Mixed dam type structure with homogeneous earth and rockfill dam and concrete faced rockfill dam and construction method

A face rockfill dam and earth-rockfill dam technology, which is applied in similar engineering fields, can solve problems such as waste of resources, and achieve the effects of convenient construction, strong practicability, and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

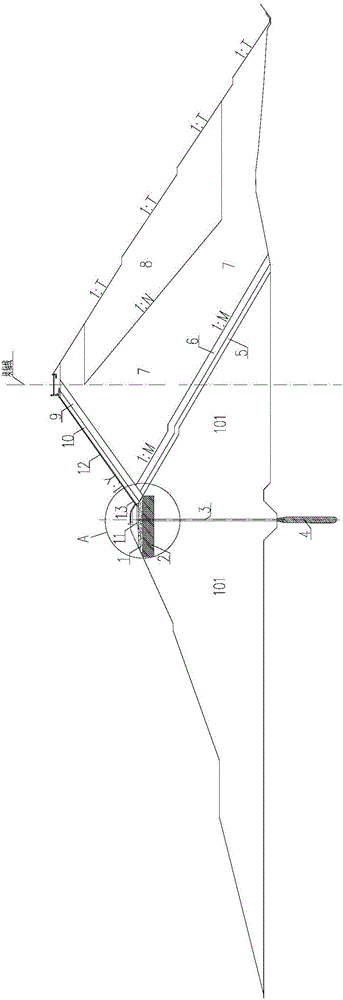

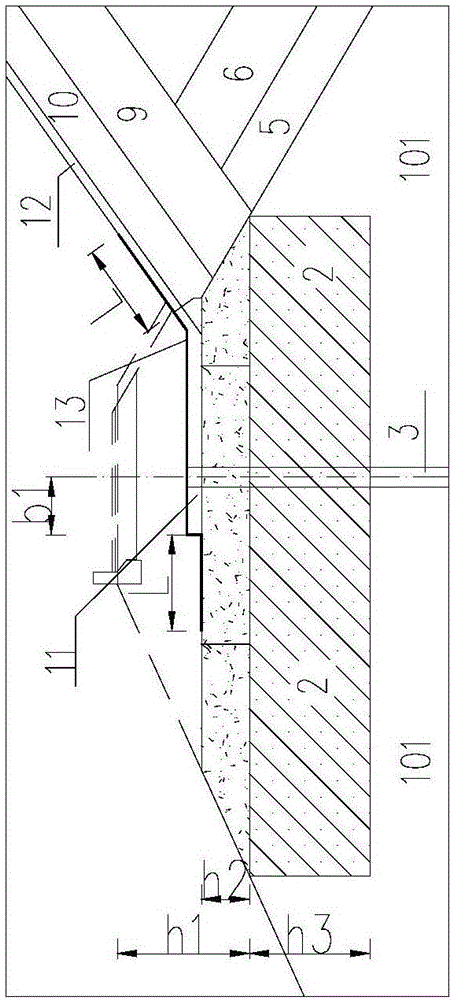

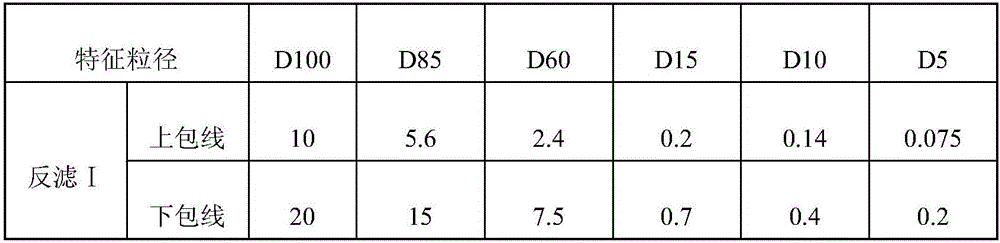

[0022] like figure 1 , figure 2 As shown, this embodiment is a mixed dam structure of a homogeneous earth-rockfill dam and a face rockfill dam, which has an original homogeneous earth-rockfill dam 101 with a certain thickness of relatively loose soil material excavated from the top and is arranged on the downstream side of the original homogeneous earth-rockfill dam. face rockfill dam; in this example, after the reconstruction of the homogeneous earth-rockfill dam, the water level in front of the dam rises, and the original homogeneous earth-rockfill dam 101 cannot meet the normal anti-seepage requirements of the dam body, and a new anti-seepage design is required; the reconstructed dam body The closed anti-seepage body is formed by combining the newly-built face plate 12+the cut-off wall 3 of the homogeneous earth-rock dam+the grouting curtain 4 at the bottom of the cut-off wall.

[0023] The face rockfill dam is composed of the main rockfill area 7, the secondary rockfill ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com