Integral line stabilizing technique for vertical pit construction

A line-stabilizing and overall technology, applied in vertical shaft equipment, mining equipment, earthwork drilling and mining, etc., can solve problems such as loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

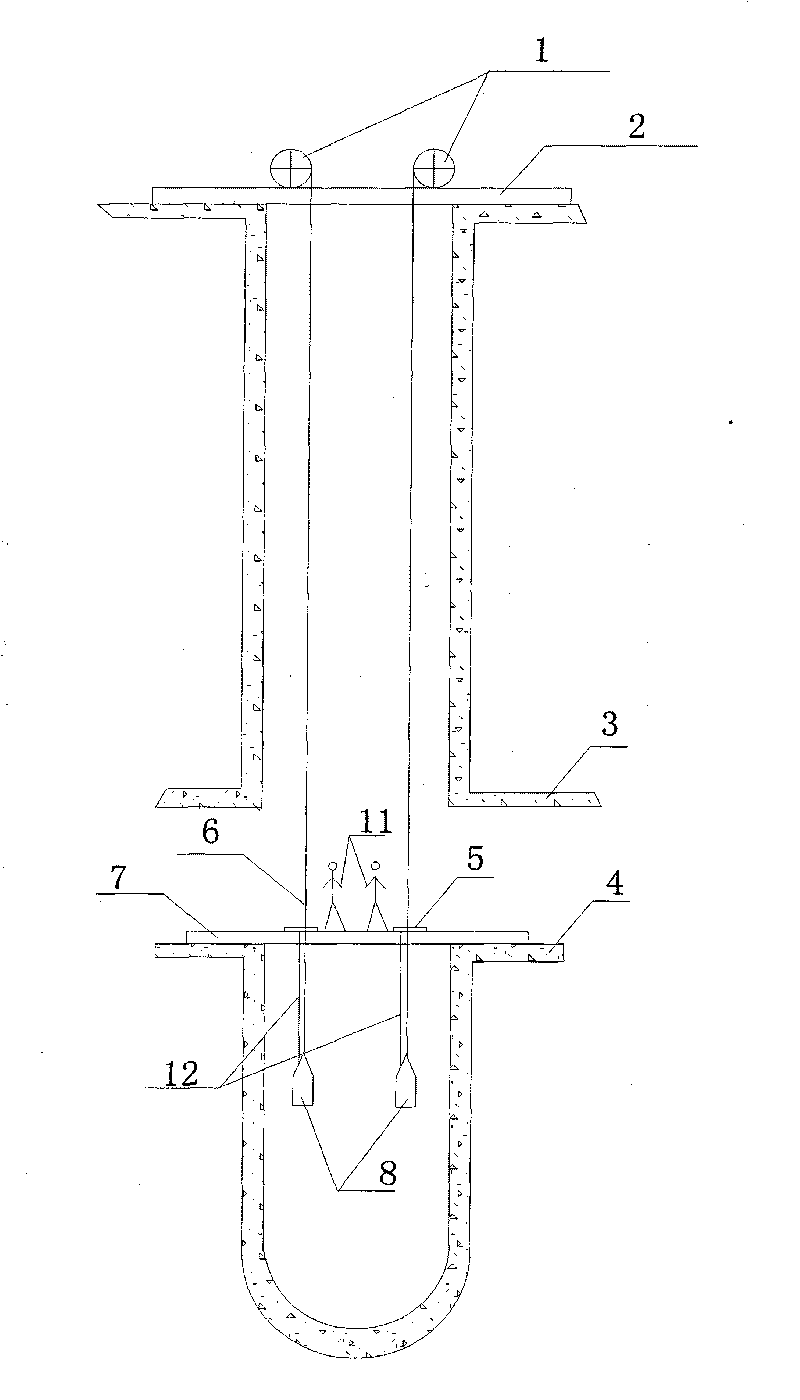

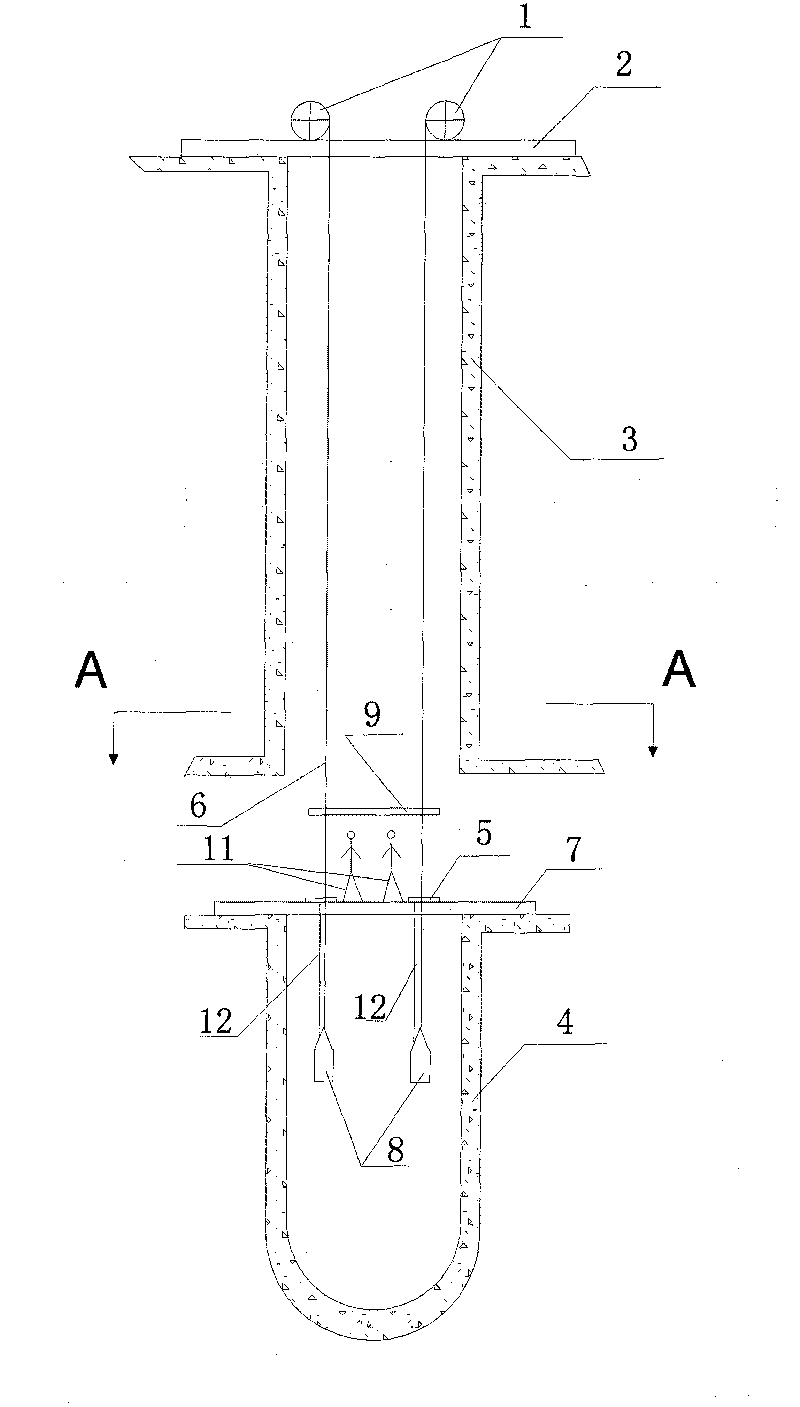

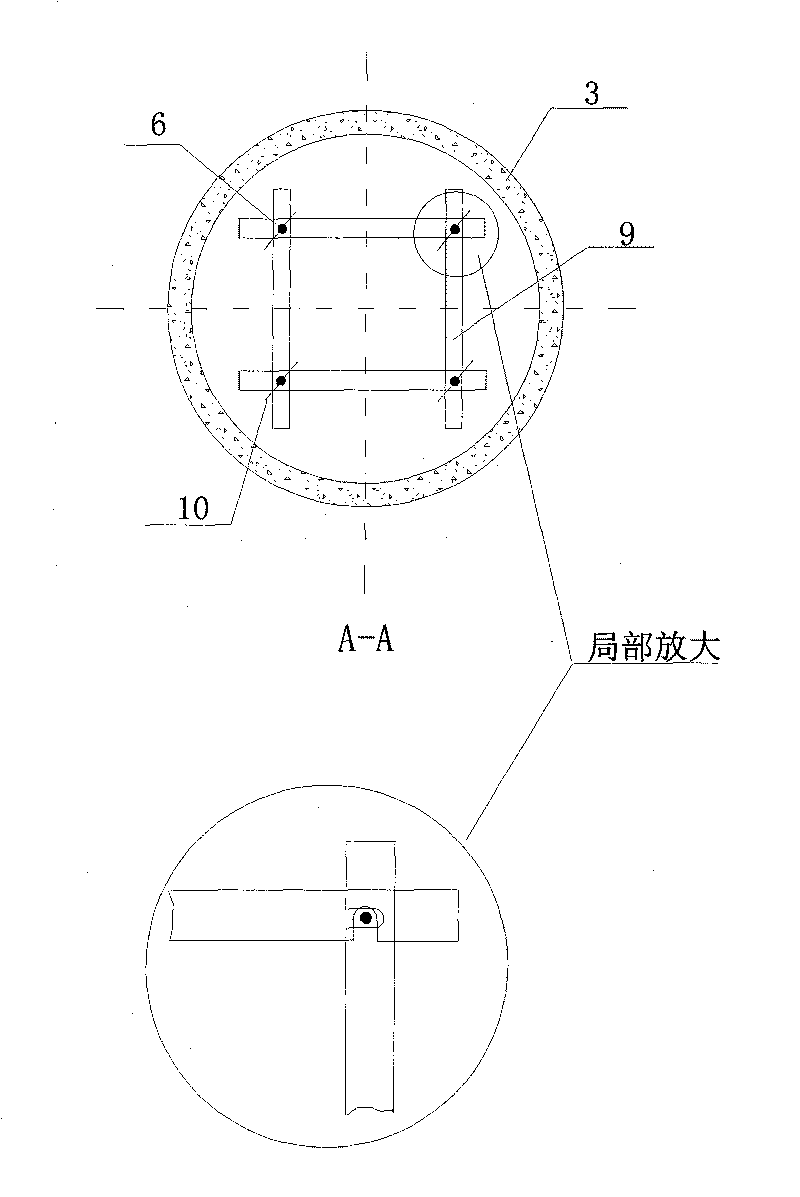

[0018] 1. First, calculate the side length of the quadrilateral according to the large line point layout diagram of the construction measures (if there are more than 4 large lines, calculate the side length of the polygon), and according to the size of the side length, select 2″~2(1 / 2) "Steel pipes are sawn into gaps according to the position of the large line point, which is used as the positioning size of two adjacent large lines. Stable line steel pipe (9) diameter size is principle with not producing obvious bending.

[0019] 2. The operator brings the line-stabilizing steel pipe (9) into the lower wellhead (4), hangs a heavy hammer (8) under the large line (6), and connects the large line with the line-stabilizing steel pipe (9) with a saw cut Integral polygon, the corner point of polygon is bound with 22# thin iron wire (10) adjacent two stable line steel pipes (9) and large wire (6) and is fixed together.

[0020] 3. After the overall stability of the large line (6), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com