Integrated internally-installed forced wet-type self-locking cycloid hydraulic motor structure

A cycloidal hydraulic motor, self-locking technology, applied in the field of machinery, can solve the problems of failure of the locking function, inability to respond quickly, and short service life of the hydraulic motor, and achieve the purpose of reducing the use requirements, increasing the use range, and reducing the opening pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

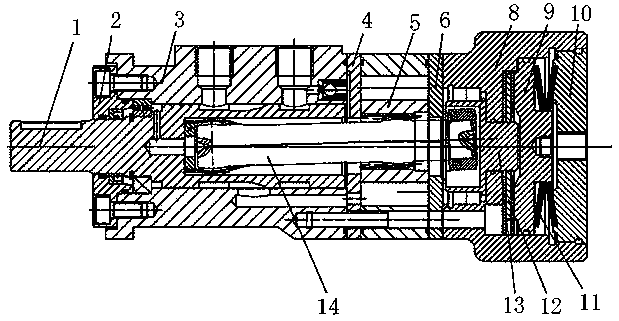

[0025] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

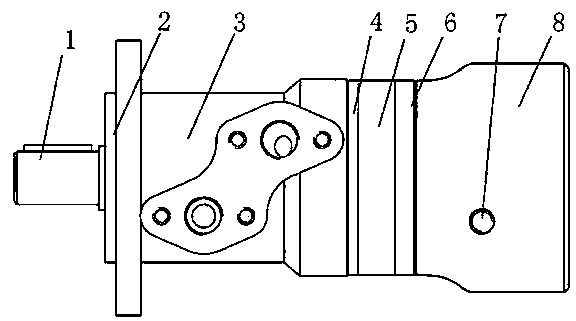

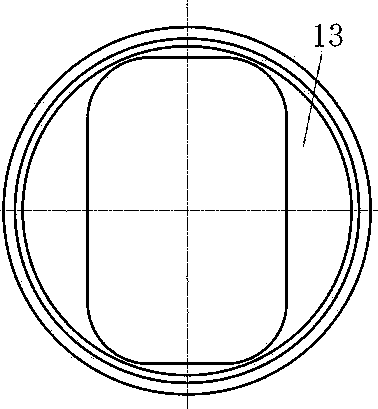

[0026] see Figure 1 to Figure 5 , the hydraulic motor in the embodiment of the present invention takes a cycloidal hydraulic motor as an example, including a power mechanism and a self-locking mechanism, wherein the power mechanism includes an output shaft 1, a linkage shaft 14, and a stator and rotor pair 5. When hydraulic oil enters, The stator-rotor pair 5 starts to rotate and drives the linkage shaft 14 to rotate, and the linkage shaft 14 drives the output shaft 1 to rotate to make the output shaft 1 output torque outward. A housing 3 is arranged outside the output shaft 1, and the front end of the housing 3 is passed through the bolt A front cover 2 is connected, a front partition 4 is provided between the casing 3 and the stator and rotor pair 5, and a rear partition 6 is provided between the stator and rotor pair 5 and the self-locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com