Double-track tunnel provided with vertical shaft smoke discharge and ventilation combined and complemented system

A dual-track tunnel and tunnel technology, which is applied to mine/tunnel ventilation, tunnel, and shaft equipment, etc., can solve problems such as unfavorable tunnel operation safety, long paths, and inability to use smoke exhaust, so as to reduce tunnel energy consumption and reduce openings. , reduce the effect of energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

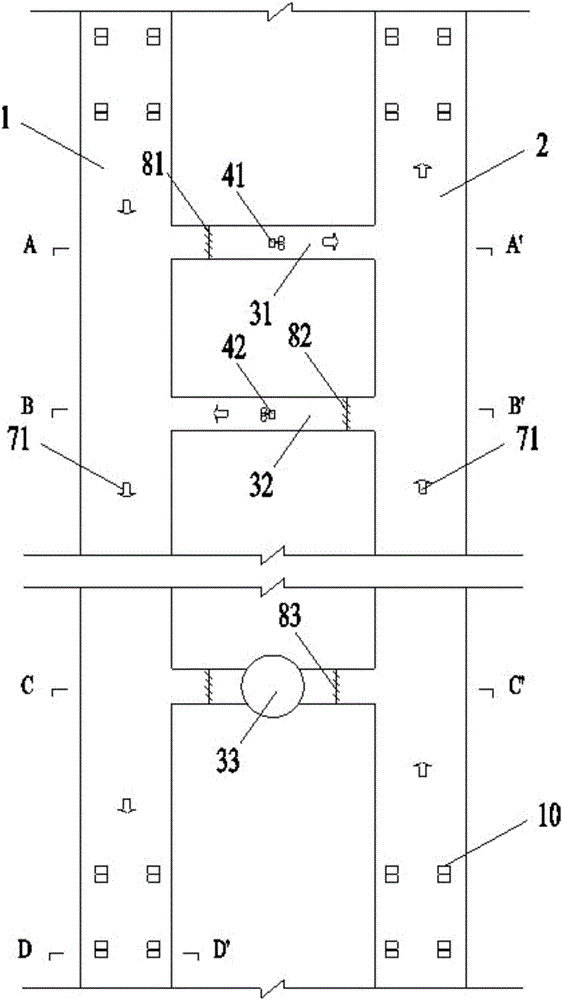

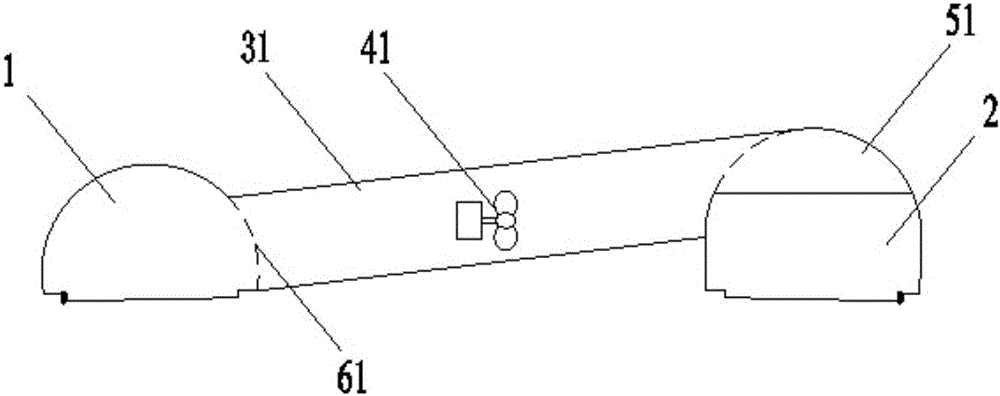

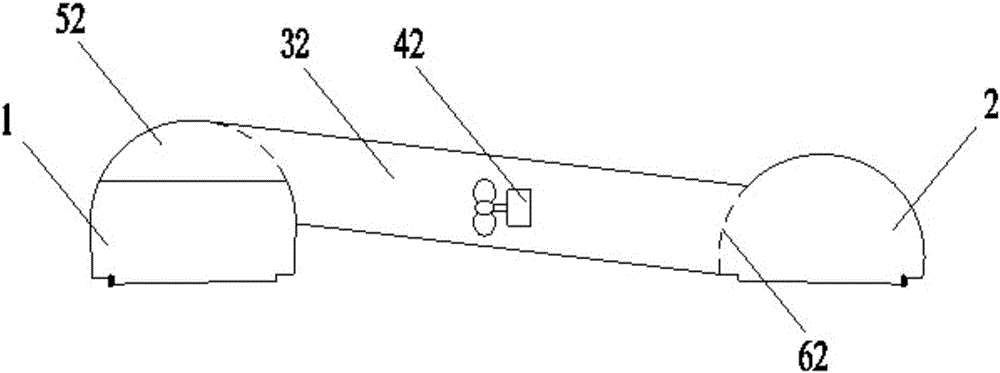

[0021] In order to describe the present invention more specifically, the technical solution of the present invention will be described in detail below by taking a 5-7 km two-lane highway tunnel as an example in conjunction with the accompanying drawings and specific implementation methods.

[0022] First, calculate and analyze the air volume required for the uplink and downlink tunnels, considering the following working conditions: ① normal operating conditions, that is, the speed of the uplink and downlink tunnels is the design speed; In the case of traffic, the speed of the working condition is 30-50km / h; ③The blockage condition, the traffic in a certain tunnel is blocked for some reason, the speed of the vehicle in the working condition is 10km / h, and the length of the blockage section is 1km; ④The fire condition, according to the critical speed It is required to determine the exhaust air volume. The required air volume calculation shall be carried out in accordance with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com