Ultra-deep support-free locking notch ring beam in sea areas

A technology without supports and locks, which is applied in shaft equipment, excavation, mining equipment, etc. It can solve the problems of small section, shallow depth, and waterproof design that cannot meet the waterproof requirements of coastal areas, so as to achieve deep excavation depth and meet the construction area. , the effect of resisting the erosion of seawater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

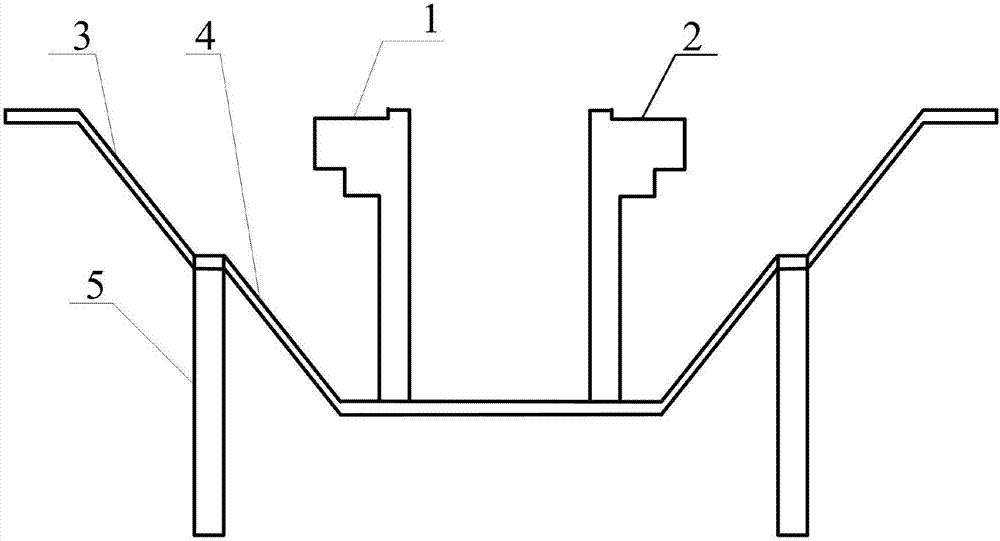

[0027] An embodiment of the present invention provides an ultra-deep unsupported lock ring beam in sea areas, including: a first support body, a second support body, a first lock ring beam 1 and a second lock ring beam 2;

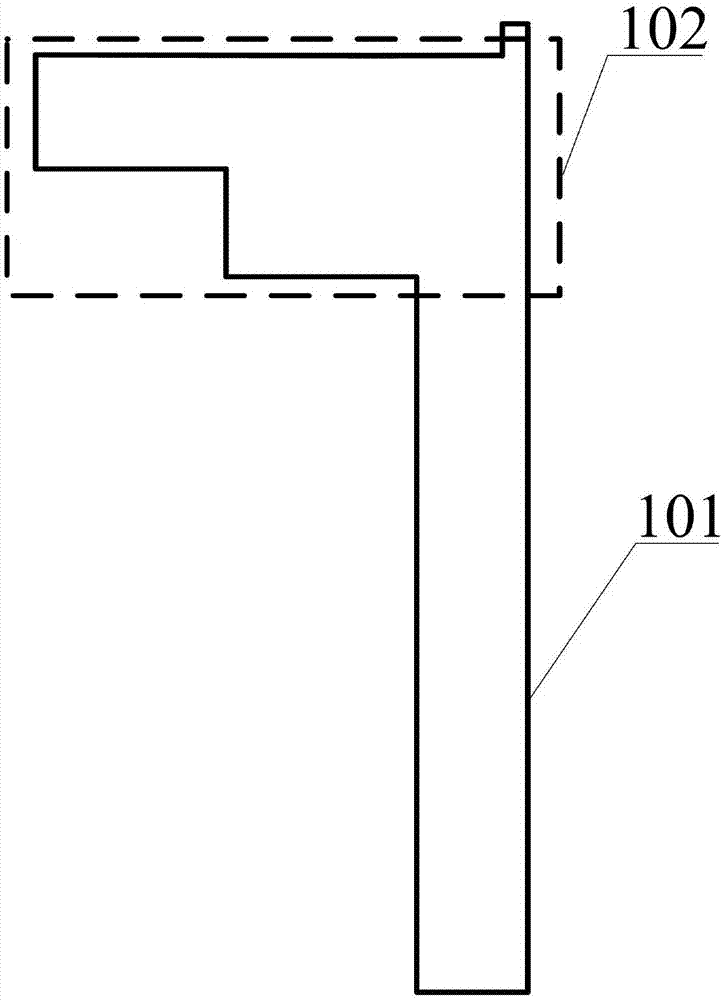

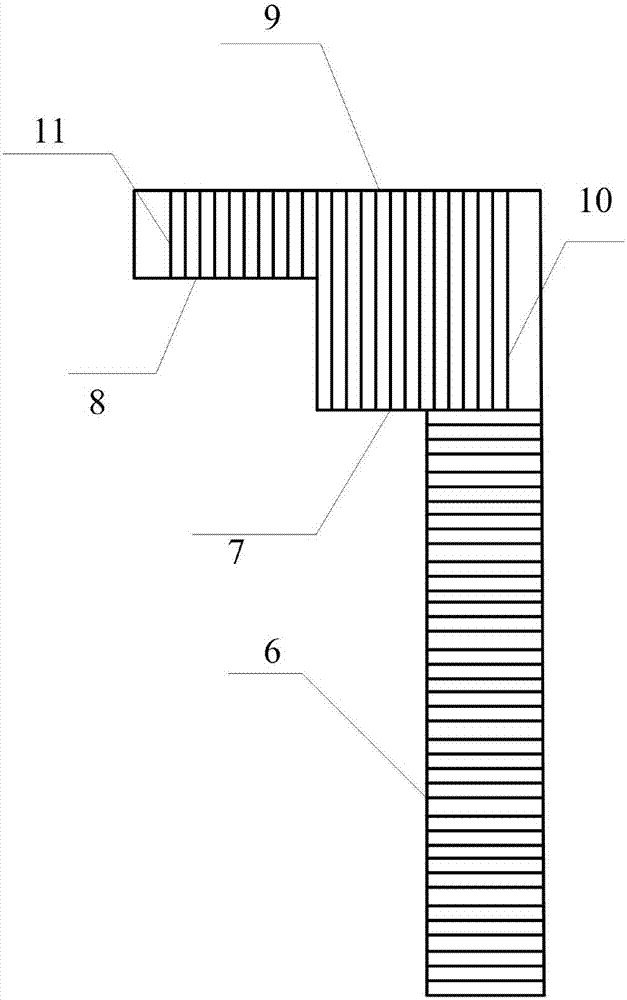

[0028] The first support body includes a first side slope 3, a second side slope 4 and a double-layer jet grouting pile 5, and a double-layer jet grouting pile 5 is passed between the first side slope 3 and the second side slope 4 connected support, and both the first side slope 3 and the second side slope 4 adopt side slope support; the first support body and the second support body are arranged symmetrically, and the first lock ring beam 1 and the second lock ring beam 2 are arranged between the first support body and the second support body, and the position of the first lock ring beam 1 is adjacent to the first support body , the second lock ring beam 2 is adjacent to the position of the second support body; the first lock ring beam 1 includes a lock ri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com