Caisson cofferdam based on prepacked foundation bed

A construction method and foundation bed technology, which are applied in caisson, infrastructure engineering, construction and other directions, can solve the problems of wasting materials, time-consuming and laborious, and high cost, and achieve the effects of convenient construction, small demolition workload, and low engineering cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

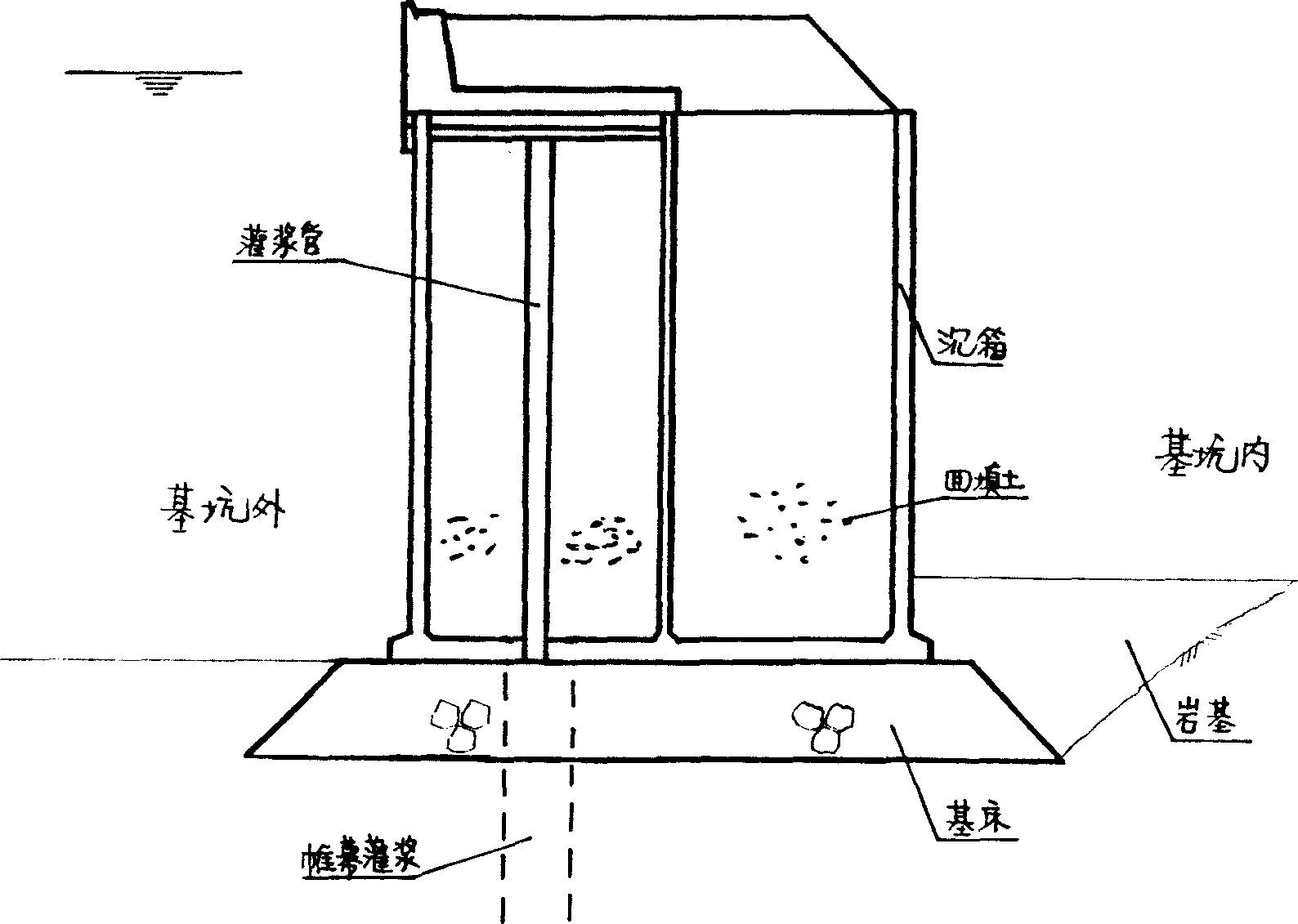

[0020] Taking the dock foundation pit as 450m×120m, the depth is 14m, the water retaining height is 13m, the outside is the sea area, and the geological conditions of the site are rock foundation, the specific construction steps are as follows:

[0021] 1. Foundation trench excavation and dredging

[0022] The foundation trench at the wharf is excavated to the rock face, the thickness of the riprap foundation bed is 2m, the bottom width is controlled at about 15m, and the silt is removed.

[0023] 2. Foundation bed riprap and leveling

[0024] Fill the foundation groove with rocks with a diameter of 80-200mm, and control the porosity at 40%. Set up the gravel dam body packed with slurry bags on both sides of the foundation bed, and cover it with geotextiles, and level the stone surface to a very fine level. And remove the floating mud on the surface.

[0025] 3. Caisson prefabrication and sinking

[0026] The width of the caisson is 13m, the height is 12m, and the length is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com