butterfly valve

A butterfly valve and valve body technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of large size and specification of butterfly valves, corrosive medium, and laborious opening of butterfly valves, so as to improve dustproof performance and corrosion resistance Ability to improve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

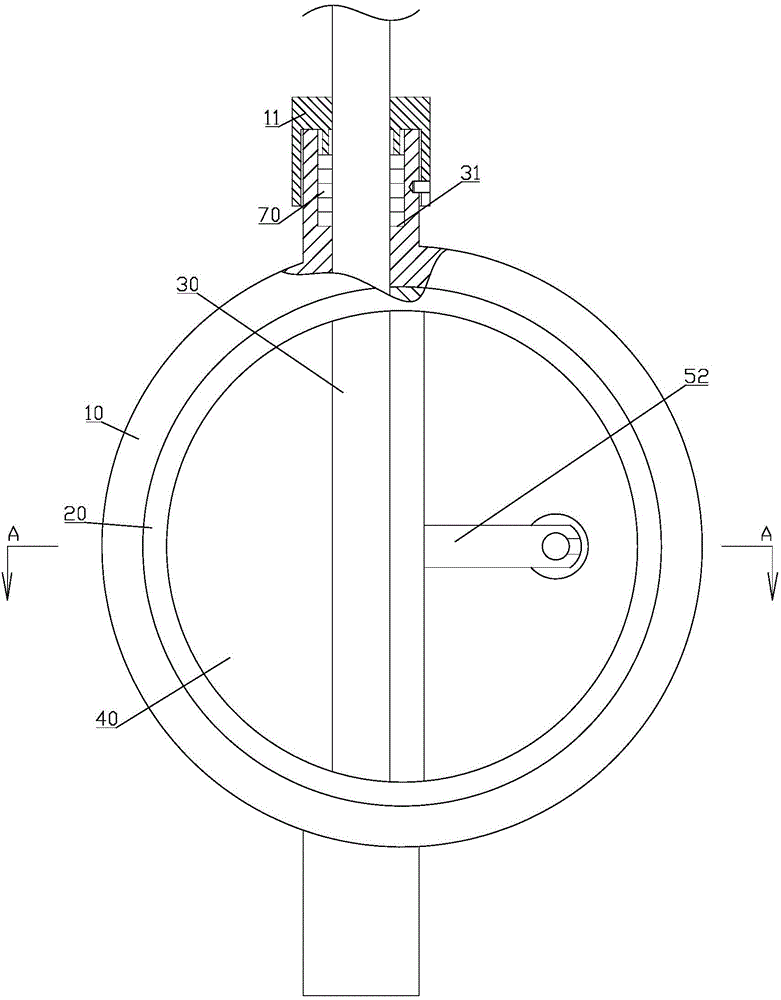

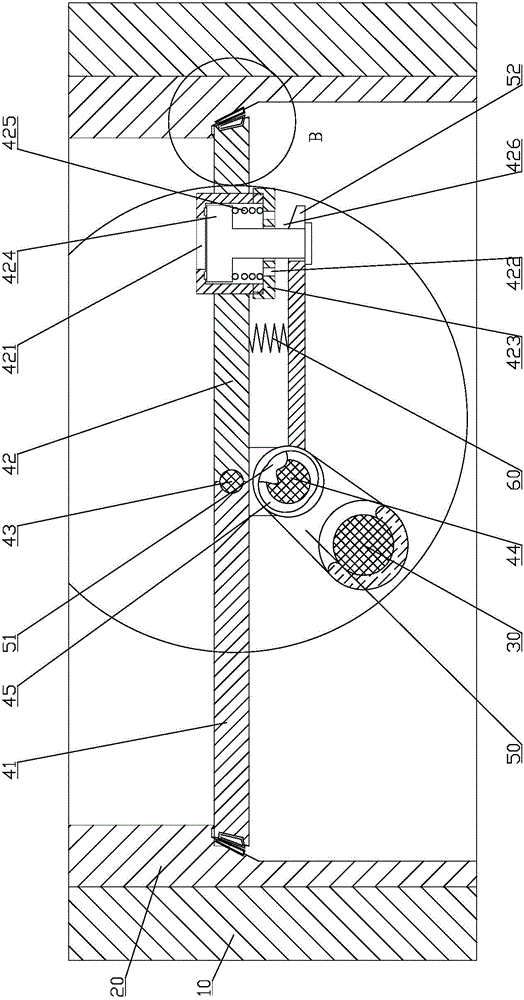

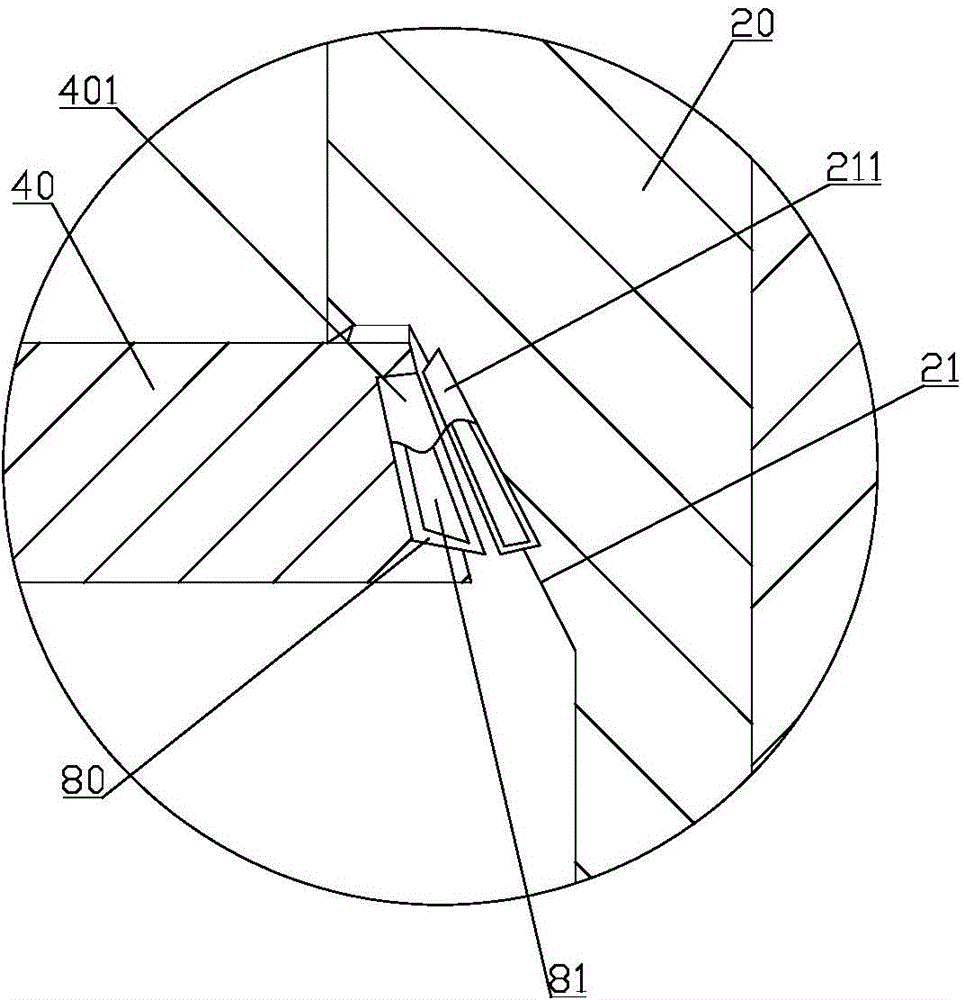

[0018] Examples, see Figure 1 to Figure 3 Shown: a butterfly valve, including a valve body 10, a valve seat 20, a valve stem 30, and a valve disc 40. specific:

[0019] The valve flap 40 includes a left flap body 41 and a right flap body 42 which are both semicircular, and the straight sides of the left flap body 41 and the right flap body 42 are hinged together by a hinge shaft 43 . That is, the left petal body 41 and the right petal body 42 are hinged together to form a complete circular valve flap 40 . The right petal body 42 is provided with a pressure relief hole 421 , and the pressure relief hole 421 is screwed with a cover 423 with a water permeable hole 422 on the side. The pressure relief hole 421 is provided with a sealing plug 424 , the upper part of the sealing plug 424 is provided with an annular groove 426 after passing through the cover 423 , and a compression spring 425 is provided between the middle part of the sealing plug 424 and the cover 423 . Apparent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com