Slag tapping system and method for full face tunnel boring machine of deep vertical shaft

A technology for full-face roadheaders and vertical shafts, which is applied in vertical shaft equipment, earthwork drilling, mining equipment, etc., which can solve the problems of reduced efficiency of muck discharge, achieve improved muck discharge efficiency, high discharge efficiency, and speed up well construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

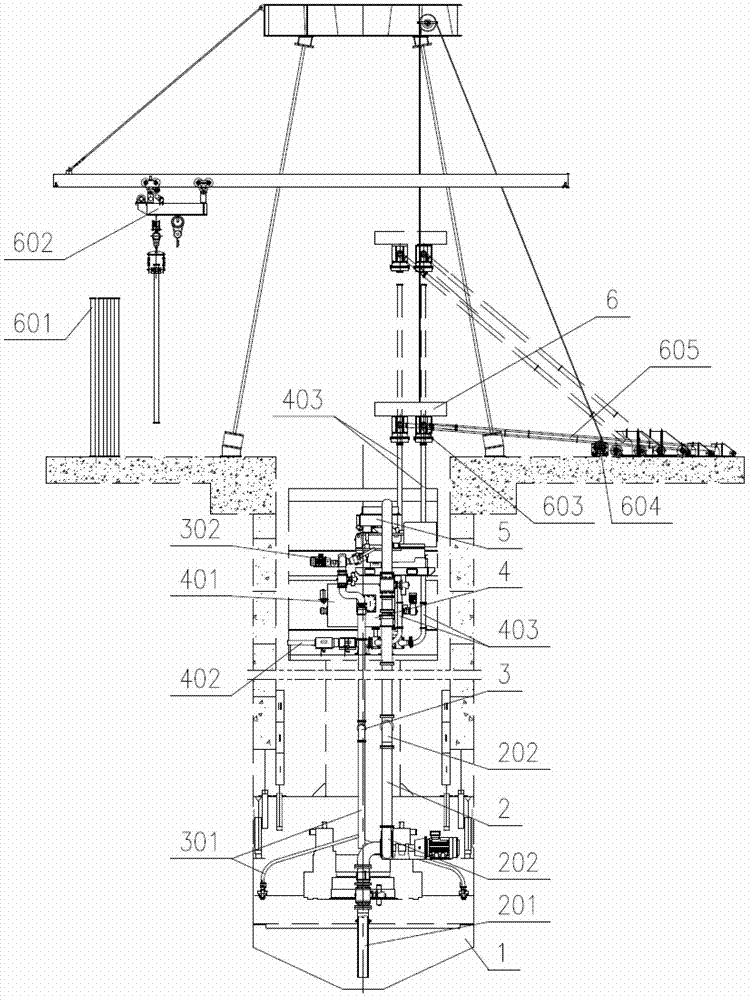

[0028] see figure 1 , the invention discloses a slag discharge system for full-face tunneling machines in deep shafts, including a slurry discharge system 2, a mud separation station 5, a slurry feed system 3 and a slag improvement pumping system 4;

[0029] The slurry discharge system 2 is composed of a slurry discharge pump 202 and a slurry discharge pipe 201; the lower port of the slurry discharge pipe 201 goes deep into the mud tank at the bottom of the cutter head 1, and the upper port of the slurry discharge pipe 201 is connected with the upper entrance of the mud water separation station 5 . The slurry discharge pump 202 generates a suction force, and the slurry in the slurry tank is conveniently sucked through the slurry discharge pipe 201, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com