Double-layer coiled tubing expansion connector

A connector and tubing technology, which is applied to drill pipes, casings, drilling equipment, etc., can solve the problems of affecting normal operation and different elongation of two-layer coiled tubing, and achieve compact structure, simple operation and reliable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

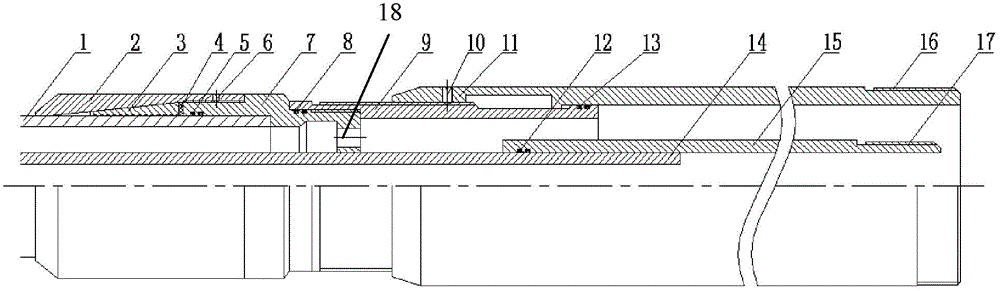

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

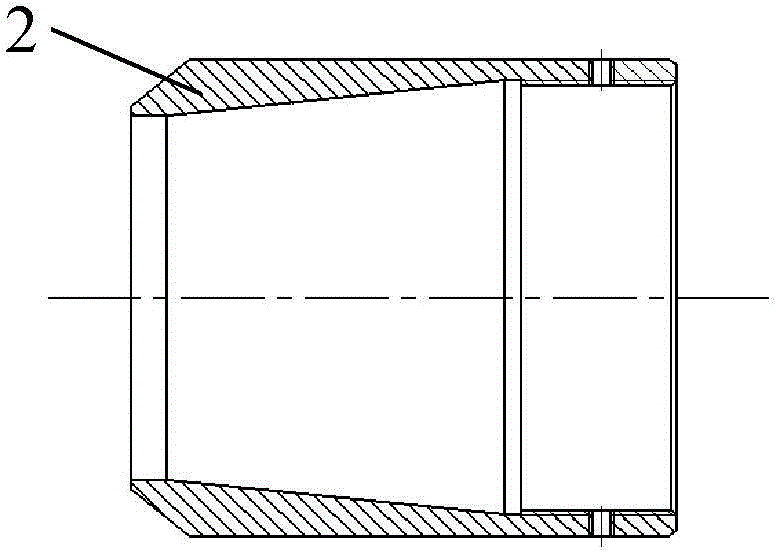

[0023] see Figure 1-Figure 7 , shown in the double-layer coiled tubing telescopic connector slip compression sleeve 2, open slip 3, compression top sleeve and inner tube centering core sleeve 7, outer cylinder adjustment joint 9, outer cylinder adjustment sleeve 11 and telescopic cylinder Inner tube adjustment sleeve 15,

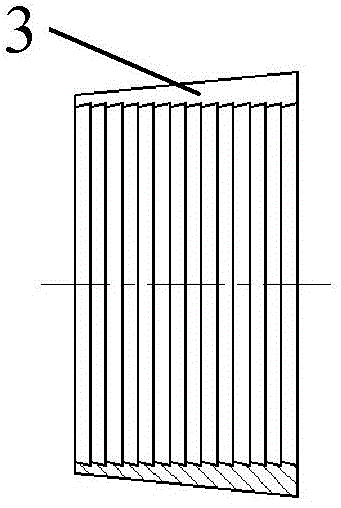

[0024] The slip compression sleeve 2, the open slip 3 and the copper ring 4 are sequentially set on the outer tube 1 of the double-layer coiled tubing, and a tapered space for accommodating the open slip 3 is formed in the slip compression sleeve 2 , the open slip 3 and the copper ring 4 are located in the slip compression sleeve 2 . The inner side of the slip compression sleeve 2 forms an inclined surface, the open slip 3 is a cylindrical structure, the inner wall of the slip is formed with serrated slip teeth, and the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com