Cylinder body oil inlet double-action multi-stage hydraulic cylinder

A double-acting, hydraulic cylinder technology, applied in the field of multi-stage hydraulic cylinders, can solve problems such as easy wear of sealing rings, failure of double-acting multi-stage hydraulic cylinders, internal leakage of hydraulic cylinders, etc., and achieve the effect of reducing interaction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

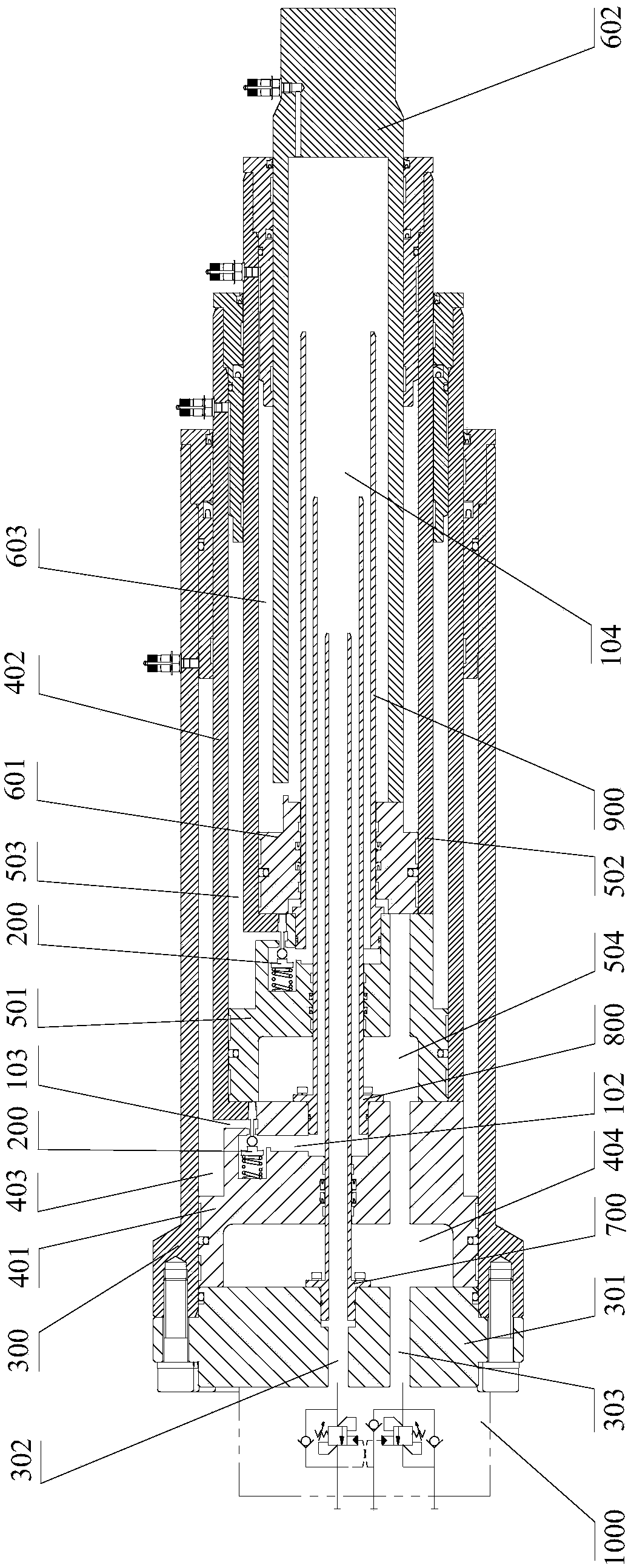

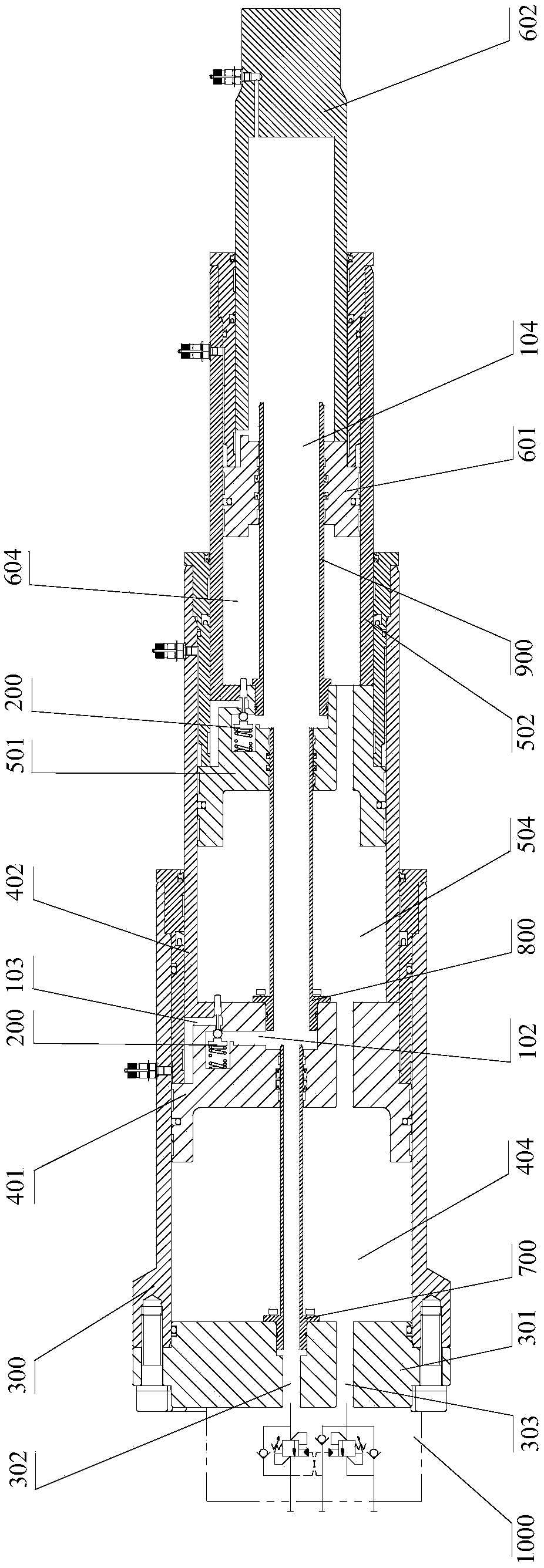

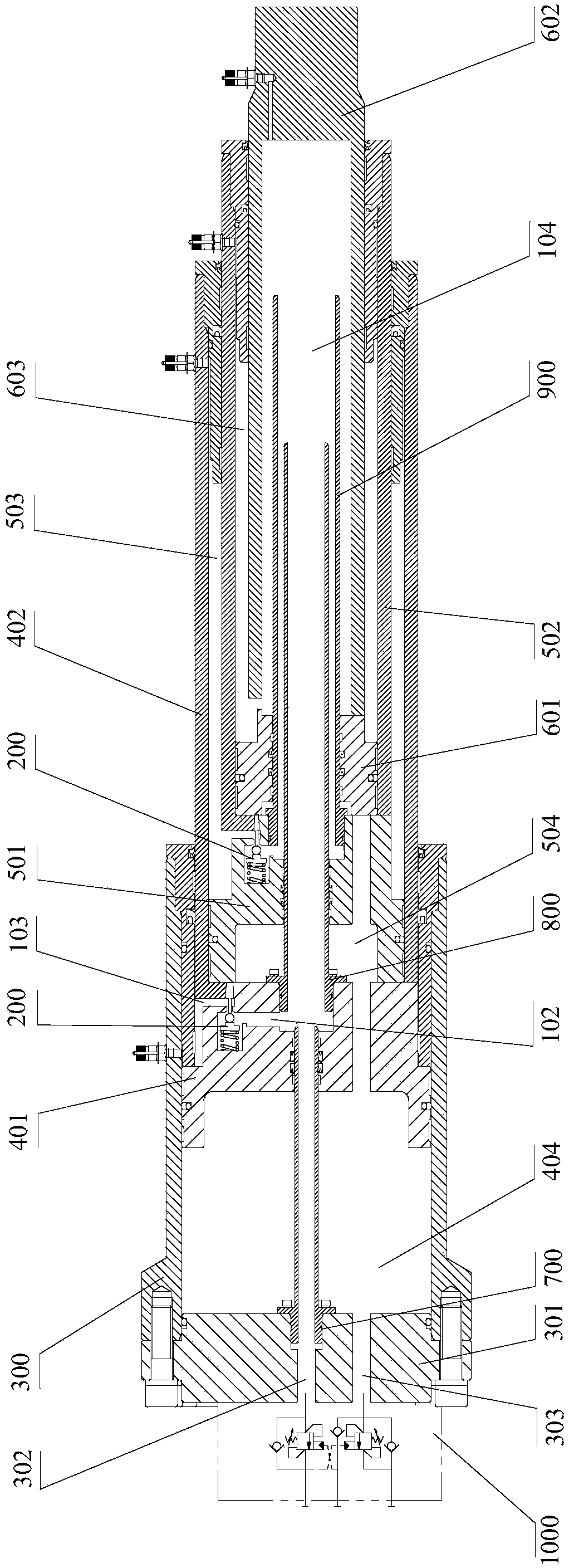

[0069] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0070] see figure 1 As shown, the embodiment of the present invention provides a cylinder block oil-inlet double-acting multi-stage hydraulic cylinder, which includes a cylinder block 300, at least two stages of piston rod assemblies, a plurality of one-way valve assemblies and a balance valve group.

[0071] Wherein, the cylinder block 300 has a cylinder head 301 fixed on its end, and the cylinder head 301 includes a first cylinder head hole 302 and a second cylinder head hole 303 arranged along the axial direction of the cylinder body 300, and the first cylinder head hole 302 and the second cylinder head hole 303 are arranged at intervals along the radial direction of the cylinder block 300 .

[0072] There are at least two stages of piston rod assemblies that are sheathed step by step, which are arranged in the cylinder body 300. Each stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com