Trenchless directional drilling construction method for pipeline burying channel

A technology of directional drilling and construction methods, applied in directional drilling, pipeline laying and maintenance, drilling equipment and methods, etc., can solve problems such as traffic congestion, many construction technical procedures, road surface damage, etc., to reduce waste and reduce construction Technical process, the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

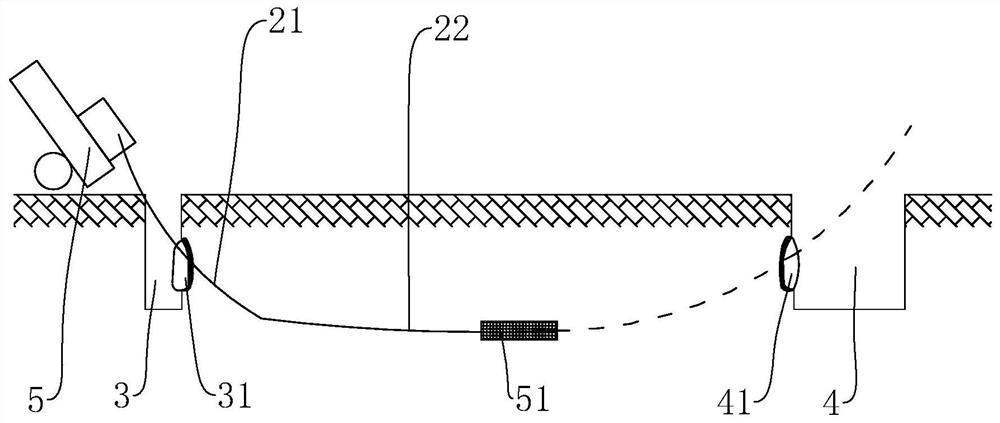

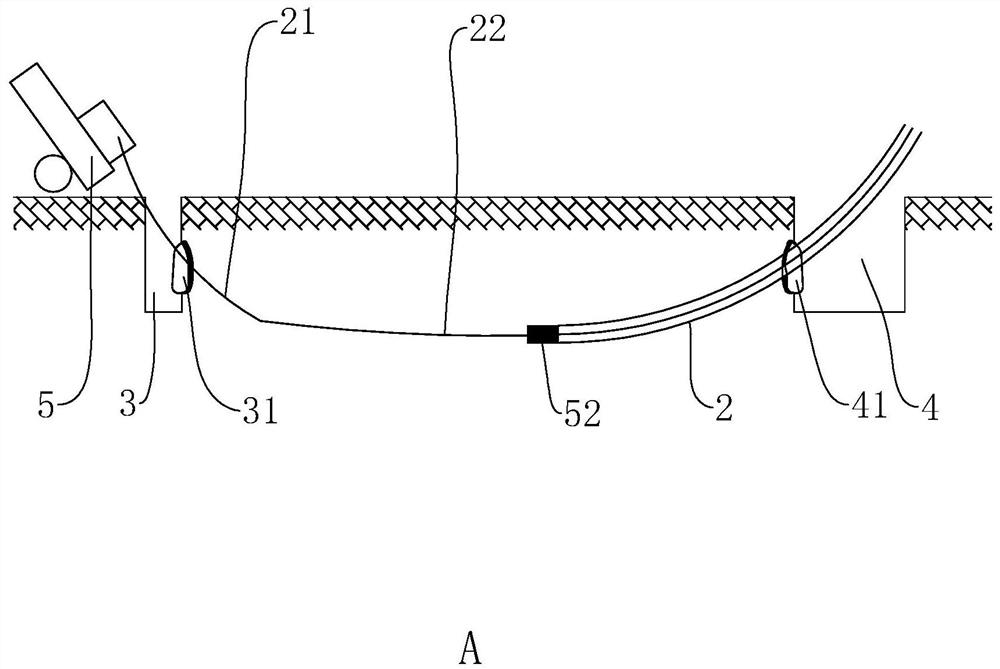

[0043] The following is attached Figure 1-6 The application is described in further detail.

[0044] The embodiment of the application combines specific construction cases to disclose a non-excavation directional drilling construction method for pipeline buried channels, which is suitable for municipal sewage pipe network construction projects, especially for municipal municipalities in township areas with dense building groups and large traffic. Pipe network construction. A certain sewage treatment plant and pipe network project is selected as a rainstorm-prone area, surrounded by mountains on three sides in a fan-shaped structure, low-lying in the middle, and facing the sea outside. The geological conditions of the project location are complicated. Refer to figure 1 , the specific construction method includes the following steps:

[0045] Step 1. Construction preparation:

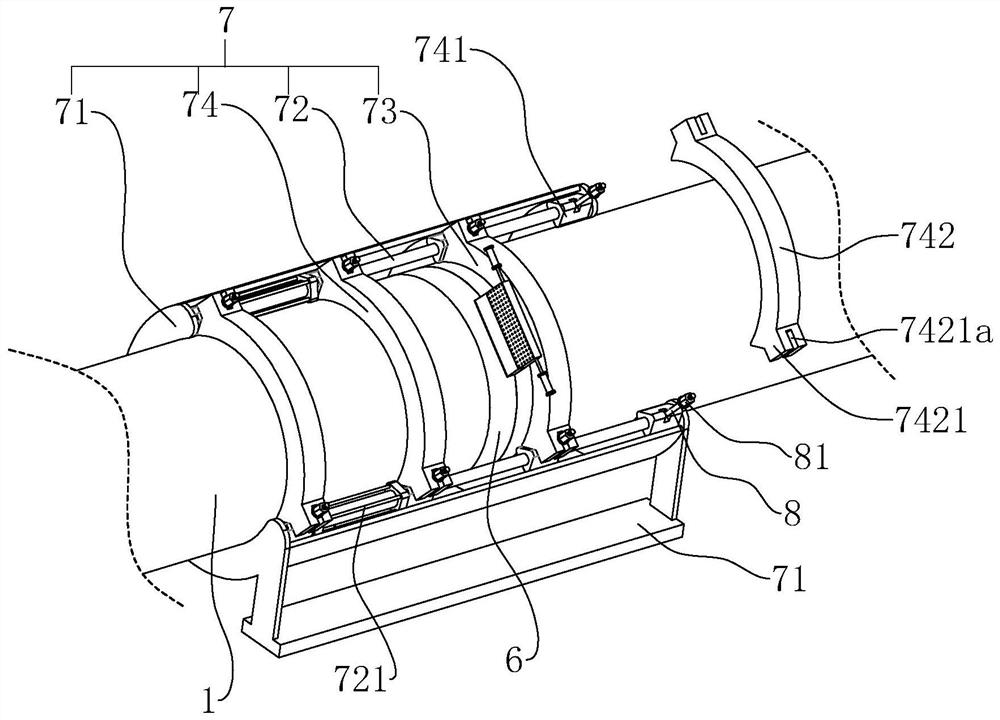

[0046] 1.1 Choose PE solid-wall pipe 1 that is resistant to external pressure, good flexibility, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com