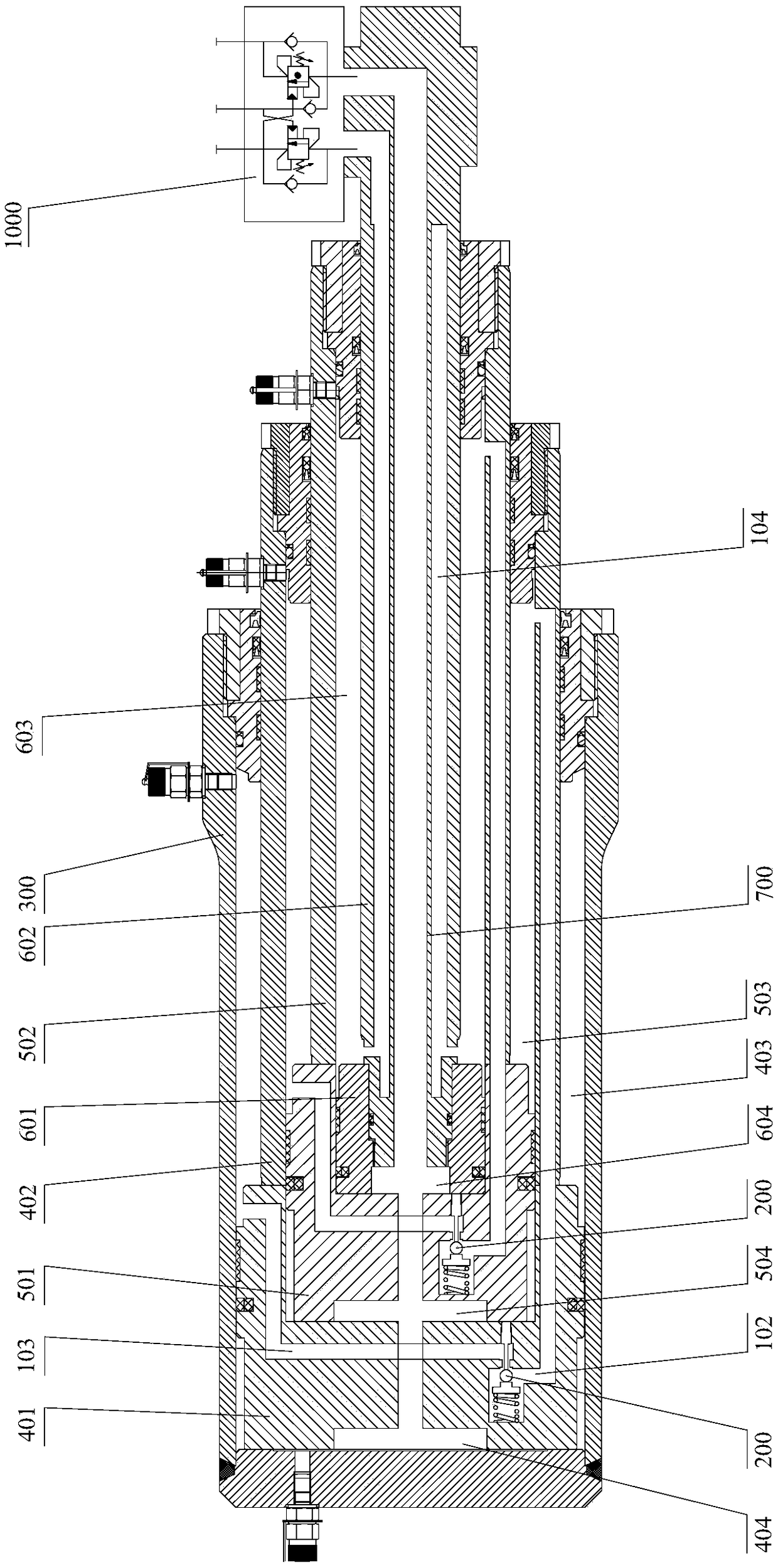

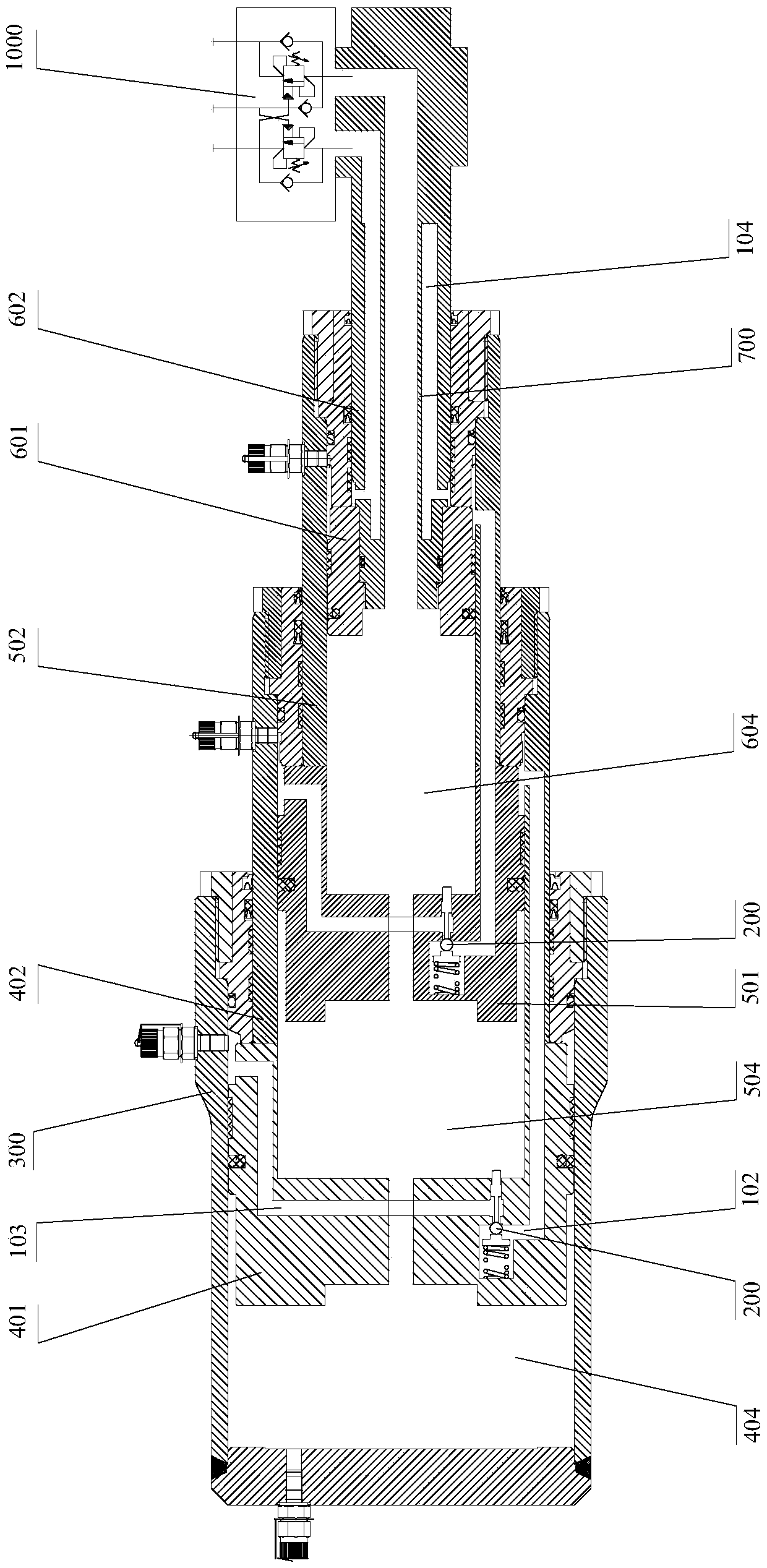

Piston rod oil inlet double-action multi-stage hydraulic cylinder

PendingCN108999836AGuaranteed scaling orderAvoid the problem that the leak is too large to work properlyFluid-pressure actuatorsHydraulic cylinderEngineering

The invention discloses a piston rod oil inlet double-action multi-stage hydraulic cylinder, and relates to the field of hydraulic cylinders. The piston rod oil inlet double-action multi-stage hydraulic cylinder comprises a cylinder body, at least two stages of piston rod assemblies arranged in the cylinder body in a sleeving mode stage by stage, multiple one-way valve assemblies, an ejection roddevice and a balancing valve assembly; each piston rod assembly comprises a piston and a piston rod; each one-way valve assembly comprises an in-cylinder one-way valve used for controlling rod cavities of the corresponding adjacent two stages of piston rod assemblies to communicate with each other or be intercepted; the ejection rod device is used for driving the in-cylinder one-way valves to be opened or closed, when the pistons in every two adjacent stages of the piston rod assemblies are separated in the stretching or retracting process, the ejection rod device is self-locked; and when thepistons in every two adjacent stages of the piston rod assemblies make contact with each other in the stretching or retracting process, the ejection rod device drives the in-cylinder one-way valves tobe opened; and the balancing valve assembly is fixed to the piston rod of the lowest stage of the piston rod assembly. According to the piston rod oil inlet double-action multi-stage hydraulic cylinder, the problem that a sealing ring is prone to being worn due to the fact that a traditional multi-stage hydraulic cylinder adopts radial holes can be solved, internal leakage of the hydraulic cylinder is avoided, and it is guaranteed that each stage of a hydraulic cylinder body can not generate the overpressure phenomenon.

Owner:中船重庆液压机电有限公司

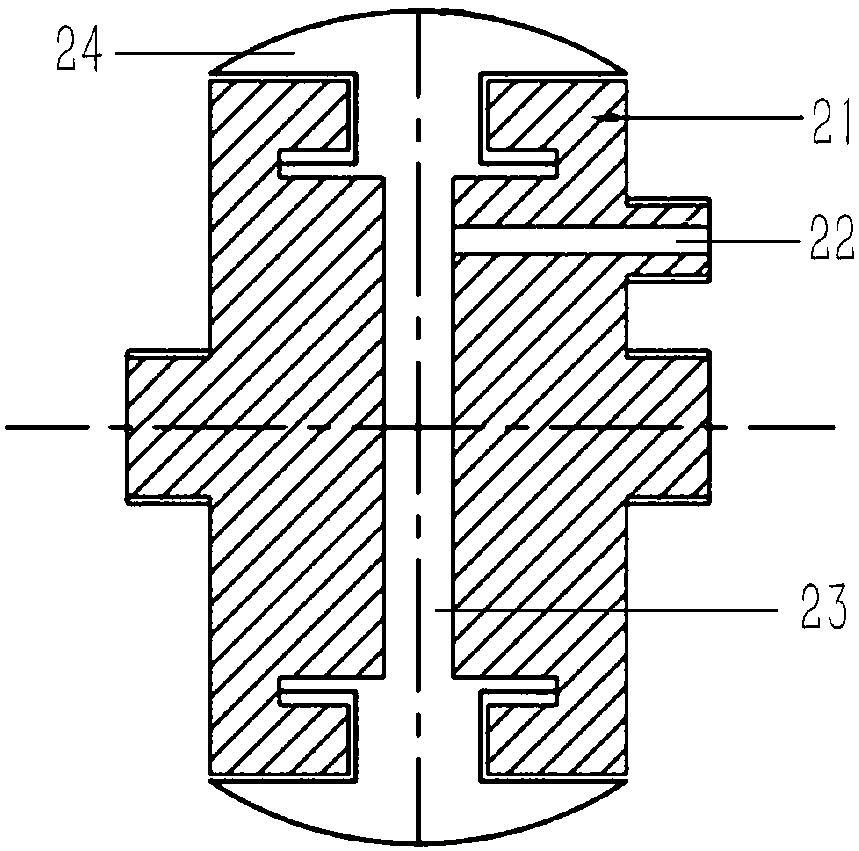

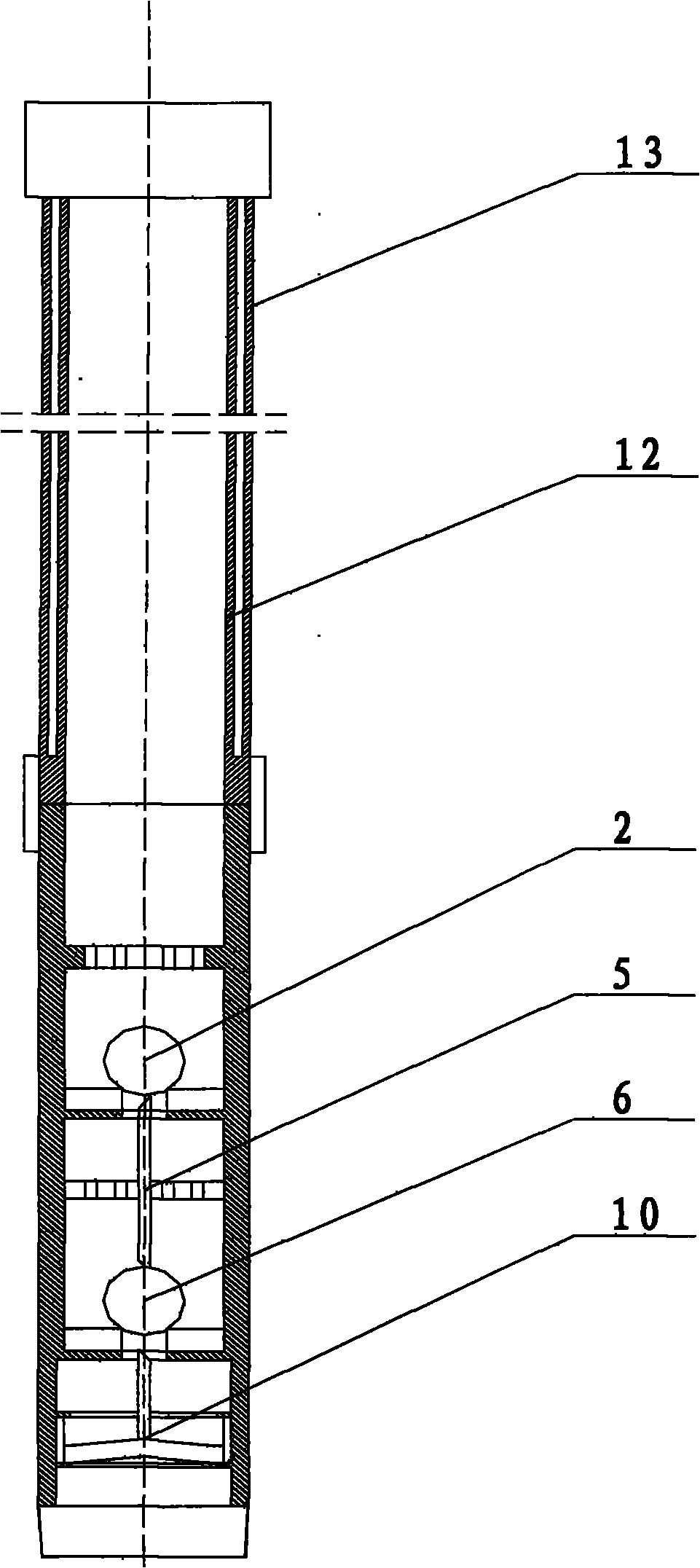

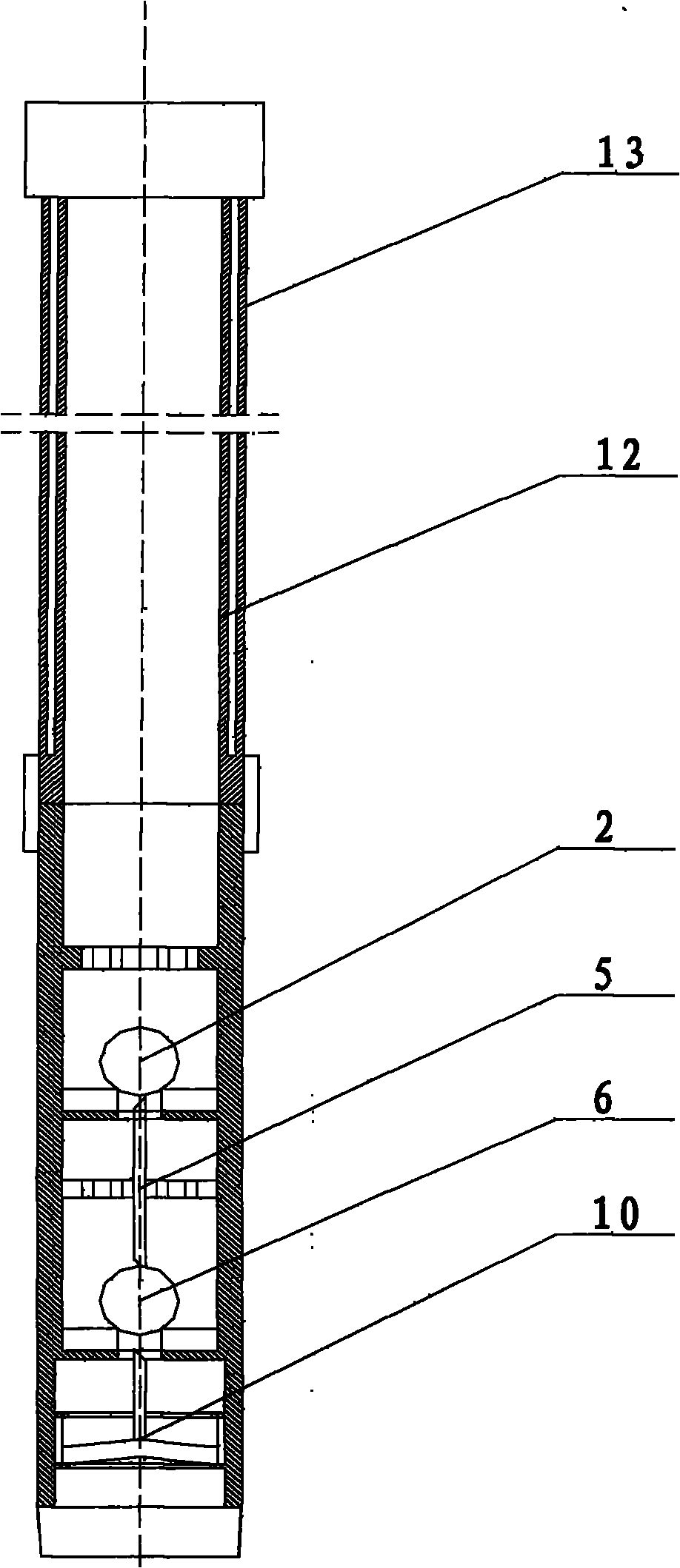

Dual-channel different-direction joint-control check valve

ActiveCN104929574APrevent returnLow cracking pressureWell/borehole valve arrangementsSealing/packingCheck valvePiston

The invention discloses a dual-channel different-direction joint-control check valve which comprises a left valve body, a right valve body, an inner piston, an outer piston, an inner reset spring and an outer reset spring. A gap with the preset size is reserved between the hole wall of a first right through hole and the hole wall of a first left through hole, a plurality of inner grooves are evenly circumferentially arranged in the outer wall of the inner piston and correspond to the gap, a plurality of outer grooves are arranged in the inner wall of the outer piston in a manner of being in one-to-one correspondence to the inner grooves, the bottom of each outer groove is provided with one pin shaft reset spring, one pin shaft is jacked into the inner groove through the pin shaft reset spring, the hole wall of the first right through hole is provided with blind holes corresponding to the pins shafts, each blind hole is provided with one slider and a slider reset spring which press the slider onto the pin shaft, and the inner piston drives the outer piston to move synchronously through the pin shafts when moving rightwards under the pressure of the left side. By the arrangement, blowout accident can be effectively prevented when accident happens.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Electroosmotic pump

ActiveUS20190184095A1Increase freedomAvoid relatively fixedPressure infusionPumpsCheck valveBiomedical engineering

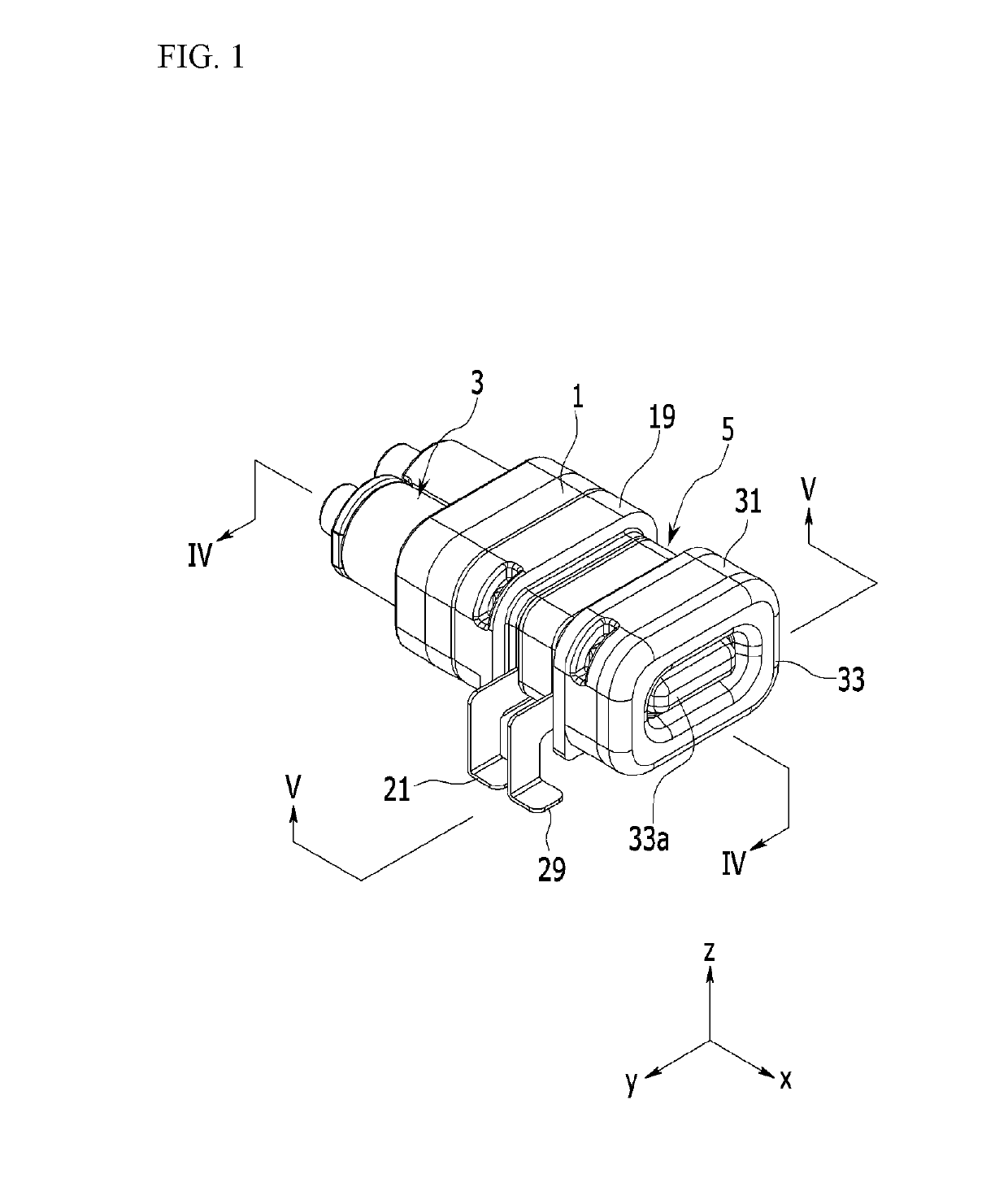

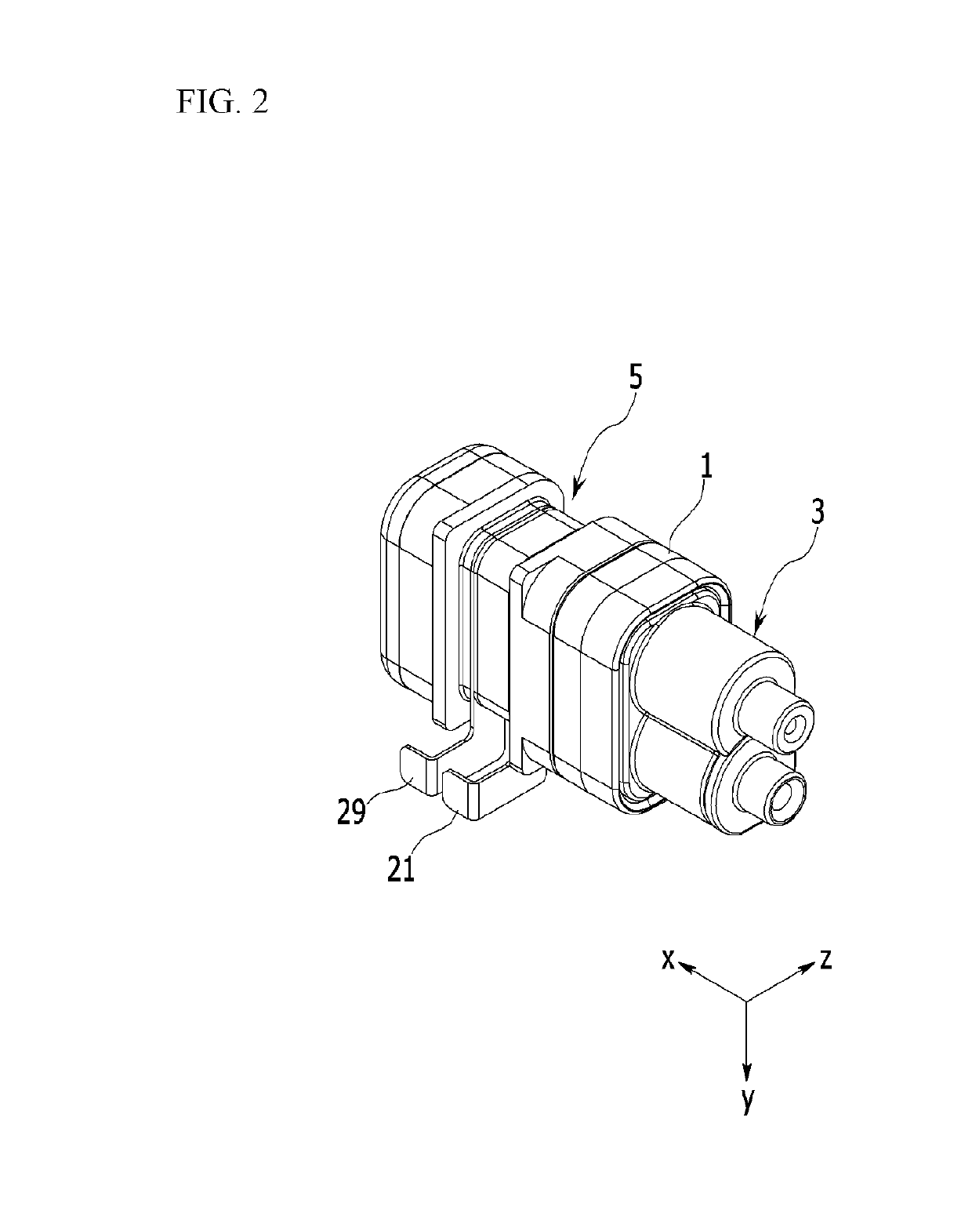

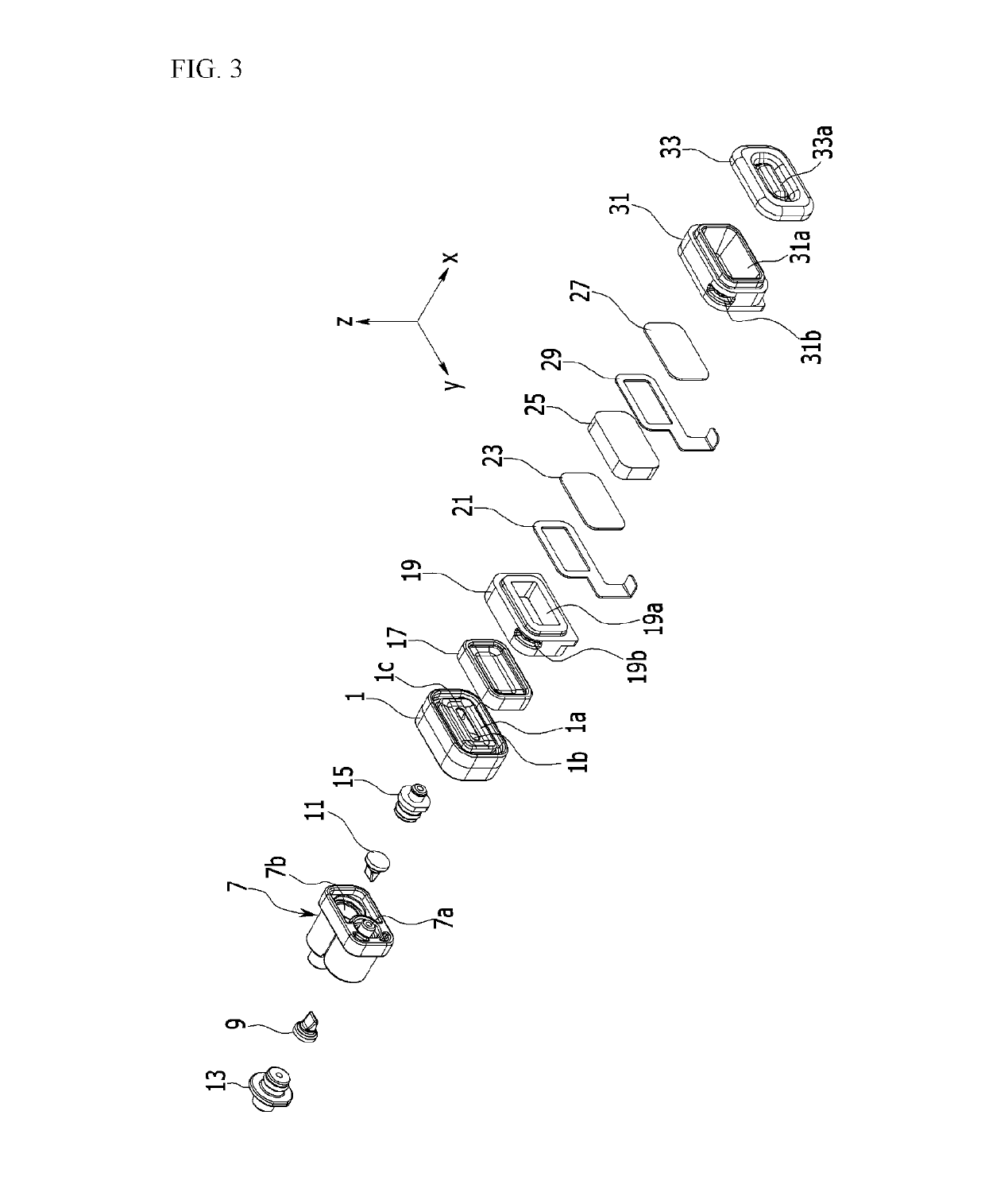

The present invention discloses a path-type liquid medicine delivery electro-osmosis pump that can be applied to a wearable medicine device.An electro osmosis pump according to the present invention includes: a connector provided with a liquid medicine inlet and a liquid medicine outlet; a check valve assembly combined to one side of the connector; and a driver that is connected to the other side of the connector and moves the liquid medicine toward the liquid medicine outlet by applying pressure to the liquid medicine while being separated from the liquid medicine, which passes through the check valve assembly.

Owner:EOFLOE

Lifting closure flexible flap valve

InactiveCN103836232ALow cracking pressureSealing specific pressure is smallCheck valvesEqualizing valvesEngineeringFlap valve

The invention relates to a lifting closure flexible flap valve, and belongs to the technical field of control devices on a medium pipeline. The lifting closure flexible flap valve comprises a basic frame fixed to the outer wall of a water outlet of a pipeline, wherein a flow pass is arranged inside the basic frame, a flange is arranged at the outer edge of the basic frame, a pressing block is fixed outside the flange, a groove is arranged between the flange and the pressing block, a flexible membrane strip is fixedly connected inside the groove, the lower end of the flexible membrane strip is fixedly connected with an opening-closing plate, the opening-closing plate is of an integrated rigid structure, the lower end of the opening-closing plate is a free end, and when the opening-closing plate is closed, the opening-closing plate makes contact with the outer end surface of the basic frame, and the outer side of the opening-closing plate is fixedly connected with a position adjusting block; an installation plate perpendicular to the basic frame is fixed to the flange, the installation plate is provided with an installation hole, a linear lifting driving device is arranged inside the installation hole, and a position adjusting wheel matched with the position adjusting block is fixed at the output end of the linear lifting driving device. The lifting closure flexible flap valve achieves low opening pressure, namely low water damage.

Owner:WUHAN SHENGYU DRAINING SYST

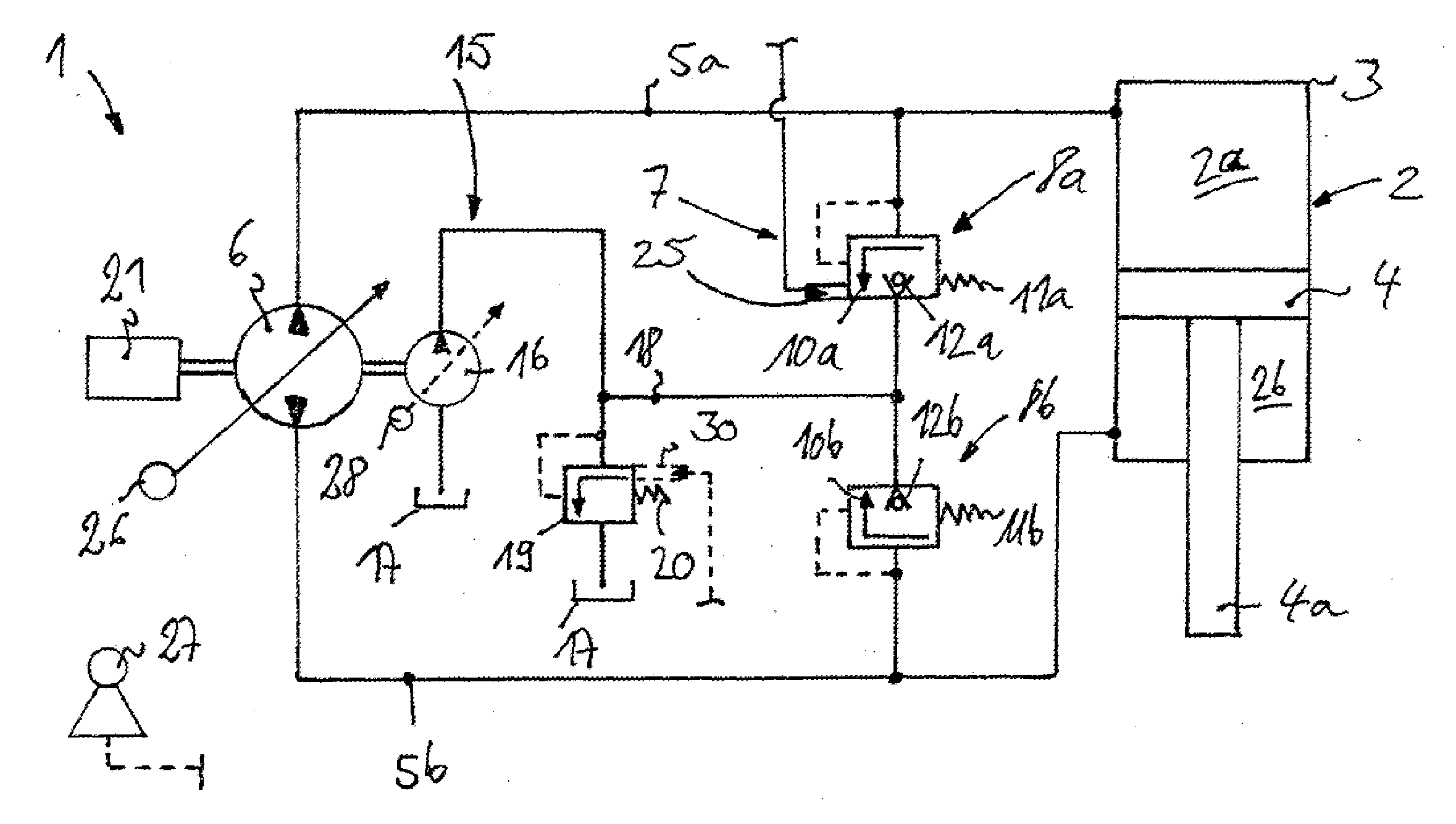

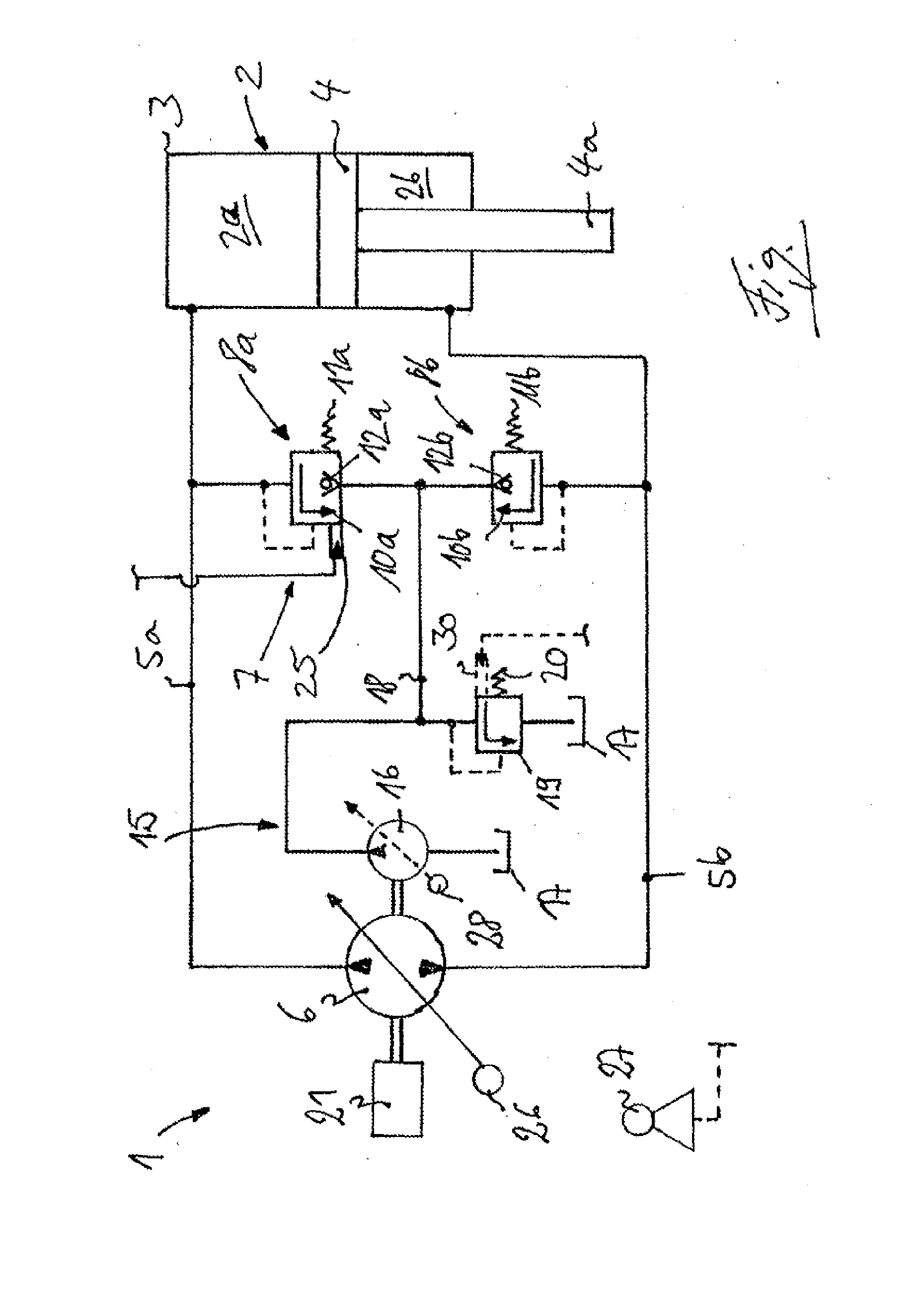

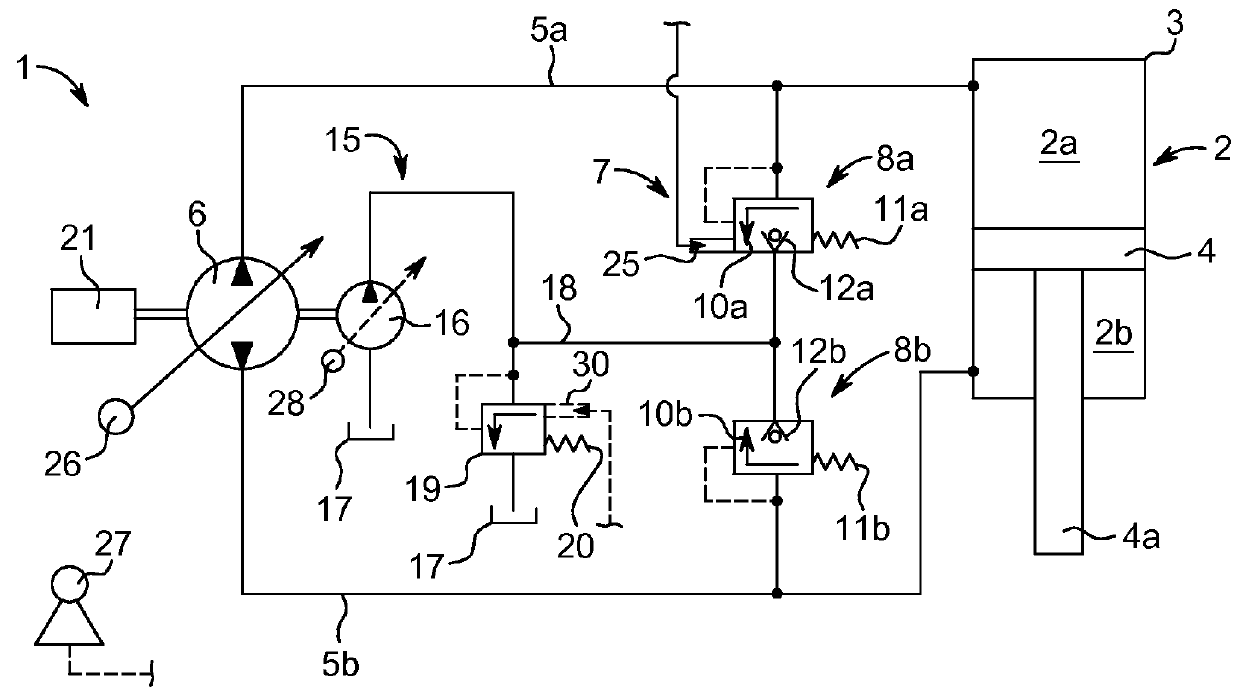

Hydrostatic Drive System

InactiveUS20130213030A1Little construction effort and expenseLow space requirementFluid couplingsTelemotorsRelief valveEngineering

A hydrostatic drive system includes a user in the form of a differential cylinder connected in a closed circuit to a high-pressure pump. A piston-side compression chamber and a piston-rod-side compression chamber of the differential cylinder are in communication with the high-pressure pump. The closed circuit includes a protection device having first and second protection valve devices that each includes a pressure relief valve and an anti-cavitation valve. The pressure relief valve of the first protection valve device is provided with an override device, by means of which the opening pressure of the pressure relief valve can be varied. When the high-pressure pump delivers into the piston-rod-side compression chamber, the pressure relief valve of the first protection valve device is adjusted by means of the override device to a reduced opening pressure and the differential volumetric flow flows out via the pressure relief valve to a low-pressure system.

Owner:LINDE HYDRAULICS

Backflow preventing device with low opening pressure, low flow resistance and reliable check

The invention discloses a backflow preventing device with low opening pressure, low flow resistance and reliable check. The backflow preventing device comprises a water inlet check valve, a water outlet check valve and a discharge valve, wherein the water inlet check valve and the water outlet check valve divide the backflow preventing device into a water inlet cavity, a middle cavity and a water outlet cavity; a first rubber diaphragm movably covers a first valve port between the water inlet cavity and the middle cavity through a water inlet spring, and isolates the water inlet cavity and the middle cavity; and in the state that an acting force F1 which is generated by multiplying an area S1 of the first rubber diaphragm in the outer ring water inlet cavity of the first valve port by water inlet pressure intensity P1 is larger than an acting force F3 of the water inlet spring on the first rubber diaphragm, the first rubber diaphragm is away from the first valve port, the water inlet cavity is communicated with the middle cavity, and the valve port of the water inlet check valve is open. The backflow preventing device has the characteristics of low opening pressure, low flow resistance and reliable check, the influence on water pressure of a terminal user is extremely small, water pressure of a specified outdoor fire hydrant outlet is met, and easily-damaged parts can be convenient to replace.

Owner:上海航天动力科技工程有限公司

Air management for enhancing pneumatic rebound training

ActiveUS20130065739A1Effectively lengthening the air springsLow cracking pressureVenting valvesAeration devicesAir managementAir spring

An air management system that allows safe and convenient forms of interval training exercise to be performed on pneumatically elevating rebound exercise equipment. The system includes at least one air intake valve and bleed valve. By providing repeatable degrees of difficulty for both air intake and air release from the extendable air springs employed for the exercise, competitive athletes and their coaches can design, employ, repeat, and compare individualized medium- or high-intensity interval protocols for optimal cardiovascular training programs.

Owner:PLYO SYST

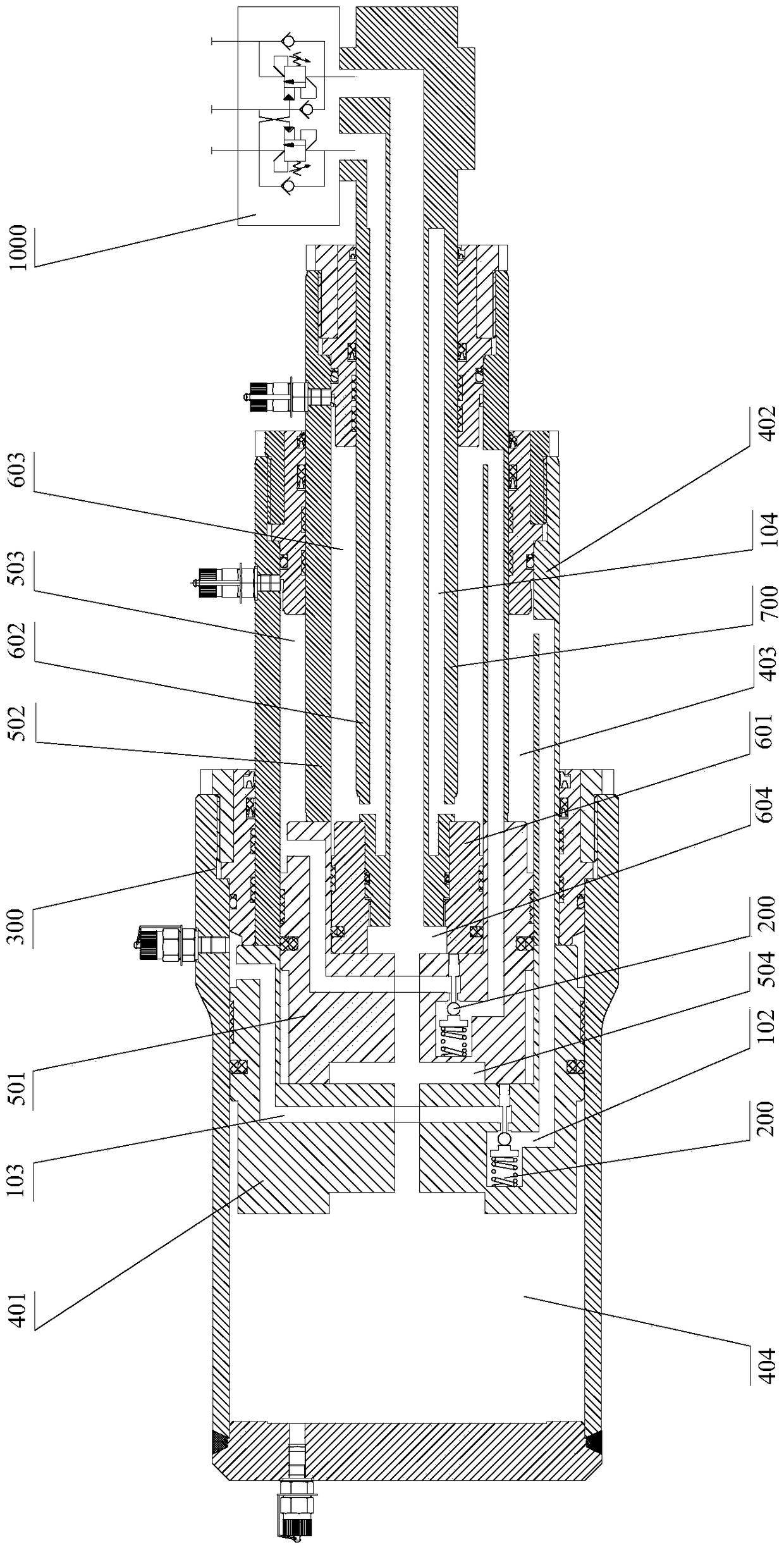

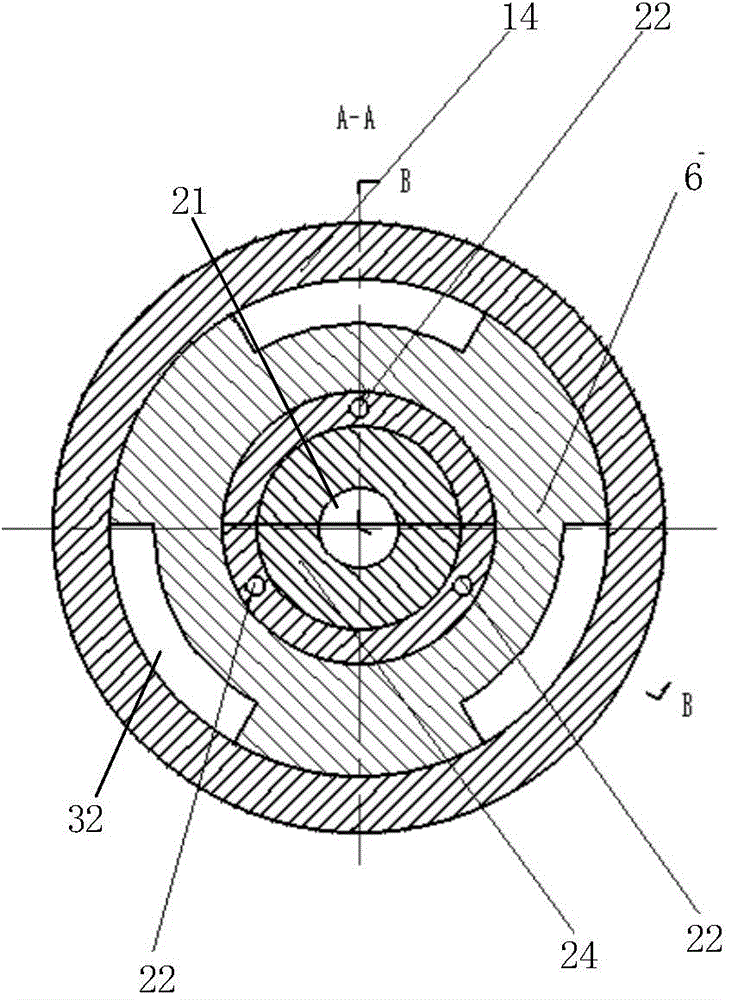

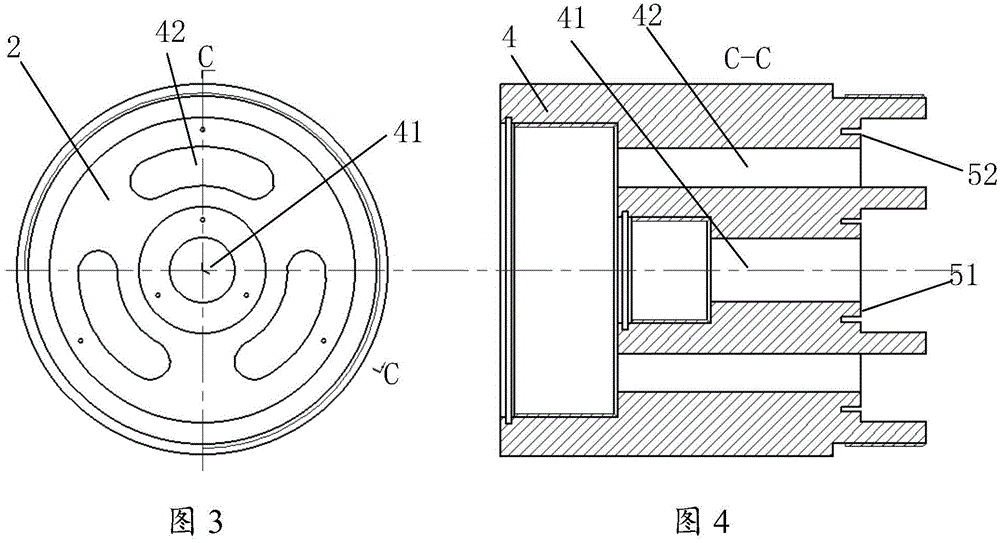

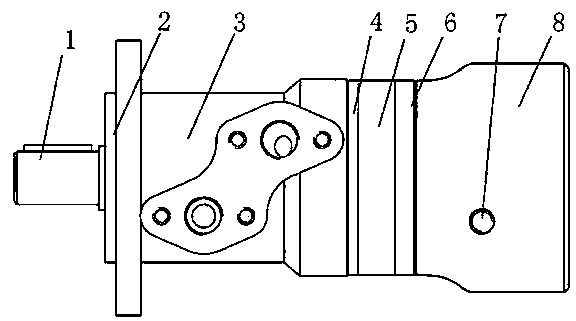

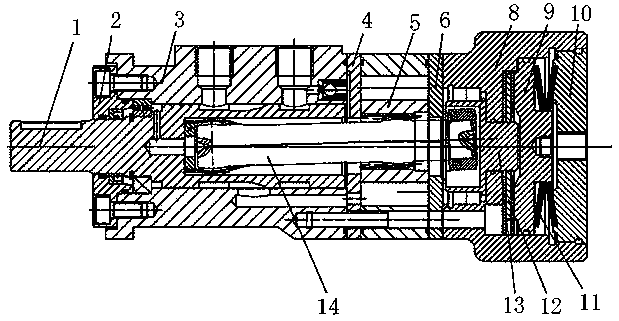

Integrated internally-installed forced wet-type self-locking cycloid hydraulic motor structure

InactiveCN103758691AReduce usage requirementsStrong pressing forceRotary piston enginesHydraulic motorLow noise

The invention relates to an integrated internally-installed forced wet-type self-locking cycloid hydraulic motor structure. The integrated internally-installed forced wet-type self-locking cycloid hydraulic motor structure is characterized in that a self-locking mechanism comprises a self-locking oil cylinder shell, the rear end of the self-locking oil cylinder shell is provided with a rear cover, a self-locking piston is arranged in the self-locking oil cylinder shell, one side of the self-locking piston and the self-locking oil cylinder shell form a sealing cavity, a self-locking friction plate pair is arranged in the sealing cavity and comprises a static friction plate and a movable friction plate, the static friction plate is connected to the self-locking oil cylinder shell, the movable friction plate is connected to a self-locking main shaft which is connected to a universal driving shaft, the other side of the self-locking piston and the rear cover form a cavity, a compressed spring is arranged in the cavity, a shuttle valve is arranged on the outer surface of the self-locking oil cylinder shell; an oil port I, an oil port II and an oil port III are formed in the shuttle valve; the oil port I and the oil port II are communicated with a stator-rotor pair through an oil channel, and the oil port III is communicated with the sealing cavity through the oil channel. The self-locking oil cylinder shell has the advantages of simple structure, small size, long service life, good reliability and low noise.

Owner:SHANDONG RNOMAC HYDRAULIC MACHINERY

Rotary interception flexible flap valve

InactiveCN103851232ALow cracking pressureSealing specific pressure is smallEngine sealsCheck valvesElectricityElectric drive

The invention relates to a rotary interception flexible flap valve, and belongs to the technical field of control devices on medium pipelines. The rotary interception flexible flap valve comprises a basic frame fixed to the outer wall of the water outlet of a pipeline; a flow channel is formed in the basic frame; the outer edge of basic frame is provided with a flange; a pressure block is fixed outside the flange; a groove is formed between the flange and the pressure block; a flexible diaphragm bar is fixedly connected into the groove; the lower end of the flexible diaphragm bar is fixedly connected with an opening and closing plate; the opening and closing plate has an integral rigid structure; the lower end of the opening and closing plate is a free end; when the opening and closing plate is closed, the opening and closing plate is contacted with the outer end face of the basic frame; the opening and closing plate is in contact connection with one end of a carrier rod; the other end of the carrier rod is electrically connected with an electric driving device. The rotary interception flexible flap valve has an interception (current-regulating) function. Flexible diaphragm cloth is adopted instead of the conventional rigid hinged structure, so that the opening pressure of the valve is very low (namely, low water loss).

Owner:WUHAN SHENGYU DRAINING SYST

Hydrostatic drive system

InactiveUS9334884B2Little effortAvoid huge expensesFluid couplingsTelemotorsPressure systemCavitation

Owner:LINDE HYDRAULICS

Air management for enhancing pneumatic rebound training

ActiveUS8262548B1Improve anaerobic conditionsEffectively lengthening the air springsAeration devicesStiltsAir managementExhaust valve

An air management system that allows safe and convenient forms of interval training exercise to be performed on pneumatically elevating rebound exercise equipment. The system includes at least one air intake valve and bleed valve. By providing repeatable degrees of difficulty for both air intake and air release from the extendable air springs employed for the exercise, competitive athletes and their coaches can design, employ, repeat, and compare individualized medium- or high-intensity interval protocols for optimal cardiovascular training programs.

Owner:PLYO SYST

Low-differential-pressure synchronous dual-fixed-valve deep-well pump

ActiveCN102022310AGood effectReduce chance of puncturePositive displacement pump componentsFlexible member pumpsDifferential pressureEconomic benefits

The invention discloses a low-differential-pressure synchronous dual-fixed-valve deep-well pump applied to the petroleum industry, which is used for extracting crude oil from a mechanical oil production well. The low-differential-pressure synchronous dual-fixed-valve deep-well pump comprises a pump barrel, an upper fixed valve and a lower fixed valve, wherein the upper fixed valve and the lower fixed valve are both installed below the pump barrel and are connected through a link rod. Because the link rod is designed between the upper fixed valve and the lower fixed valve, the synchronous opening and closing of the double fixed valves are ensured, the lower fixed valve ensures that the flow velocity of well fluid is greatly reduced, and the service life of the oil well pump is prolonged. The invention effectively solves the problems of lagged opening and closing of the fixed valves, low depth ratio of the pump, high differential pressure inside and outside the pump barrel, increased clearance between a plunger piston and the pump barrel, increased pump leakage and the like in the traditional deep-well pump. The invention increases pump efficiency, prolongs pump inspection period, obviously reduces production cost and has obvious economic benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

butterfly valve

Owner:NINGBO TIANJILONG INTELLIGENT CONTROL TECH

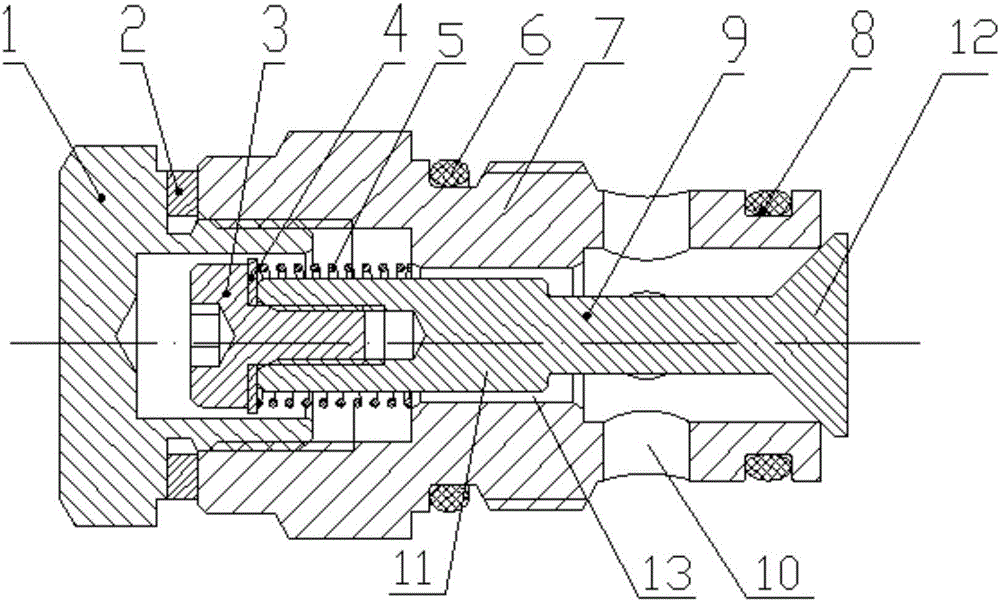

Thread plug-in mounting type oil filling valve

InactiveCN106640819ALow cracking pressureReduce volumeServomotor componentsWear resistanceMechanical engineering

The invention relates to a thread plug-in mounting type oil filling valve. The objective of the invention is to solve the technical problems of poor reliability, no wear resistance and high opening pressure of the existing oil filling valve. The thread plug-in mounting type oil filling valve provided by the invention comprises a blanking cap, a sealing pad, a screw, a spring, a valve sleeve and a valve core of the oil filling valve, the valve sleeve is cylindrical, a spring return cavity is arranged at the middle of one end of the valve sleeve, an oil filling cavity is arranged at the other end of the valve sleeve, a guide hole is formed in the middle of the valve sleeve, the guide hole is communicated with the spring return cavity and the oil filling cavity, an oil through hole is formed in the valve sleeve and is communicated with the oil filling cavity, the valve core of the oil filling valve is composed of a cylindrical guide bar and a conical oil sealing block, the valve core of the oil filling valve is arranged in the valve sleeve, an annular oil through gap is formed between the cylindrical guide bar and the guide hole, the spring is installed at one end of the cylindrical guide bar and is fixed by the screw, the conical oil sealing block of the valve core of the oil filling valve is arranged at an oil outlet of the oil filling cavity of the valve sleeve and is in tight fit with the same, the blanking cap is connected with the spring return cavity, and the sealing pad is arranged between the blanking cap and the valve sleeve.

Owner:TAIZHONG GRP YUCI HYDRAULIC IND

Air tolerant implantable piston pump

ActiveUS9968733B2Reduce energy consumptionLow cracking pressurePositive displacement pump componentsFiltering accessoriesInlet channelEngineering

An implantable infusion device includes a reservoir for housing an infusion medium and a drive mechanism having an inlet chamber, a piston and a piston channel. The inlet chamber is in fluid communication with the reservoir. The piston channel is in fluid communication with the inlet chamber, and has a distal end and a proximal end, the proximal end being closer to the inlet channel than the distal end. The piston is axially moveable within the piston channel to drive infusion medium out of the distal end of the piston channel. The clearance between the piston and the channel is sufficiently small to prevent undissolved gas in the inlet chamber from passing through the clearance. The inlet chamber may be sufficiently large to allow undissolved gas to accumulate without adversely affecting the performance of the infusion device.

Owner:MEDTRONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com