Patents

Literature

200results about "Shaft equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

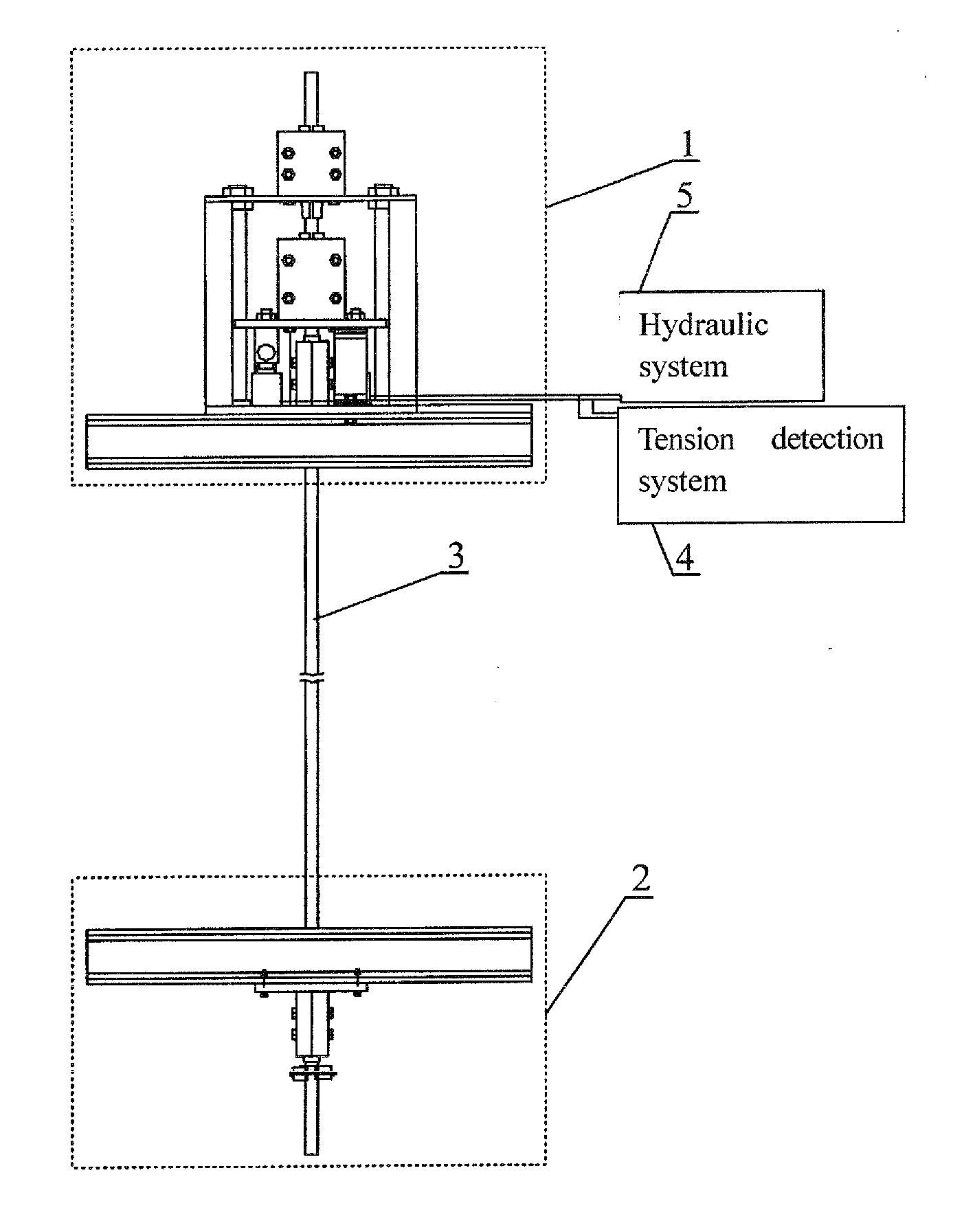

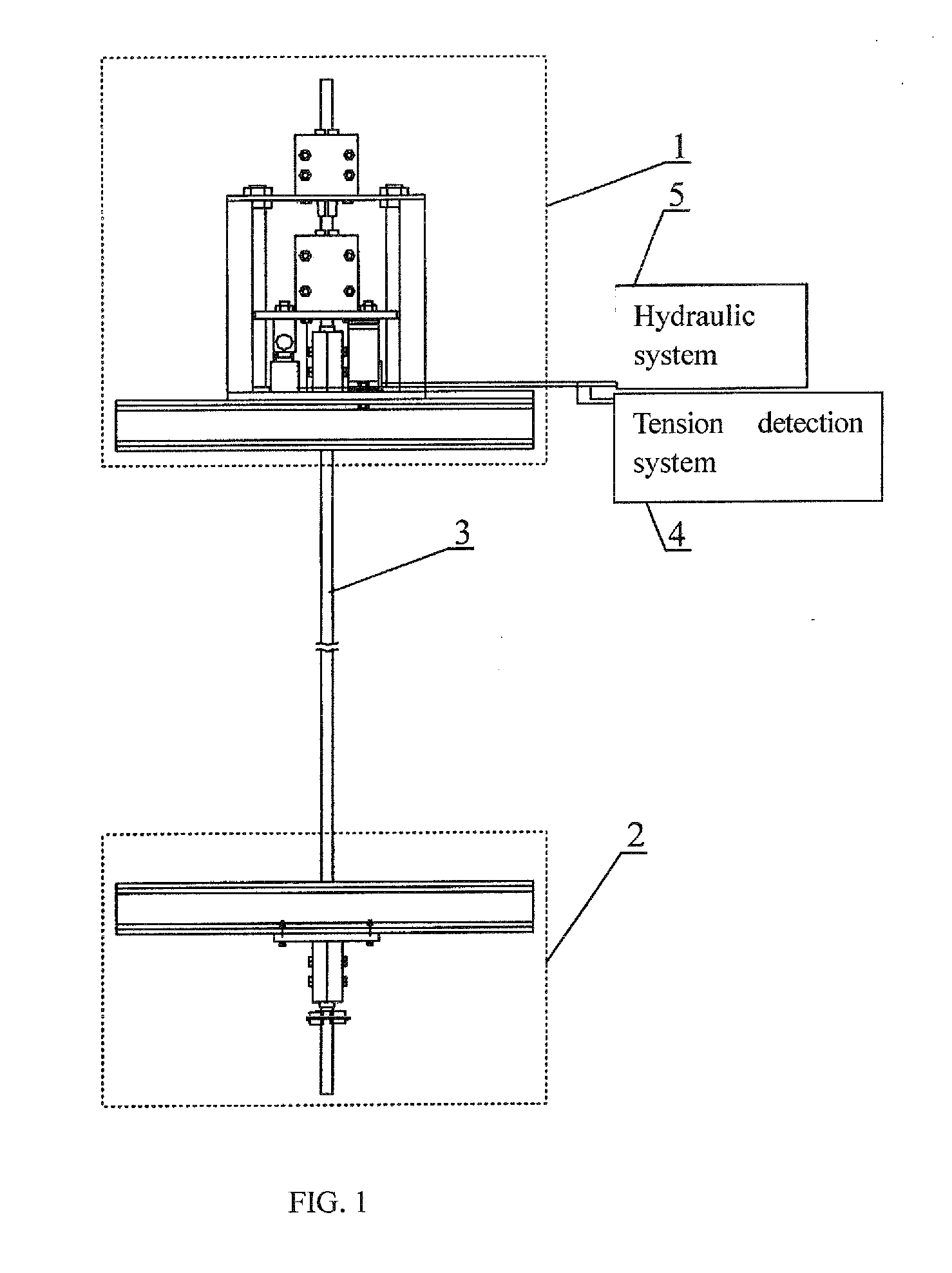

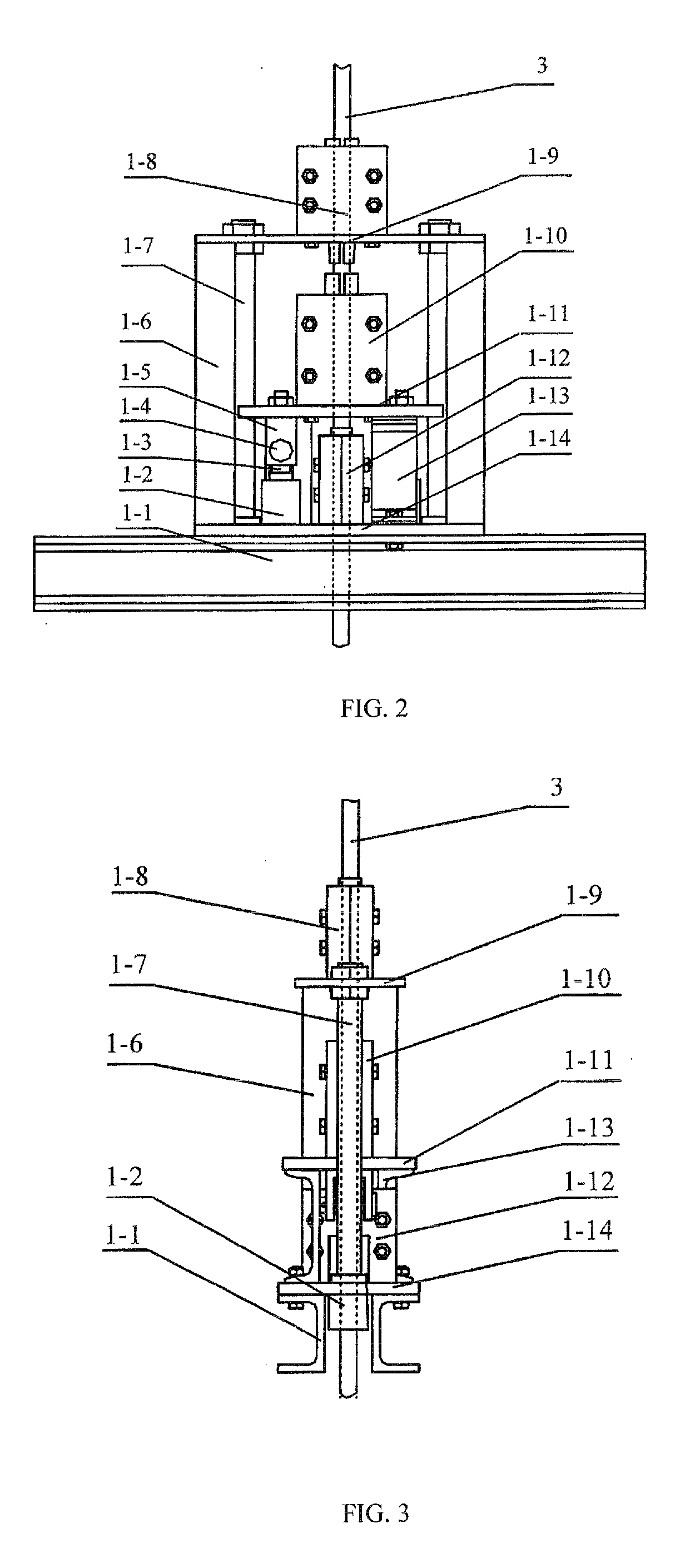

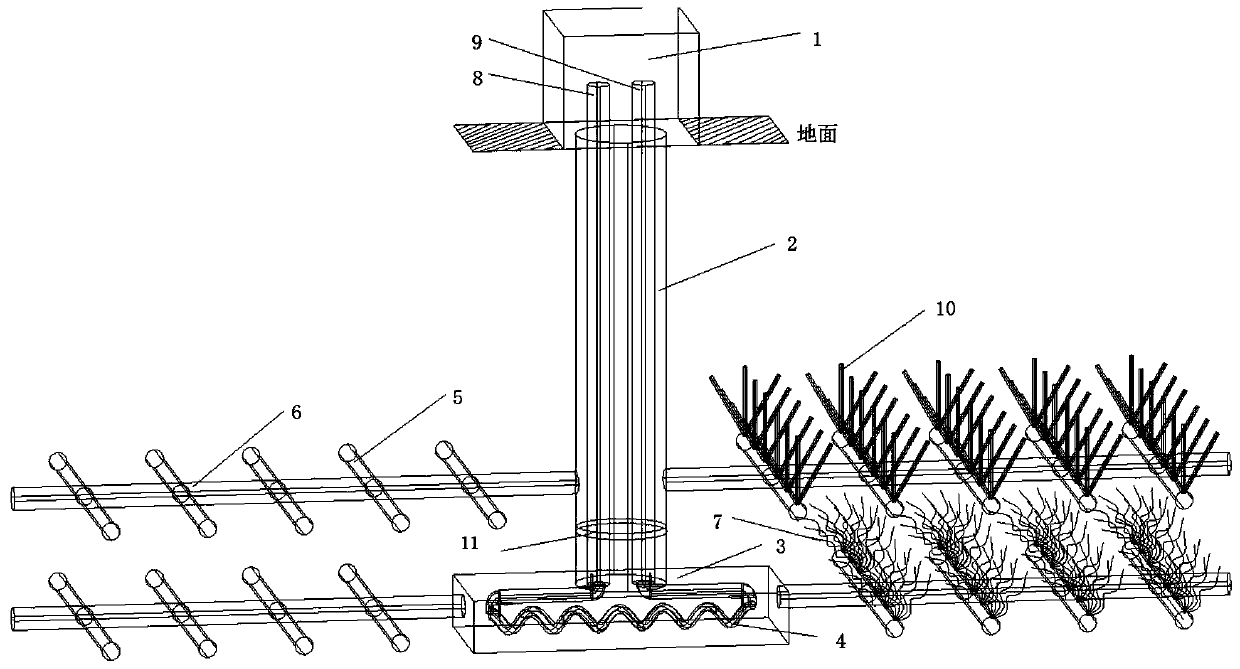

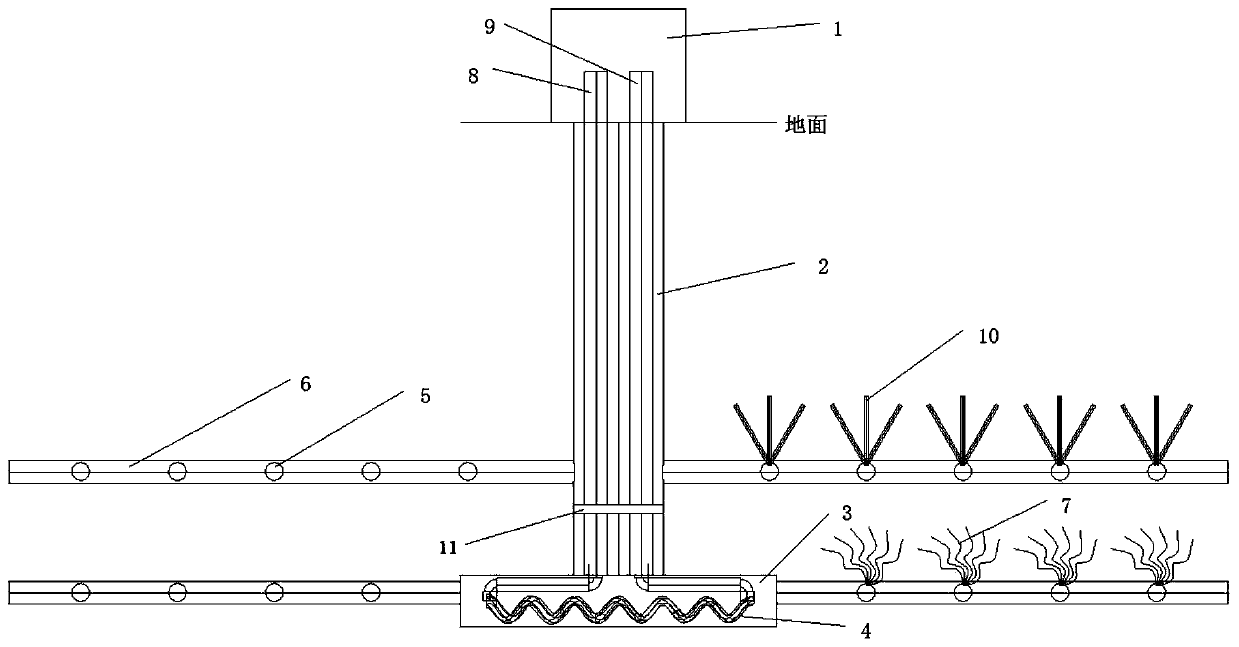

Apparatus and method for automatically adjusting tension on mining elevator flexible guide rail

Disclosed are an apparatus and a method for automatically adjusting the tension on a mining elevator flexible guide rail. The apparatus comprises an automatic tightening apparatus (1) at the opening of the well, and a fixing apparatus (2) on the bottom of the well, respectively connected to two ends of the steel cable (3). The automatic tightening apparatus (1) at the opening of the well is connected to a hydraulic system (5) and to a tension measuring system (4). The automatic tightening apparatus (1) at the opening of the well comprises a lower retainer seat (1-14) arranged on an upper bearer beam (1-1), a tightening oil cylinder body (1-2) and a plunger thereof (1-3), a pin shaft retainer (1-11), a support frame (1-6), a fall-proof holder (1-13), a pin shaft holder (1-5), a fall-proof cable retainer (1-12), a tightening fixed cable retainer (1-10), two guide columns (1-7) and guide grooves thereof, an upper retainer seat (1-9), and a cable orientation-adjusting cable retainer (1-8). The fixing apparatus (2) on the bottom of the well comprises a fixing plate (2-3), and a fixed cable retainer (2-5). The apparatus and the method allow the flexible guide rail to be structurally simple, convenient to process, reliable in performance, and easy to install and to maintain. The apparatus and the method allow restriction of vertical orientation and horizontal deflection, and are capable of real-time detection and automatic adjustment of the tension in the flexible guide rail of the elevator.

Owner:CHINA UNIV OF MINING & TECH +1

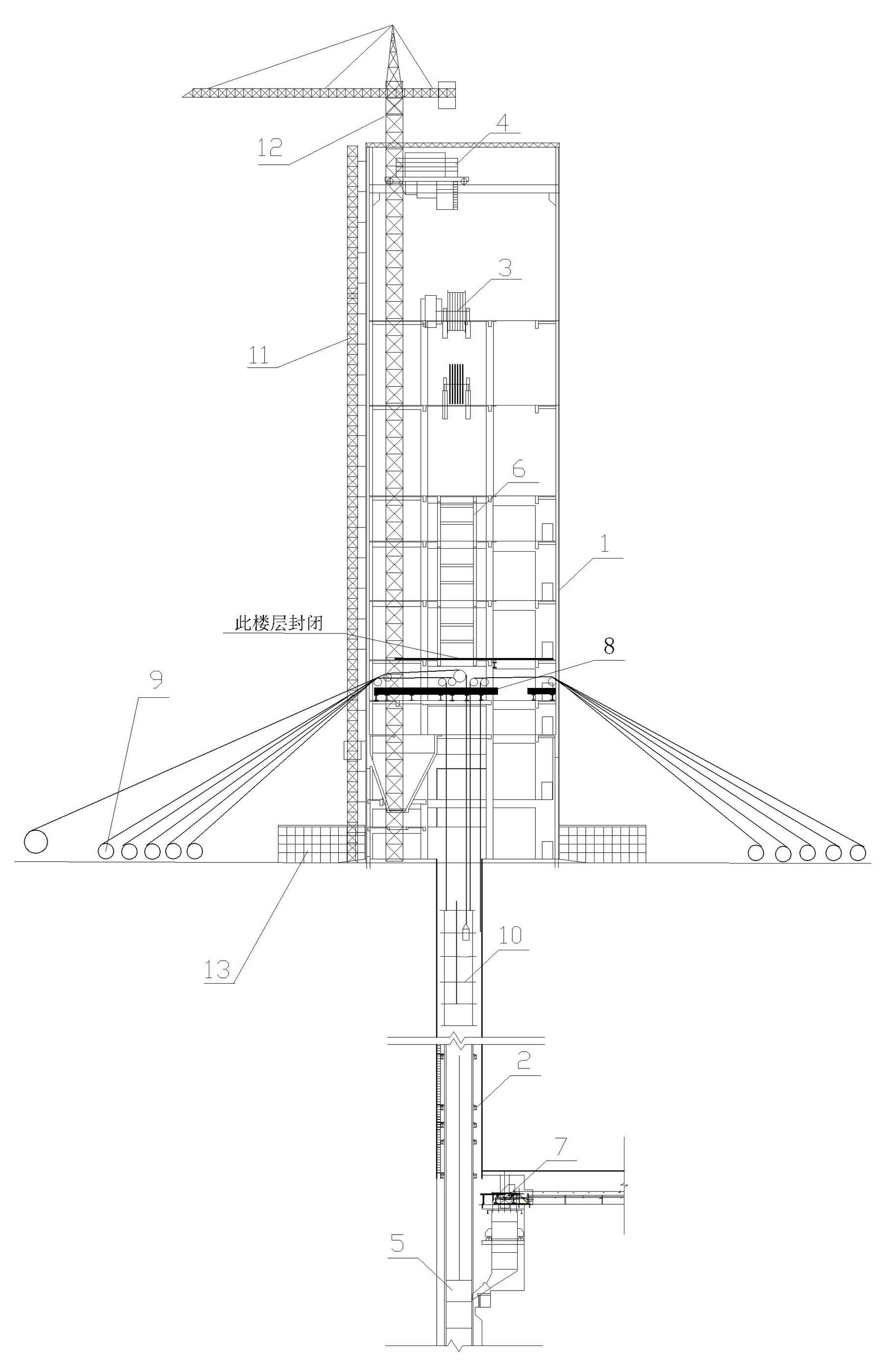

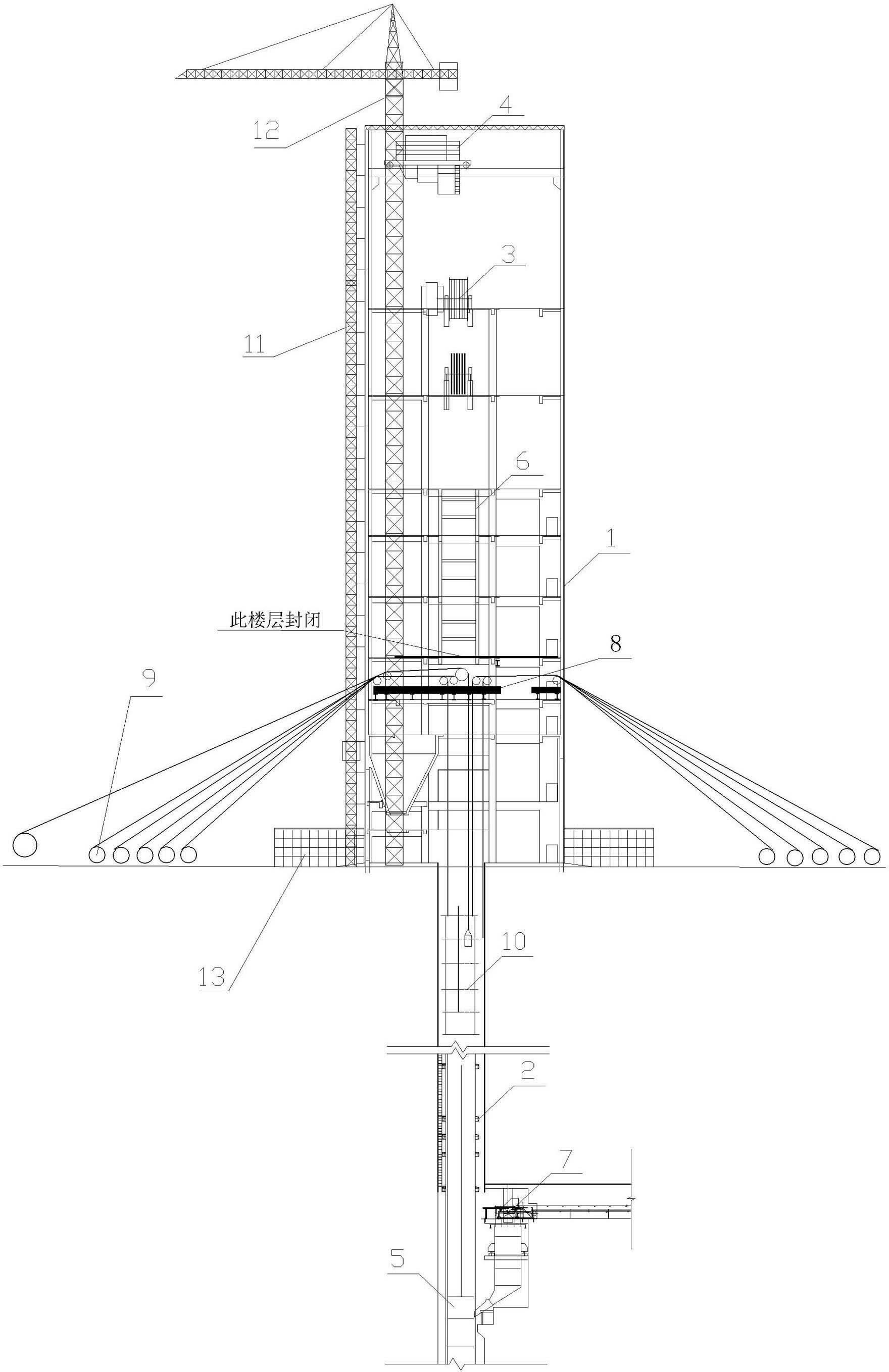

Slag tapping system and method for full face tunnel boring machine of deep vertical shaft

ActiveCN103195431AImprove emission efficiencySpeed up well constructionShaft equipmentDischarge efficiencySlag

The invention provides a slag tapping system and method for a full face tunnel boring machine of a deep vertical shaft. The slag tapping system comprises a slurry discharge system, a slurry separation station, a slurry feed system and a muck improving pumping system, wherein the slurry discharge system is composed of a slurry discharge pump and a slurry discharge pipe; a lower opening of the slurry discharge pipe stretches into a muddy water cabin at the bottom of a cutter, an upper opening of the slurry discharge pipe is connected with an upper inlet of the slurry separation station; two outlets are arranged on the lower portion of the slurry separation station, one outlet is connected with the slurry feed system, and the other outlet is connected with the muck improving pumping system; the slurry feed system is composed of a slurry feed pump and a slurry feed pipe which is connected with the muddy water cabin; and the muck improving pumping system comprises a muck crushing, improving and stirring device, a muck conveying pump and a slag discharge pipe which are sequentially connected, one end of the muck crushing, improving and stirring device is connected with a slag outlet of the slurry separation station, and the outlet end of the slag discharge pipe leads to the outside of the vertical shaft. Devices of the system are not affected by the depth of the vertical shaft, continuous tapping can be guaranteed, the discharge efficiency of muck is greatly improved, and therefore the deep vertical shaft building speed is accelerated.

Owner:CHINA RAILWAY CONSTR HEAVY IND

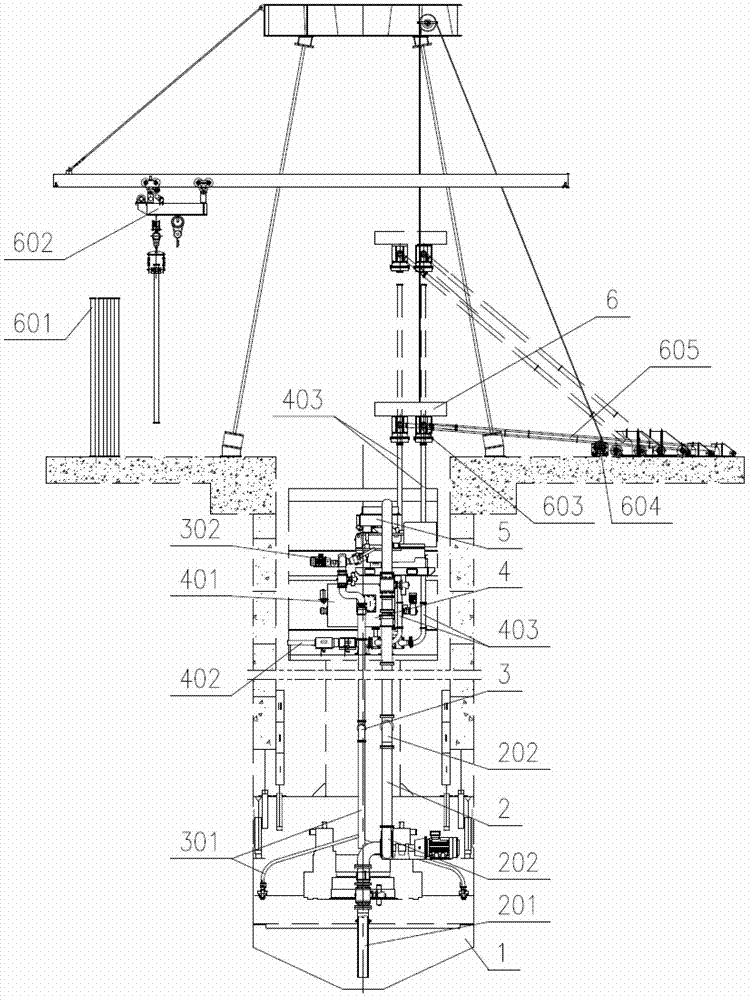

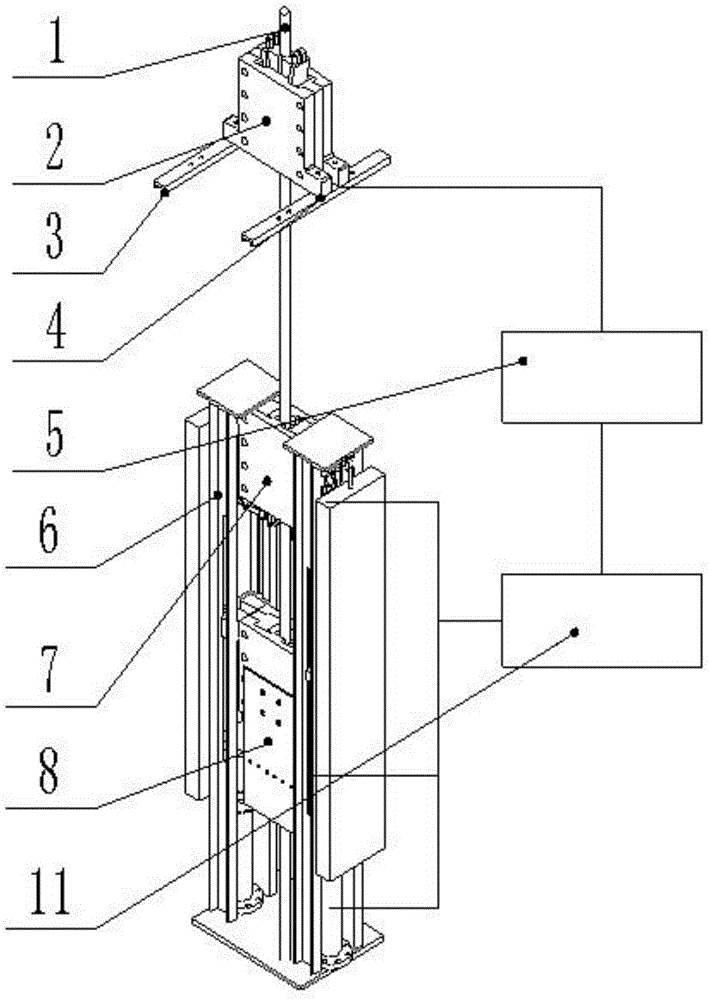

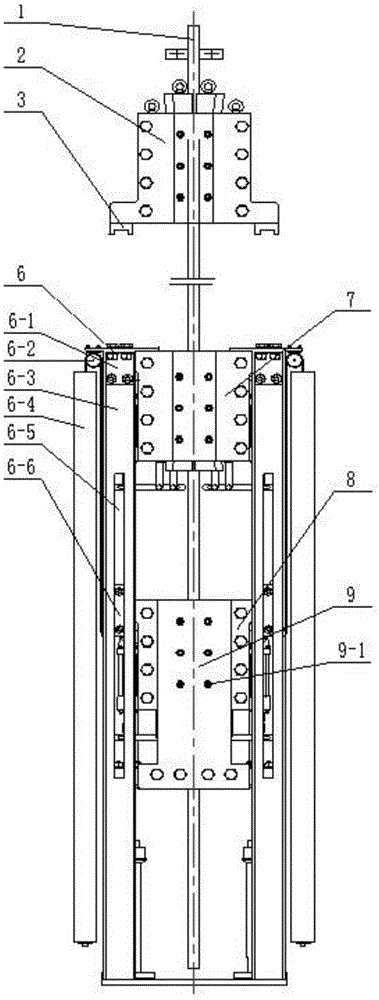

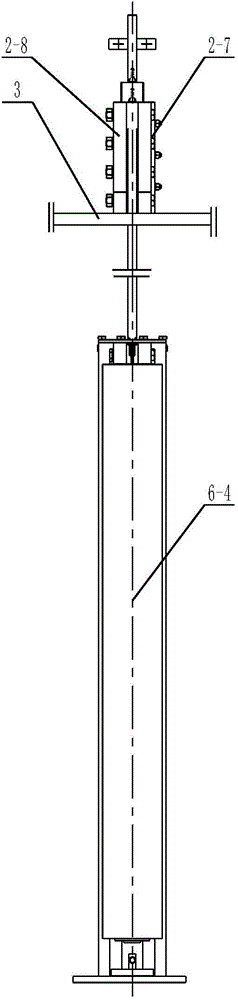

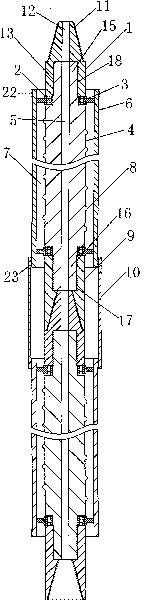

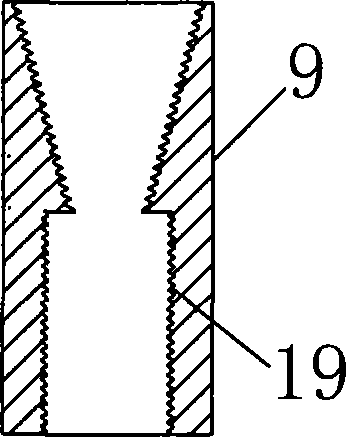

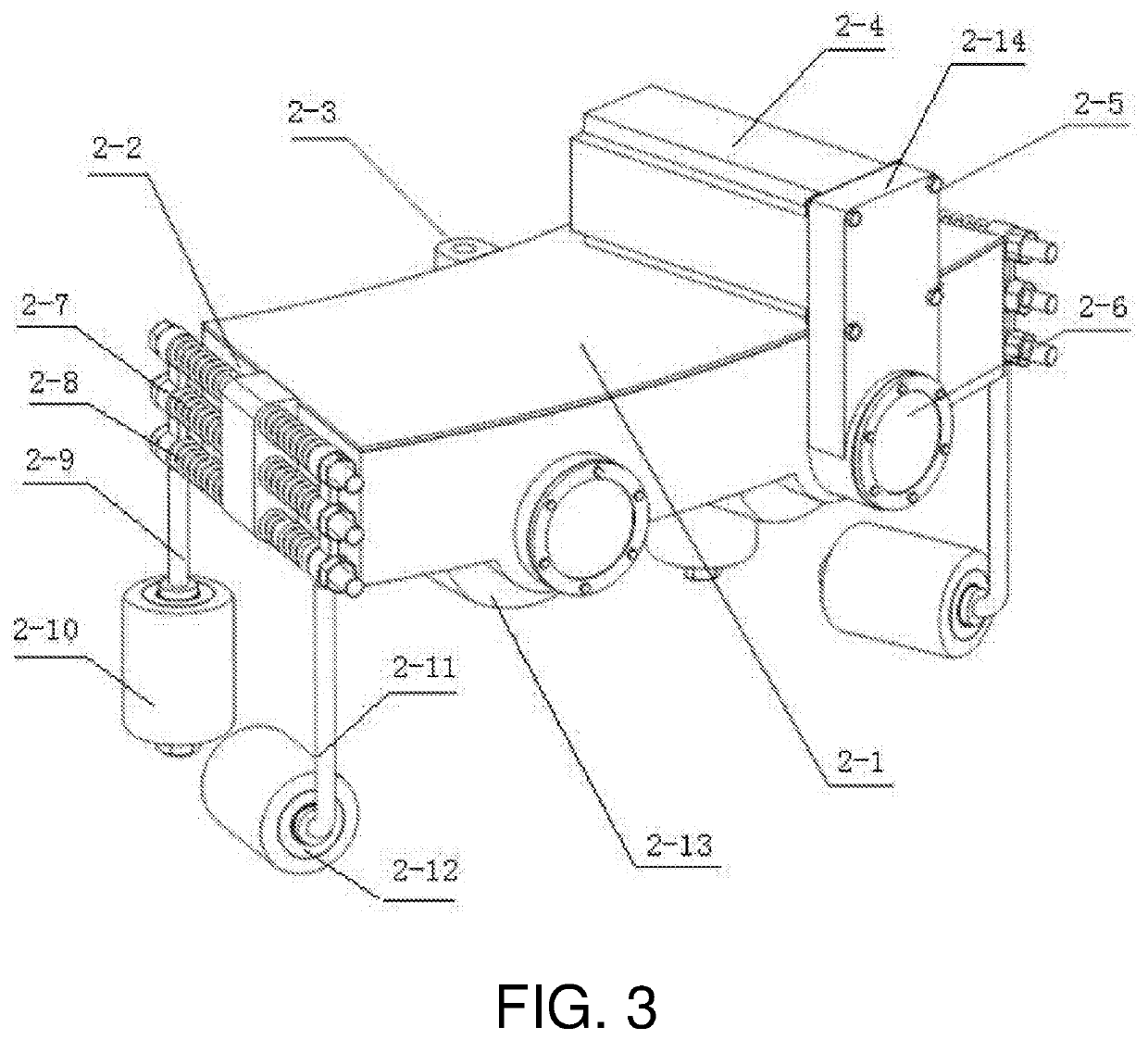

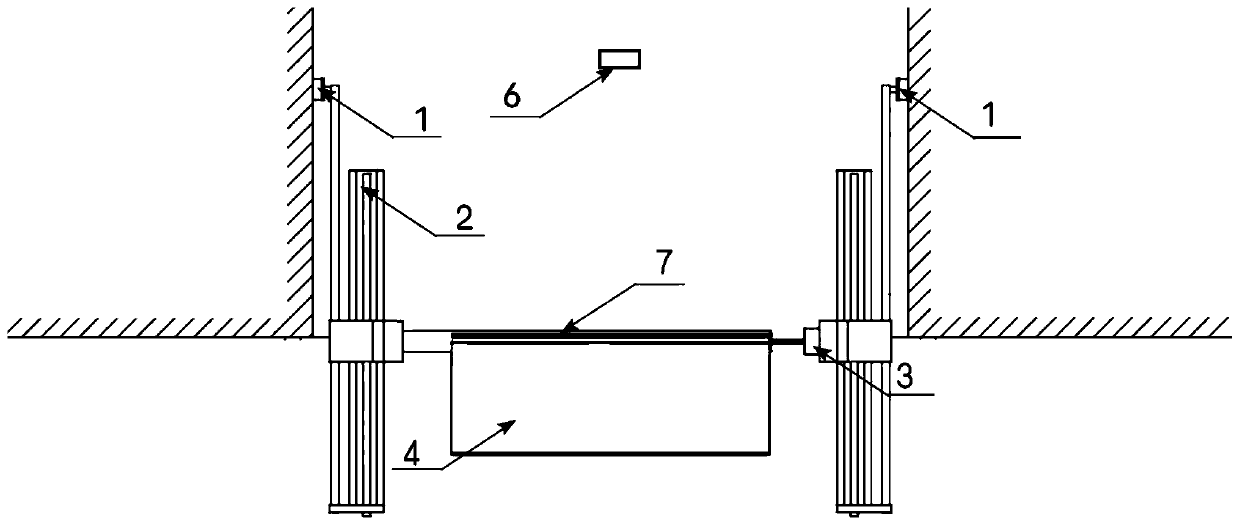

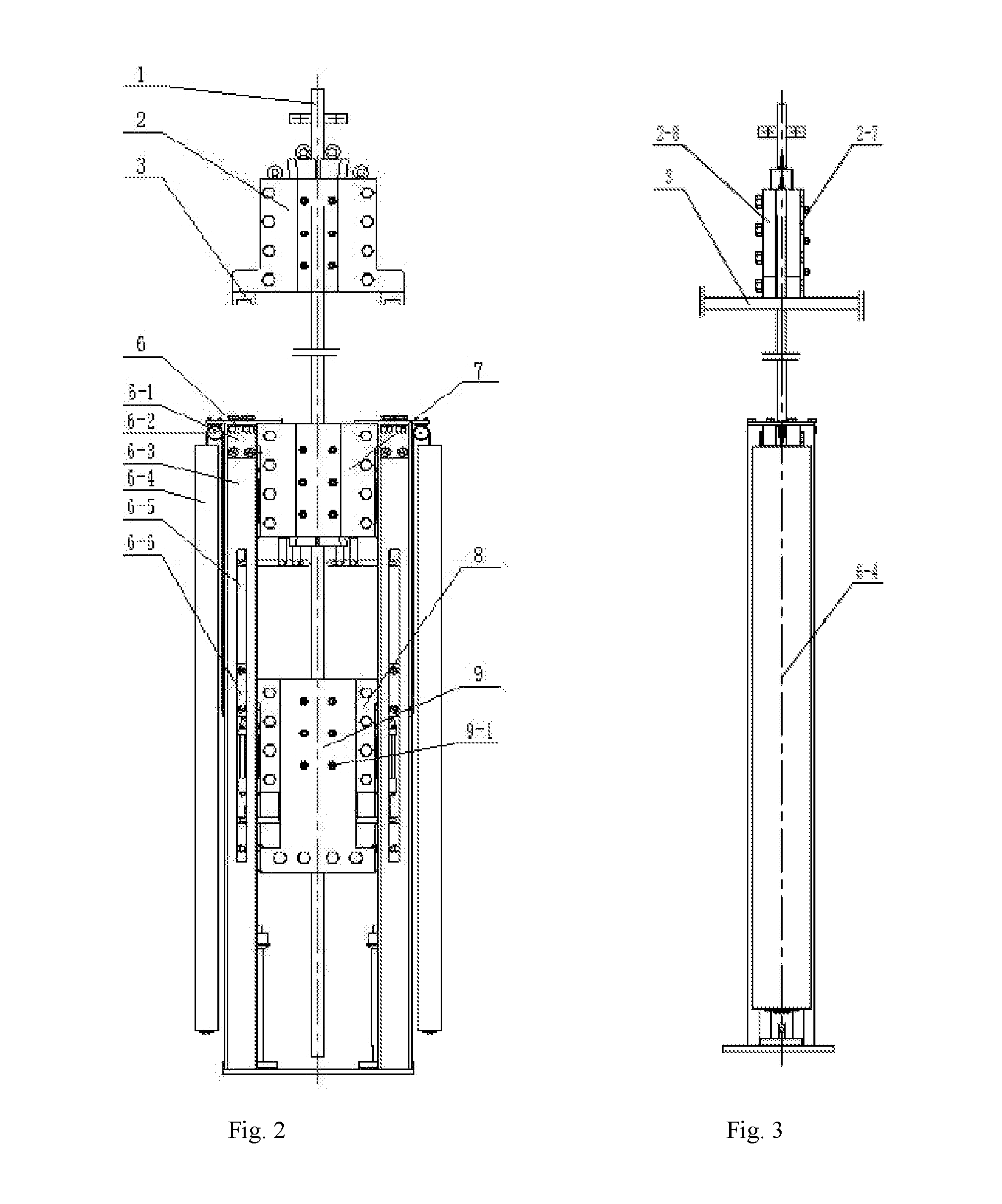

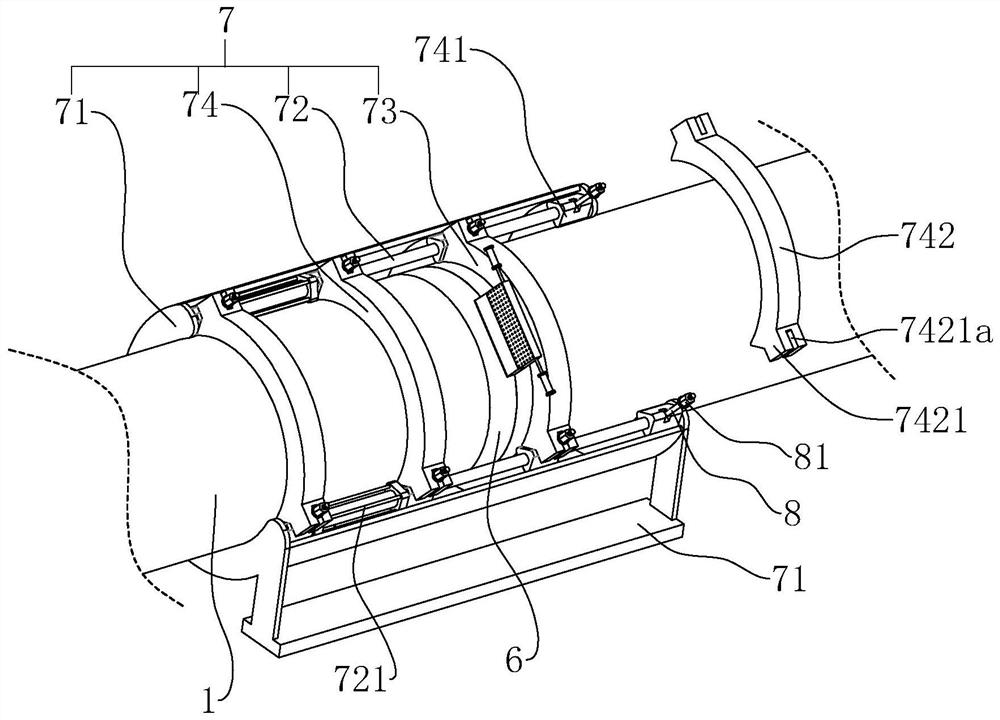

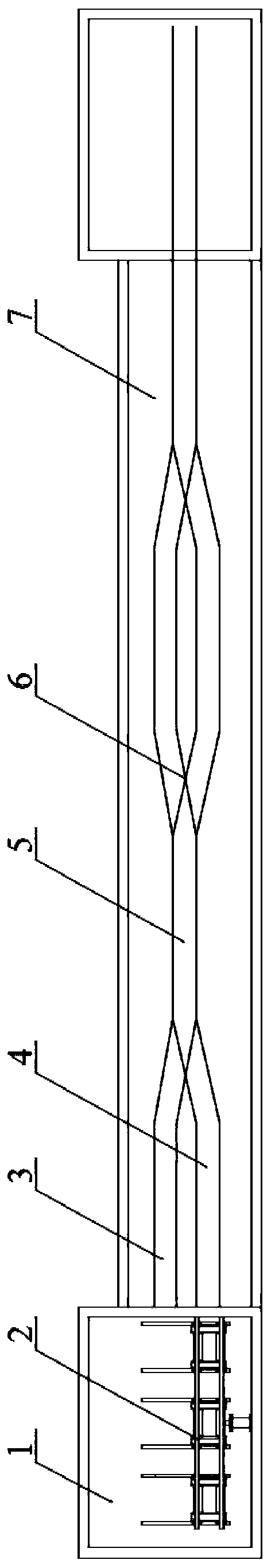

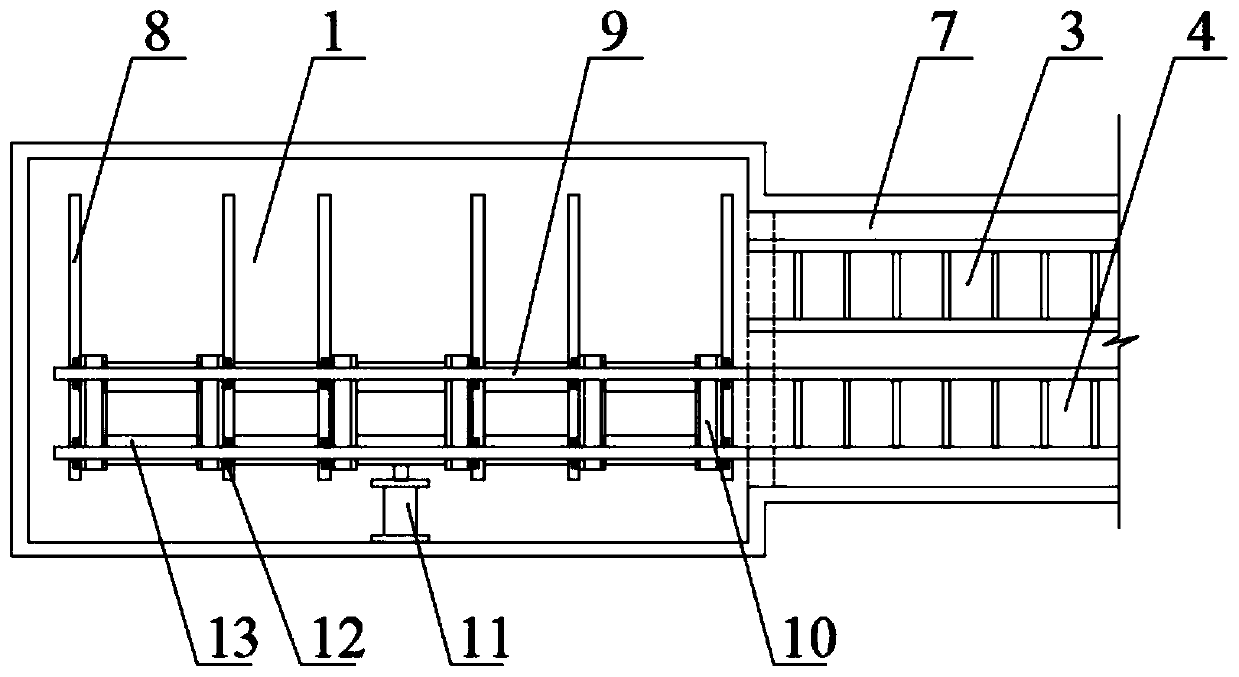

Ultra-deep vertical shaft guide steel cable tensioning device and tensioning method

The invention discloses an ultra-deep vertical shaft guide steel cable tensioning device and tensioning method. The tensioning device comprises an upper cable clamping device, a cable regulation guide frame, a lower hydraulic cable locking device and a lower hydraulic cable regulating device, wherein the upper cable clamping device is provided with a cable clamp and a pressure sensor; the cable regulation guide frame comprises a steel frame body, double upper fixing splints, a balance weight and a balance weight steel cable; double moving splints are arranged inside a guide groove of the steel frame body; the double moving splints are provided with the cable clamp and a lower guide pulley; the double upper fixing splints are provided with an upper guide pulley; the balance weight is provided with a fastening joint; the upper cable clamping device, each of the lower hydraulic cable locking device and the lower hydraulic cable regulating device comprises a wedged iron block and a shim; each of the lower hydraulic cable locking device and the lower hydraulic cable regulating device also comprises a level wedge regulating mechanism and a wedge regulating hydraulic cylinder; a wedge regulating hydraulic pressing rod is connected with the wedged iron block; the bodies of the wedge regulating hydraulic cylinders are connected with the shims. The steel cable tensioning device and the tensioning method disclosed by the invention can be used for realizing automatic regulation and control of the tensile force of an ultra-deep vertical shaft guide steel cable.

Owner:CHINA UNIV OF MINING & TECH

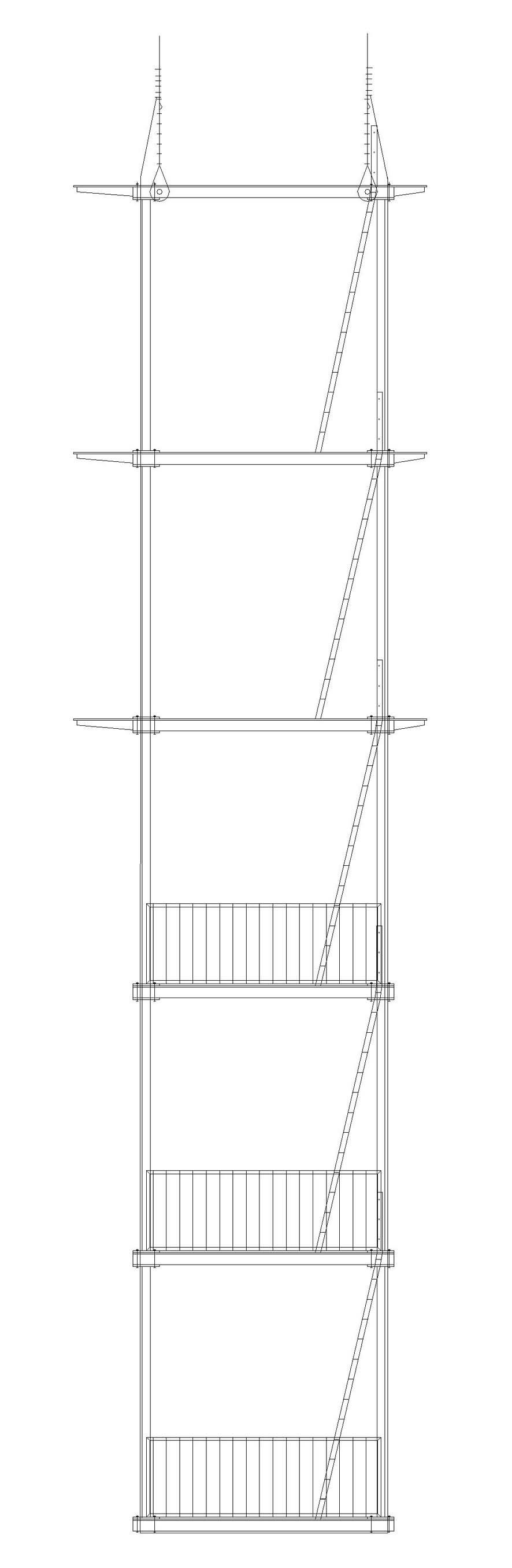

Fast construction method of headframe lifting system

InactiveCN102536249AHigh speedShorten construction timeShaft equipmentHeadframeArchitectural engineering

The invention discloses a fast construction method of a headframe lifting system, which belongs to the technology of construction of mines. When a headframe foundation and a headframe main body are constructed to about 23 meters, shaft equipment components are processed, large temporary facilities of shaft equipment are arranged, during construction of the headframe main body above about 23 meters, the shaft equipment is mounted, a crane above a hall of an elevator is hoisted before the headframe main body is finished and the top of the headframe main body is sealed, the crane is installed, and the elevator is hoisted and mounted after the top of a headframe is sealed. After the top of the headframe is sealed, the constructed headframe is decorated, simultaneously, the elevator and a sleeve frame in the headframe are mounted, after the headframe equipment is mounted, equipment of upper and lower openings is mounted, ropes are wound and a lifting container is hung after the elevator is mounted, finally, debugging running is carried, and then construction and installation operations of the headframe lifting frame are totally finished. The fast construction method of the headframe lifting system has the advantages that work hour utilization rate is high, construction speed is fast, and engineering quality is improved advantageously. Constructors, equipment and materials are reasonably allocated via parallel cross operation, and engineering manufacturing cost is lowered.

Owner:CHINA COAL NO 5 CONSTR

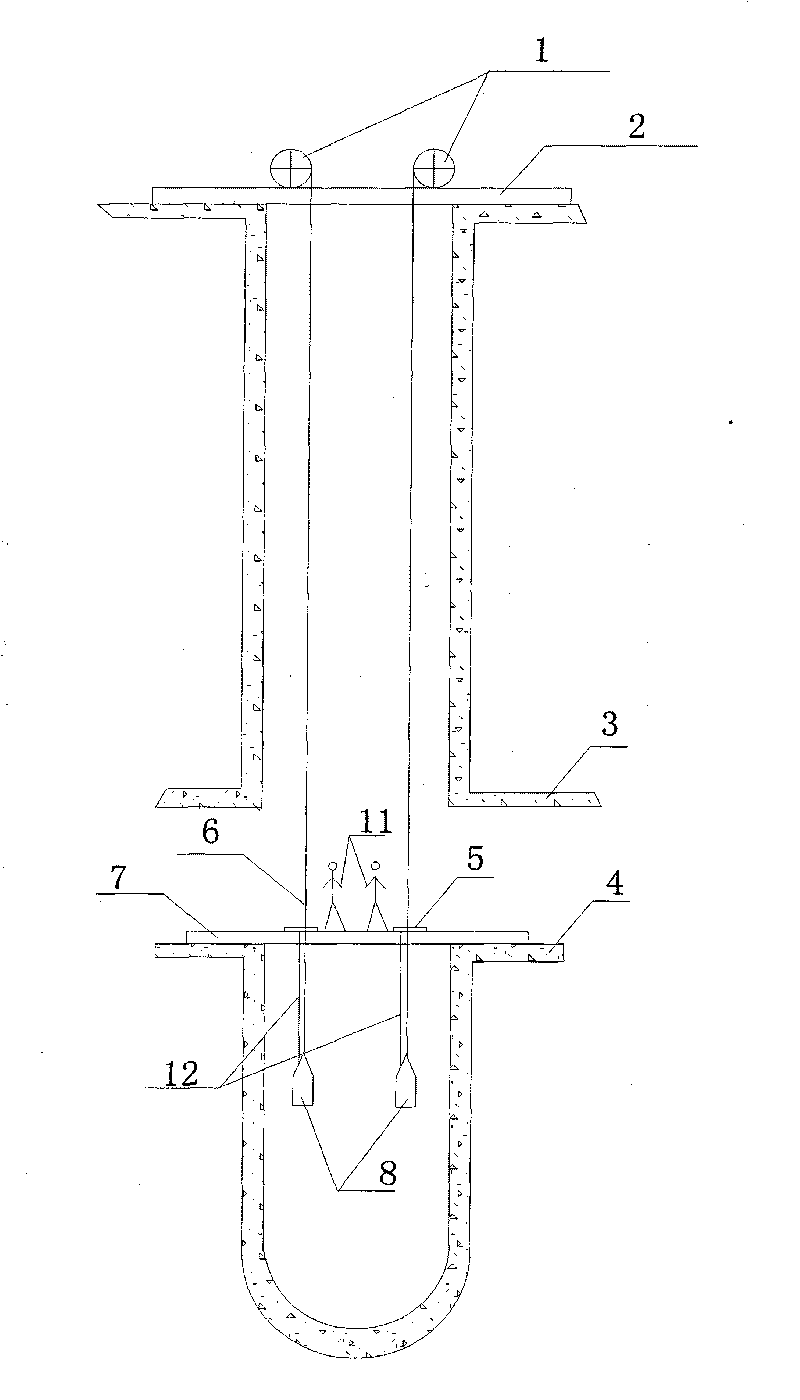

Geothermal development system and construction method thereof

ActiveCN110030745ASmall footprintHigh porosityCollector components/accessoriesLighting and heating apparatusEngineeringHigh pressure water

The invention discloses a loose blasting type hot ore development system and a construction method thereof. The hot ore development system comprises a ground lifting system, a large-diameter verticalshaft, an underground high-temperature high-pressure heat exchange water tank, a heat exchange flow guide channel, a water-rock geothermal flow storage layer, a movable sealing device and the like, wherein the water-rock geothermal flow storage layer is formed by access blasting tunnels and a main tunnel. The hot ore development system is provided with an injection pipeline and a collecting pipeline along the inner wall of the large-diameter vertical shaft, the injection pipeline communicates with the collecting pipeline through the heat exchange flow guide channel of the underground high-temperature high-pressure heat exchange water tank in dry hot rock, the circulating main tunnel is arranged around the underground high-temperature high-pressure heat exchange water tank, and the plurality of rows of access blasting tunnels are horizontally arranged along the main tunnel, a hot ore blasting fracture flow storage layer is formed through caving mining method loose blasting, moreover, the movable sealing device is arranged above the vertical shaft of a blasting layer, through a U-shaped pipe principle, through the injection pipeline and the collecting pipeline, cold water and hot water in the high-temperature high-pressure water tank exchange heat energy, the water with the heat energy is conveyed to the ground to be converted into electric energy for people to use, and dual heat exchange is realized.

Owner:MECHSOFTTECHNOLOGY U S A CO LLC +2

Double-track tunnel provided with vertical shaft smoke discharge and ventilation combined and complemented system

InactiveCN105971626AReduce path lengthReduce energy consumptionTunnel/mines ventillationTunnelsNatural ventilationDistribution power system

The invention discloses a double-track tunnel provided with a vertical shaft smoke discharge and ventilation combined and complemented system. The double-track tunnel provided with the vertical shaft smoke discharge and ventilation combined and complemented system comprises two tunnel tracks, complementary contact air ducts and a smoke discharge vertical shaft, wherein the complementary contact air ducts and the smoke discharge vertical shaft are arranged between the two tunnel tracks. Axial flow fans are arranged in the contact air ducts and used for airflow organization between the two tunnel tracks. An axial flow fan is arranged in the smoke discharge vertical shaft. An air duct is formed in the bottom of the vertical shaft and communicates with an upper tunnel body and a lower tunnel body, and a pair of electric air valves is arranged in the air duct. The electric air valves in the air duct at the bottom of the vertical shaft are opened when no fire exists and used for natural ventilation. When a fire occurs, the electric air valve at the bottom of the portion, in the tunnel body on the no-fire side, of the vertical shaft and the air valves and the axial flow fans in the complementary contact air ducts are closed, and the axial flow fan in the smoke discharge vertical shaft is started for fire smoke discharge. According to the double-track tunnel provided with the vertical shaft smoke discharge and ventilation combined and complemented system, complementary ventilation is achieved through the contact air ducts, and thus the work amount of a ventilation system and a power supply and distribution system can be reduced; and the smoke discharge vertical shaft is used for smoke discharge when a fire occurs and natural ventilation when no fire exists, so that the corresponding vertical shaft scale and the project cost can be reduced, and the service energy-saving capacity and the disaster preventing capacity are improved.

Owner:ZHEJIANG PROVINCIAL INST OF COMM PLANNING DESIGN & RES CO LTD

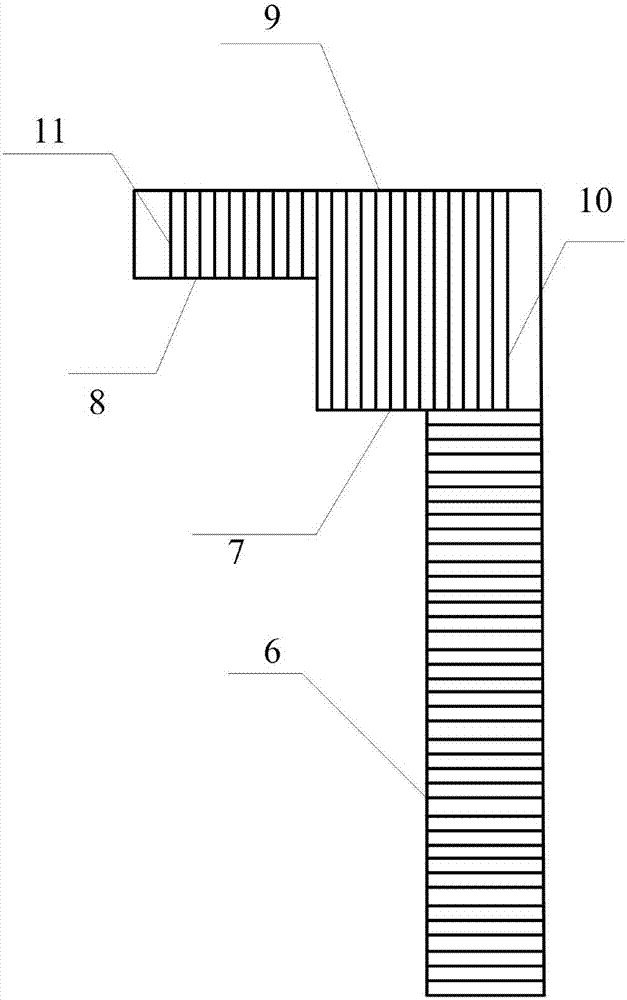

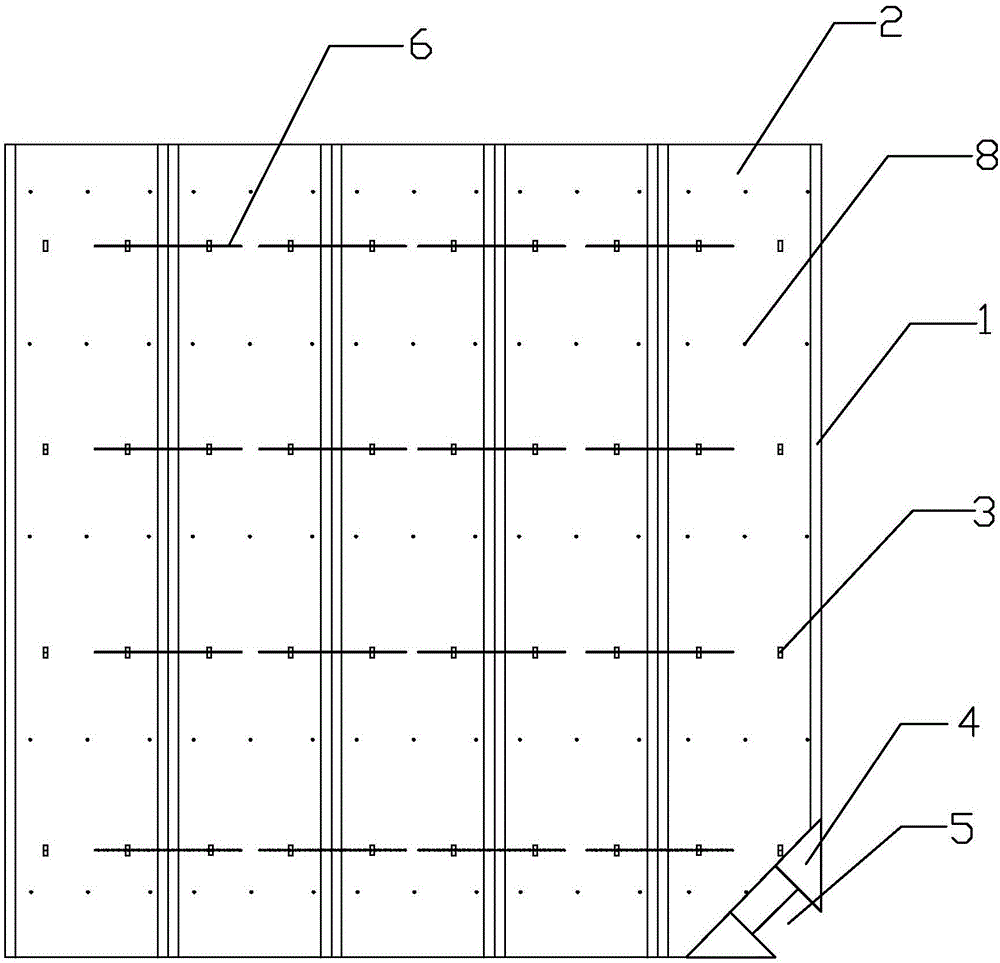

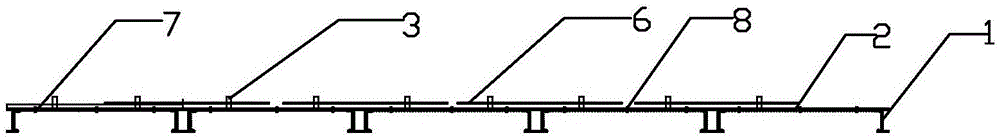

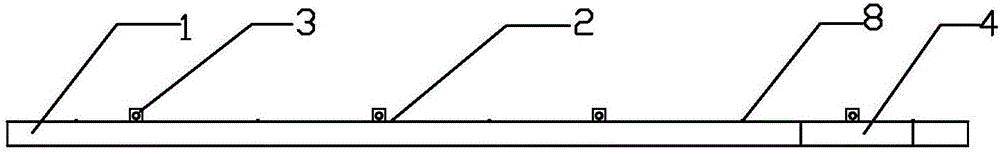

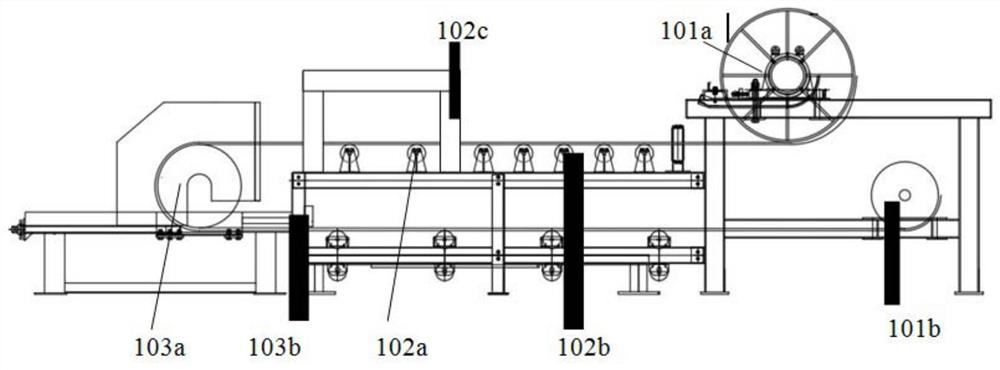

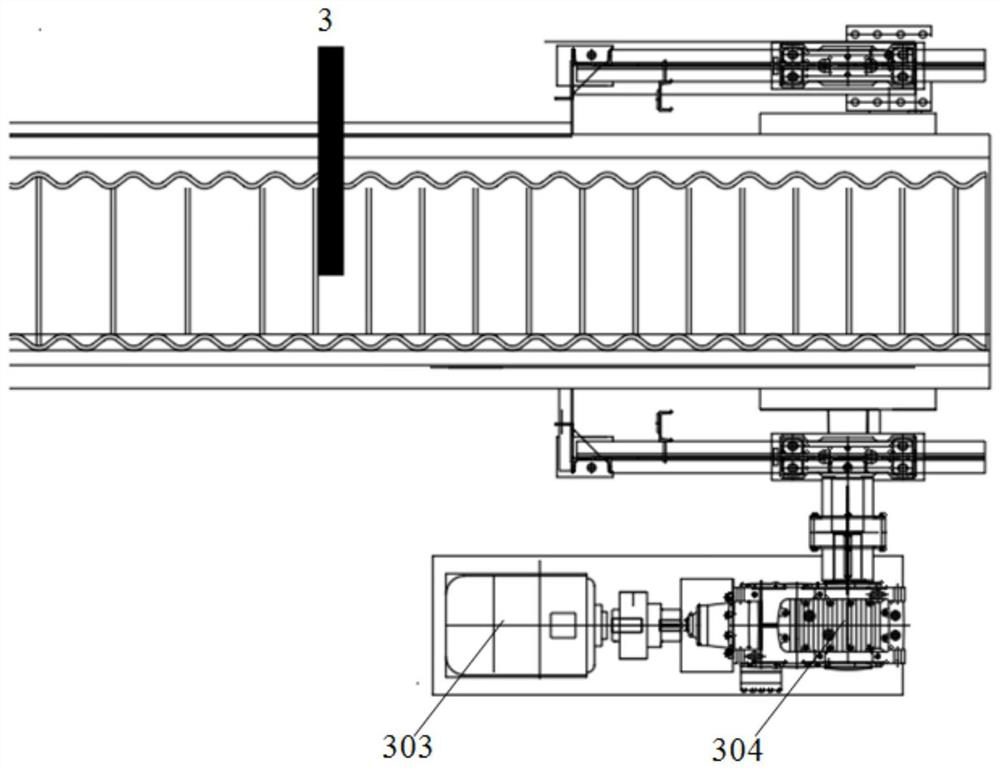

Flexible guide rail of mining elevator and arrangement method thereof

ActiveCN102249130ASimple structureEasy to installElevatorsShaft equipmentEngineeringWorking environment

The invention provides a flexible guide rail of a mining elevator and an arrangement method thereof. The flexible guide rail mainly consists of steel wire rope guide rails, a tensioning device, a connecting device and steel wire rope guide sleeves, wherein, the upper end of each steel wire rope is connected through the tensioning device arranged on an upper bearing beam on a platform of a well frame, the other end of each steel wire rope guide rail is connected through the connecting device arranged on a lower bearing beam in a pit of the well frame, and each steel wire rope guide rail vertically passes through the steel wire rope guide sleeves arranged on a car and a counterweight; and the steel wire rope guide rails are arranged at one side or two sides of the car, wherein, two or threeguide rails are arranged at one side of the car, two, three and four guide rails are respectively arranged at opposite angles, three angles and four angles at the two sides of the car, and one guide rail is respectively arranged at two sides of the counterweight. The flexible guide rail provided by the invention is particularly applicable to the mining elevator in the case of multilevel working face mining in an underground mine, and is also applicable to the mining elevator in the case of a severe downhole working environment and shaft deformation; and the flexible guide rail has the advantages of simple structure, easy machining property and reliable performance, and is simple in installation and maintenance.

Owner:CHINA UNIV OF MINING & TECH +1

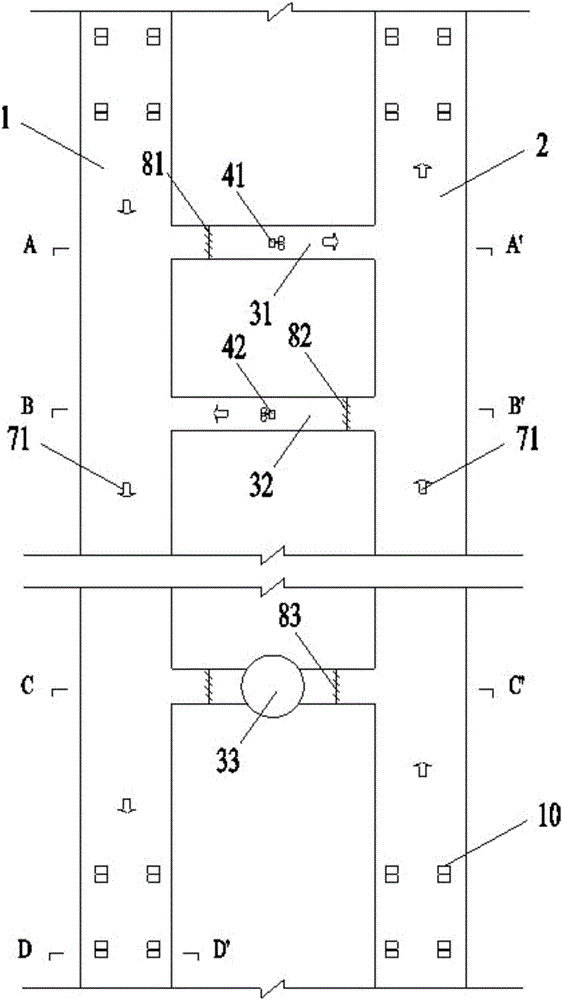

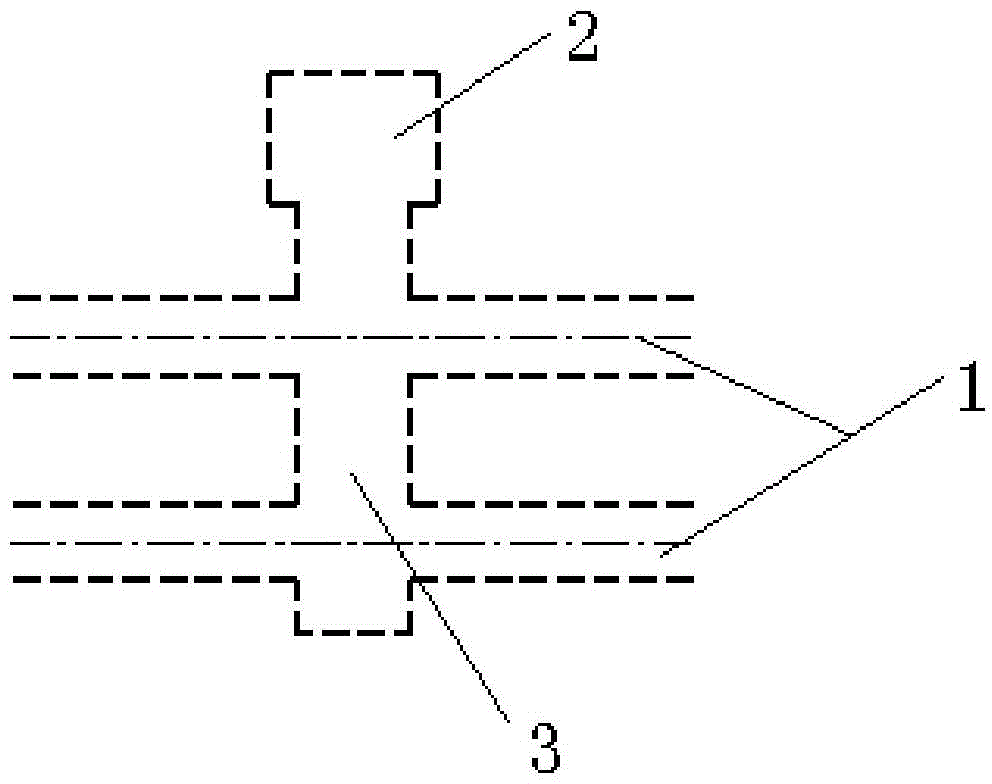

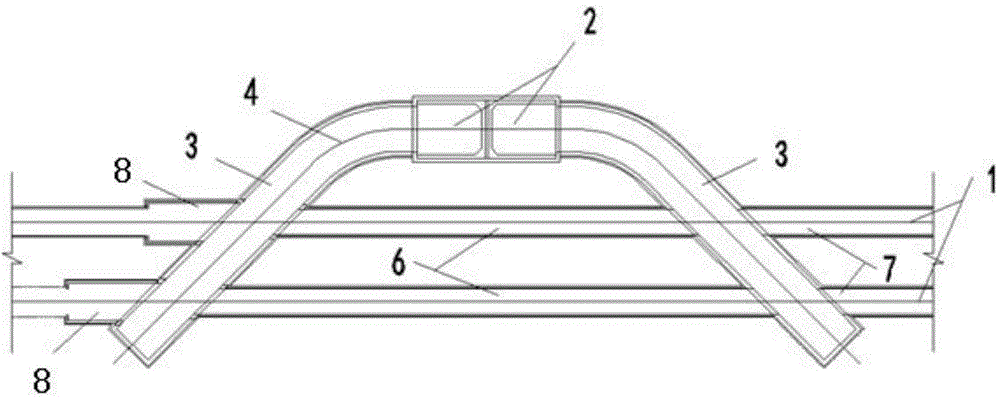

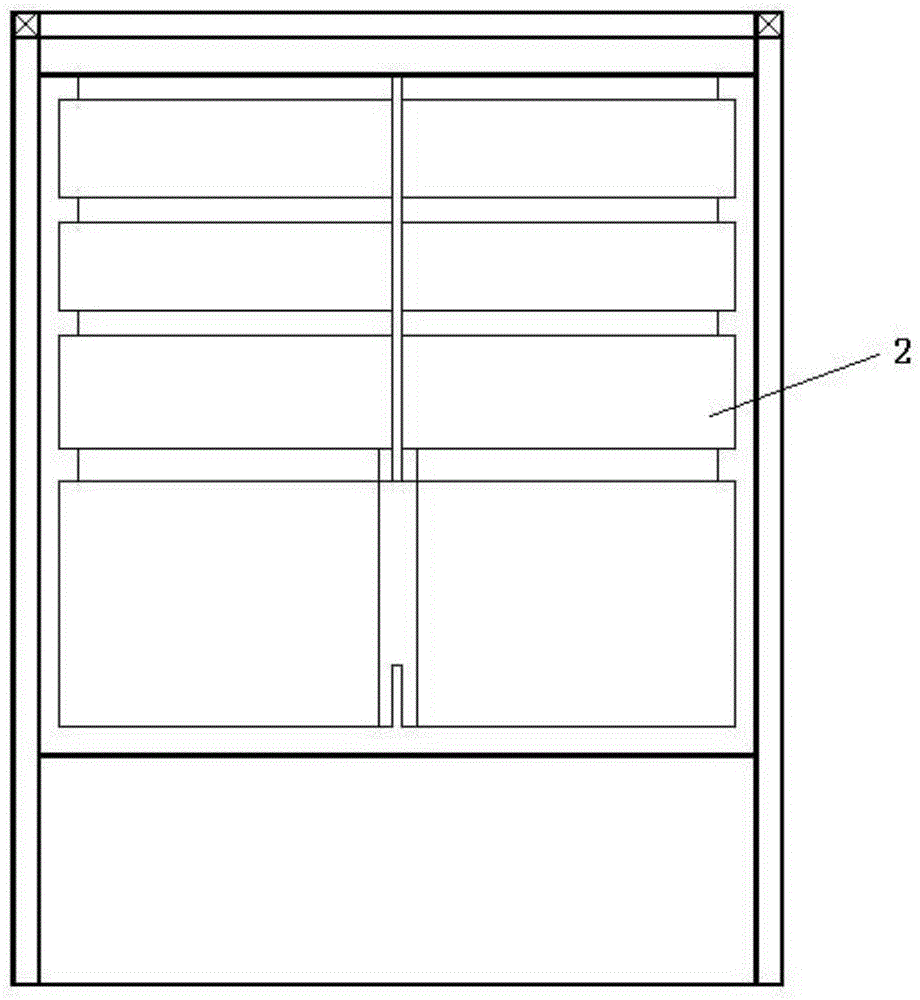

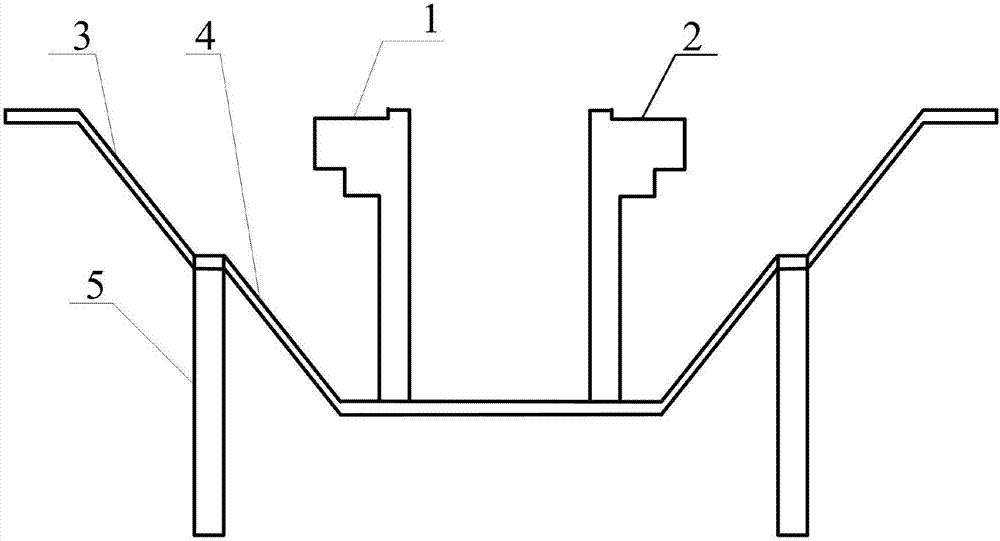

Urban subway n-shaped double-shaft and double transverse passage plane arrangement system

InactiveCN104818994ASafe and stable structureImprove construction progressTunnelsShaft equipmentNarrow rangeArchitectural engineering

The invention discloses an urban subway n-shaped double-shaft and double transverse passage plane arrangement system. The system comprises a tunnel middle line (1), and is characterized by also comprising a shaft (2) and two transverse passages (3), wherein the shaft (2) is excavated in one side of the tunnel middle line (1) in a concealed manner; the transverse passages (3) are communicated with the shaft (2) through cambered transition sections (3) respectively; the middle parts of the transverse passages (3) are crossed with the tunnel middle line (1) at a certain angle. The system has a safe and stable structure and can simultaneously meet the requirement on concealed excavation and shield construction without mutual affection. The shafts and the n-shaped double transverse passages realize concealed excavation in a narrow range and parallel construction of a shield; the construction progress and the construction efficiency are improved; the cost is saved; a reference is provided for design and construction of the shafts and the transverse passages of metros in future.

Owner:中铁二十二局集团第一工程有限公司 +1

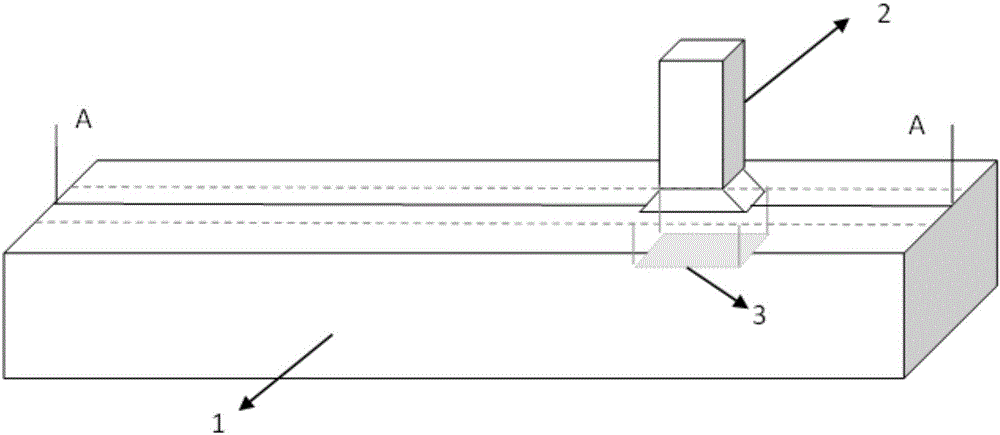

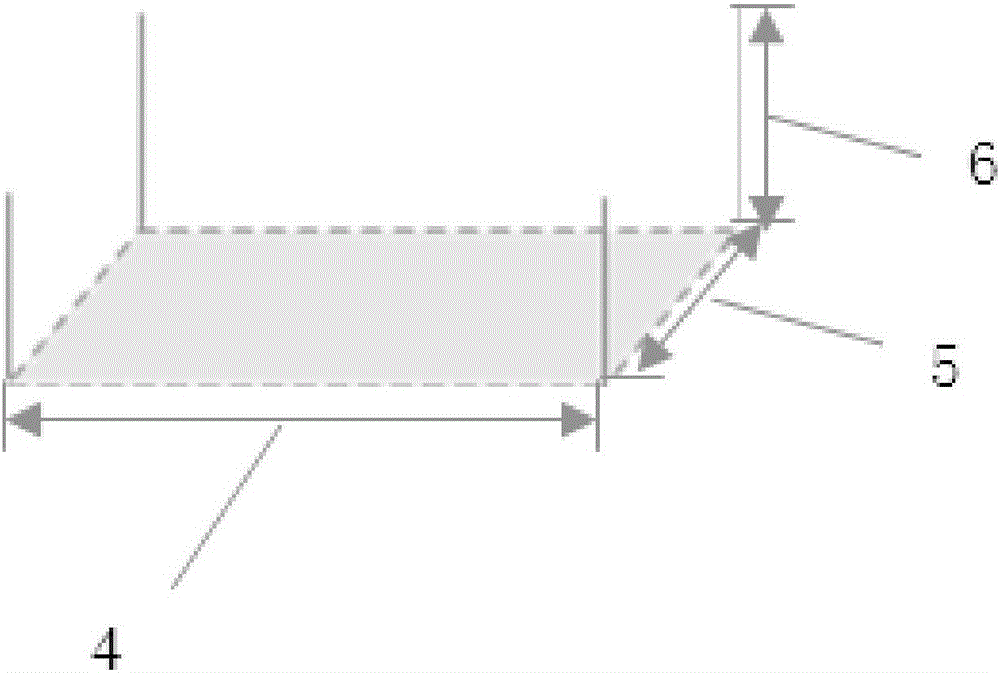

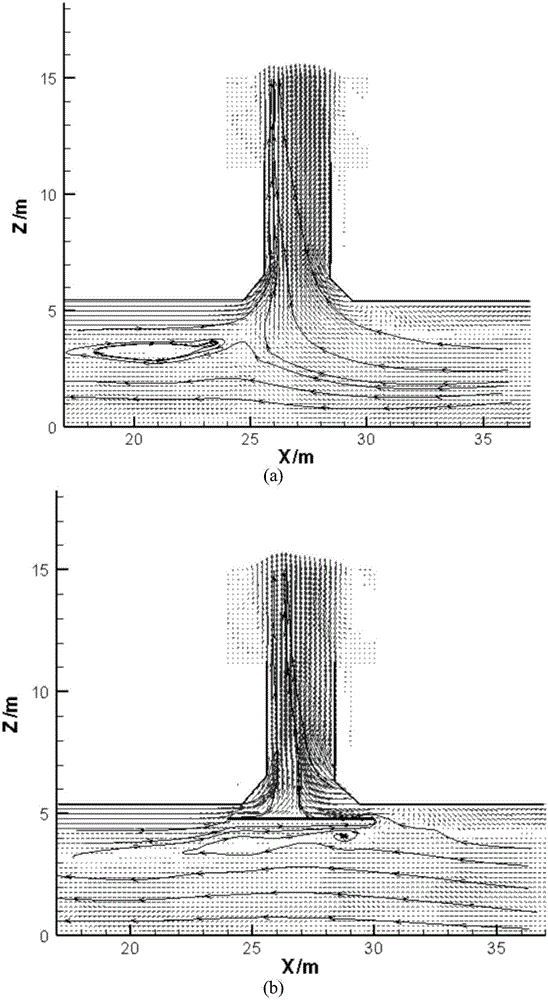

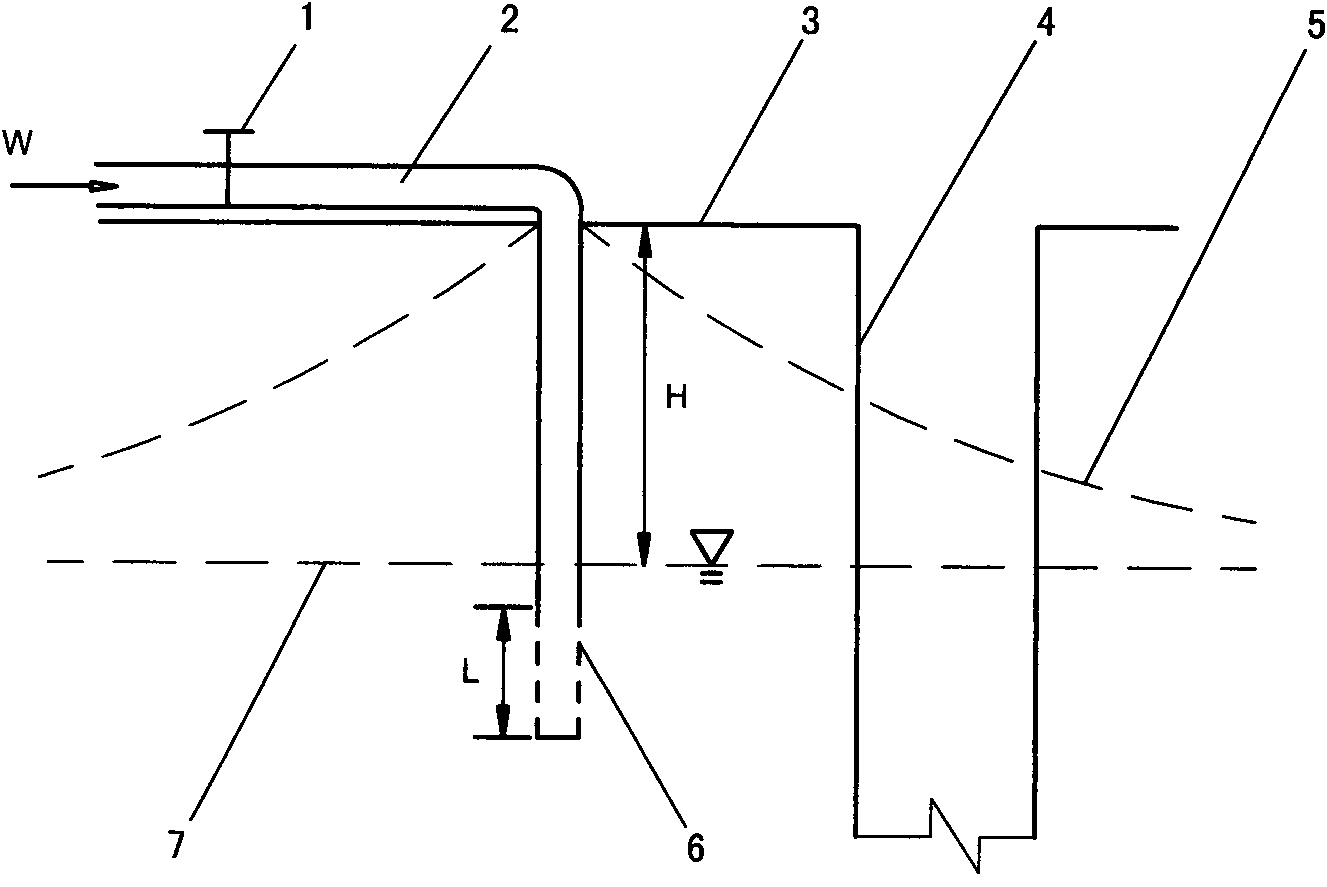

Method of inhibiting smoke plug-holing to improve natural smoke extraction efficiency of vertical shaft

InactiveCN106703865AImprove natural smoke extractionWill not affect trafficDust removalFire preventionEngineeringSmoke flow

The invention provides a method of inhibiting smoke plug-holing to improve natural smoke extraction efficiency of a vertical shaft; a retaining plate is arranged in the lower portion of a vertical shaft in a tunnel in order to change movement condition of a smoke flow in the tunnel and the vertical shaft in case of a fire, smoke layering plug-holing is inhibited, and smoke extraction effect is improved. The tunnel is 60 m long, 12 m wide and 5.4 m tall, the cross section of an upper opening of the vertical shaft is 3 m in length and 3 m in width, the section of a lower opening is 5 m in length and 3 m in width, the lower portion of the vertical shaft is 45 degrees angled to a tunnel roof, and such design is explained using the vertical shaft 5m tall as an example; meanwhile, the area of the retaining plate is 0.5-2.0 times the area of the lower opening of the vertical shaft, a vertical distance from the retaining plate to the tunnel roof is 0.06-0.28 times the height of the tunnel, plug-holing can be inhibited, and smoke extraction efficiency is improved greatly. The method has the advantages that the structure is simple, economic input is low, the adverse influence on smoke extraction due to plug-holing during natural smoke extraction of the vertical shaft can be overcome effectively, and the method has a promising application prospect and important practical significance.

Owner:UNIV OF SCI & TECH OF CHINA

Deep well drilling waterpower deslagging device of floor anchor rod hole of tunnel

InactiveCN101749039AIncrease drilling speedAdd depthShaft equipmentAnchoring boltsInlet channelWell drilling

The invention relates to a deep well drilling waterpower deslagging device of a floor anchor rod hole of a tunnel, which effectively solves the difficulties that the deslagging effect in the drilling process of a floor anchor rod hole drilling device and the increase of the drilling rate of the anchor rod hole is restricted. The invention has the technical scheme that a drill pipe both ends of which extend out of a sleeve is arranged in the sleeve, the upper end of the drill pipe is connected with an upper connector connecting piece, the lower end of the drill pipe is connected with a lower connector connecting piece, the upper end and the lower end of the drill pipe and the sleeve are fixed together via a closed-type bearing and a bearing sleeve connecting piece to form a deslagging structure with a dewatering and deslagging channel, the periphery wall of the drill pipe is provided with a spirally wound annular rib, a water inlet channel is arranged in the drill pipe, and the deslagging structures are connected with each other via a sleeve connecting pipe. The invention has the advantages of simple structure, convenient operation and good deslagging effect, greatly increases the drill rate and hole forming depth of the floor anchor rod, and is innovative on a deslagging device.

Owner:HENAN POLYTECHNIC UNIV

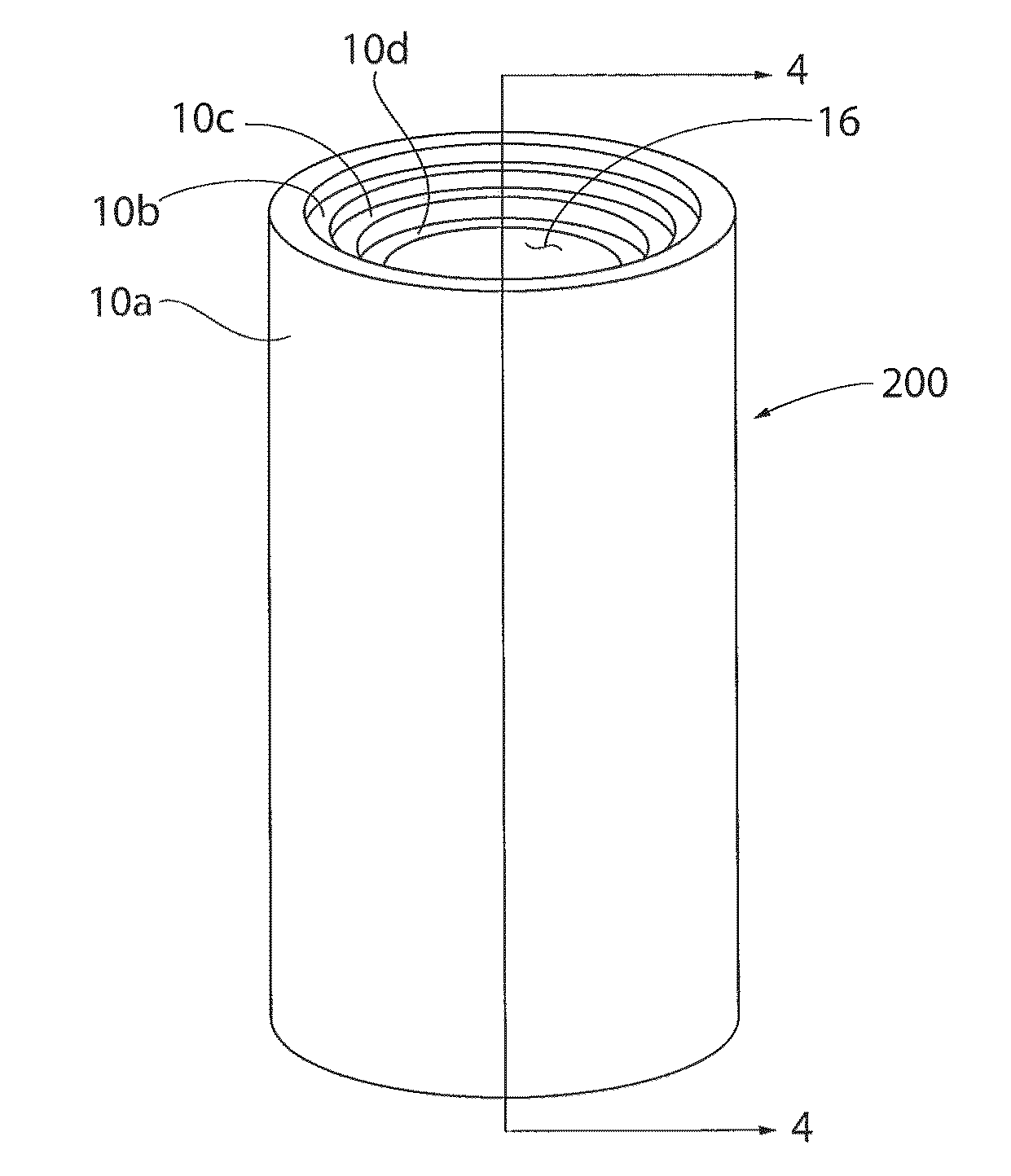

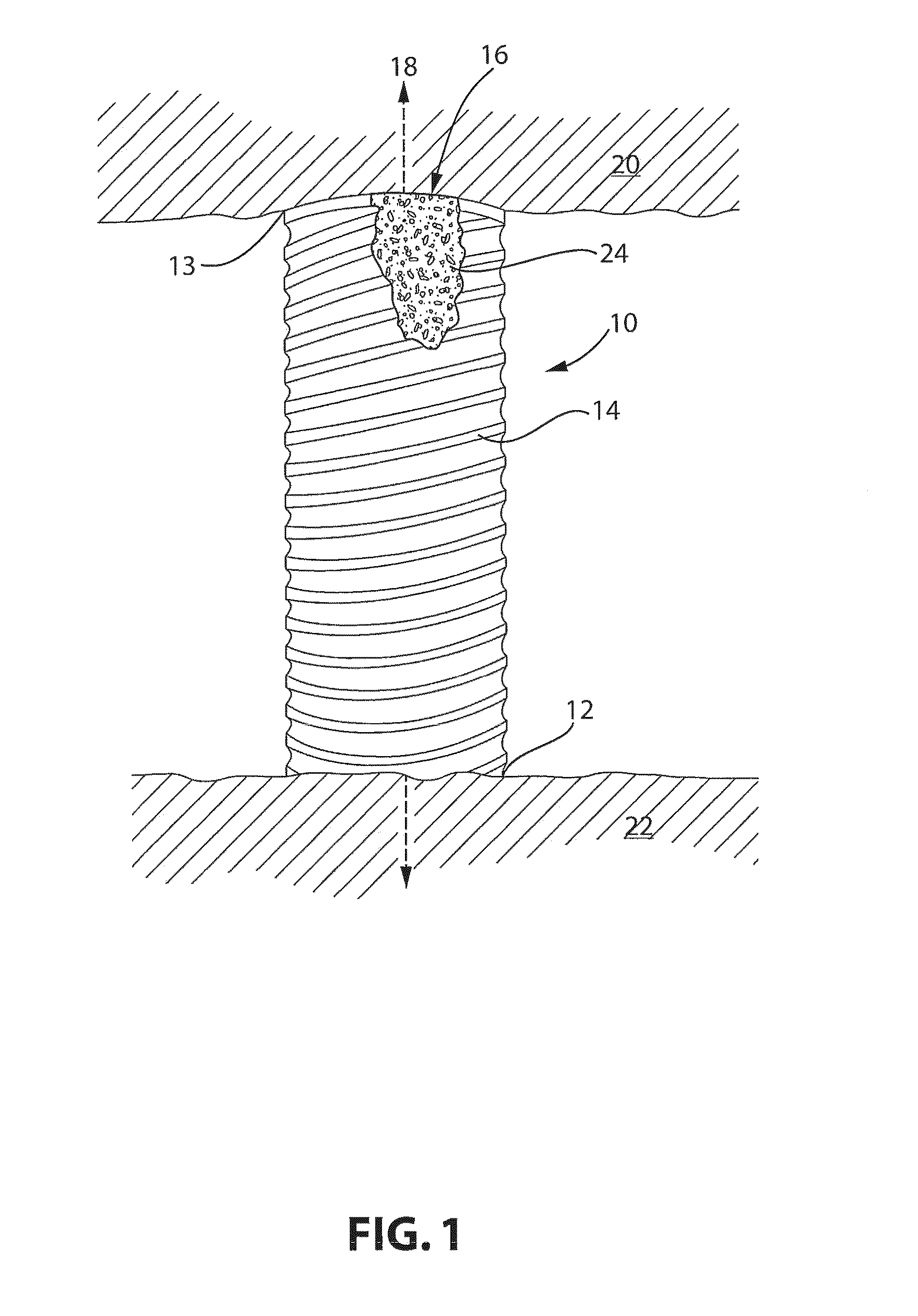

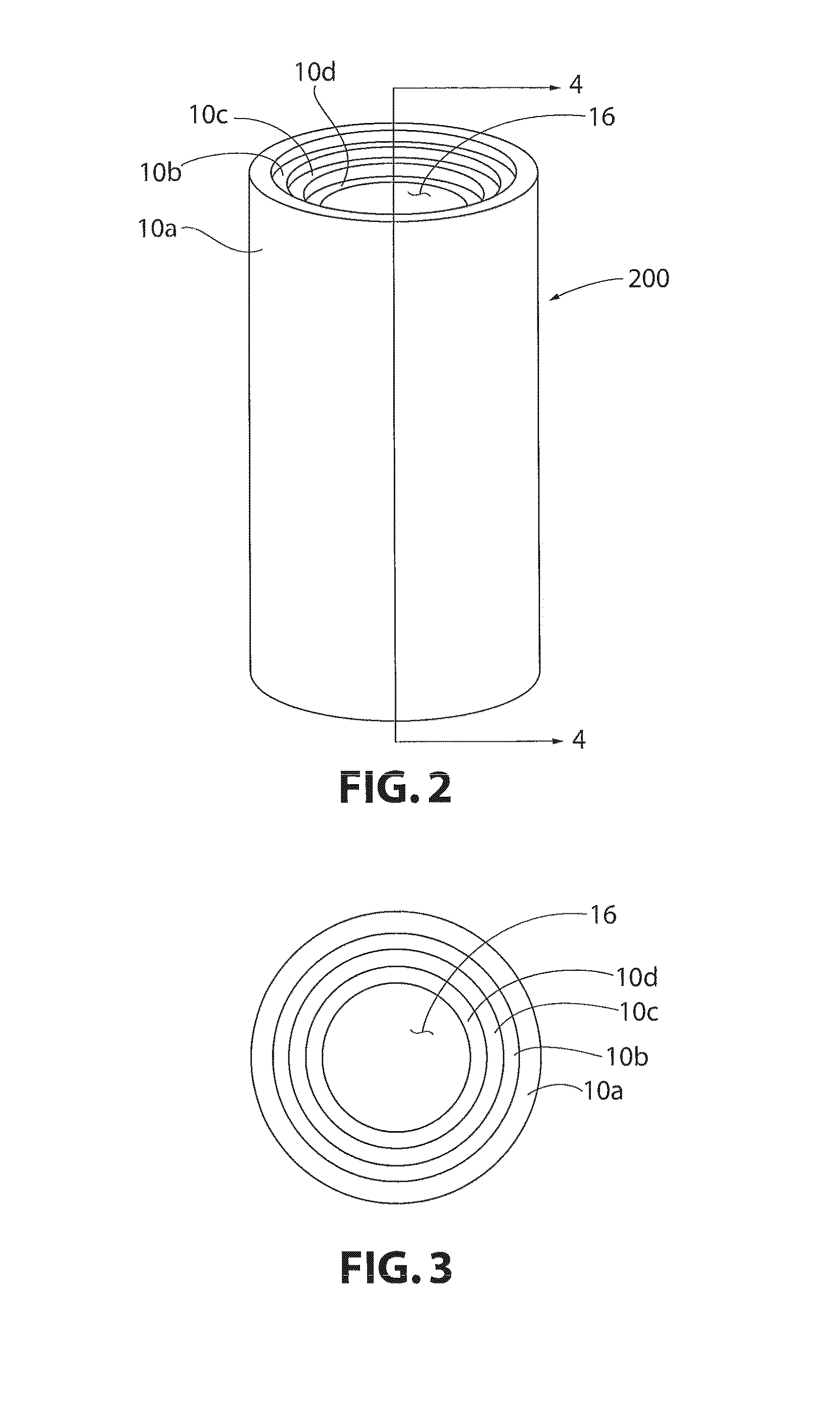

Nested mine roof supports

This invention is directed to a means for transporting a mine roof support set including a plurality of nested containers. Each container in the set has a progressively smaller cross-sectional dimension, or a tapered, frusto-conical shape, to allow the containers to be nested one within the other. The plurality of nested containers allows more efficient transportation of the mine roof support set to a mine site. The containers can be separated at the mine site and filled with a load-bearing material. The containers filled with the load-bearing material are then placed with their longitudinal axis between a mine roof and a mine floor.

Owner:MICON

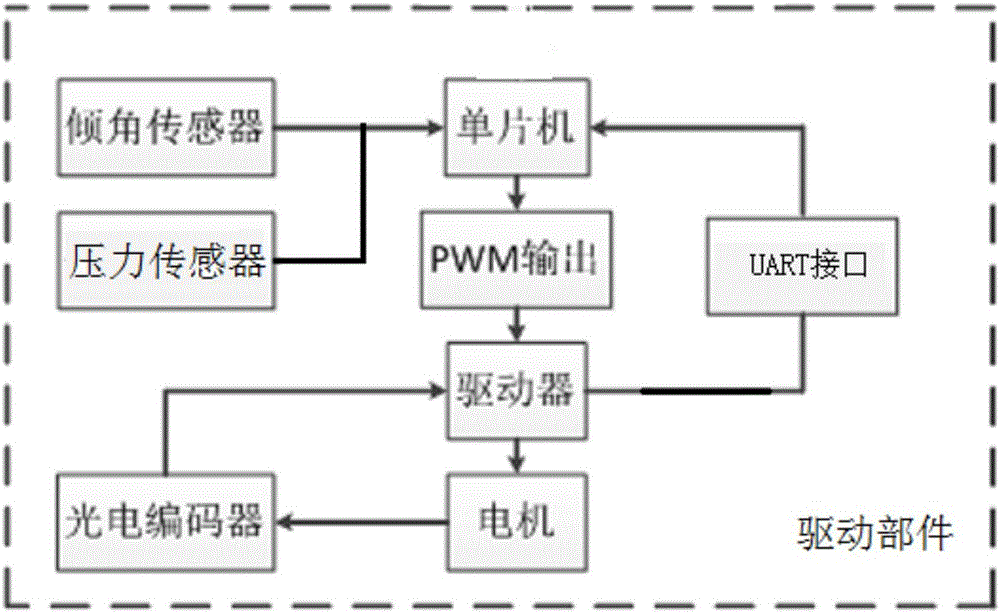

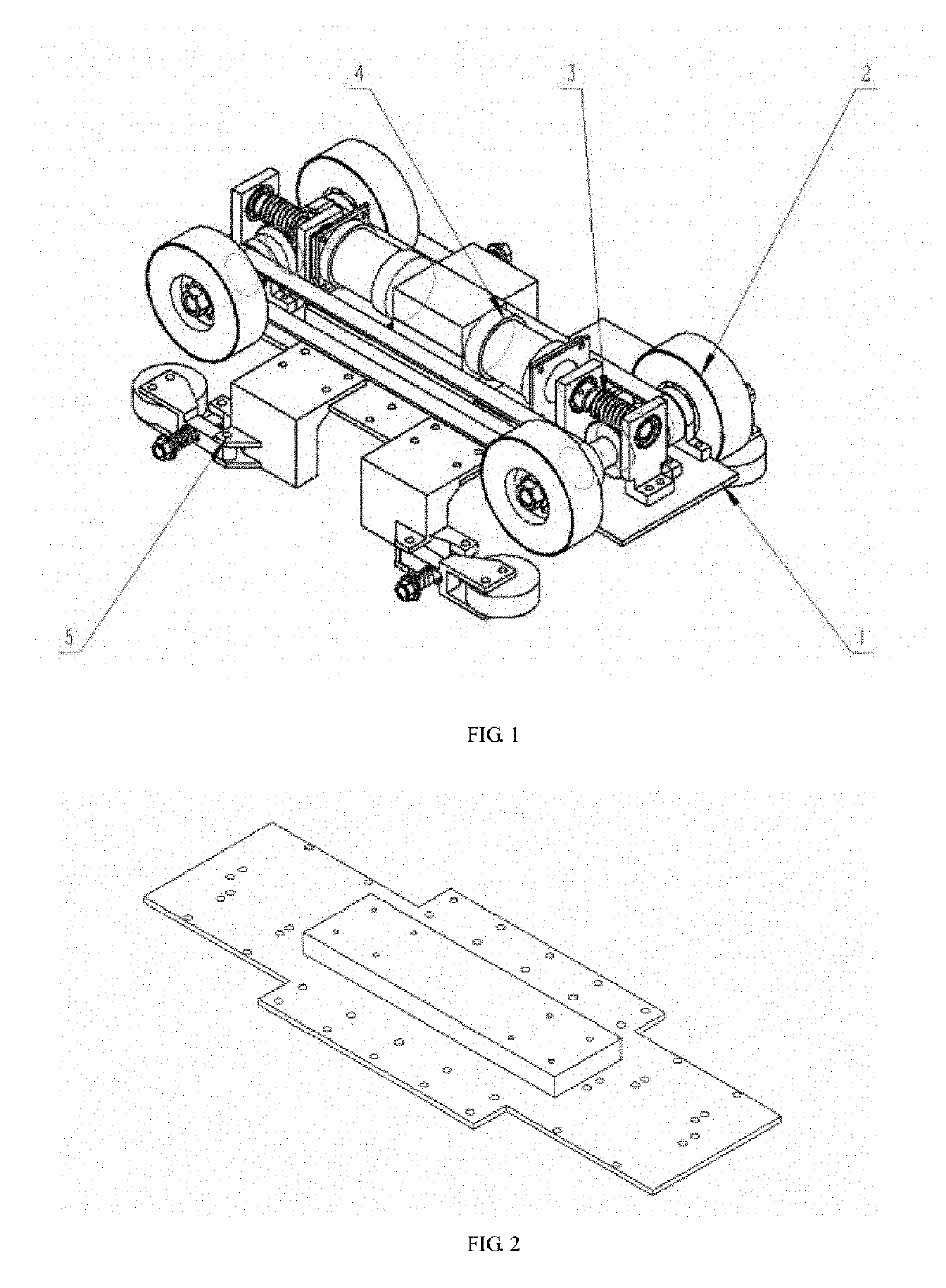

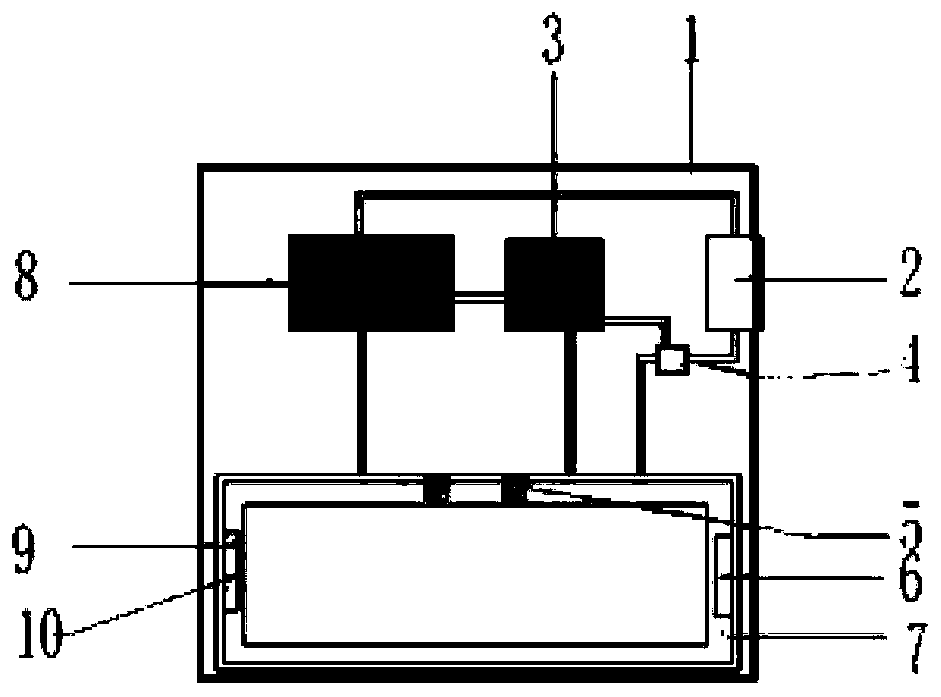

Routine inspection device and method for rigid cage guides

ActiveCN106394717ADetection speedImprove detection accuracyMining devicesElevatorsElectricitySurface layer

The invention discloses a routine inspection device and method for rigid cage guides. The routine inspection device comprises a moving component, a transmission component, a driving component, a guiding component and an outer shell, wherein the moving component, the transmission component, the driving component, the guiding component and the outer shell are arranged on a main body base plate. The driving component comprises an inclinometer and a pressure sensor, wherein the inclinometer and the pressure sensor are connected with a single chip microcomputer; the single chip microcomputer is connected with a driver; the driver is connected with brushless direct-current motors; and an output shaft of each brushless direct-current motor is provided with an optical-electricity encoder connected with the driver. The moving component comprises driving output shafts and driven output shafts; wheel flanges on the driving output shafts and wheel flanges on the driven output shafts are connected with wheel hubs; permanent magnets are arranged in the wheel hubs; and a rubber surface layer is arranged outside each wheel hub. The transmission component comprises worms, worm wheels, synchronous belt pulleys and synchronous belts, wherein each worm is connected with the output shaft of the corresponding brushless direct-current motor; each worm wheel is arranged on the corresponding driving output shaft and engaged with the corresponding worm; the synchronous belt pulleys are arranged on the driving output shafts and the driven output shafts; and the synchronous belts are wound on the synchronous belt pulleys. The guiding component comprises guiding wheels. By means of the routine inspection device and method for the rigid cage guides, rigid cage guide inspection speed is increased, and production efficiency of a coal mine enterprise is improved indirectly.

Owner:CHINA UNIV OF MINING & TECH

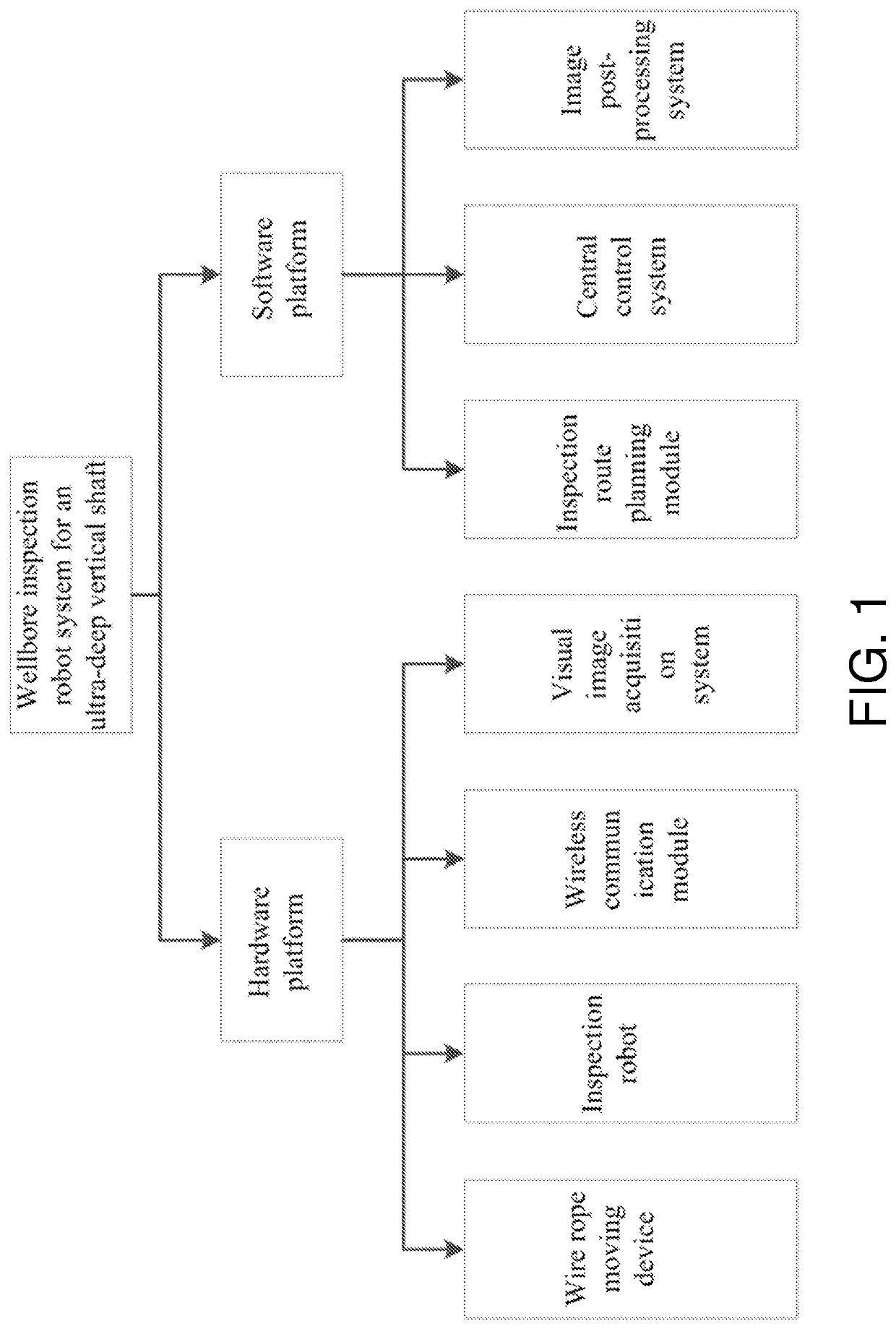

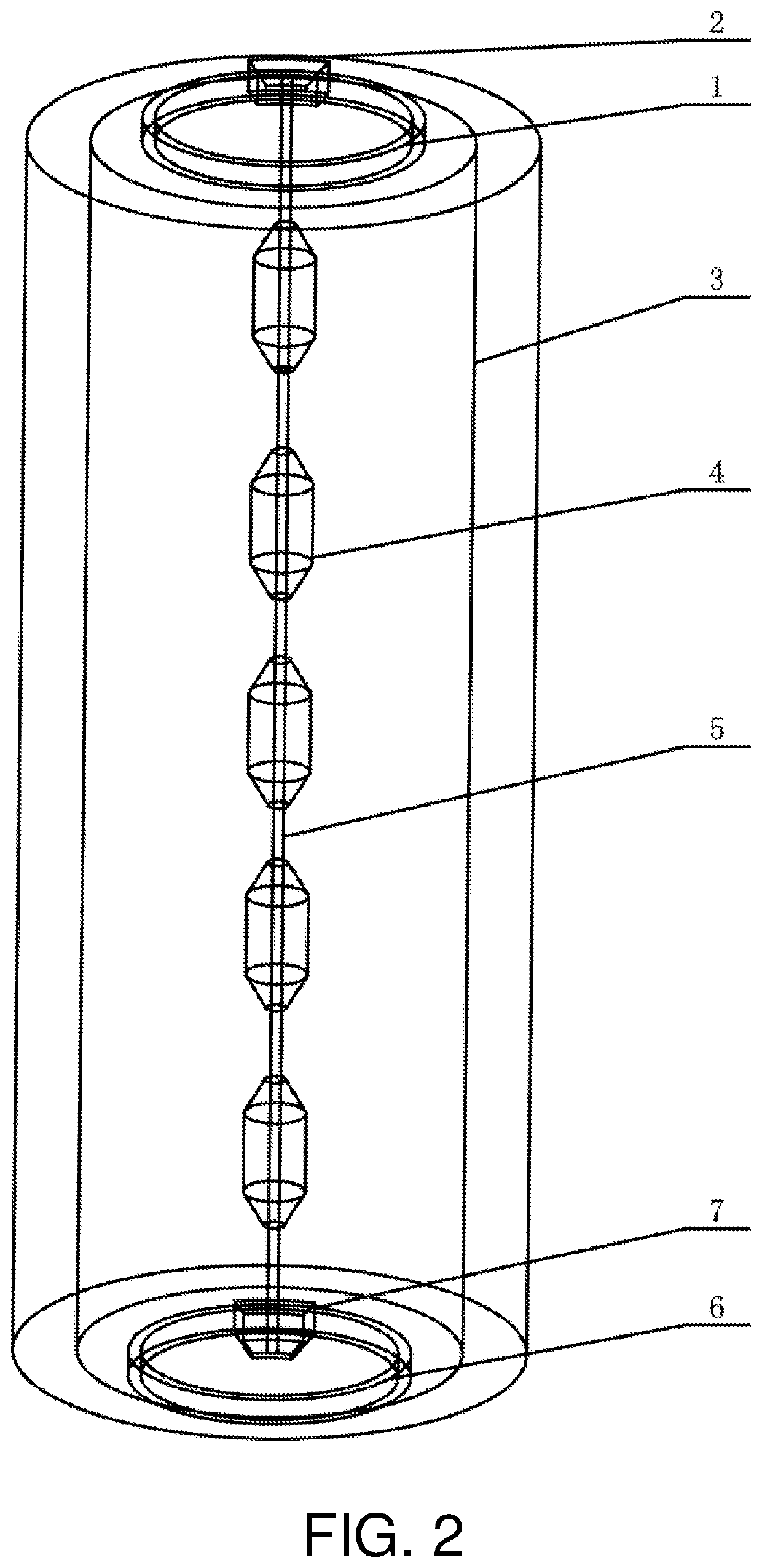

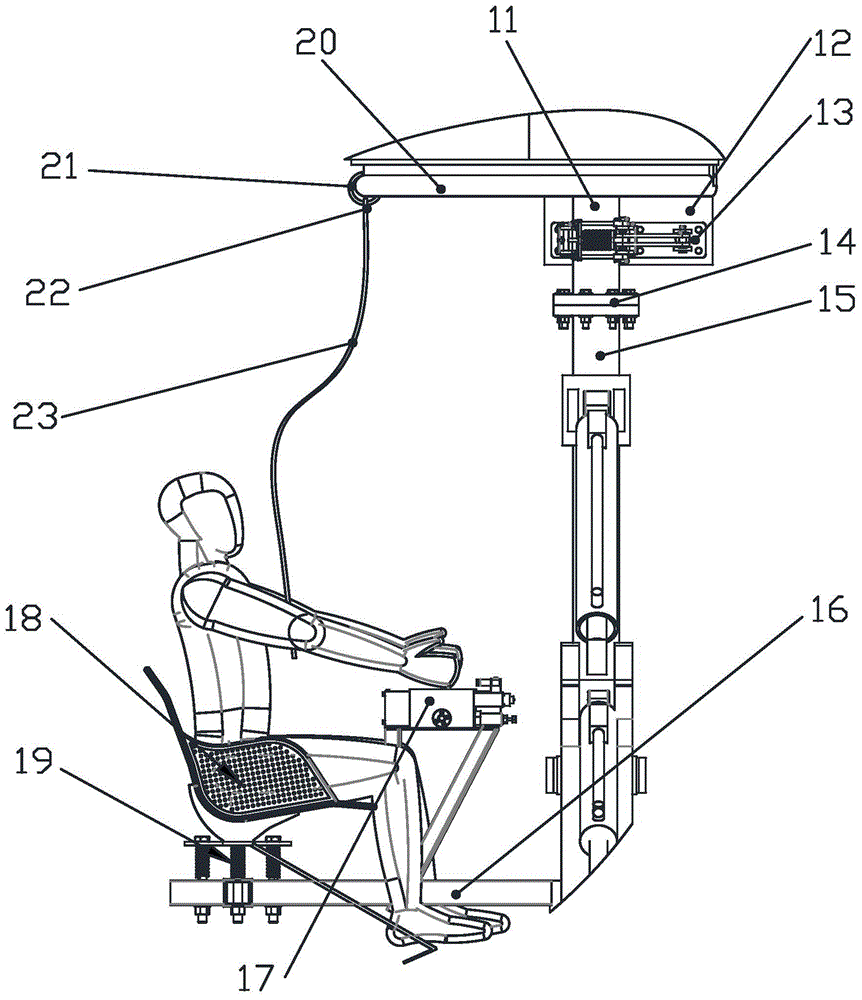

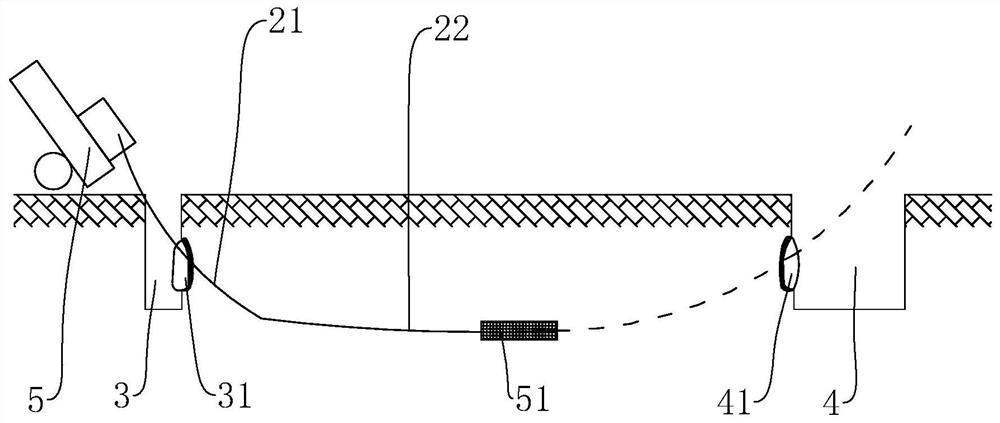

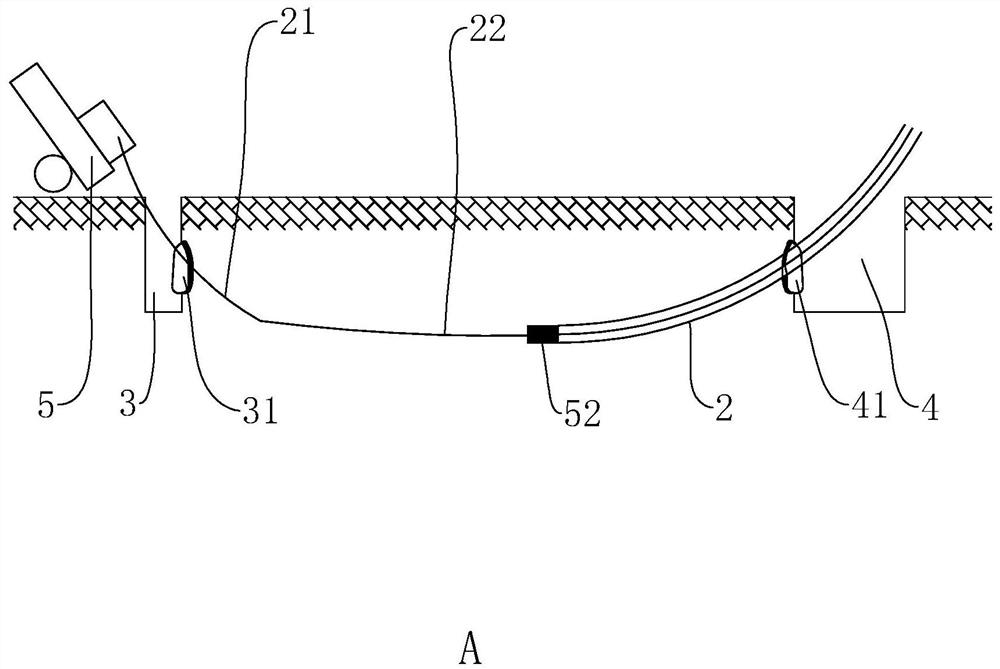

Wellbore inspection system and method for ultra-deep vertical shaft

ActiveUS20210262336A1Real time monitoringGuaranteed uptimeTelevision system detailsDrilling rodsWireless image transmissionControl system

Disclosed are a wellbore inspection system and method for an ultra-deep vertical shaft. The wellbore inspection system includes a wire rope moving system, inspection robots, a visual image acquisition system, a wireless communication module, a central control system, and an image post-processing system of an upper computer. The wire rope moving system includes a surface wire rope guide rail, an underground wire rope guide rail, a surface wire rope moving device, an underground wire rope moving device, and a wire rope. The visual image acquisition system includes explosion-proof cameras. After image information acquired by the explosion-proof cameras is processed by a lower computer, the processed image is transmitted by a wireless image transmission module to the image post-processing system of the upper computer. The central control system is connected to the inspection robots and the wire rope moving system, and the inspection robots are connected to the central control system.

Owner:CHINA UNIV OF MINING & TECH

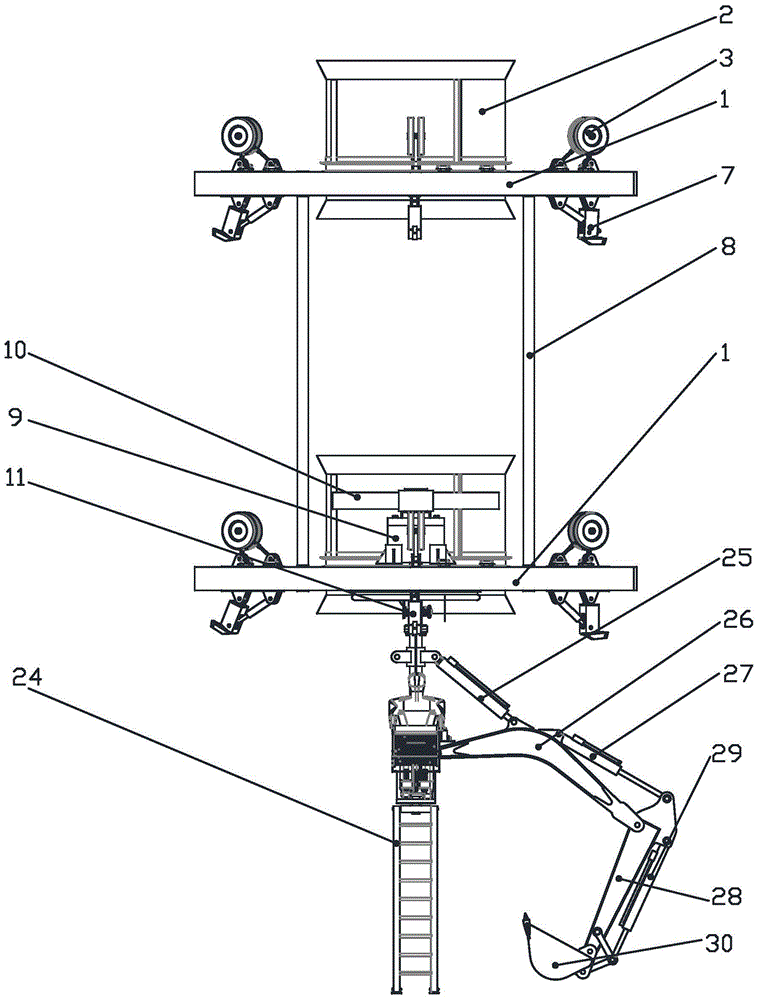

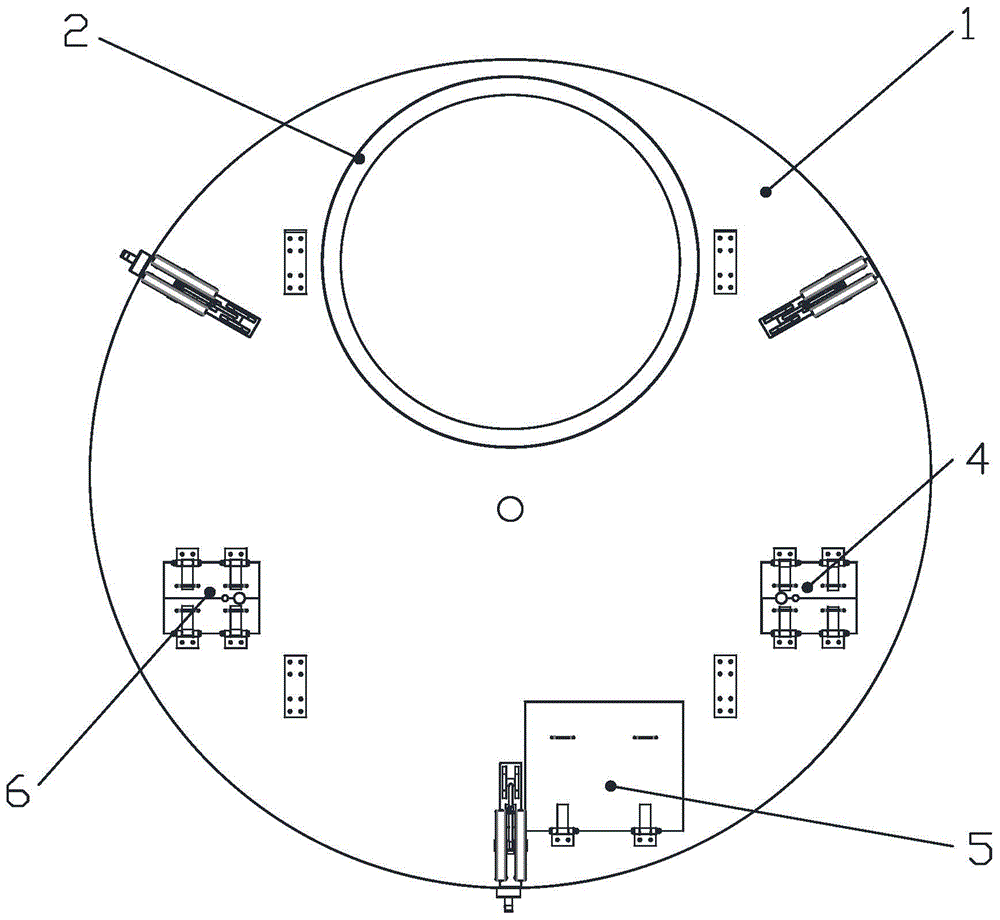

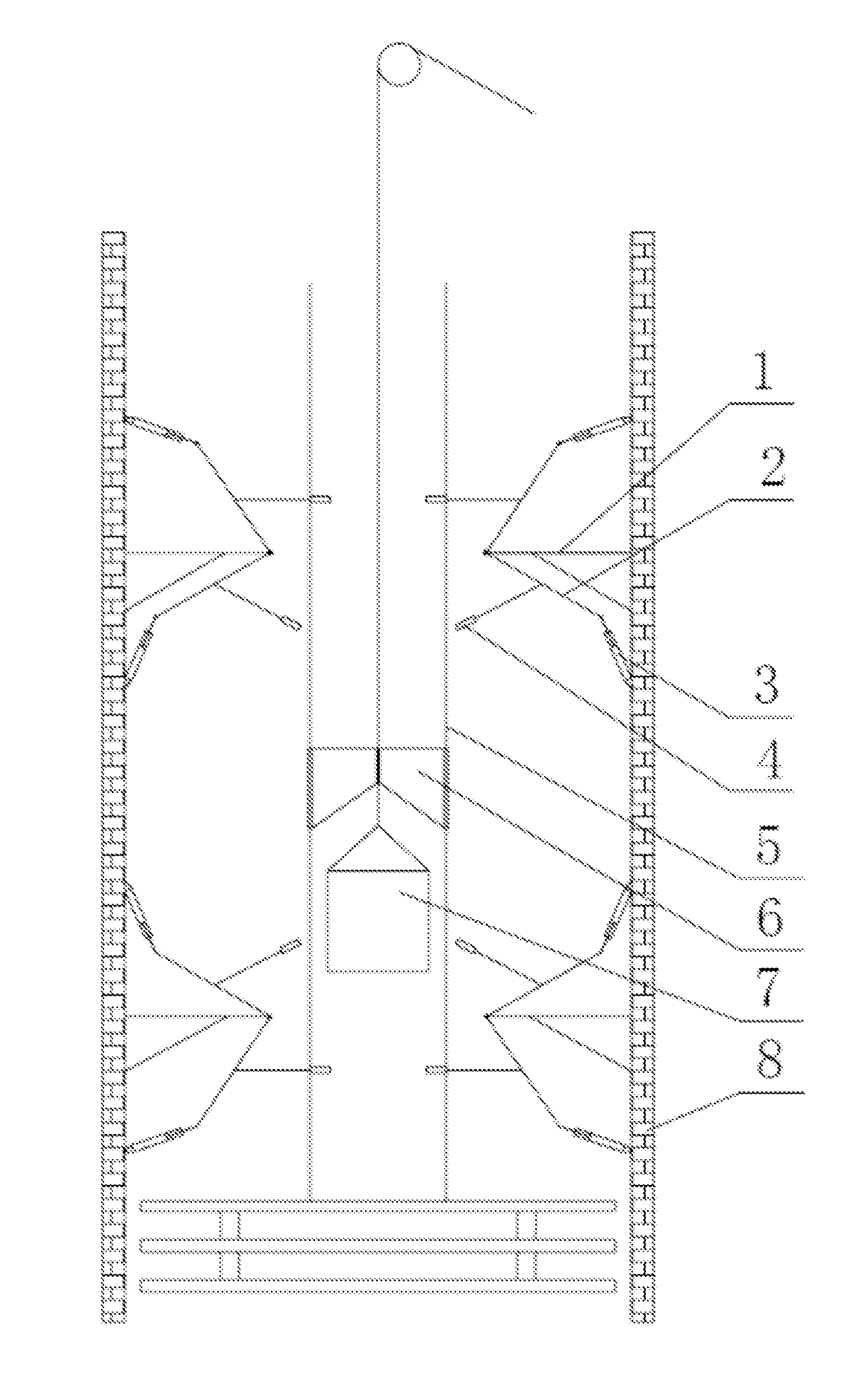

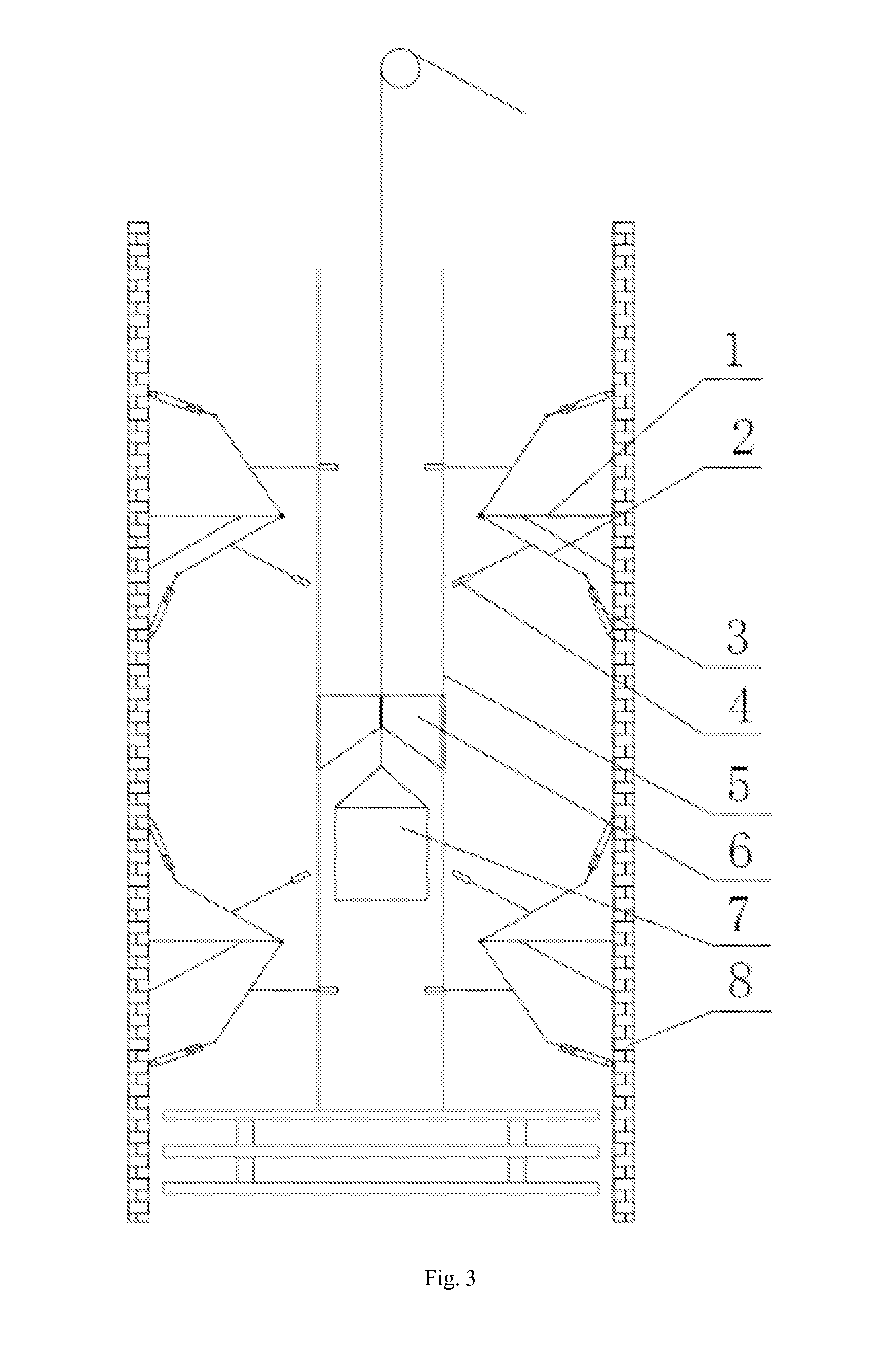

Special work robot for vertical shaft construction

InactiveCN104453916AEven by forceImprove positional stabilityShaft equipmentPower cableThrust bearing

The invention provides a special work robot for vertical shaft construction to solve the problems of an existing vertical shaft excavating device that mechanization degree is low and loading and crushing labor intensity is high. The robot comprises an upper hanging scaffold assembly and a lower hanging scaffold assembly, wherein the upper hanging scaffold assembly and the lower hanging scaffold assembly are fixedly connected through standing columns, each hanging scaffold assembly is provided with a horn mouth assembly, a power cable cover assembly, a manhole lid door assembly, a blasting cable cover door assembly, a tire support leg assembly and a well wall pressing device assembly, the lower hanging scaffold assembly further comprises a base assembly, a swing cylinder is arranged on the base assembly, the center of the lower hanging scaffold assembly is connected with a rotary shaft component in a penetrated mode, the swing cylinder is connected with the rotary shaft component through a radial bearing and a thrust bearing, an excavating assembly is connected to the lower side of the rotary shaft component, and a control panel is further arranged below the rotary shaft component and is provided with an electromagnetic proportional multi-way valve used for controlling the excavating assembly. By the adoption of the robot, automation degree is increased, labor intensity is relieved, labor efficiency is improved, and vertical shaft working face tunneling footage is increased.

Owner:SHANDONG UNIV OF SCI & TECH

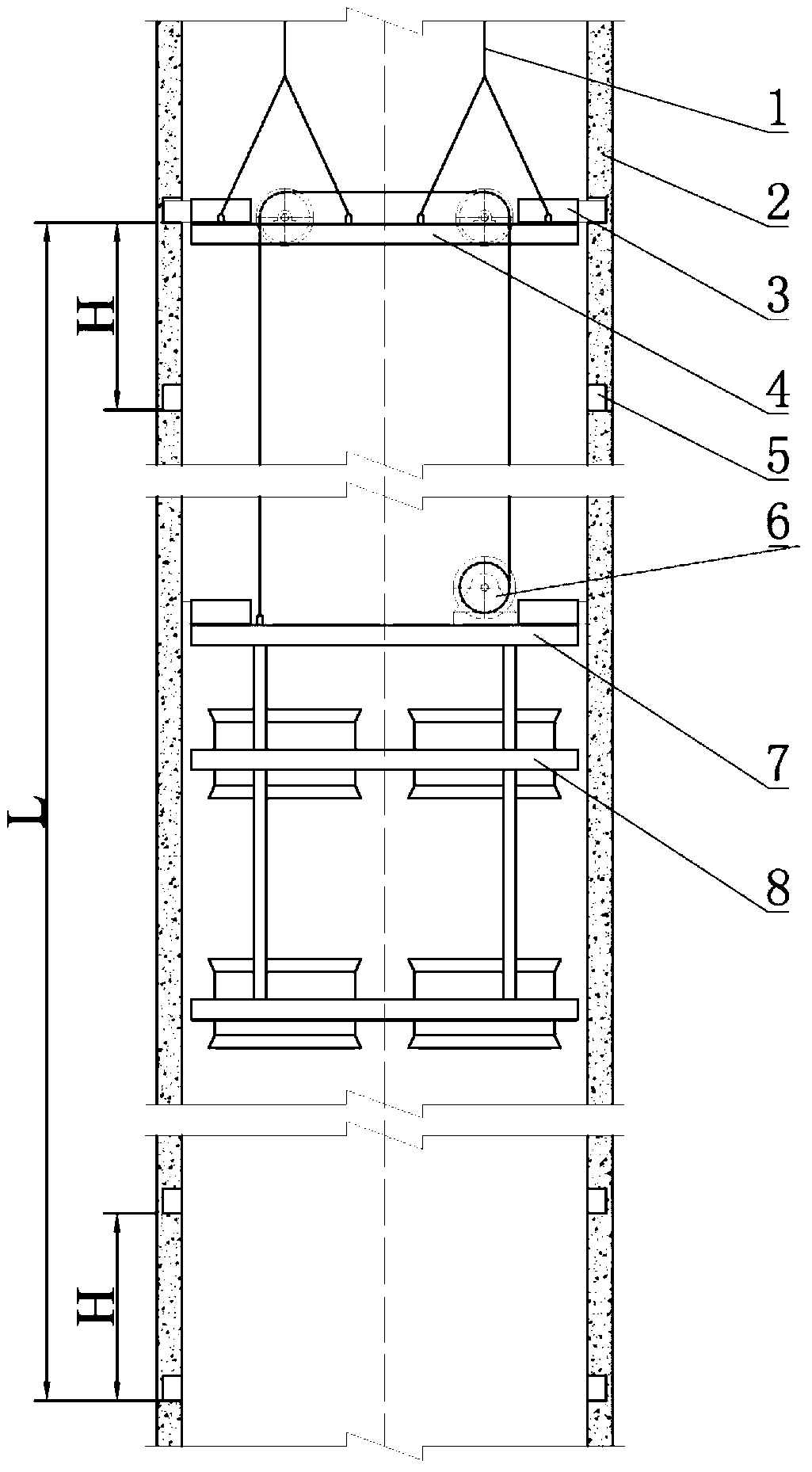

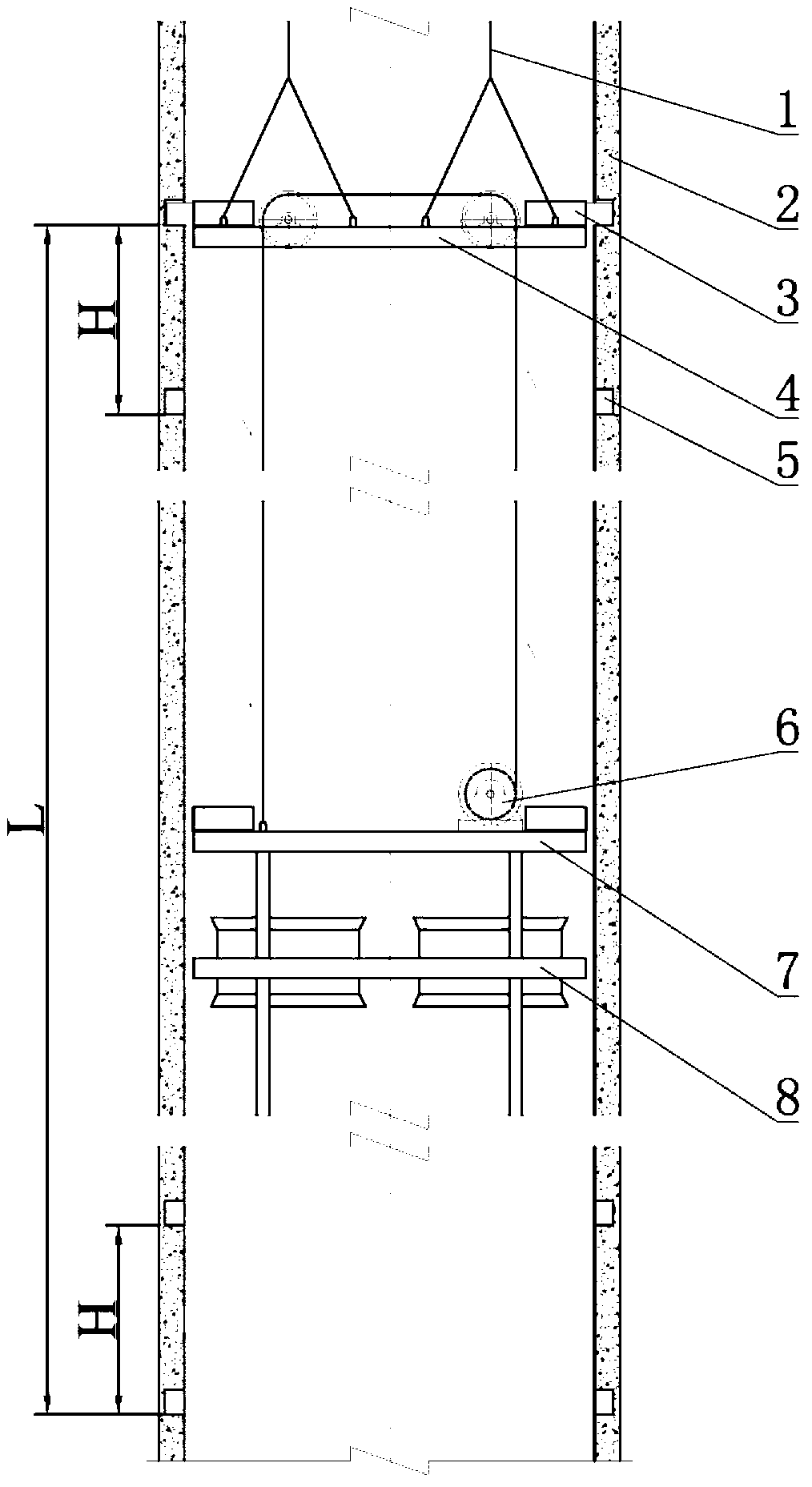

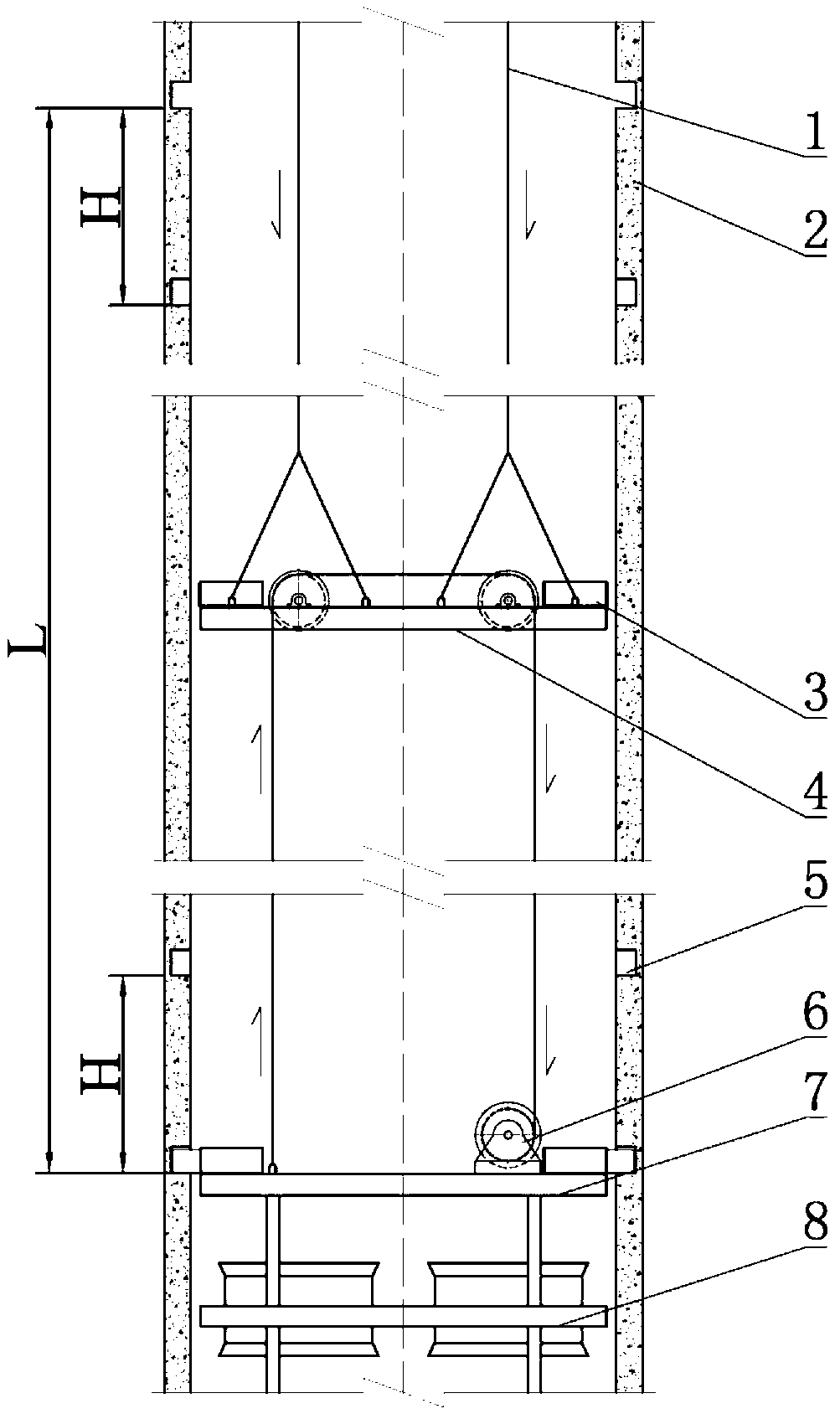

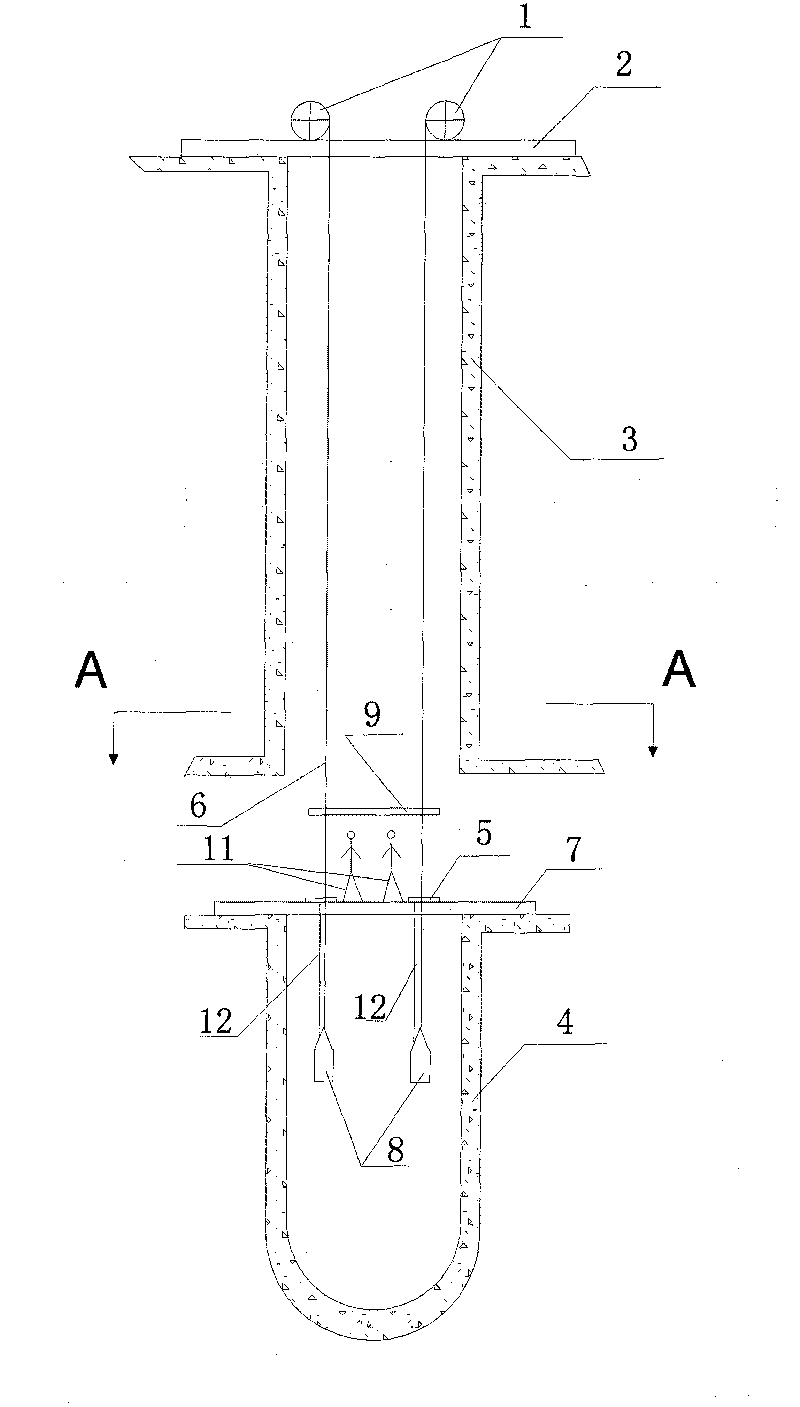

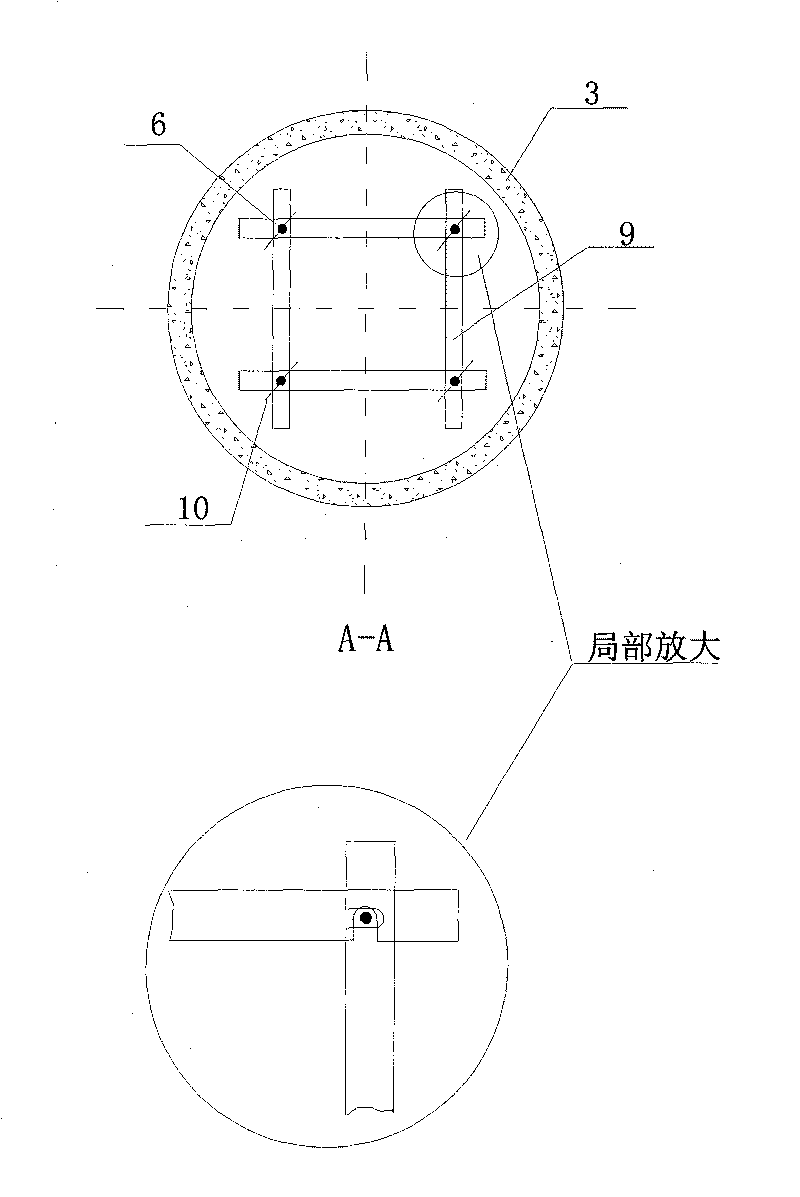

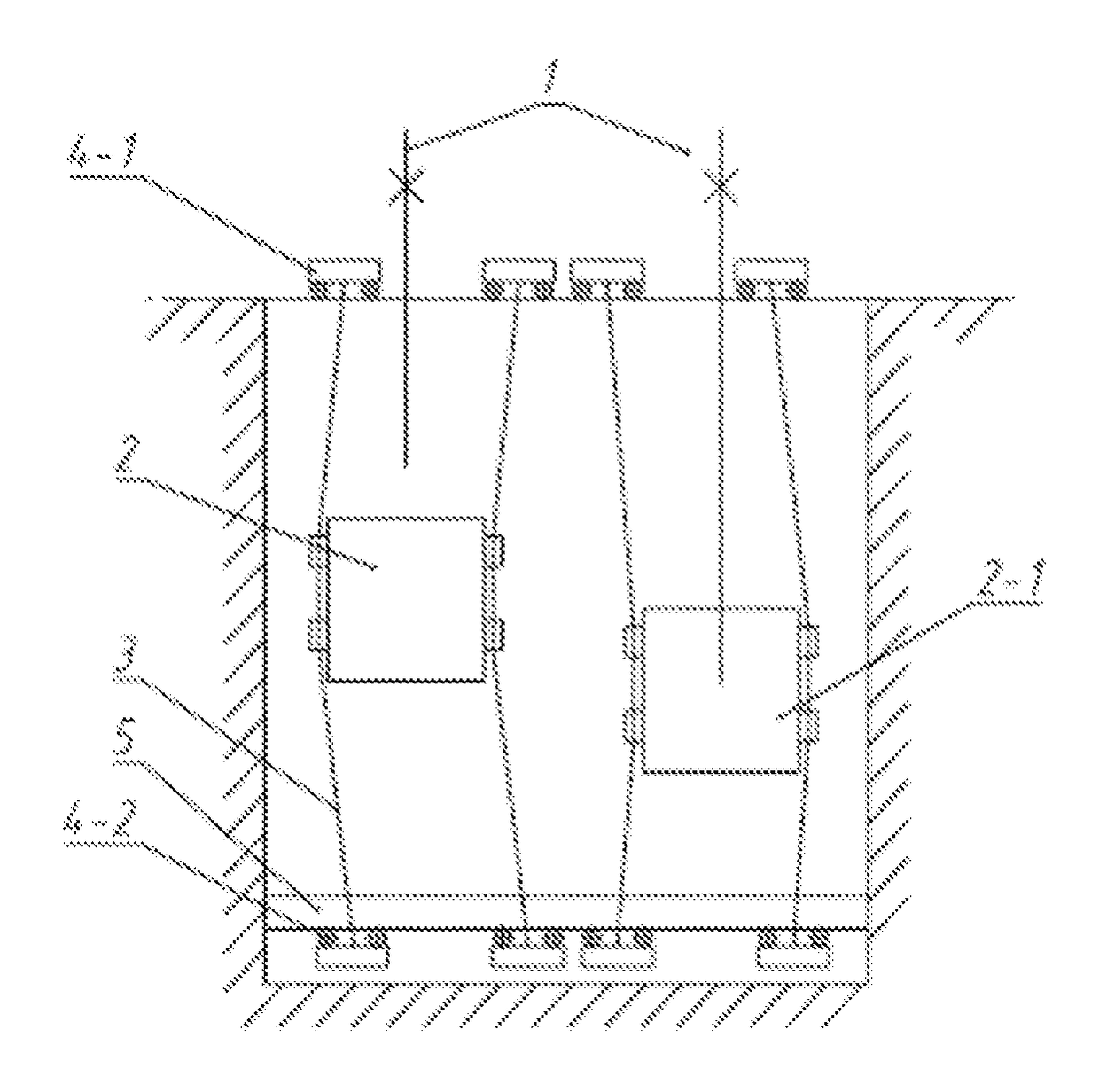

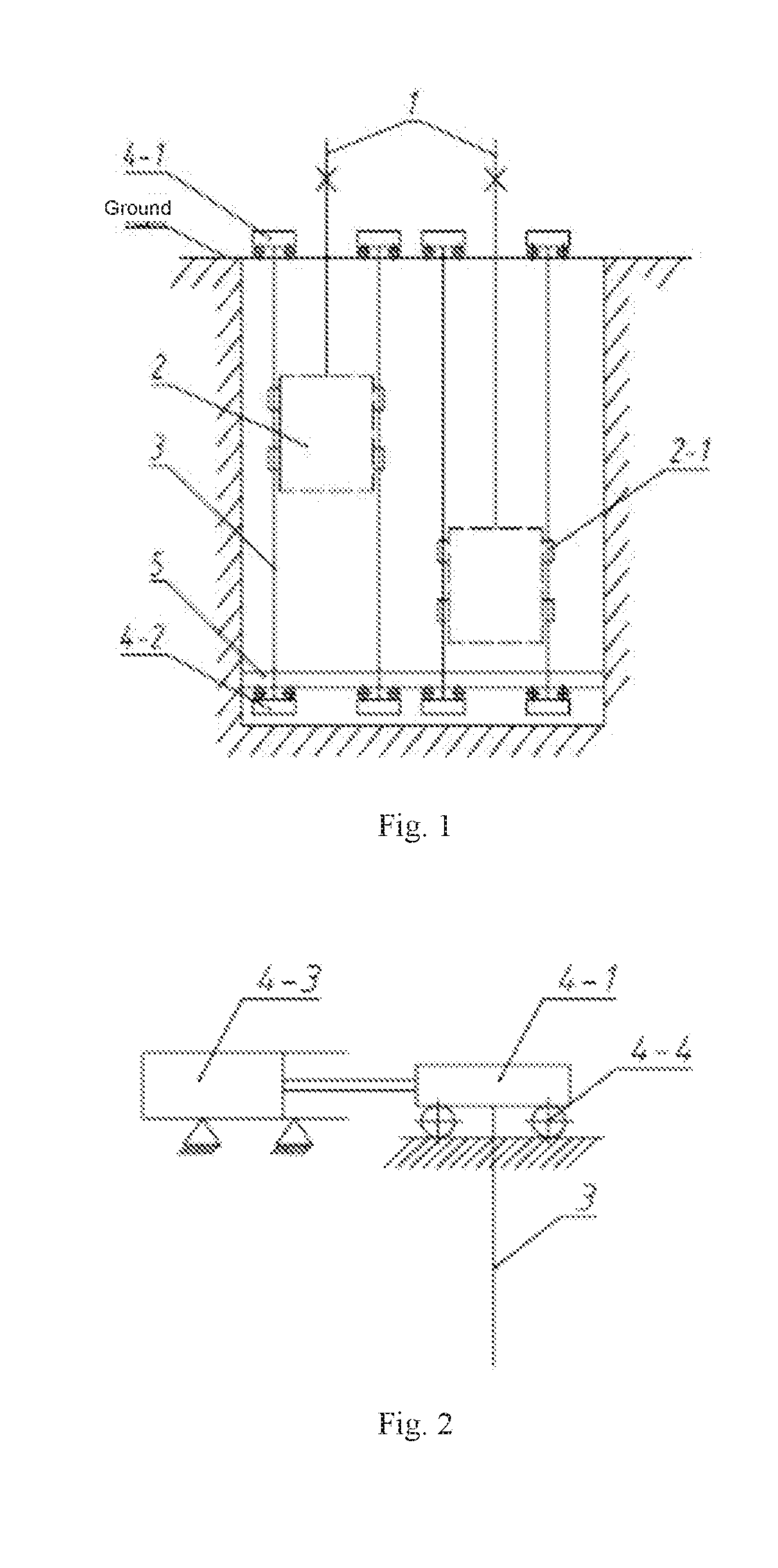

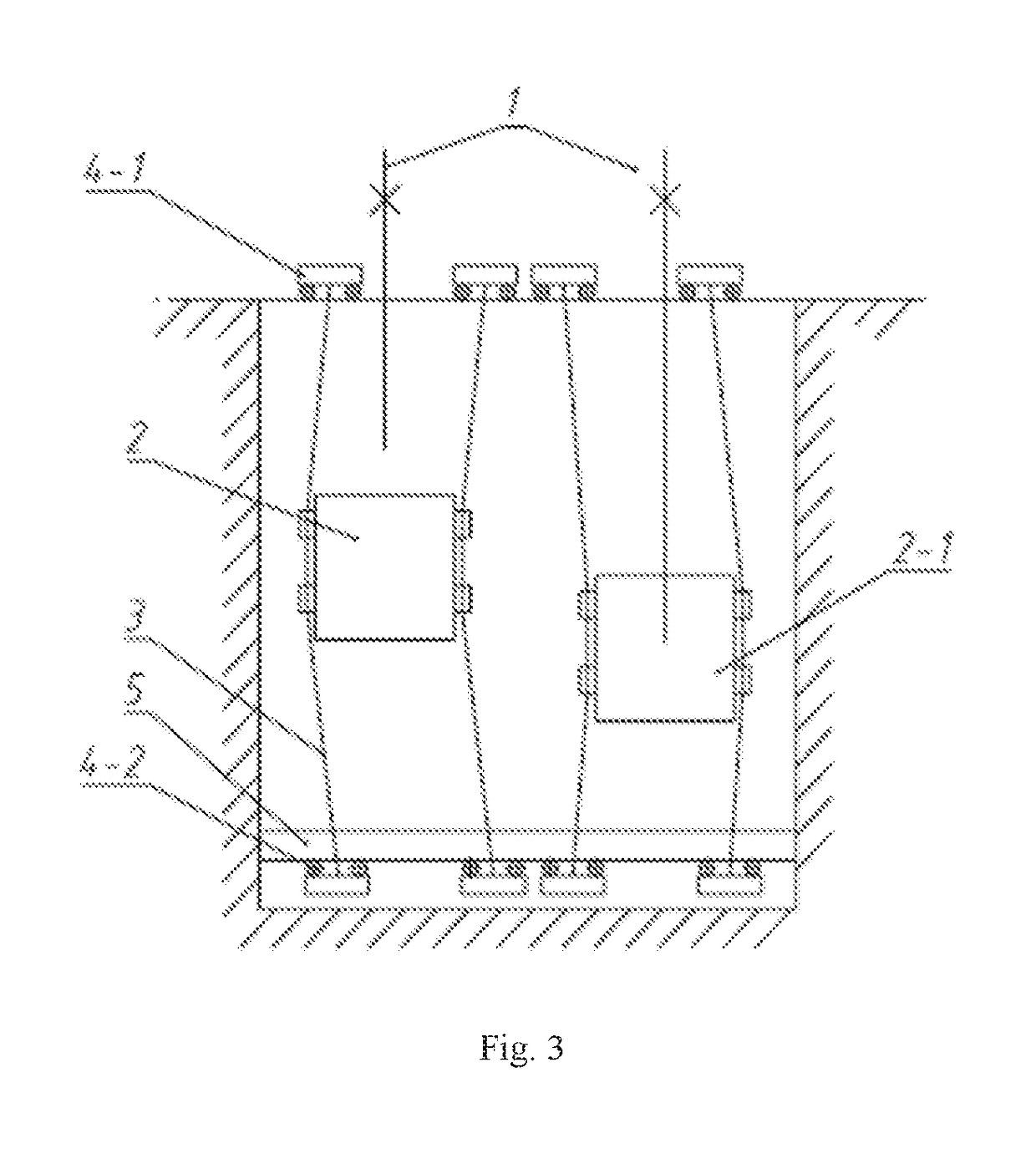

Sinking platform in-well hanging equipment and method

ActiveCN103277104ASolve the problem of suspensionSolving Mobility IssuesShaft equipmentEngineeringWinch

The invention discloses sinking platform in-well hanging equipment and method. The equipment comprises stabilizing ropes, an upper-layer platform, a lower-layer platform and a sinking work plate, the lower ends of the stabilizing ropes are connected with the upper-layer platform which is connected with the lower-layer platform through a steel wire rope hanging device, the sinking work plate is arranged at the bottom of the lower-layer platform, horizontal inserting and connecting devices are arranged at the outer edges of the upper-layer platform and the lower-layer platform, and a plurality of layers of beam sumps or annular grooves matched with the horizontal inserting and connecting devices are arranged along the vertical direction on the well walls. The sinking platform in-well hanging equipment integrates advantages of steel wire rope hanging of conventional platforms and beam-sump-type supporting of walking platforms, sinking platform in-well hanging without a ground sinking winch is realized, the problem that the sinking platform is difficult in hanging and inconvenient to move during existing deep vertical shaft construction are solved, and quickness, reliability and high efficiency in deep vertical shaft construction are realized.

Owner:CHINA UNIV OF MINING & TECH

Integral line stabilizing technique for vertical pit construction

InactiveCN101705824AEasy to quickly stabilize the lineRelatively dimensionally accurateShaft equipmentSteel tubeBuilding construction

During rockshaft equipment construction of mine vertical pit, to precisely install cage guide beams, cage guides and the like, a plurality of jug lines conforming to dimension stipulated by construction measures are required to be descended from the ground to rockshaft end opening before construction, and fixed firmly at the end opening to be as vertical reference positioning lines for installation of rockshaft equipment. A steel saw is adopted to saw notches on four steel tubes at the position corresponding to the jug lines according to the diameter of the jug lines to be as the positioning dimension and relative position for fixing two adjacent jug lines, and two ends of each steel tube stretch out of the fixing line. A construct can fix the four jug lines two by two with notch-sawed steel tubes near the line stabilizing beam in the pit to lead the four jug lines to form an integral square frame. The square frame can only sway as an integral in the process of line stabilizing without appearing any single jug line swaying solely. The relative dimension of the four jug lines is absolutely correct, after the jug line square frame stabilizes in the pit shaft, the operating personnel can fix the jug lines on the line stabilizing beam in the pit with a jug line fixing clip.

Owner:MECHANICAL & ELECTRICAL INSTALLATION ENG CO LTD OF CHINA COAL NO 3 CONSTR GRP CORP LTD

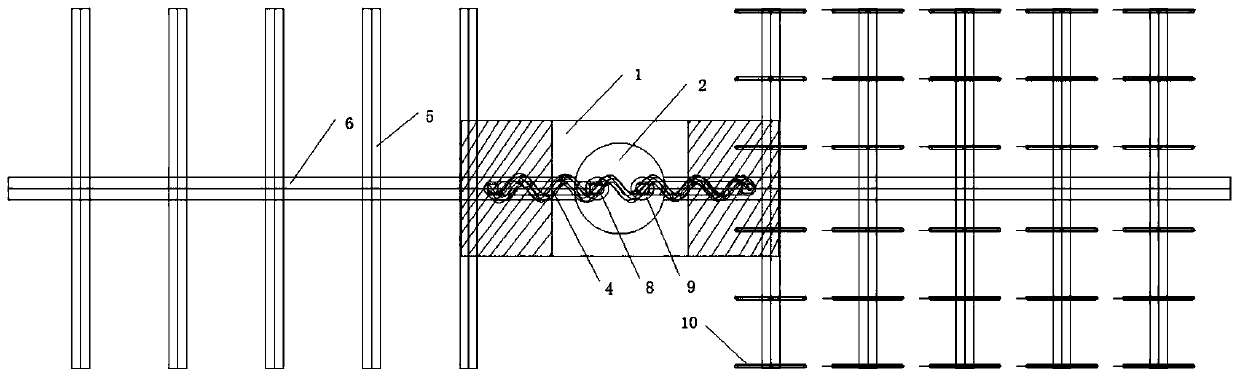

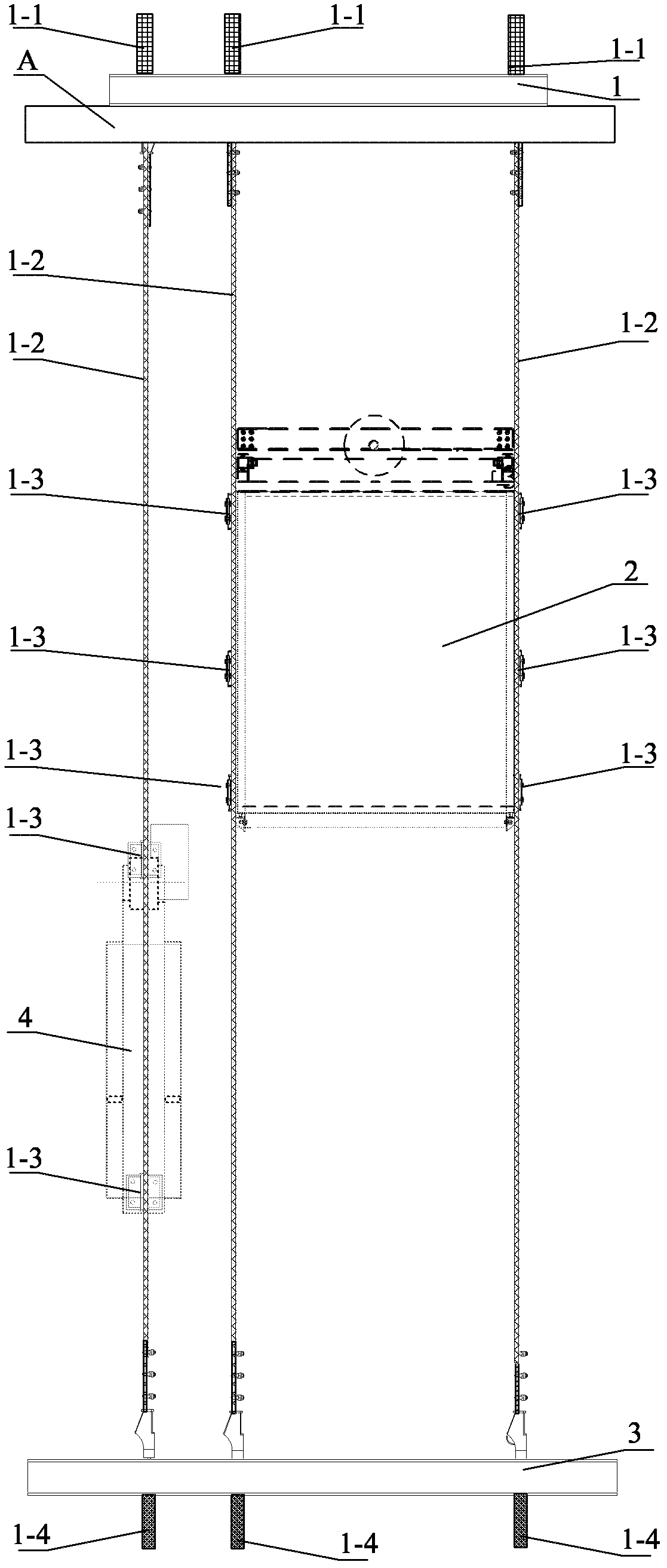

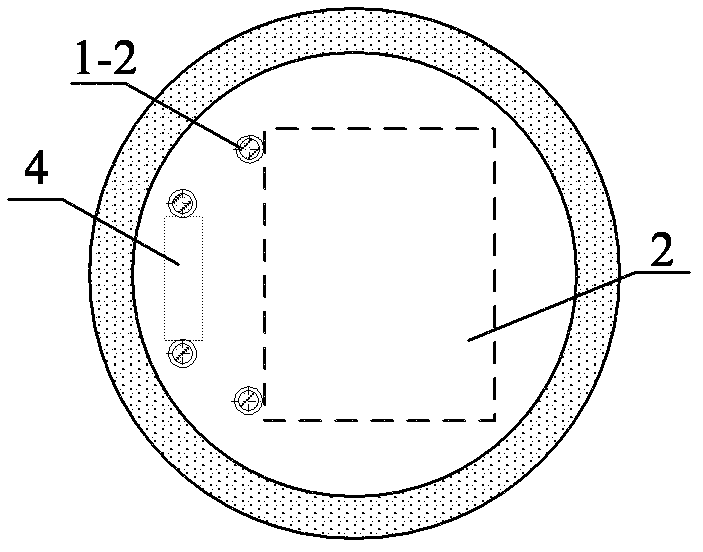

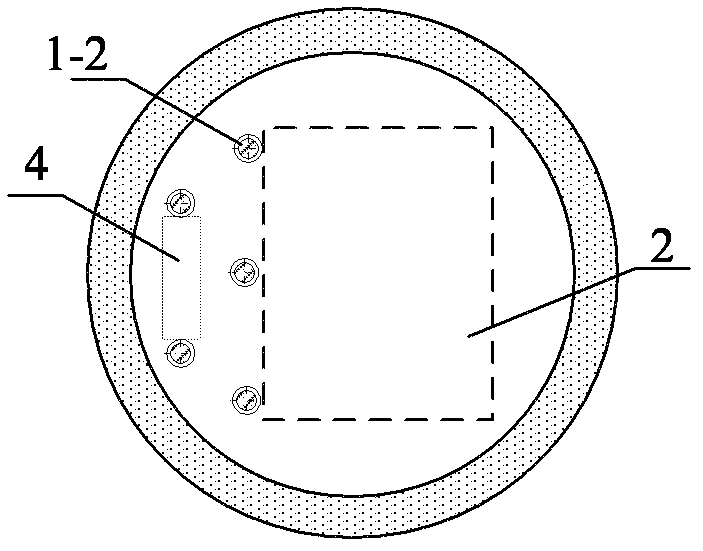

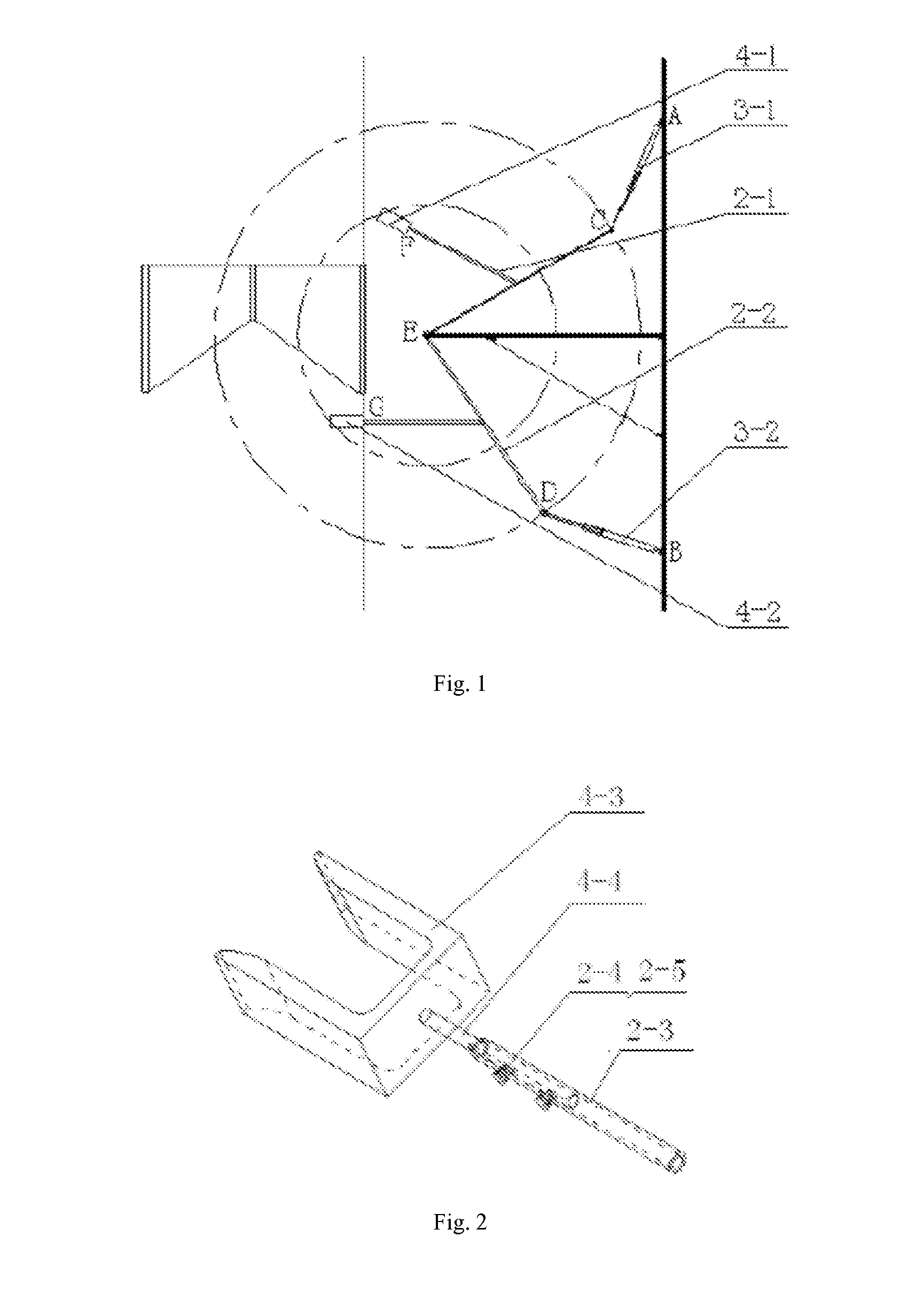

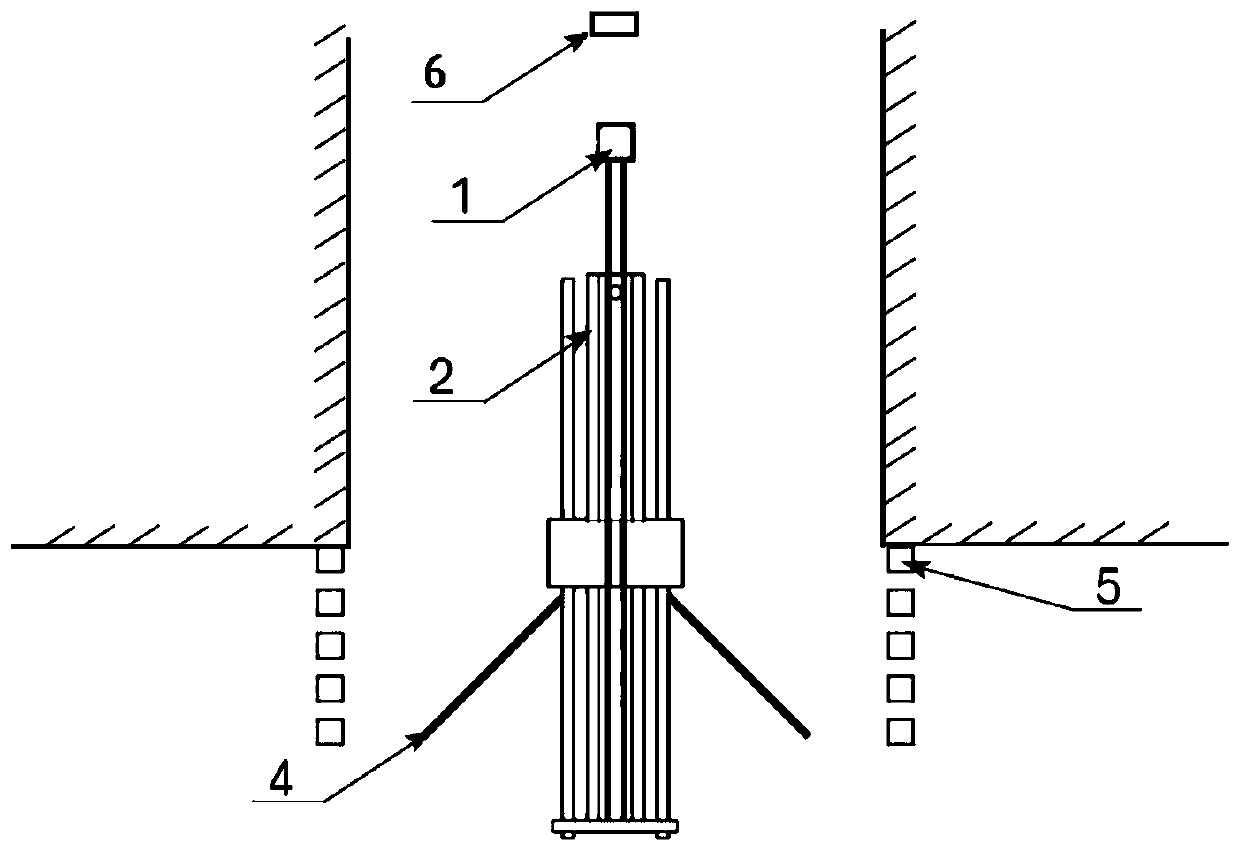

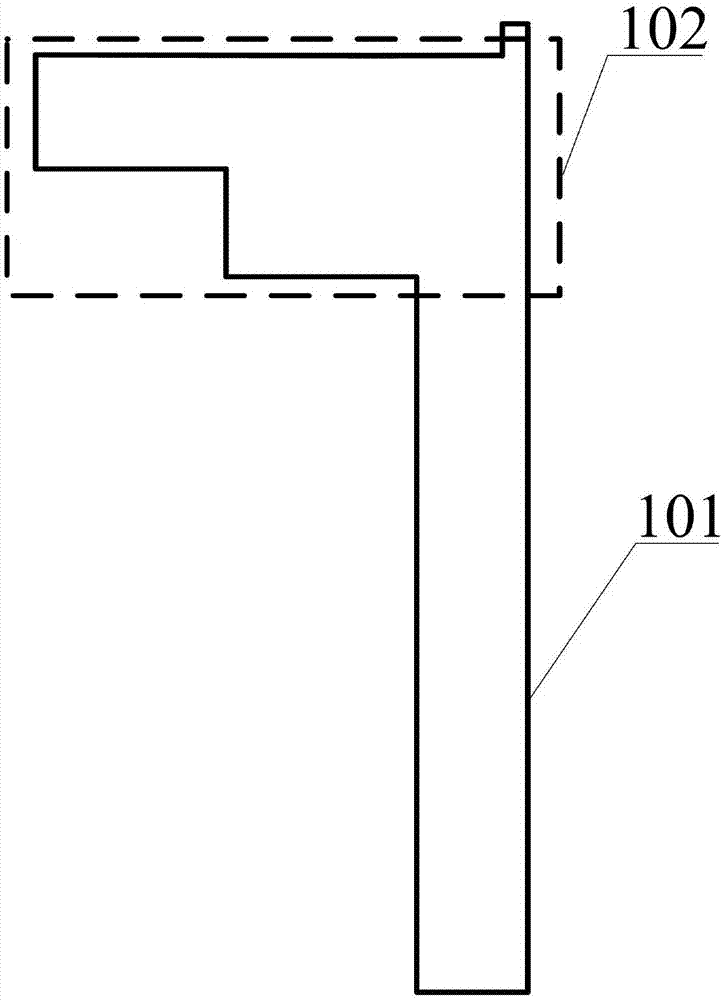

Guide rail rope deflection inhibition mechanism and method for parallel soft cable suspension system

InactiveUS20160017708A1Effective preservationImprove securityElevatorsMine liftsEngineeringBuilding construction

A guide rail rope deflection inhibition mechanism and method for a parallel soft cable suspension system in ultradeep vertical shaft construction. The guide rail rope deflection inhibition mechanism comprises a T-shaped installation support base, a rotating frame, a hydraulic support rod, and a chuck. The T-shaped installation support base comprises a vertical support rod and a horizontal support rod. The hydraulic support rod comprises an upper hydraulic support rod and a lower hydraulic support rod. The rotating frame comprises an upper Y-shaped frame and a lower Y-shaped frame. The chuck comprises an upper chuck and a lower chuck. The guide rail rope deflection inhibition method treats two guide rail rope deflection inhibition mechanisms as one group, and arranges at least two groups along the vertical direction on the shaft wall. While guaranteeing the smooth sliding of a direction guiding frame, the freedom of the guide rail rope part is restrained by the chuck, thereby enhancing the stability and safety of hoisting containers.

Owner:CHINA UNIV OF MINING & TECH

Suck throughpreventionsmoke exhausting auxiliary device of a tunnel shaft

ActiveCN110230494AImprove the effect of natural smoke extractionSuppresses the problem of sucking throughTunnel/mines ventillationShaft equipmentRescue workSmoke

The invention discloses suck throughprevention smoke exhausting auxiliary device of a tunnel shaft. The suck throughprevention smoke exhausting auxiliary device of the tunnel shaft is characterized inthat the tunnel shaft suck throughprevention smoke exhausting auxiliary device comprises a conical baffle, the conical baffle is arranged at the opening of the bottom of the tunnel shaft, the conicalbaffle is composed of two adjusting plates, the two adjusting plates are assembled in aherringbone shape, and the opening ofa herringbone faces downwards. Compared with the prior art, the suck throughprevention smoke exhausting auxiliary device of the tunnel shaft has the following advantages that the air suck through problem of natural smoke exhaust of the shaft is suppressedby adding an extra angleadjustable conical baffle under the shaft, temperature of external smokeis sensed through an additional sensor, the angle of the conical baffle is adjusted in real time to ensure that the efficiency of the natural smoke exhaust of the shaft is kept at a high level at all times and further ensure life safety of internally trapped personnel and favorable development of rescue work after fire occurs.

Owner:HEFEI UNIV OF TECH

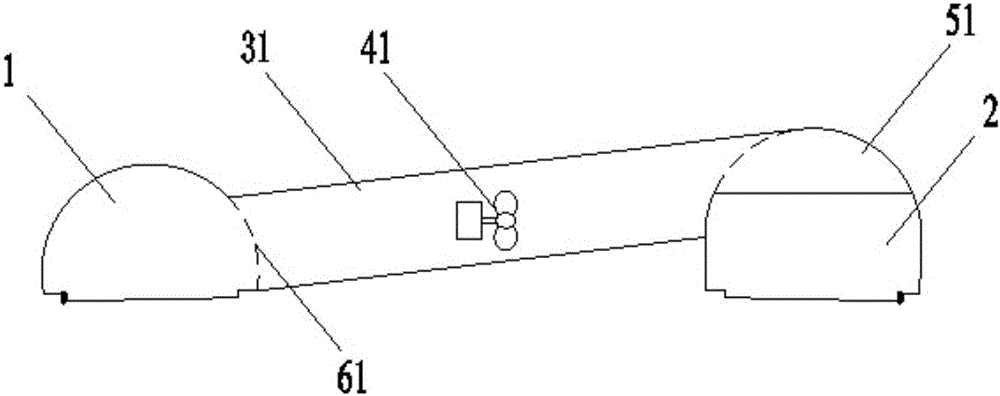

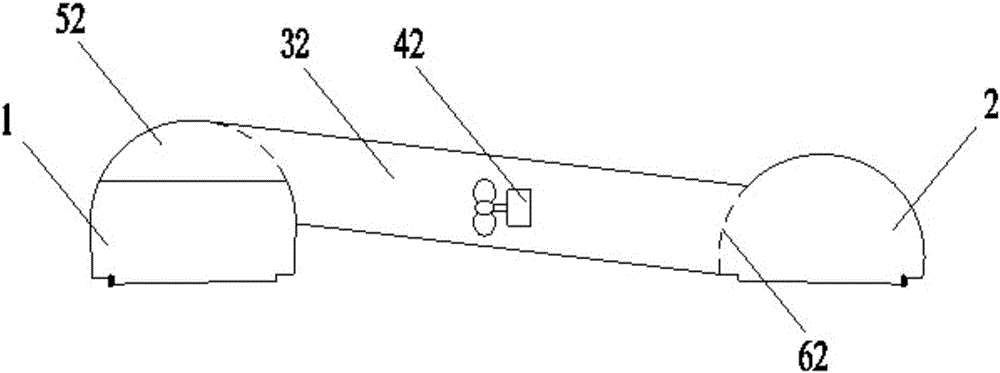

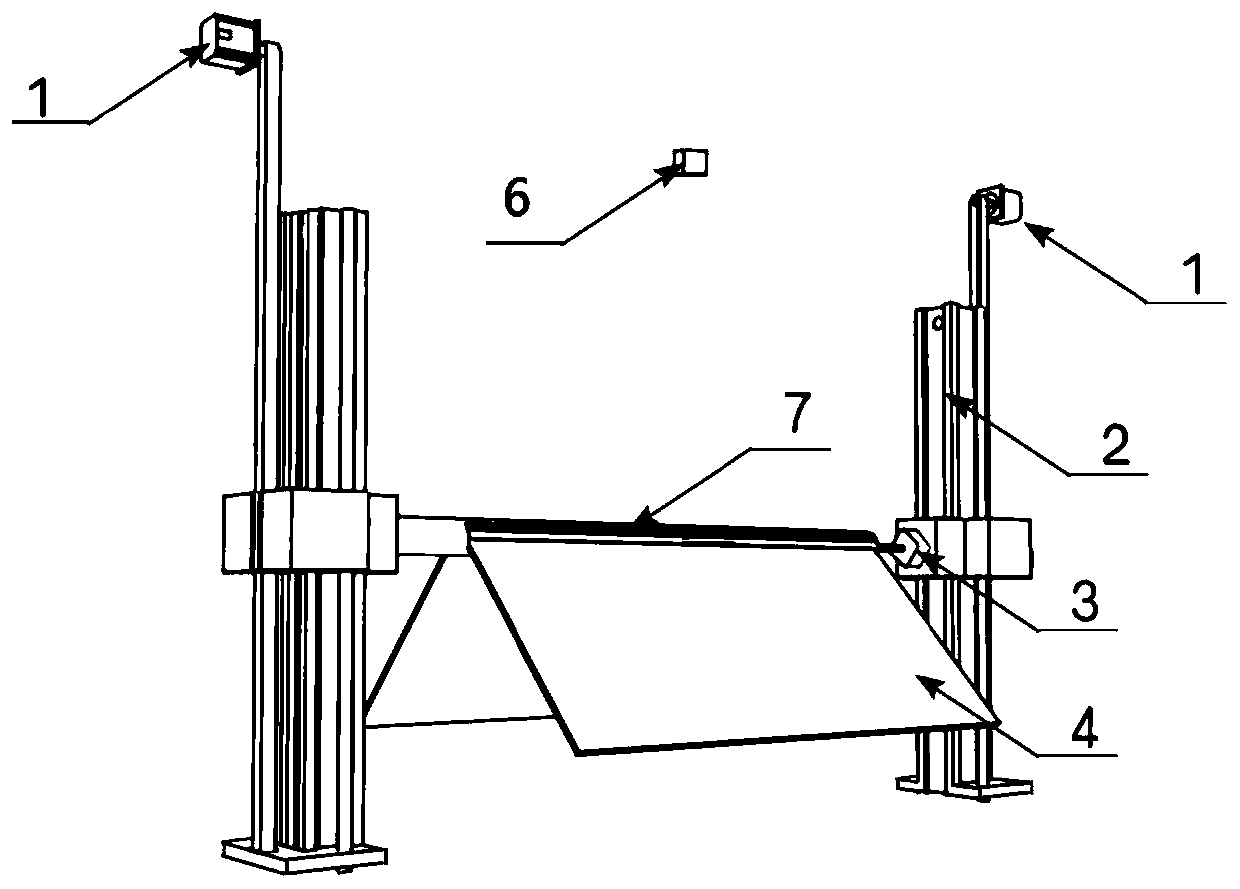

A horizontally movable vertical shaft rope guide and regulating method thereof

InactiveUS20170305722A1Minimize impactReduce impactMine liftsShaft equipmentHydraulic cylinderEngineering

The present invention relates to a horizontally movable vertical shaft rope guide and a regulating method thereof which are suitable for guiding of hoisting containers in vertical shafts. The vertical shaft rope guide comprises a hoisting rope, and two hoisting containers suspended from the tail ends of the hoisting rope, wherein, cage guide ropes are led through guide cage lugs arranged on the two sides respectively, a tensioner arranged on the ground at the shaft top is connected to the upper end of each cage guide rope, and a connector arranged under a steel slot at the shaft bottom is connected to the lower end of each cage guide rope; a hydraulic cylinder is connected at the other side of each tensioner and the corresponding connector, and the hydraulic cylinder is connected to the tensioner or connector. During hoisting in the vertical shaft, the hydraulic cylinders are controlled to act in advance, to push the tensioners or connectors to move towards the center between the two hoisting containers, so that the cage guide ropes led through the guide cage lugs on the two sides of the hoisting containers get close to each other at the same time and wrap the hoisting container; thus, the horizontal displacement of the hoisting containers is restrained, and the impact of air flow on the two hoisting containers is minimized when the two hoisting containers meet.

Owner:CHINA UNIV OF MINING & TECH

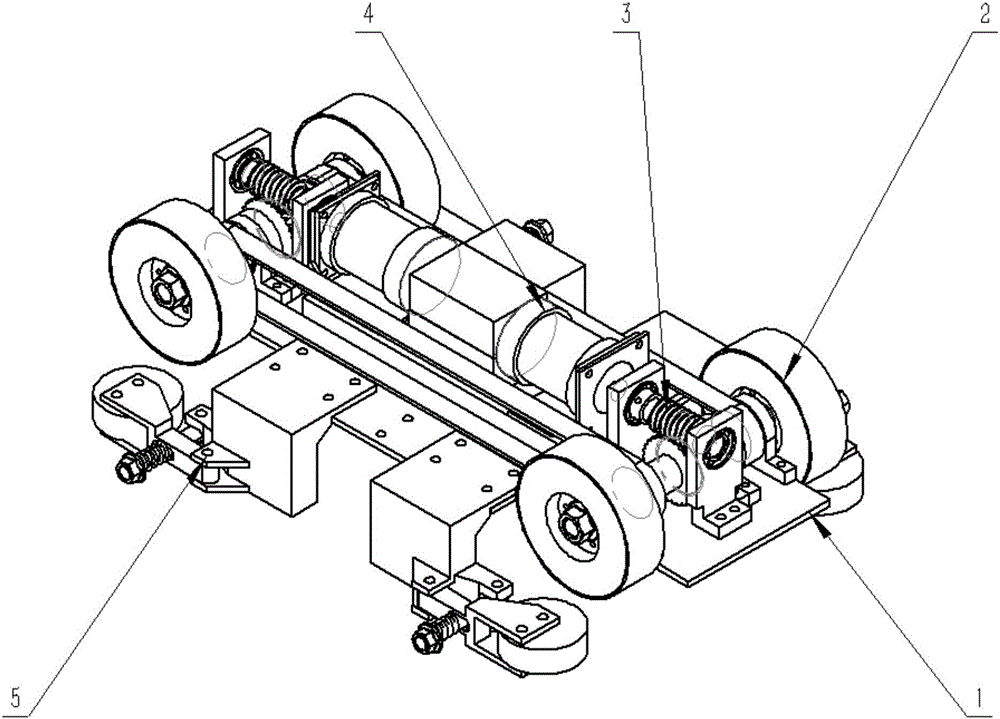

Device and method for periodically inspecting rigid guide

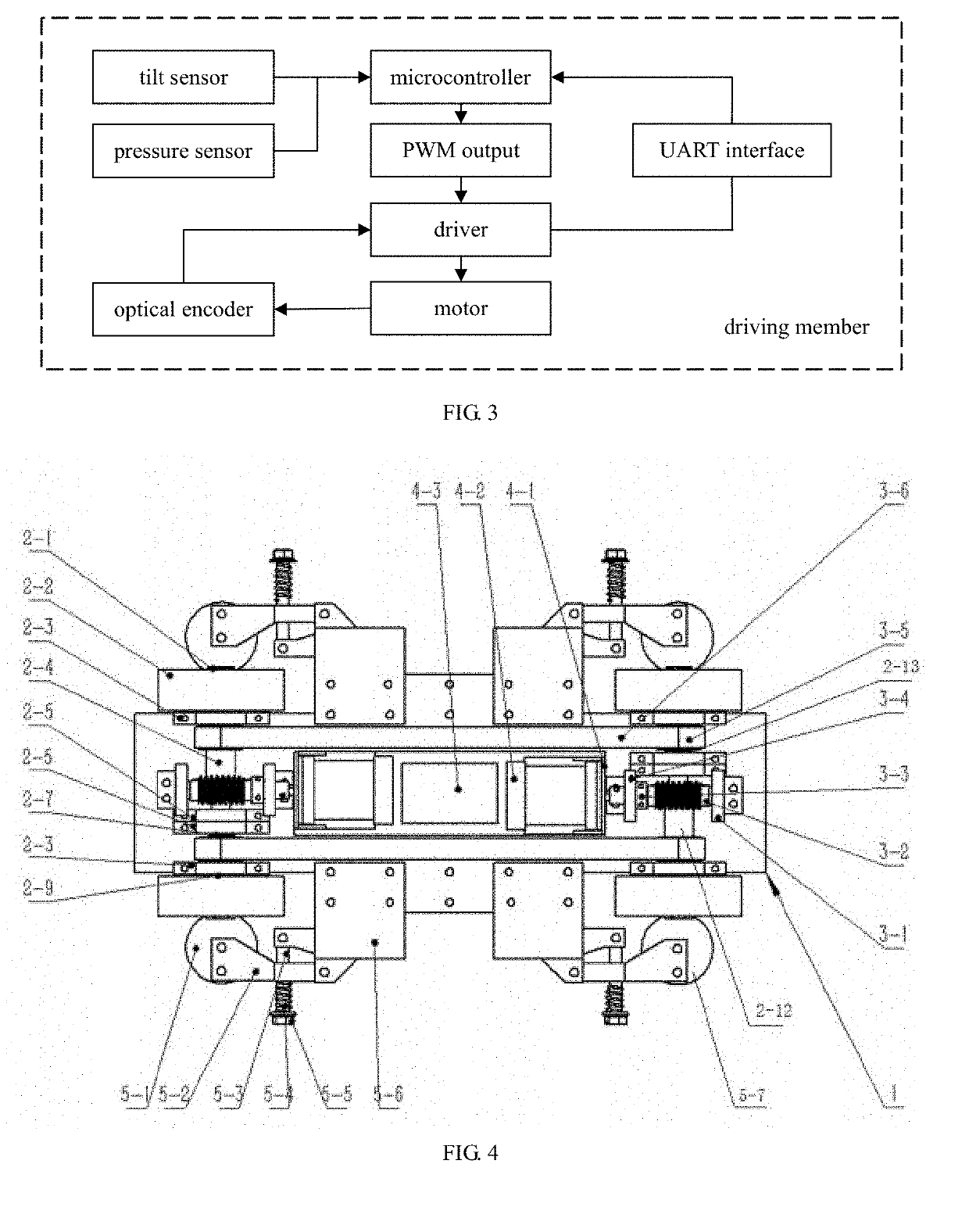

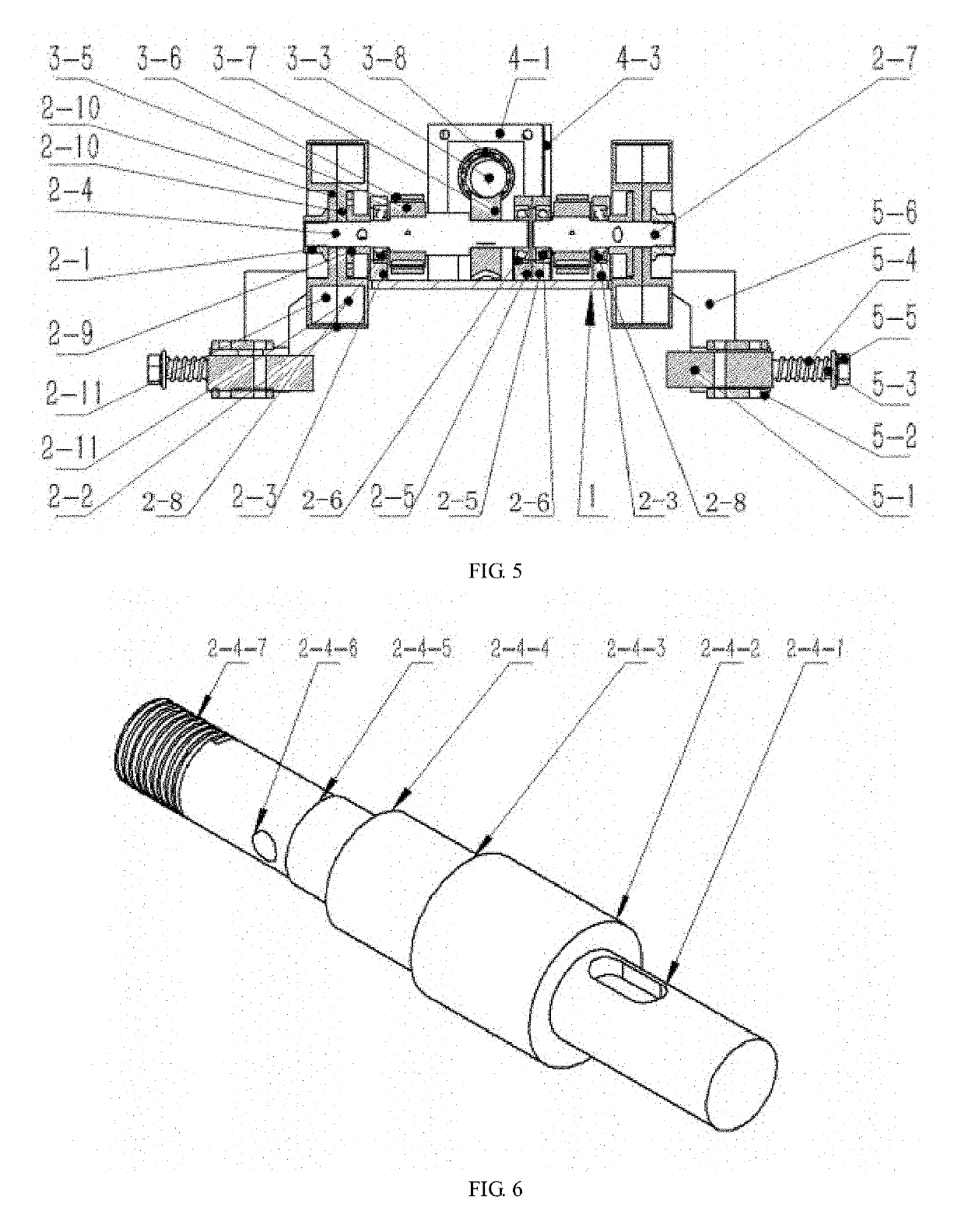

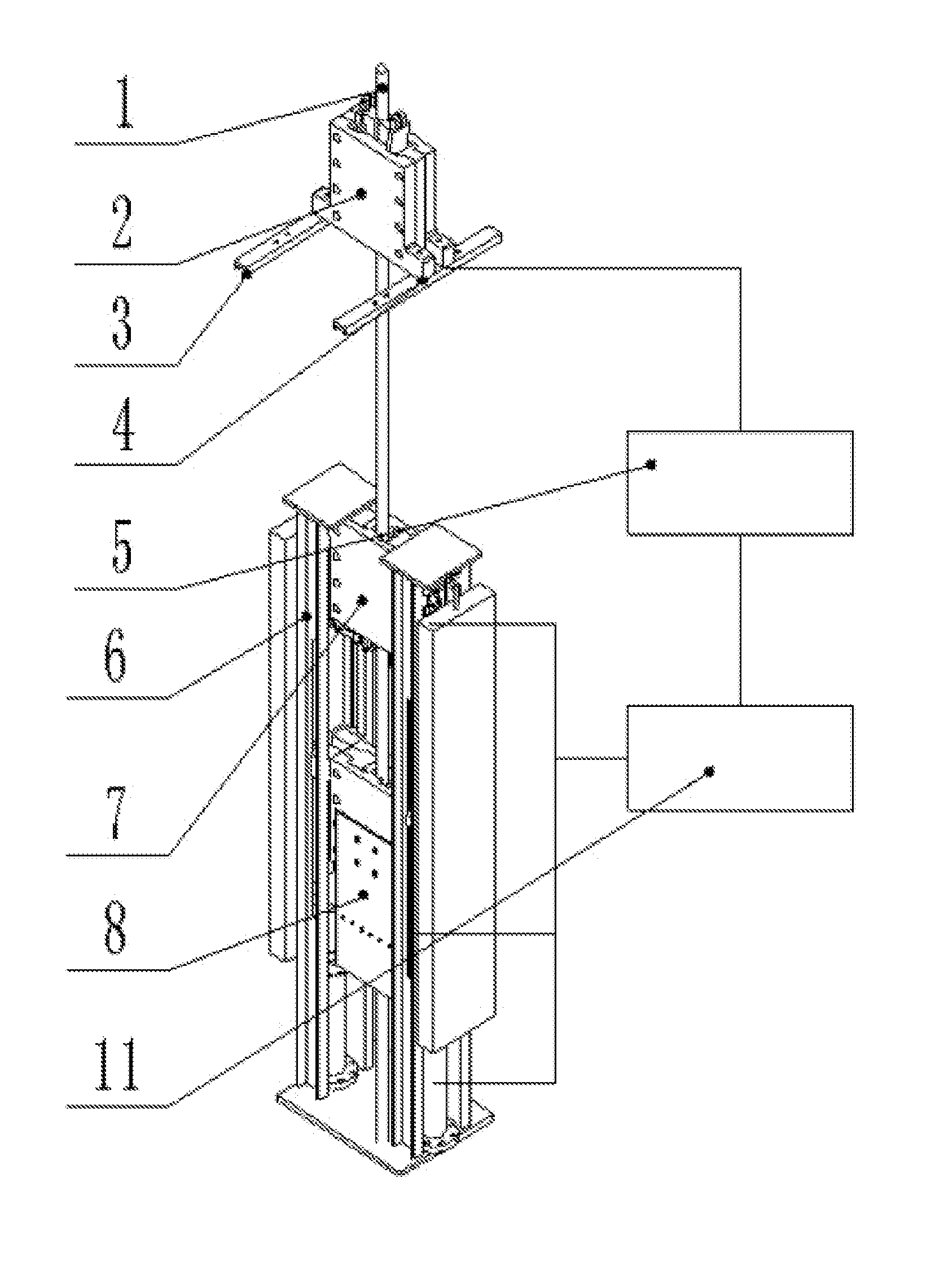

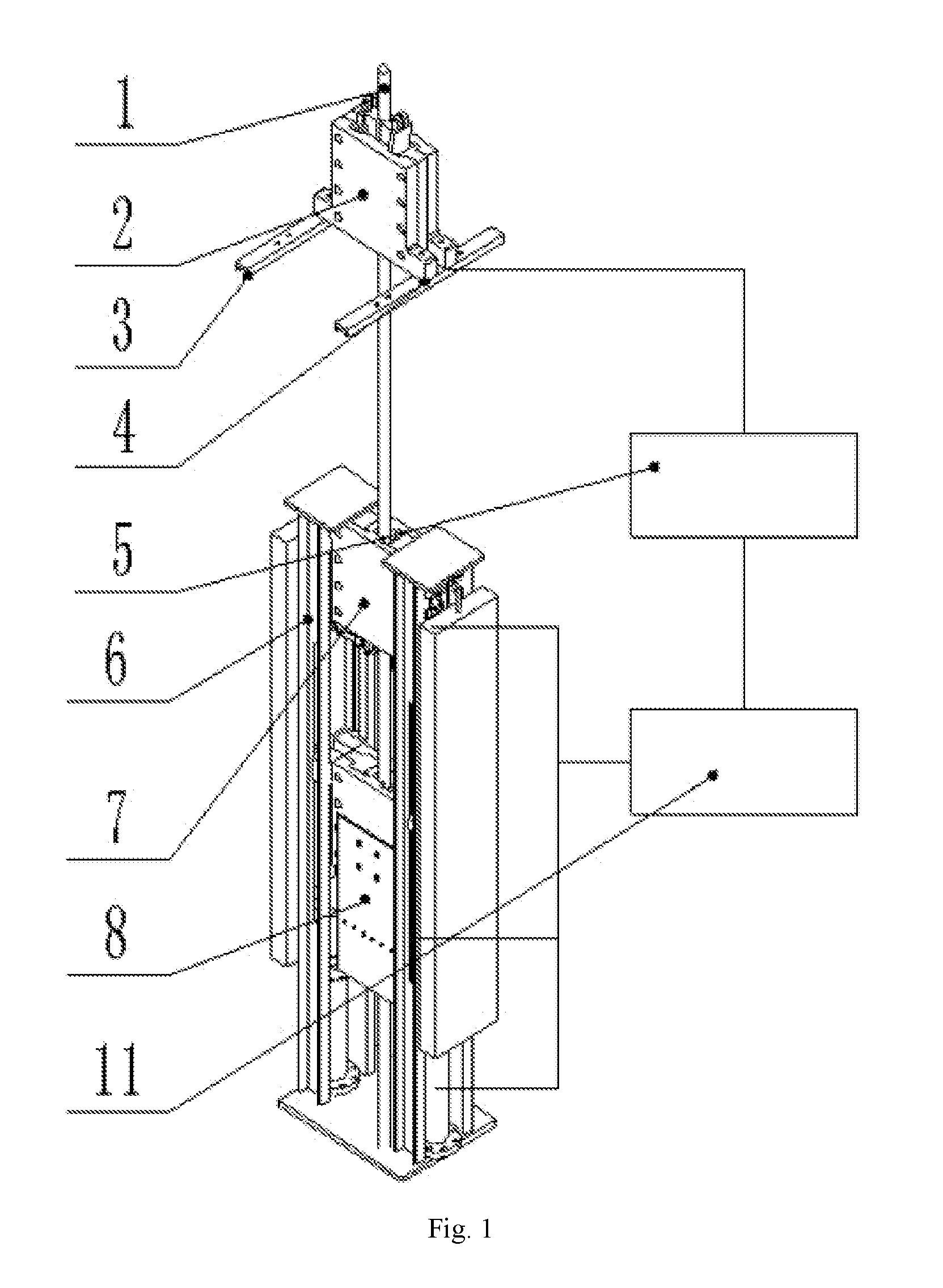

ActiveUS20190225287A1Increase speedShorten the timeMining devicesElevatorsMicrocontrollerEngineering

The present invention discloses an apparatus and method for patrol-inspection of a rigid cage channel. The patrol-inspection apparatus comprises a moving member, a transmission member, a driving member, a guide member, and a housing on a main bottom plate. The driving member comprises a tilt sensor and a pressure sensor connected to a microcontroller, the microcontroller is connected to a driver, the driver is connected to a brushless DC motor, and an output shaft of the brushless DC motor is provided with an optical encoder connected to the driver; The moving member comprises a driving output shaft and a driven output shaft, wheel flanges on the driving output shaft and the driven output shaft are each connected with a wheel hub, a permanent magnet is provided in the wheel hub, and a rubber skin is provided on the outer side of the wheel hub; The transmission member comprises a worm connected with the output shaft of the brushless DC motor, a worm wheel on the driving output shaft and meshed with the worm, timing pulleys on the driving output shaft and the driven output shaft, and a timing belt wound on the timing pulleys. The guide member comprises a guide wheel. The present invention increases inspection speed of the rigid cage channel and improves indirectly the production efficiency of the coal mine enterprise.

Owner:CHINA UNIV OF MINING & TECH

Tensioning device and tensioning method for steel wire rope of cage guide of ultra-deep vertical shaft

ActiveUS20170015522A1Effective regulationEffective controlElevatorsShaft equipmentHydraulic cylinderArchitectural engineering

Owner:CHINA UNIV OF MINING & TECH

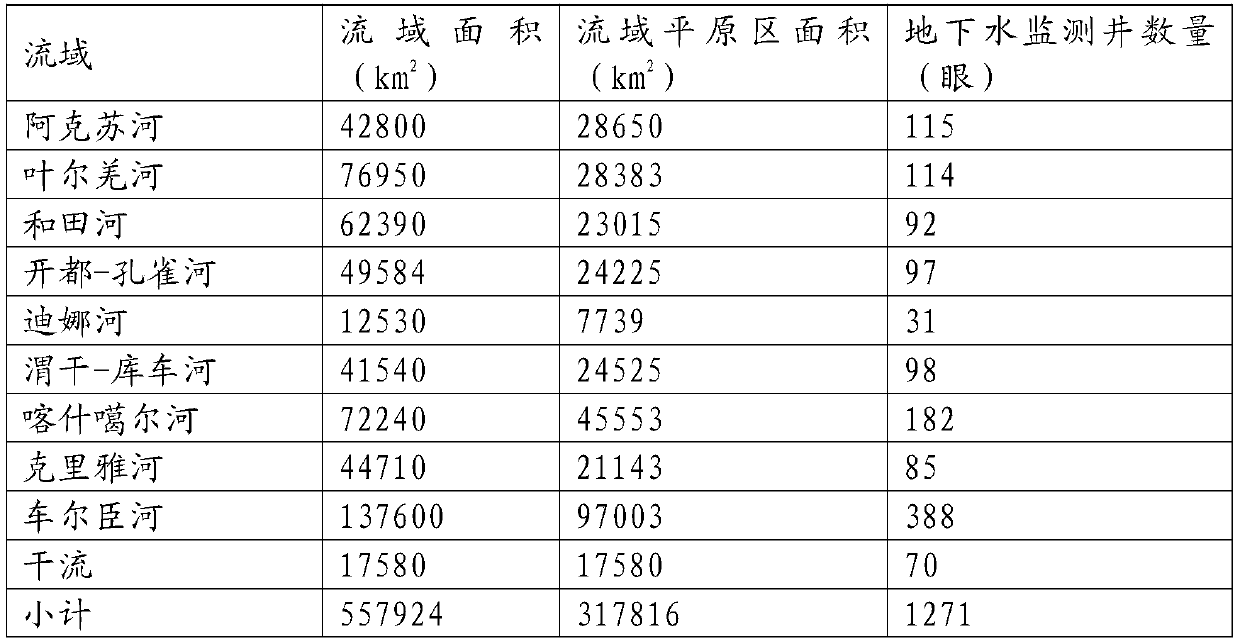

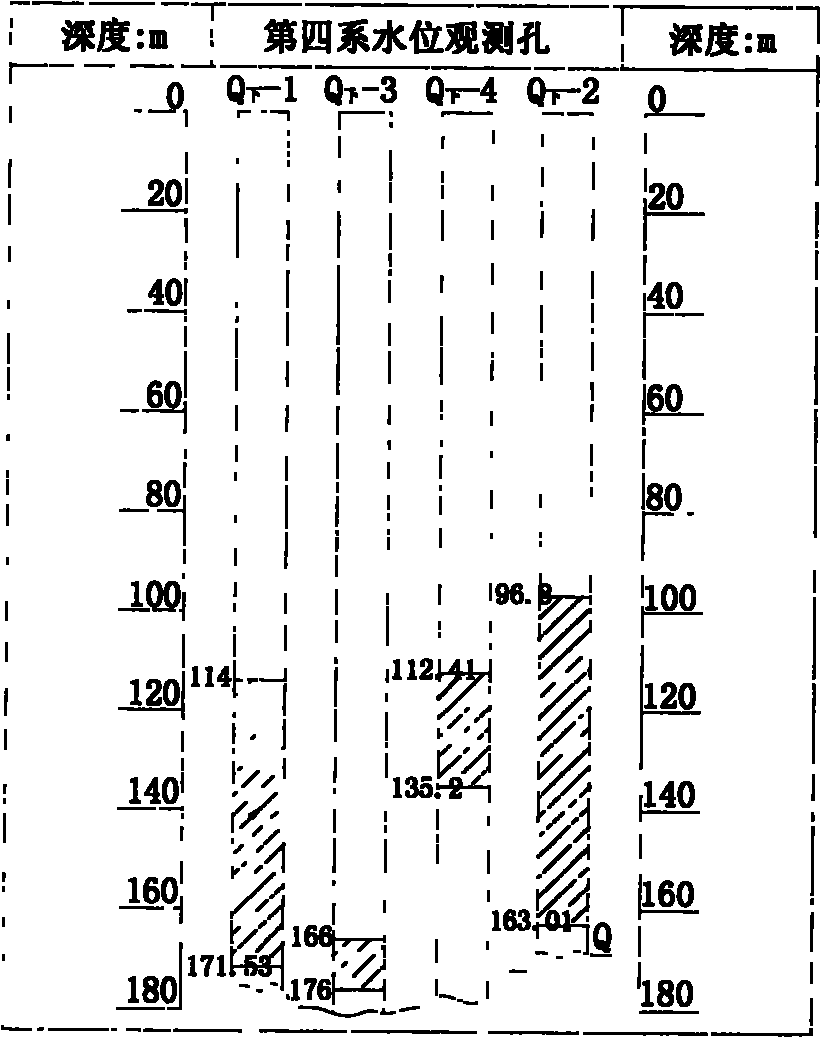

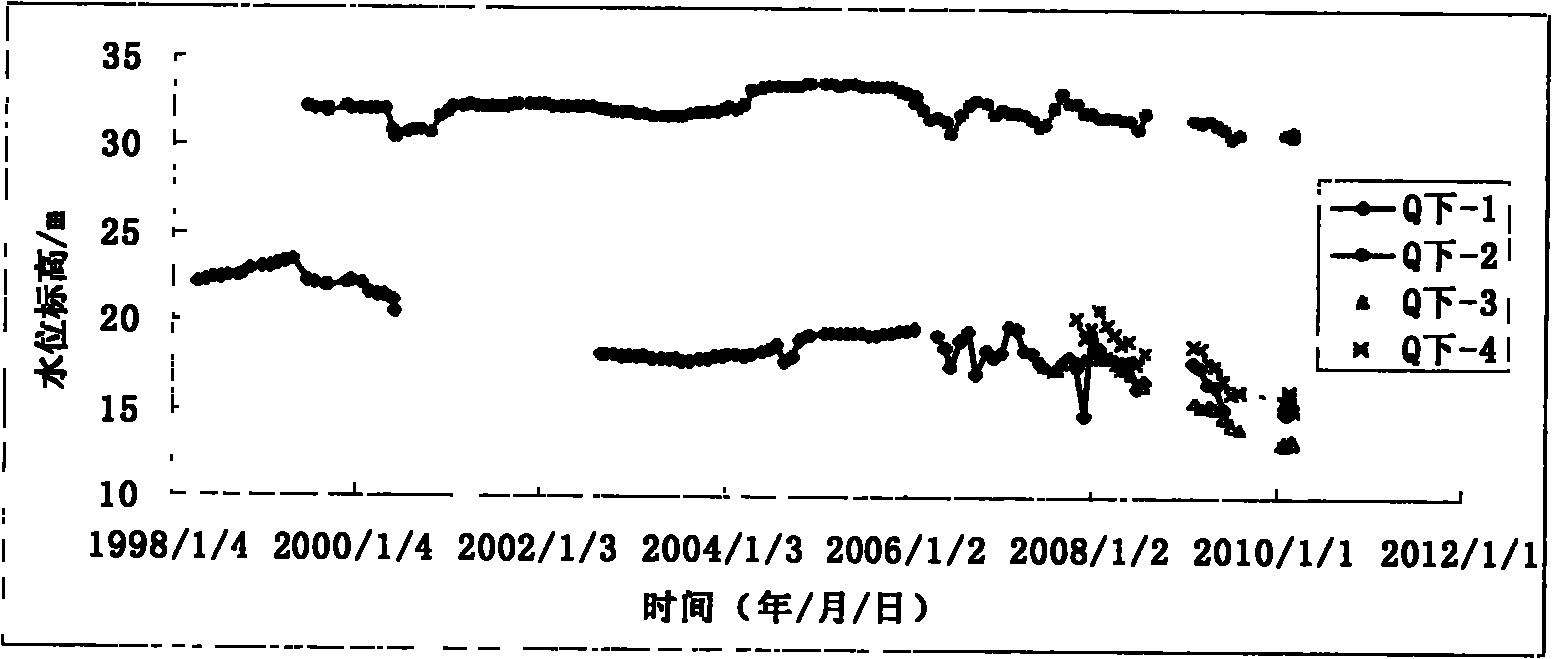

Real-time dynamic monitoring method for arid region inland river basin underground water

InactiveCN110031596AReal-time data transmissionQuick DataMeasuring open water depthTesting waterAridData acquisition

The invention discloses a real-time dynamic monitoring method for arid region inland river basin underground water. The method mainly comprises the steps of preparation before underground water monitoring well distribution, underground water monitoring well distribution principle determination, underground water monitoring well distribution density determination, construction of underground watermonitoring wells, arrangement of automatic water level monitoring devices and regular management of the underground water monitoring wells and surrounding facilities. According to the method, on the basis of investigating underground water conditions of different hydrogeological units in a basin, the underground water level monitoring wells covering the whole basin are distributed in the basin, intelligent water level meters are arranged in the underground water monitoring wells, data transmission terminals of the intelligent water level meters are connected to data receiving terminals througha wireless network to realize regular whole-basin real-time underground water level monitoring and remote transmission, underground water level manual collection cost is effectively lowered, data collection time is shortened, and the timeliness and accuracy of data are greatly improved.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

Ultra-deep support-free locking notch ring beam in sea areas

ActiveCN106869147AIncrease construction areaResist erosionExcavationsShaft equipmentStructural engineeringCoastal zone

The invention discloses an ultra-deep support-free locking notch ring beam in sea areas and relates to the technical field of engineering construction. By means of the ultra-deep support-free locking notch ring beam in sea areas, the problems that in the prior art, an existing vertical shaft locking notch ring beam is small in construction operation profile and small in depth, and the waterproof design cannot meet the waterproof requirement of coastal regions are solved. The ultra-deep support-free locking notch ring beam in sea areas comprises a first support, a second support, a first locking notch ring beam body and a second locking notch ring beam body. The first support comprises a first side slope, a second side slope and a dual-layer jet grouting pile, wherein the first side slope and the second side slope are connected and supported by the dual-layer jet grouting pile and both adopt side slope supporting. The first support and the second support are arranged symmetrically. The first locking notch ring beam body and the second locking notch ring beam body are arranged between the first support and the second support. The first locking notch ring beam body is adjacent to the first support. The second locking notch ring beam body is adjacent to the second support.

Owner:SHANDONG UNIV OF SCI & TECH

Trenchless directional drilling construction method for pipeline burying channel

InactiveCN112252973AAvoid destructionLow costArtificial islandsPipe laying and repairArchitectural engineeringPipe

The invention relates to a trenchless directional drilling construction method for a pipeline burying channel. The trenchless directional drilling construction method comprises the following steps that 1, pipe distribution is conducted, specifically, hot melting connection is conducted on the end faces of two PE solid-wall pipes; 2, directional drilling is conducted, specifically, a working pit and a receiving pit are manufactured, and a directional drilling machine is adopted for hole drilling; 3, back chambering construction is conducted, specifically, chambering is conducted in a step-by-step chambering mode to form a pipeline; 4, the pipe is pulled back, specifically, the pipe is pulled by adopting a pipe puller; and 5, inspection wells are manufactured, specifically, foundation pits are excavated in the two sides of an effective pipe section, the prefabricated inspection wells are installed, the prefabricated inspection wells are in waterproof connection with the PE solid-wall pipes, and then the foundation pits and the peripheries of the prefabricated inspection wells are backfilled. Only the working pit and the receiving pit need to be excavated in the ground, drilling, chambering and pipe pulling operations are carried out at the positions of the working pit and the receiving pit, and environmental influences such as multiple construction technology procedures, a largeamount of road surface damage and traffic obstruction caused by pipeline open excavation construction can be avoided.

Owner:广东省构建工程建设有限公司 +1

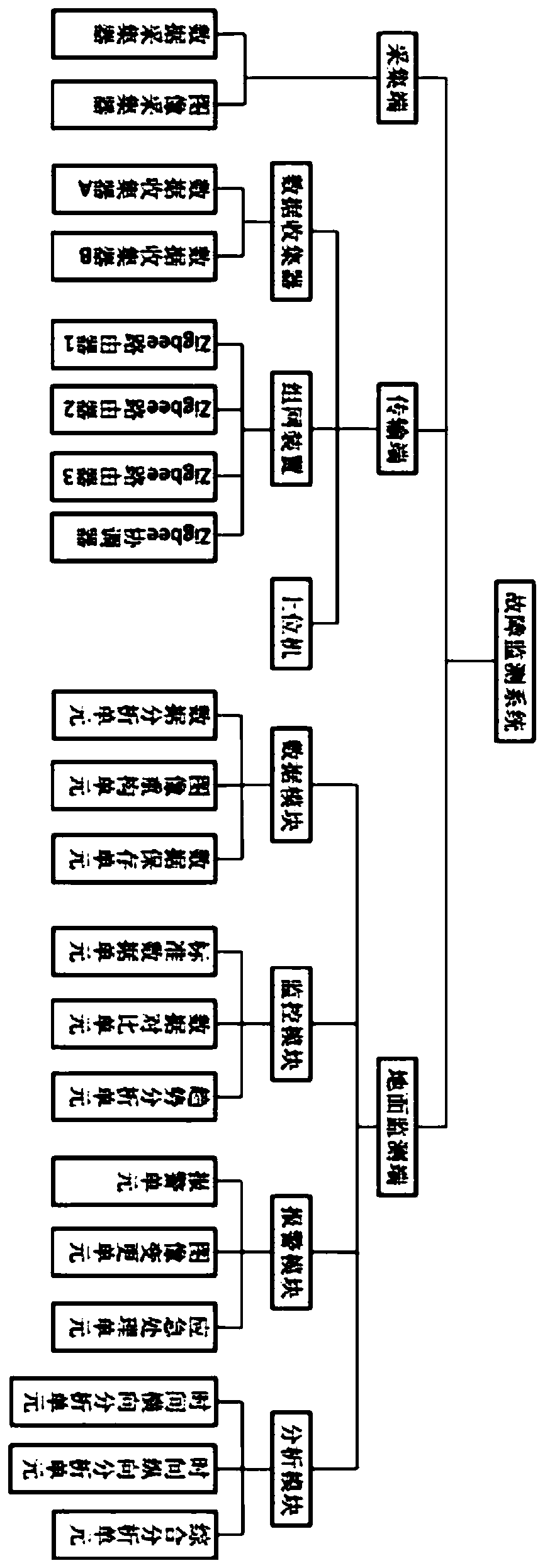

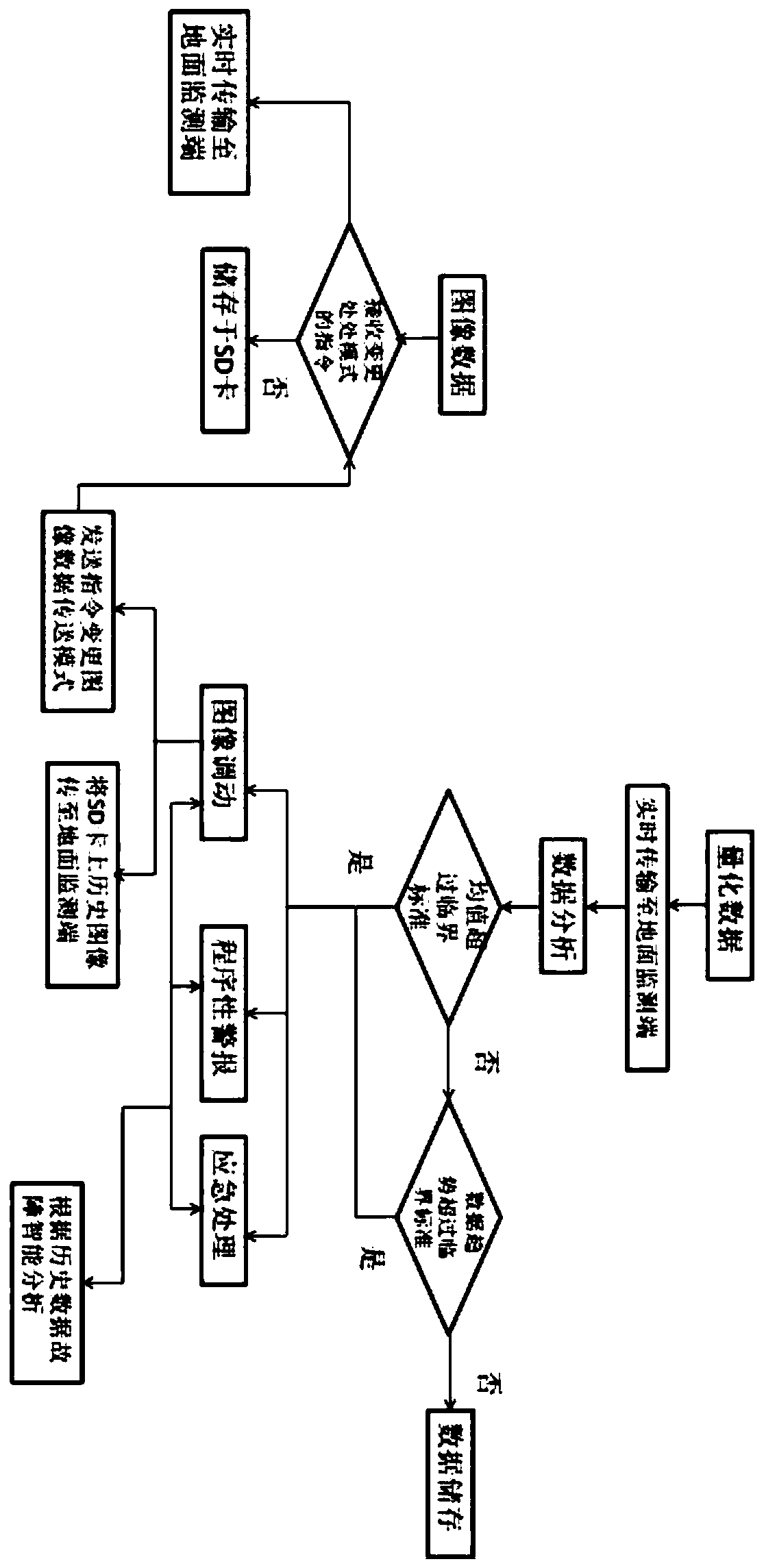

Fault monitoring system for mine shaft and method

ActiveCN110821566AReasonable designAvoid damageTelevision system detailsMining devicesAmbient dataNetwork structure

The invention discloses a fault monitoring system for a mine shaft. The system comprises a collection end, a transmission end and a ground monitoring end. The collection end is mainly used for collecting required data at the mine shaft; the transmission end is designed based on ZigBee, and is a network structure used for transmitting data; and the ground monitoring end is an intelligent control station used for analyzing, sorting and judging data, can collect various kinds of performance and environment data of the mine shaft, achieves the functions of automatic analysis, monitoring, storage,alarming and fault recognition, has a unique trend comparison mode, can conduct monitoring and predicting in the early stage of hidden danger, and automatically calls relevant image data after an abnormal condition occurs to provide sufficient data for engineers to carry out ground analysis, in this way, the maintenance engineering amount is increased, and the safety is improved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Method for preventing vertical shaft wellhole from being damaged

ActiveCN101985881AAvoid destructionWater level increased and stabilizedMining devicesShaft equipmentTap waterEngineering

The invention relates to a method for preventing a vertical shaft wellhole from being damaged by adopting a ground water injection water level stabilization method, comprising the following concrete steps: 1) analyzing the alluvium structure and water regimen, and selecting a loose aquifer of which the water level continuous descends within over three years from the alluvium as a water injection position; 2) constructing a water injection hole around the wellhole with the shape consistent with that of a long-term hydrological observation well; 3) injecting water into the water injection position by tap water or a water pump through a water injection hole; and 4) monitoring the water injection effect in the water injection process, wherein the monitoring contents comprise aquifer water level monitoring and well wall variation monitoring, and the water injection rate is adjusted based on the monitored water injection effect. The method can ensure the water levels of the wellhole and theaquifer nearby to be increased and relatively steady, reduce compression deformation and additional pressure strain on the well wall caused by loosened soil layers around the wellhole due to drop of the water level, thus preventing the well wall from being damaged. Researching from the perspective of hydrology-geological conditions of mines, in the invention, a method for fundamentally solving the problem of preventing the wellhole from being damaged is searched out based on the well wall fracture mechanism, and has obvious prevention effect, is convenient to construction, and is safe and economic.

Owner:兖矿能源集团股份有限公司 +1

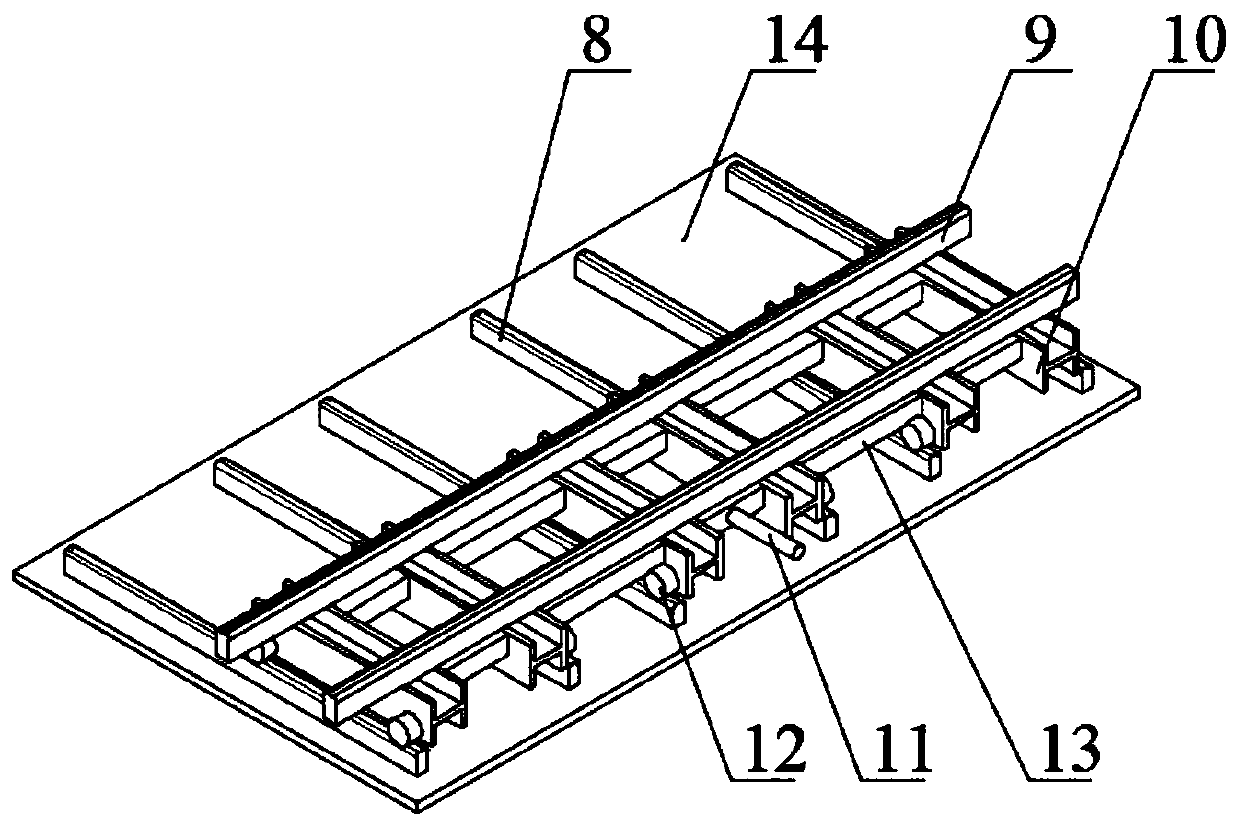

Track transportation system for subway shield tunnel quick slag tapping

PendingCN110552712ARealize separate transportationSolve transportation inefficienciesRailway componentsMovable tracksSlagShield tunnelling

The invention discloses a track transportation system for subway shield tunnel quick slag tapping. The track transportation system for subway shield tunnel quick slag tapping comprises a switching track fixedly installed in a shield tunnel, and further comprises multiple sections of first tracks and second tracks which are arranged in parallel at intervals and a transverse track moving device slidably installed in a shield shaft, and each first track and the corresponding second track are adjustably connected with the switching track through a turnout; the transverse track moving device comprises transverse tracks, transverse moving brackets, longitudinal tracks and a hydraulic jack, the transverse tracks are fixed to a bottom plate of the shield shaft, and the transverse moving brackets are slidably supported on the transverse tracks; the longitudinal tracks adjustably connected with the first tracks and the second tracks are fixedly installed on the tops of the transverse moving brackets; and the hydraulic jack used for providing transverse moving power for the transverse moving brackets is fixedly installed on the side wall of the shield shaft. According to the track transportation system, the connecting total length of track cars does not need to be taken into account, the effect that full-load track cars and no-load track cars simultaneously run can be achieved, and the muck transportation efficiency can be improved to the maximum limit within the limited shield shaft horizontal depth range.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

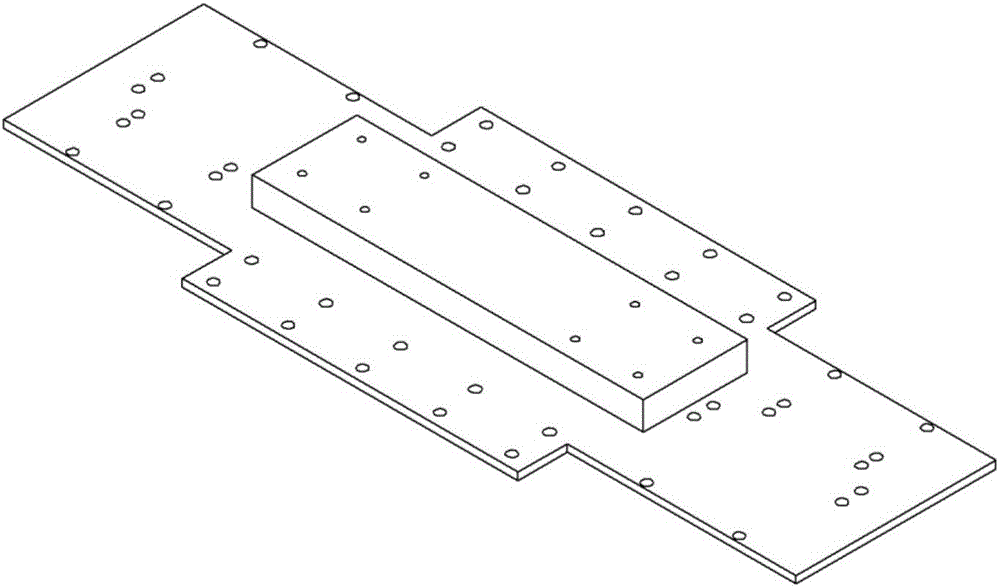

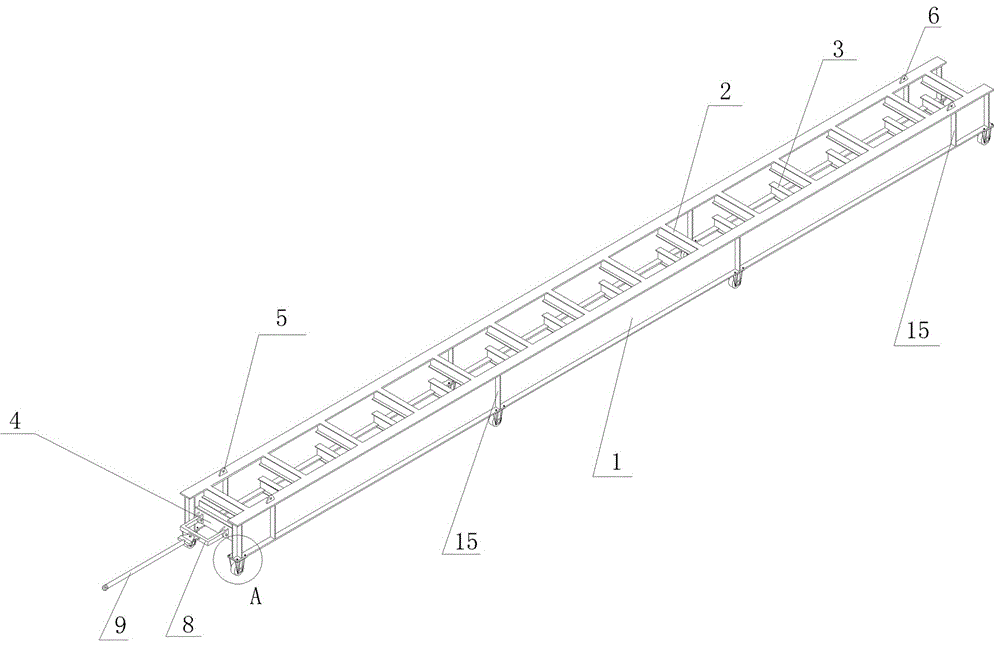

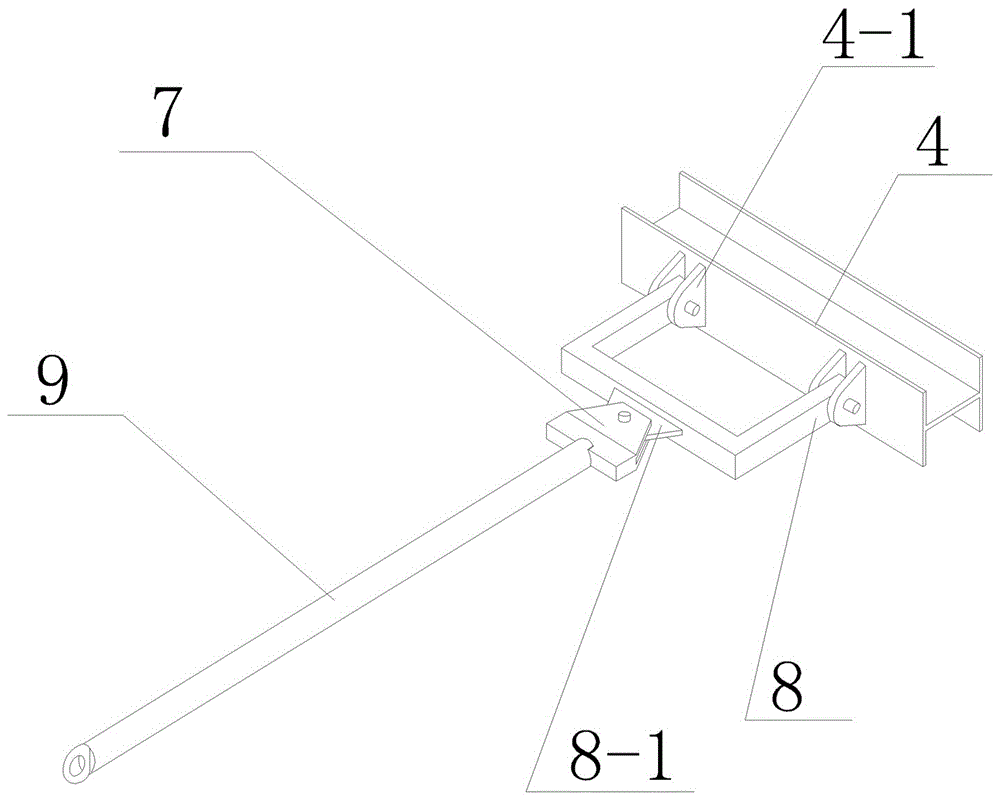

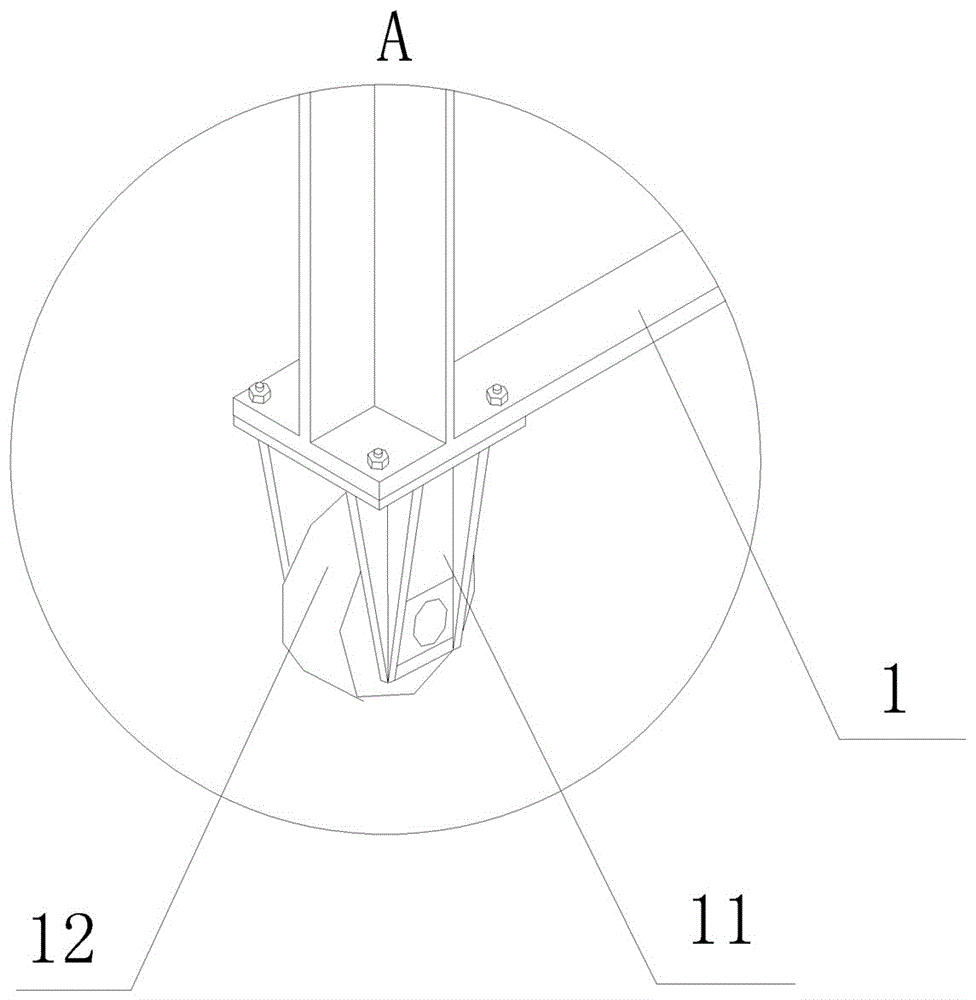

Hoisting device of underground railway line turnout assembly and hoisting method

ActiveCN105692447ANo deformationReduce mutual interferenceShaft equipmentLoad-engaging elementsLogistics managementEngineering

The invention discloses a hoisting device of an underground railway line turnout assembly and a hoisting method. The device comprises a hoisting framework, a traction mechanism and a walking mechanism. The hoisting method comprises the steps that the hoisting device is transported to a vertical well mouth and hoisted by hoisting equipment, and the hoisting device is transported into a vertical well; and the hoisting device is dragged by a tractor to walk into a hole, the hoisting equipment is in close cooperation, the hoisting device is pulled by the tractor to walk in the hole, and the turnout assembly is hoisted to a storage position. The hoisting device and the hoisting method have the beneficial effects that during underground station construction, the turnout assembly is hoisted into the hole from the vertical well mouth, and compared with the manner of transporting in the turnout assembly from a tunnel portal, the transport distance is remarkably reduced, the construction efficiency is improved, and the logistics cost is reduced; and the turnout assembly does not deform in the transfer process, and the turnout pavement precision can be easily controlled.

Owner:CHINA RAILWAY 16TH BUREAU GRP CO LTD +1

Protection device for vertical shaft tunnel blast construction and construction method thereof

InactiveCN107435539ASimple and fast constructionSecurityTunnelsShaft equipmentSheet steelNoise reduction

The invention discloses a protection device for vertical shaft tunnel blast construction. The protection device comprises a protection cover capable of being assembled and is characterized in that the protection cover capable of being assembled comprises I-shaped steel used for manufacturing a skeleton; the I-shaped steel is fixedly connected with a steel plate; the I-shaped steel and the steel plate form a half-open rectangular framework; and hoisting rings are arranged on the steel plate side by side. By hoisting and fixing the protection device before blast, sound insulation, noise reduction and flying rock protection can be achieved during blast, and the protection device can be pulled out and hoisted out after blast; construction is easy and convenient, and protection is safe and reliable; and the problem of harm of blast noise and blast flying rock to peripheral civil houses and personnel is effectively solved.

Owner:CCCC SECOND HARBOR ENG

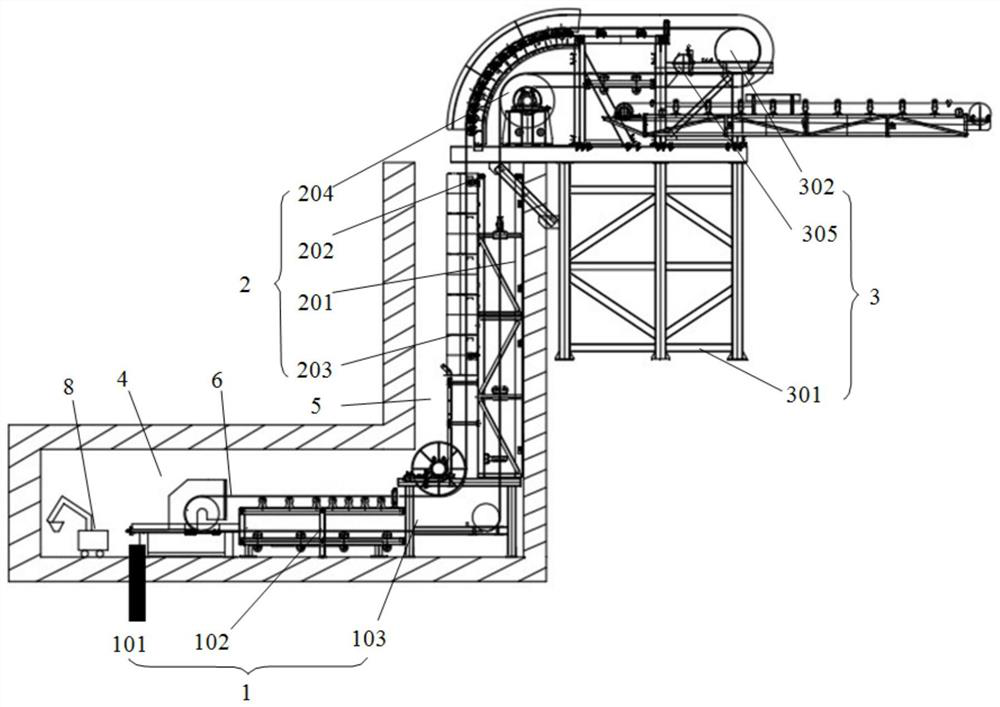

Material conveying device for construction

ActiveCN112357500AGuaranteed driving speedReduce construction efficiencySievingScreeningArchitectural engineeringEarth surface

The invention relates to a material conveying device for construction. The material conveying device at least comprises a first horizontal conveying part arranged in a tunnel, a vertical lifting partarranged in a vertical shaft and a second horizontal conveying part arranged on the ground surface. The first horizontal conveying part is arranged at the intersection of the tunnel and the vertical shaft. The vertical lifting part can convey ballast soil from the first horizontal conveying part to the second horizontal conveying part in a redirection conveying mode. The first horizontal conveyingpart is arranged at the intersection of the tunnel and the vertical shaft, and the position of the first horizontal conveying part is kept unchanged. When the length of an extending conveying part needs to be increased, only construction operation needs to be conducted at the bottom of the vertical shaft, the transportation cost of operation tools and materials is low, and due to the fact that the operation area of an excavating device is far away from the vertical shaft, operation of the excavating device is not affected, and the tunneling speed of the tunnel can be effectively guaranteed.

Owner:BEIJING UNI-CONSTR GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com