Nested mine roof supports

a technology of mine roof support and nested structure, which is applied in the direction of shaft equipment, de-stacking articles, stacking articles, etc., can solve the problems of inconvenient transportation of containers for a mine roof support from the manufacturing site, and the voids of various sizes left in the mine,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

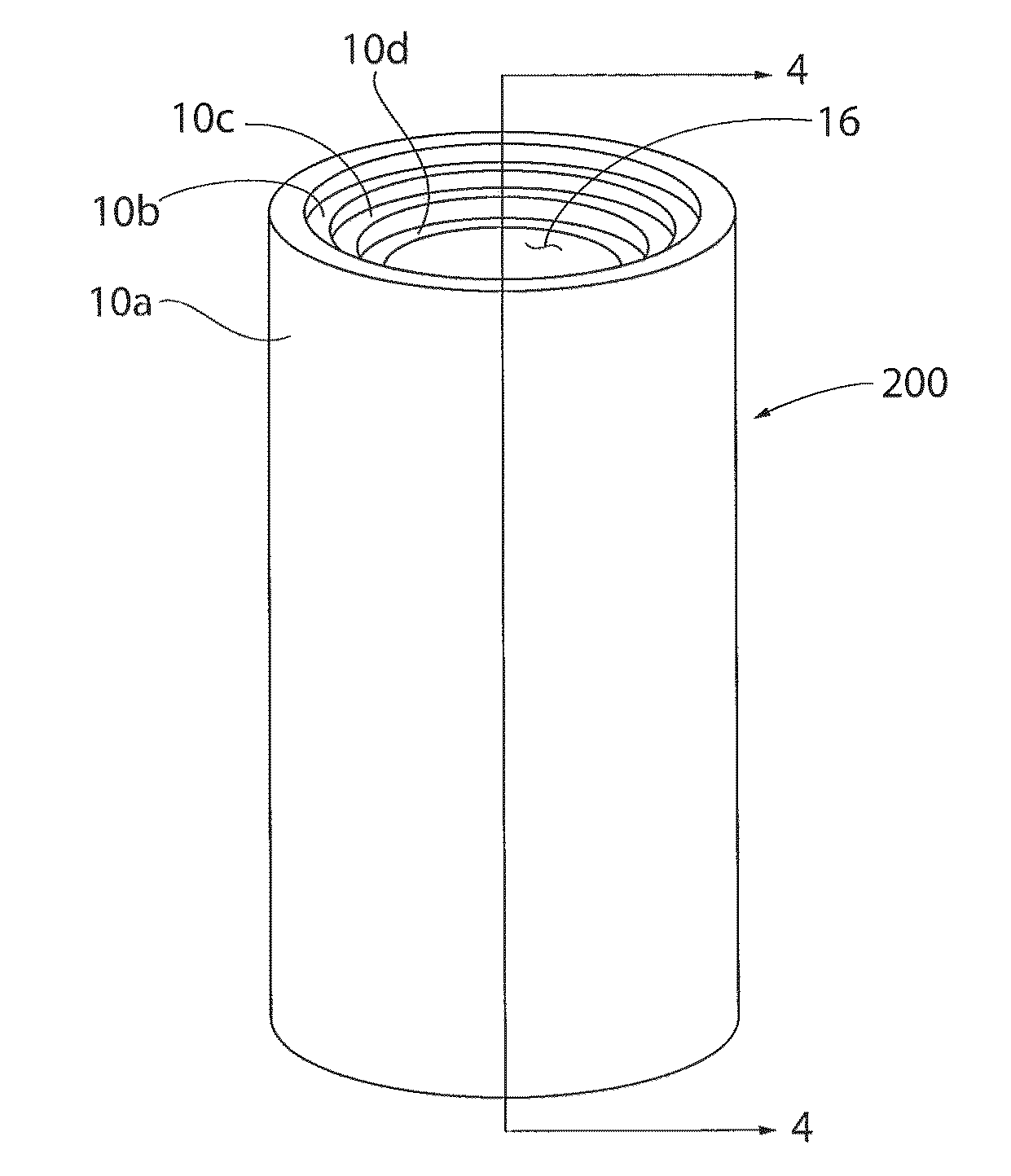

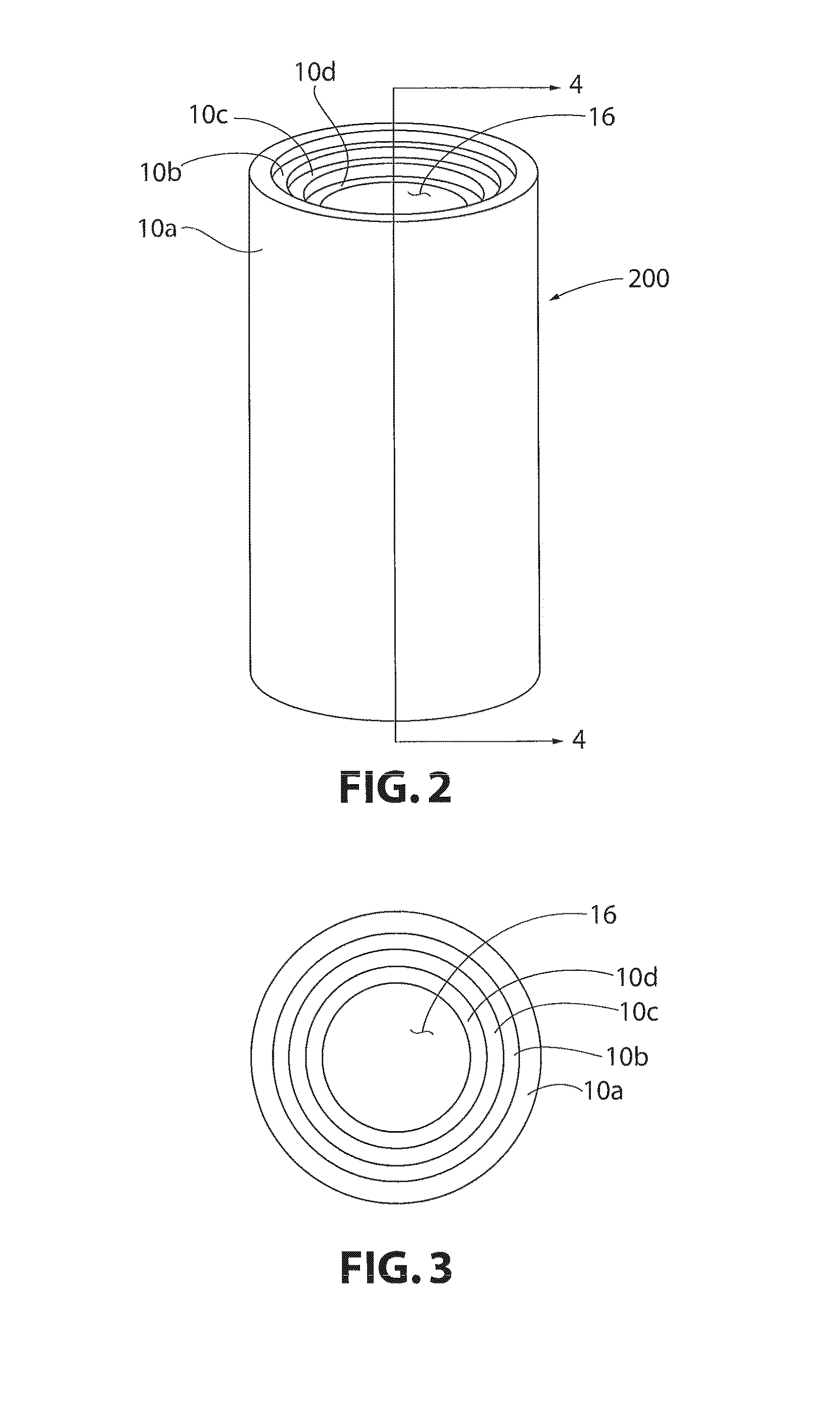

[0020]The present invention includes a mine roof support set comprising a plurality of containers having a longitudinal axis and adapted to be placed in a void in a mine, with the longitudinal axis extending between the mine roof and the mine floor, and filled with a load-bearing material.

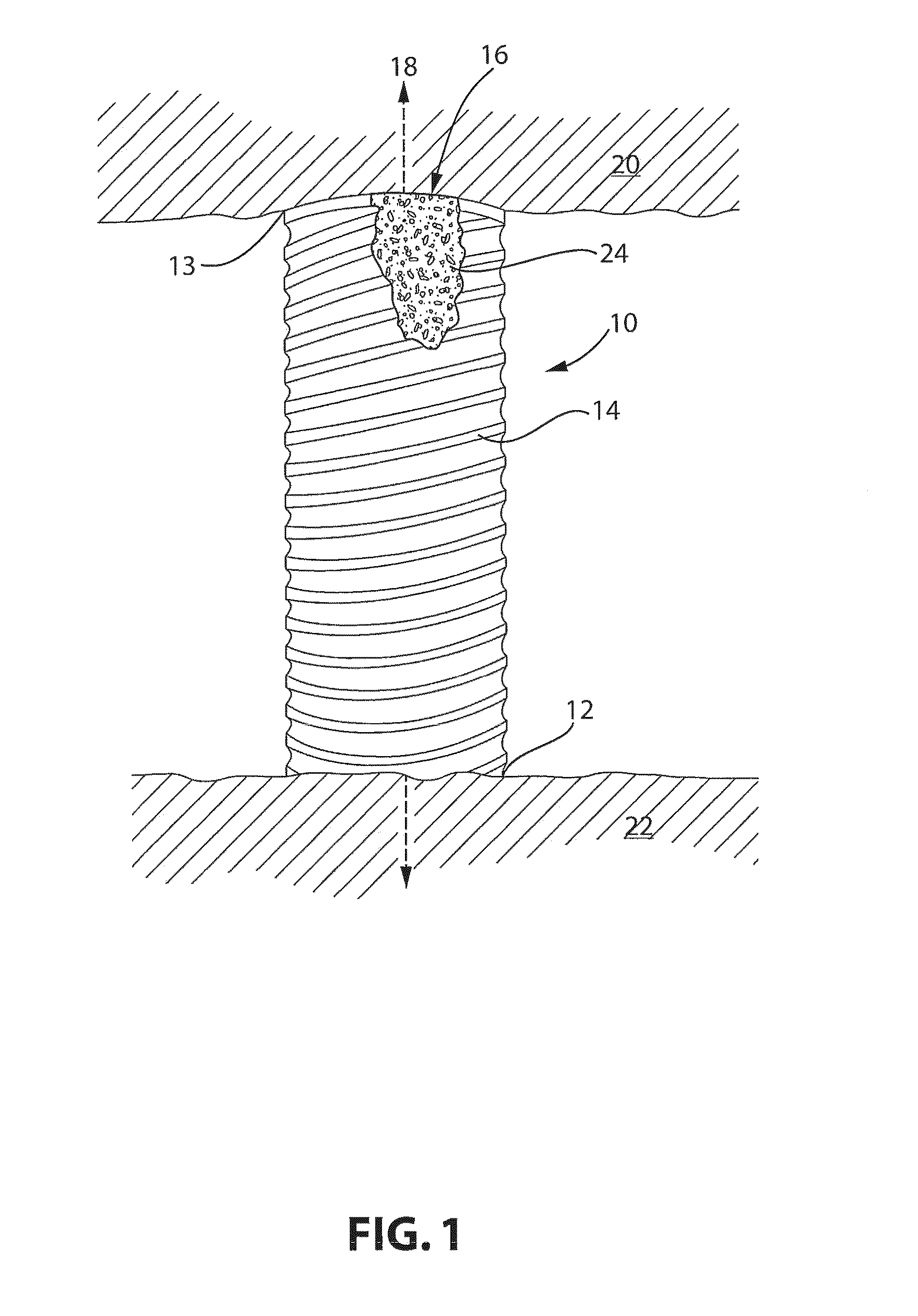

[0021]FIG. 1 shows one embodiment of such a container 10. The container has a bottom end 12, a top end 13, and a sidewall 14 extending from the bottom end 12 to the top end 13. The bottom end 12 and / or the top end 13 may be substantially open or may be covered by an end cap (not shown). The sidewall 14 defines a cavity 16.

[0022]In use, the container is placed with its longitudinal axis 18 extending between a mine roof 20 and a mine floor 22 such that the bottom end 12 of the container 10 is in contact with the mine floor 22. The cavity 16 is then filled with a load-bearing material 24. In one embodiment of the invention, the load-bearing material 24 is particulate and flowable which provides effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com