Piston rod oil inlet double-action multi-stage hydraulic cylinder

A piston rod and double-acting technology, applied in the field of hydraulic cylinders, can solve problems such as easy wear of sealing rings, internal leakage of hydraulic cylinders, and failure of double-acting multi-stage hydraulic cylinders to achieve the effect of reducing the interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

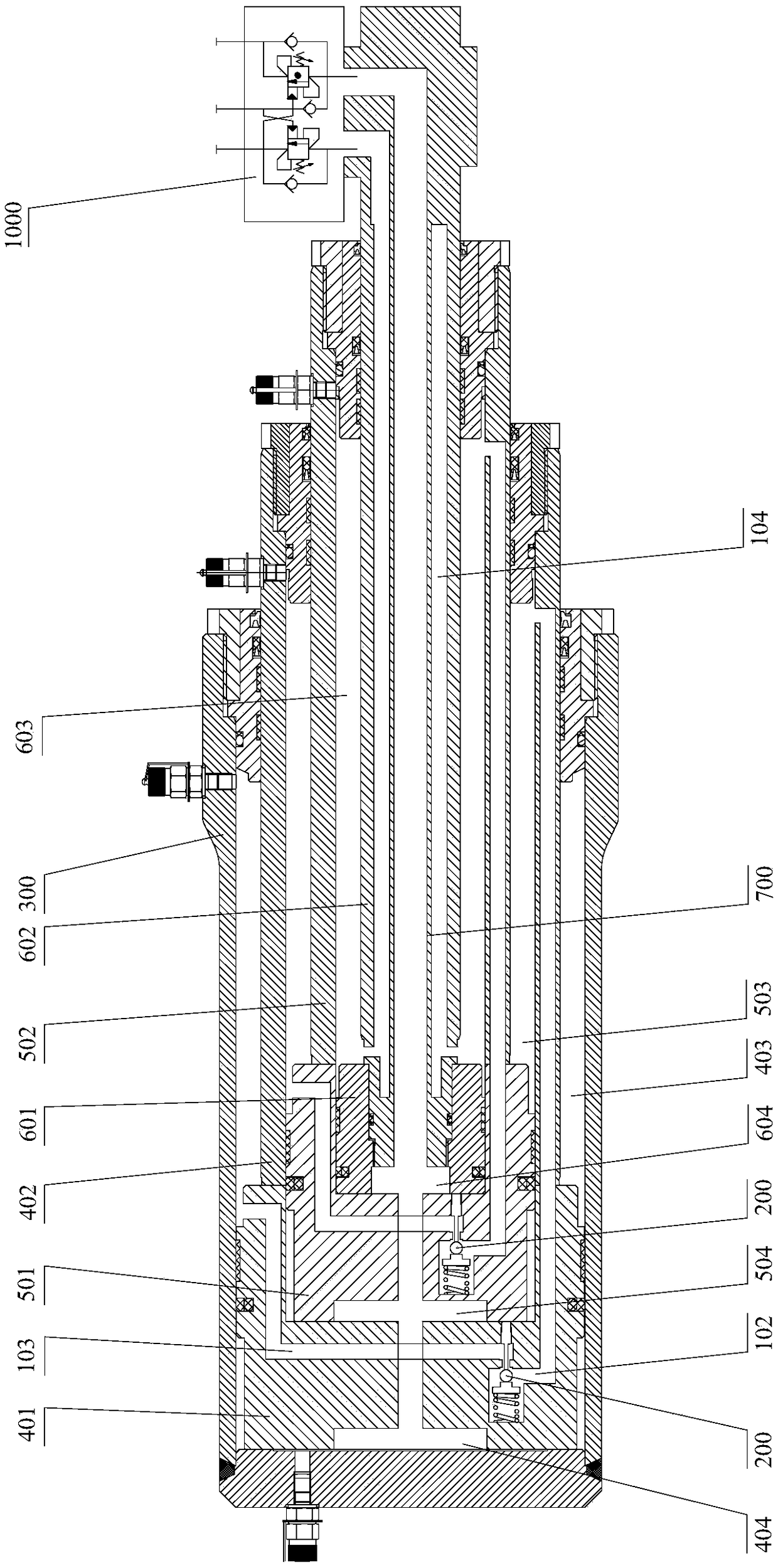

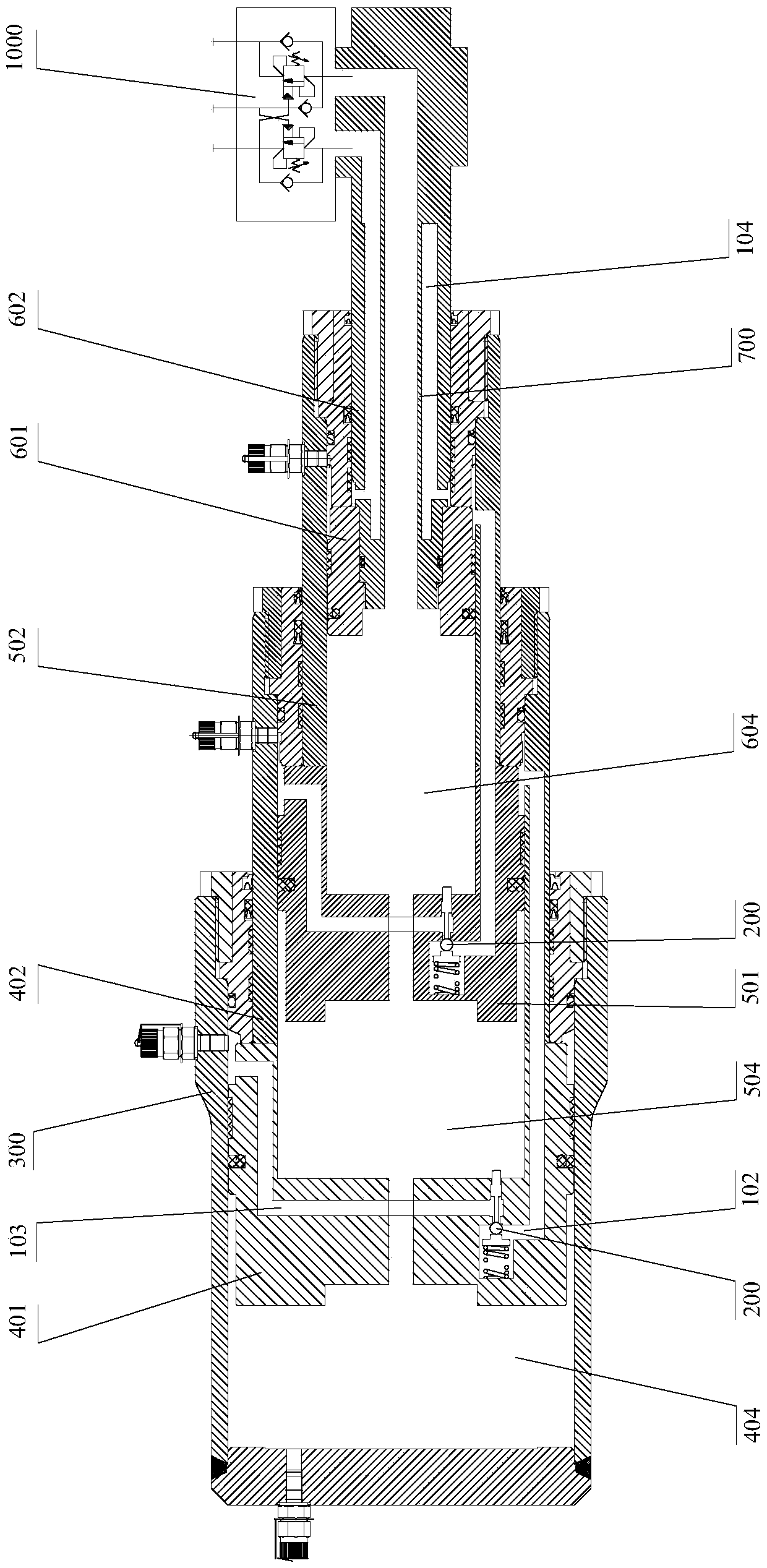

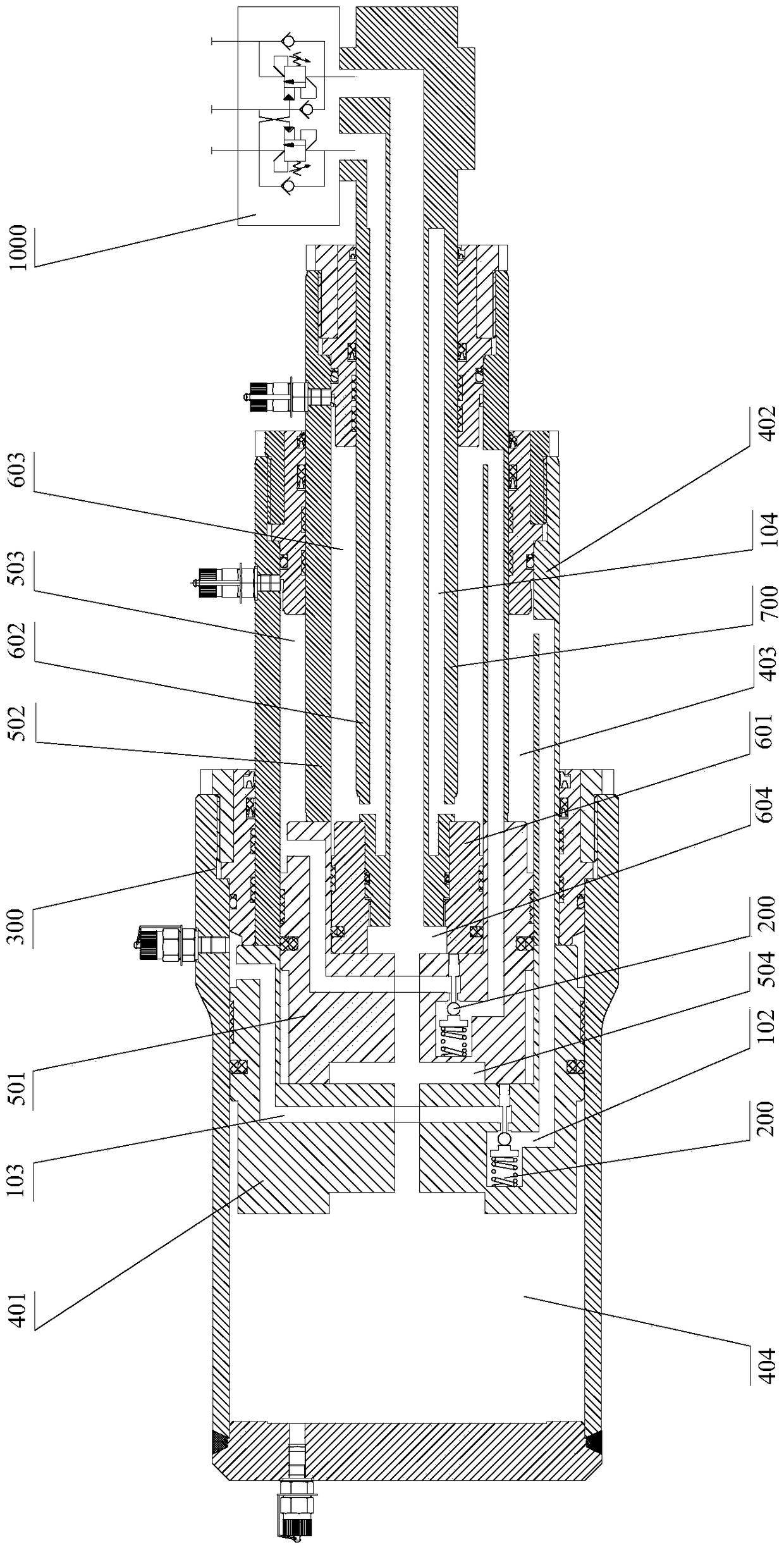

[0064] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0065] see figure 1 As shown, the embodiment of the present invention provides a piston rod oil-inlet double-acting multi-stage hydraulic cylinder, which includes a cylinder body 300, at least two stages of piston rod assemblies nested step by step, a plurality of one-way valve assemblies and a balance valve group.

[0066] Wherein, at least two stages of piston rod assemblies are set in the cylinder body 300 step by step, each stage of piston rod assembly includes a piston and a piston rod fixed on the piston, and each stage of piston rod assembly divides its containing space into Corresponding levels of rod chambers and rodless chambers.

[0067] a plurality of one-way valve assemblies, each one-way valve assembly disposed in the piston of a higher-stage piston rod assembly of adjacent two-stage piston rod assemblies, each one-way valve ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com