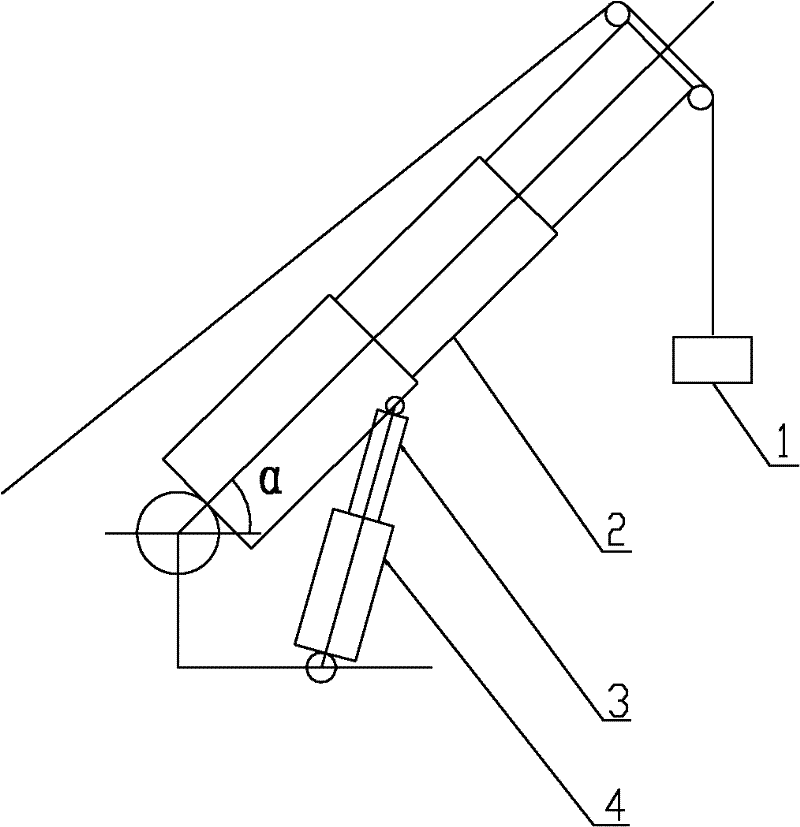

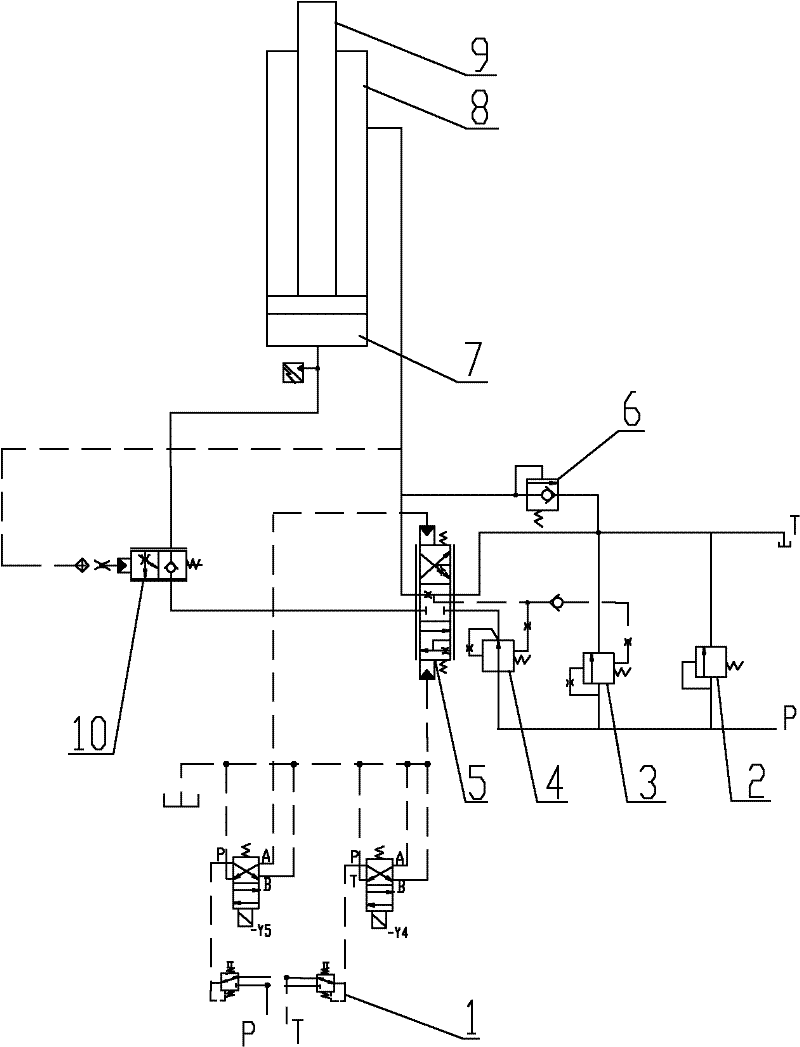

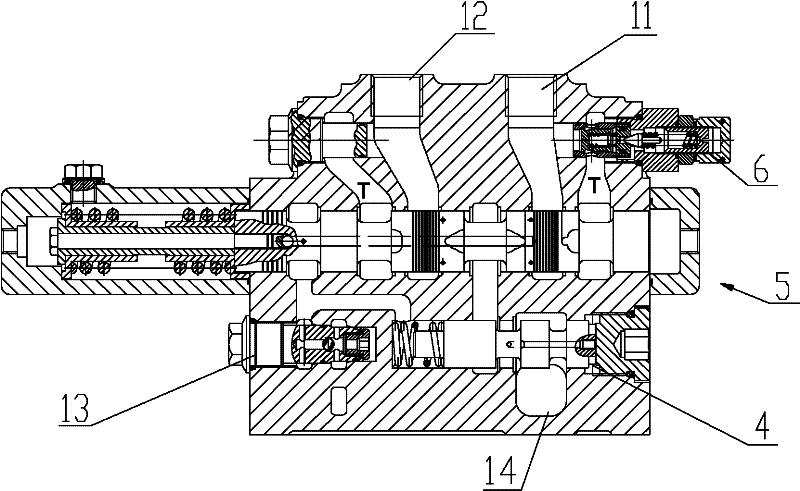

Crane luffing control valve and crane luffing hydraulic system

A technology for controlling valves and cranes, applied in cranes, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of changing control methods and high production costs, and achieve elimination of jitter, improvement of control accuracy, and improvement of stability and fretting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The core of the invention is to provide a crane luffing control valve. The control valve can significantly improve the micro-movement of the crane when it is luffing, and eliminate the shaking phenomenon when the handle is slightly opened.

[0047] Another core of the present invention is to provide a crane luffing hydraulic system provided with the crane luffing control valve.

[0048] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0049] In this article, terms such as "up, down, left, right" indicating orientation are based on the positional relationship of the drawings, and should not be interpreted as an absolute limitation on the scope of protection. Similarly, terms such as "first, second" It is only for the convenience of description to distinguish different components w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com