Axial flow fan and air valve thereof as well as cooling tower and air cooler

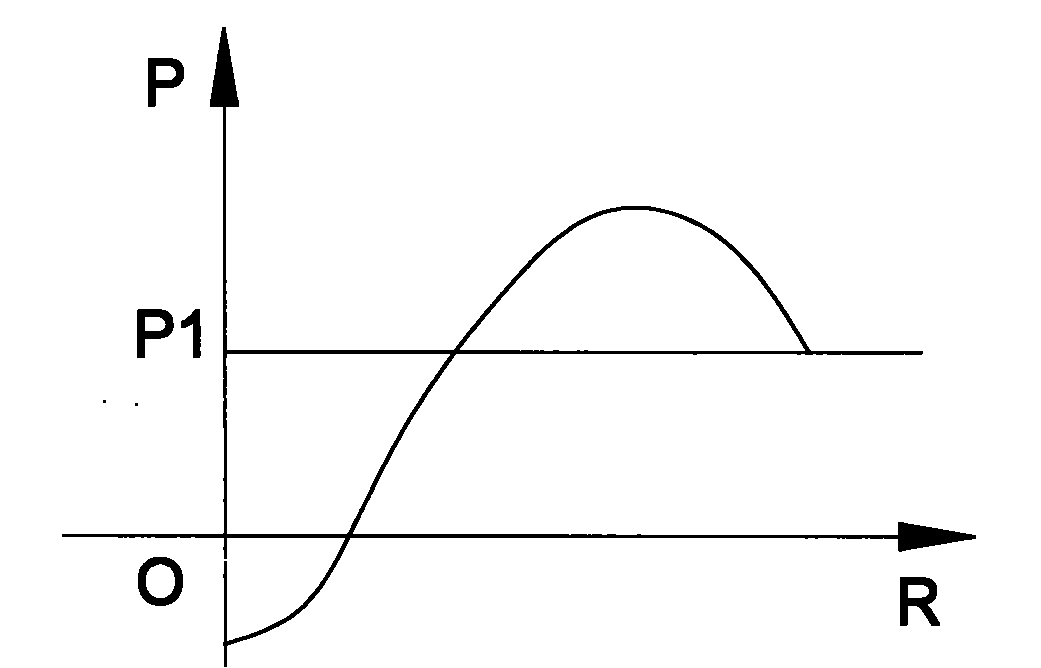

A fan and air valve technology, applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of increasing the exhaust resistance of the air outlet, increasing the opening pressure of the air valve, and increasing the exhaust resistance of the air outlet, etc., to achieve increased Increase the total air flow and efficiency, improve the effect of straight jet flow, and reduce the effect of resistance between eddies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

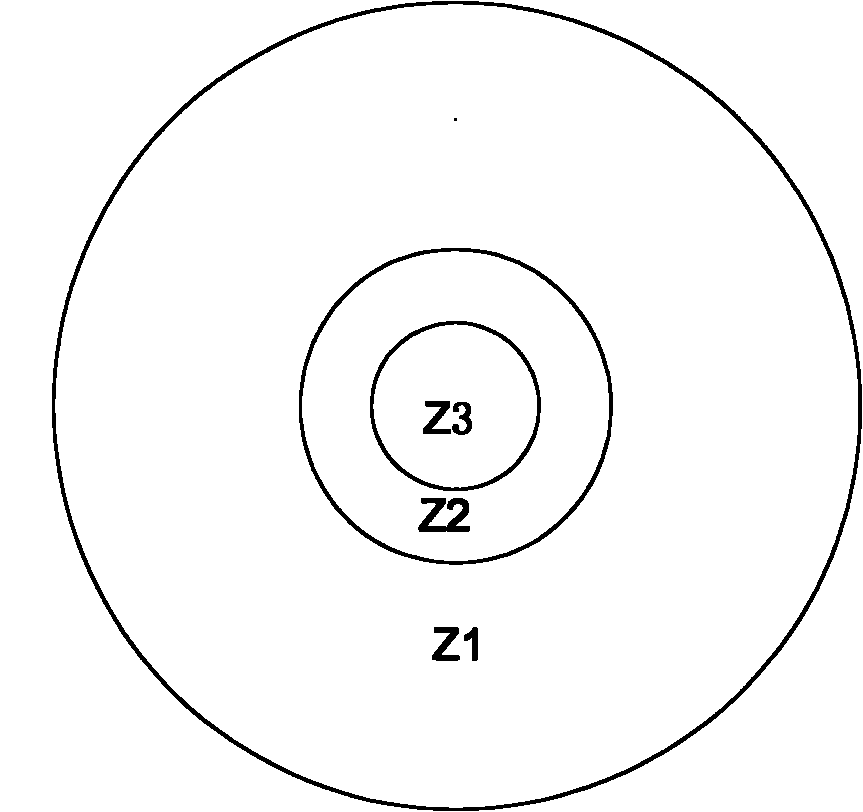

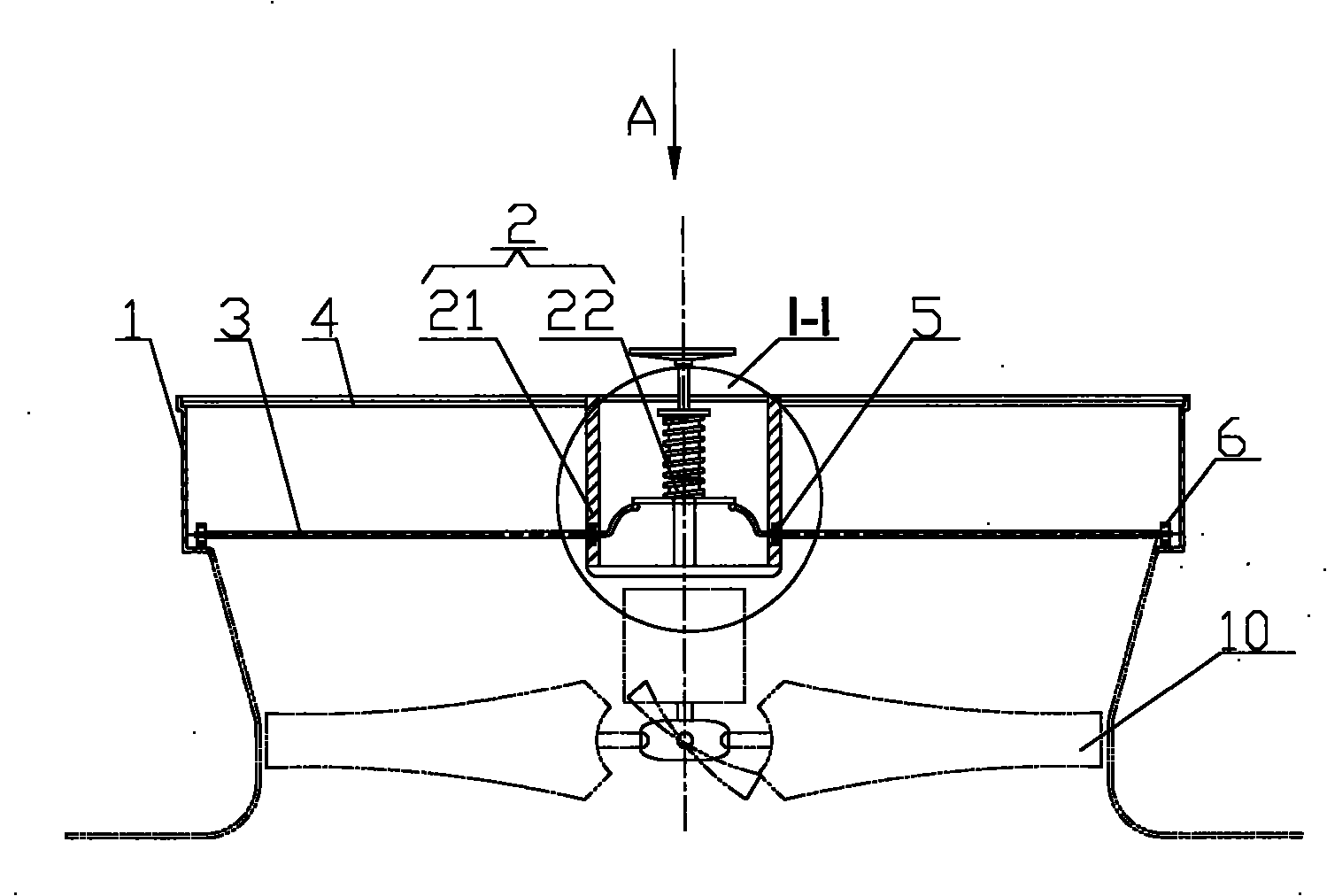

[0057] The air valve for an axial flow fan provided in Embodiment 1 includes an outer cylinder 1, a center seat 2 and a plurality of blades 3; the number of blades 3 can be determined according to actual needs. Generally speaking, the number of blades 3 is related to the installation conditions. In the case of the same diameter, the fewer blades 3, the greater the installation space requirement, and the more blades 3, the smaller the installation space requirement. The center seat 2 is located in the outer cylinder 1 and relatively fixed with the outer cylinder 1 through the support beam 4 to form the valve body of the damper. In this example, the outer cylinder 1 is a cylindrical cylinder, and its lower end is fixed to the fan body of the axial flow fan 10; Located in the central area of the cylindrical central cylinder 21 , the space inside the outer cylinder 1 corresponds to the air outlet of the fan; preferably, the centerlines of the outer cylinder 1 , the central cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com