Backflow preventing device with low opening pressure, low flow resistance and reliable check

A backflow preventer and opening pressure technology, applied in the direction of control valve, functional valve type, engine components, etc., can solve the problems of large flow resistance and large water pressure loss, and meet the requirements of outlet water pressure, low opening pressure, and easy replacement. Damaged parts convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

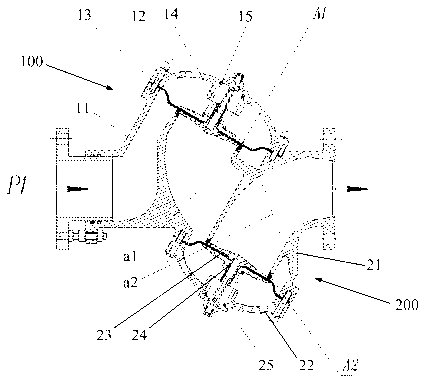

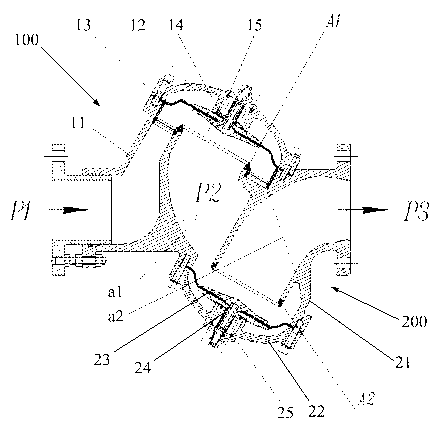

[0022] see figure 1 , figure 2 , the low opening pressure, low flow resistance, and reliable backflow preventer of the present invention at least include a water inlet check valve, a water outlet check valve and a drain valve, but the structures of the water inlet check valve and the water outlet check valve are changed , working method and installation position, and the disc is not on the flow path.

[0023] The water inlet check valve 100 includes a first valve body 11, a first valve cover 12, a first rubber diaphragm 13, a first guide limit rod 14 and a water inlet spring 15; the first valve body 11 is connected to the first valve body by bolts The cover 12 is connected, and the first rubber diaphragm 13 is pressed between the first valve body 11 and the first valve cover 12. The first rubber diaphragm 13 is connected to the first valve cover 12 through the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com