Hoisting device of underground railway line turnout assembly and hoisting method

A technology for lifting and transporting devices and railway lines, which is used in transportation and packaging, earth-moving drilling, shaft equipment and other directions, can solve the problems of difficult process arrangement, affecting laying accuracy, lifting and transporting switch components, etc. The effect of control, simplification of construction plan, and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

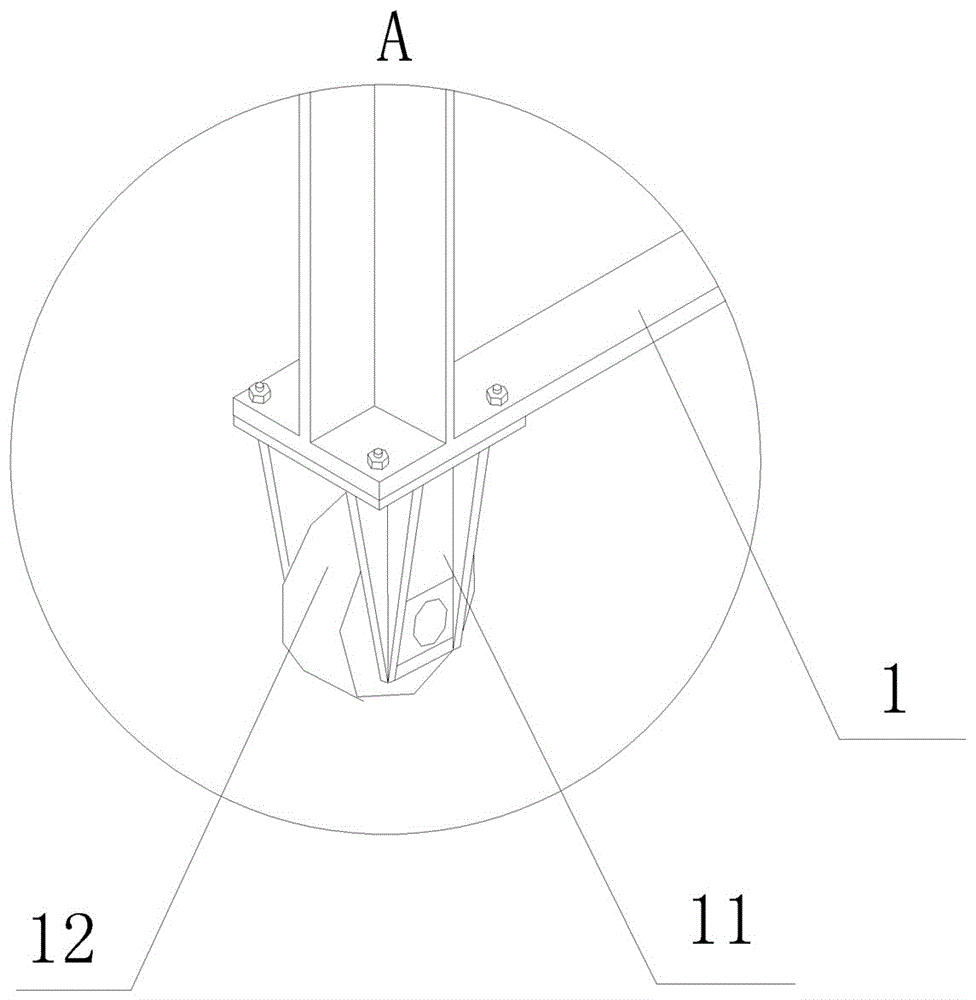

[0034] According to Figure 1-11 The examples and examples further illustrate the present invention.

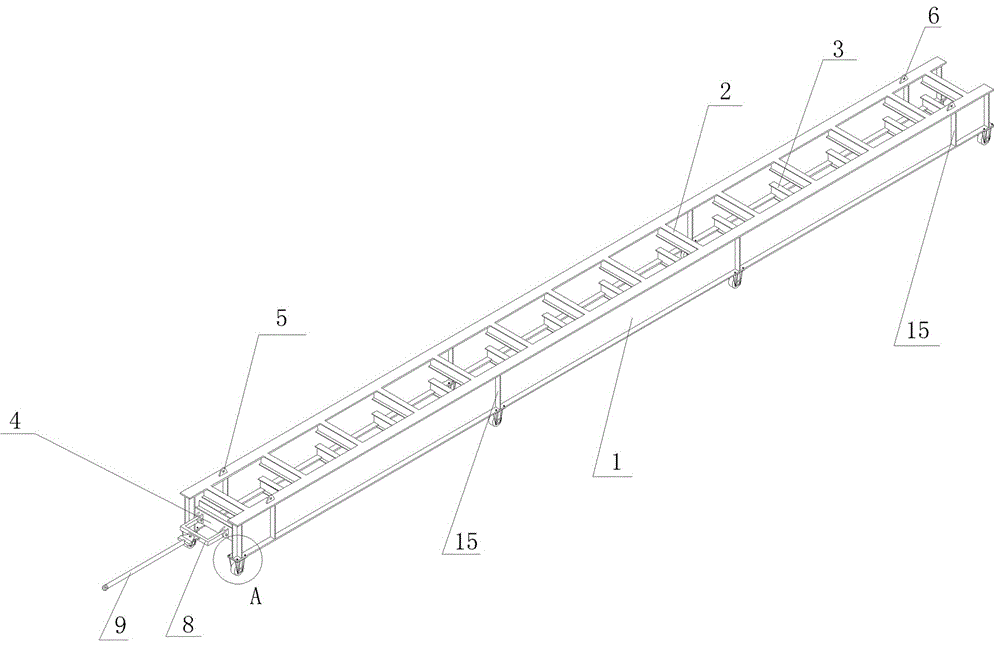

[0035] The lifting device of this embodiment includes a lifting frame, a traction mechanism and a walking mechanism;

[0036] The lifting frame includes a front frame and a rear frame fixedly connected to the front frame, a traction beam 4 fixedly arranged at the front end of the front frame, a pair of front ears 5 and a pair of rear ears 6;

[0037] The front frame and the rear frame have the same structure; the front frame includes a pair of longitudinal beams 1, an upper beam 2 and a lower beam 3 uniformly distributed between the pair of longitudinal beams 1;

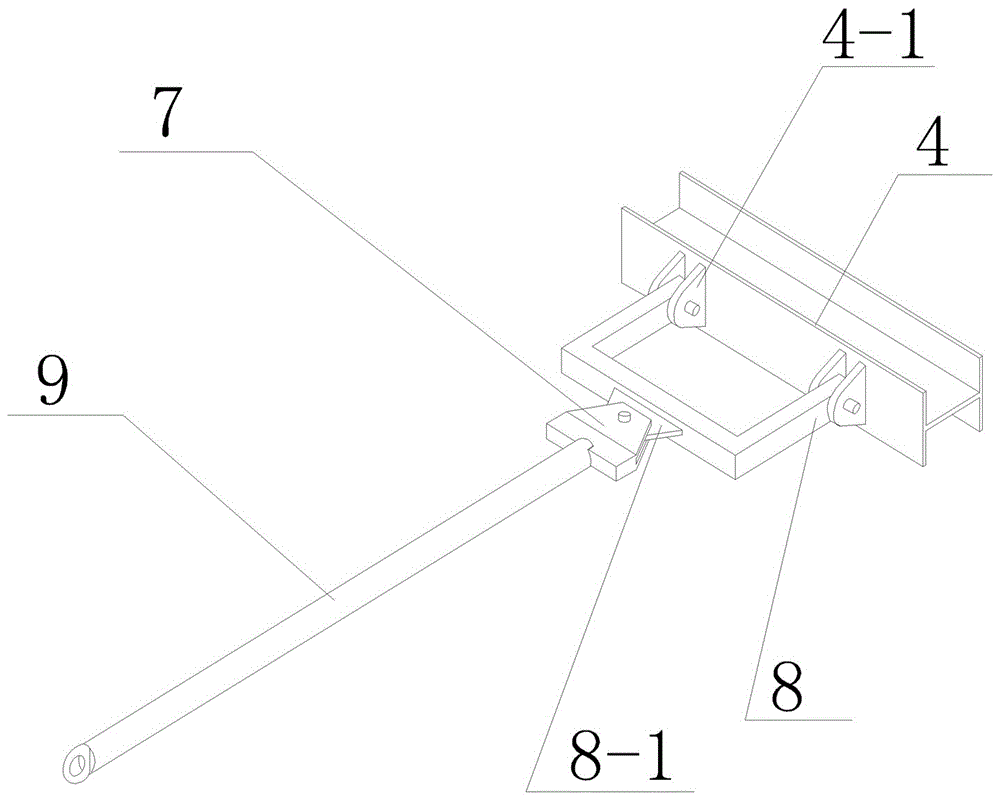

[0038] The traction beam 4 is fixedly arranged between a pair of longitudinal beams 1; a pair of traction lugs 4-1 are provided on the front end surface of the traction beam 4;

[0039] A pair of front ears 5 are arranged on the rail bearing surface of the front longitudinal beam 1 of the front frame; a pair of rear ears 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com