Rotary interception flexible flap valve

A flexible and flexible film technology, which is applied in the direction of lifting valve, engine sealing, control valve, etc., can solve the problem of no flapping door, and achieve the effect of easy sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

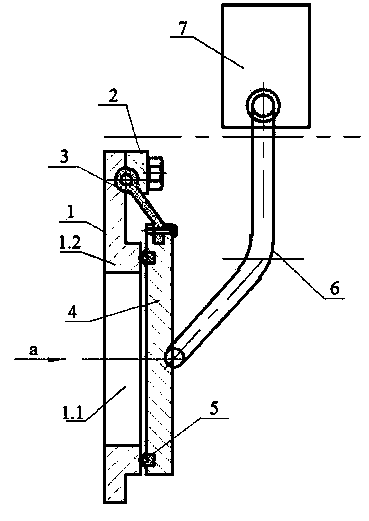

[0012] Such as figure 1 As shown, the present invention includes a basic frame 1 fixed on the outer wall of the pipe outlet, the basic frame 1 is provided with a flow channel 1.1, the outer edge of the basic frame 1 is provided with a flange 1.2, and the flange 1.2 is externally fixed There is a pressure block 2, a groove is provided between the flange 1.2 and the pressure block 2, and a flexible diaphragm strip 3 is fixedly connected in the groove, and the flexible diaphragm strip 3 is an elastic diaphragm in the manufacture of diaphragm valves Elastic material, the lower end of the flexible diaphragm strip 3 is fixedly connected with the opening and closing plate 4, the opening and closing plate 4 is an integral rigid structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com