Suck throughpreventionsmoke exhausting auxiliary device of a tunnel shaft

An auxiliary device and tunnel technology, applied in shaft equipment, mine/tunnel ventilation, mining equipment, etc., can solve problems such as the decline of the smoke exhaust effect of the shaft, and achieve the effect of improving the effect and ensuring the safety of life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

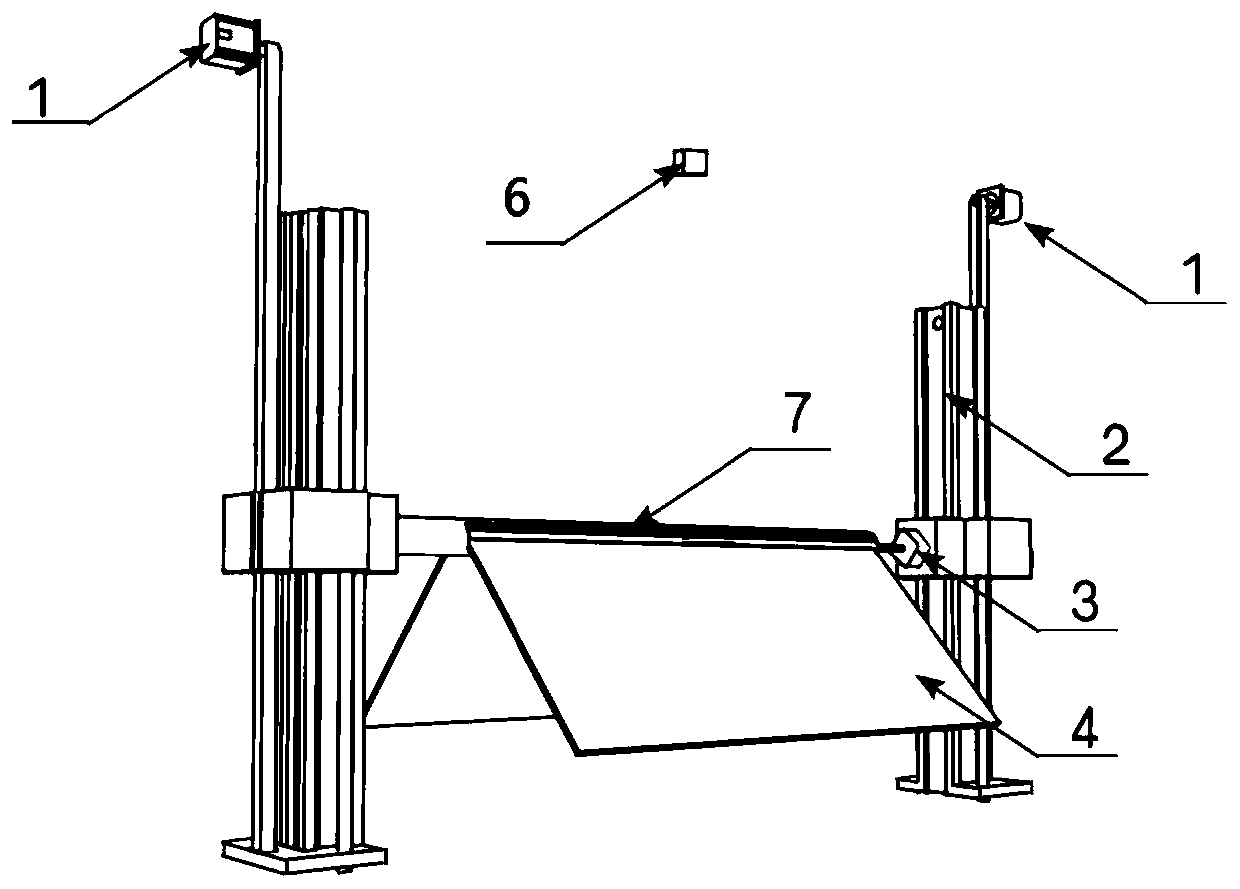

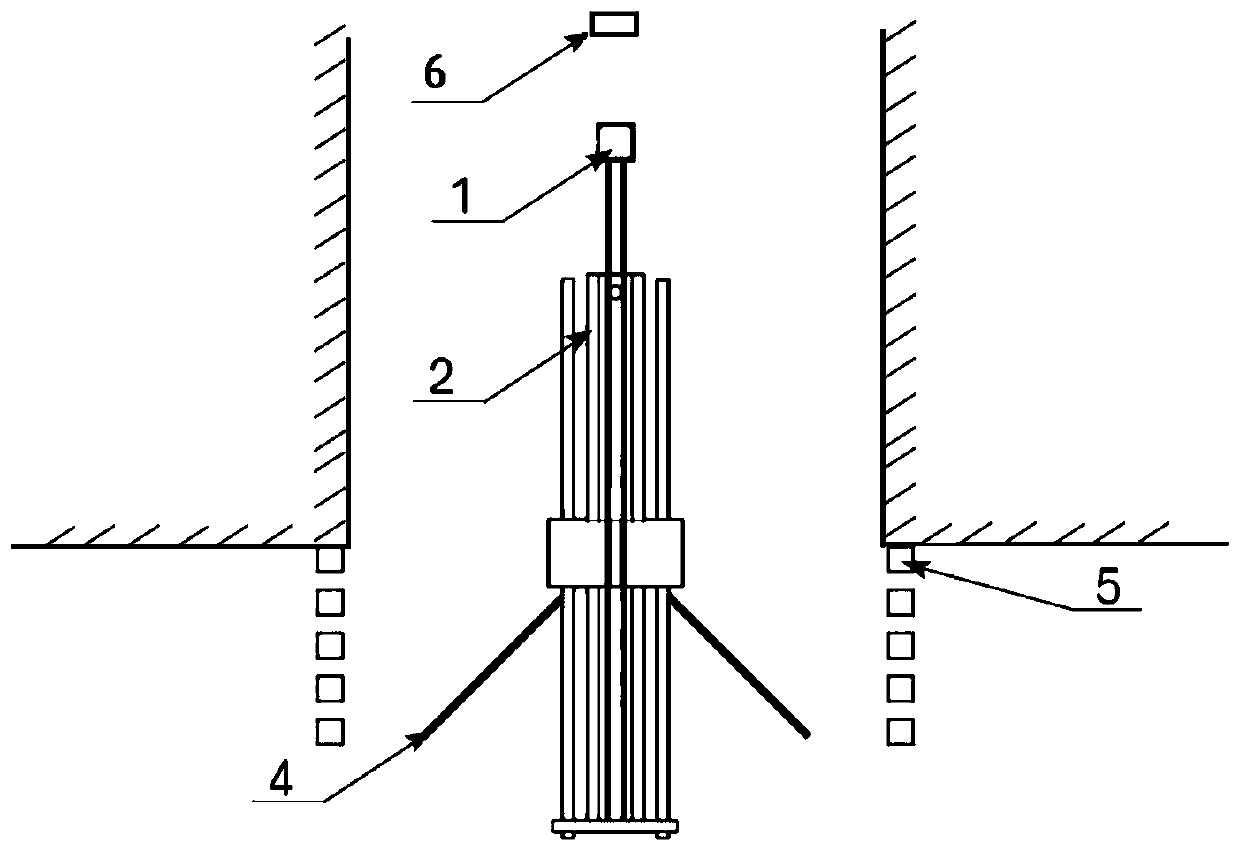

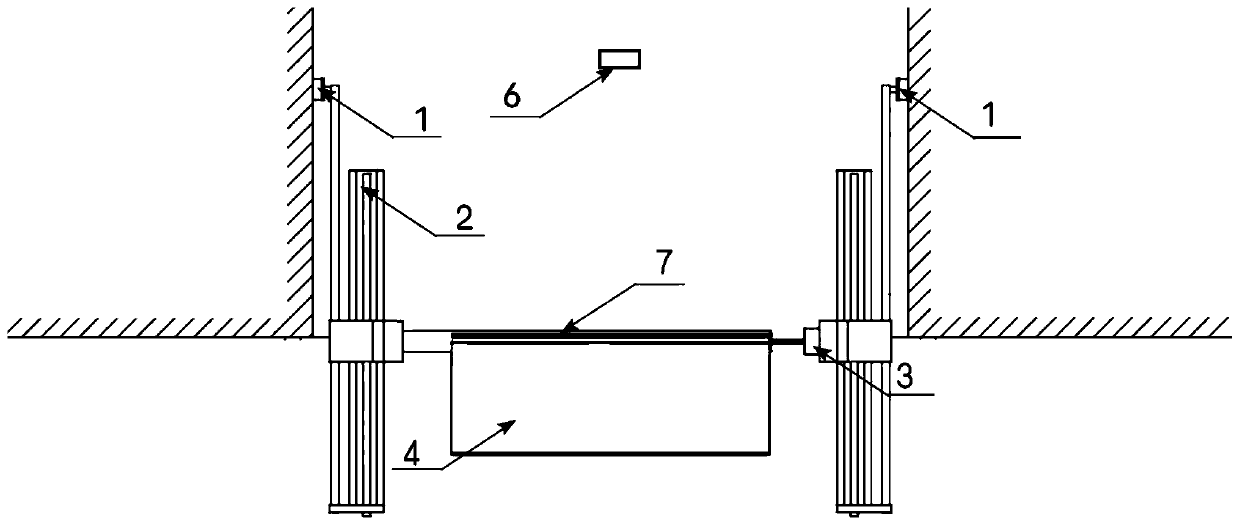

[0026] An auxiliary device for anti-sucking and exhausting smoke in a tunnel shaft, characterized in that: the auxiliary device for preventing inhalation and exhausting the tunnel shaft includes a conical baffle, the conical baffle is arranged at the bottom opening of the tunnel shaft, and the conical baffle is formed by Two adjustment plates 4 are formed, and the two adjustment plates 4 are assembled in a "herringbone" shape, and the opening of the herringbone is arranged downward. By adding a conical baffle under the shaft, the air inhalation problem of natural smoke exhaust from the shaft can be suppressed. In terms of safety, adding a conical baffle to the tunnel ceiling for the shaft smoke exhaust will not affect the overall structure of the tunnel, and Under normal circumstances, it does not affect the normal progress of tunnel traffic; changing the angle and height of the conical plate according to the temperature ensures that the smoke exhaust efficiency of the tunnel s...

Embodiment 2

[0039] The above-mentioned auxiliary device for anti-sucking and exhausting smoke in a tunnel shaft can use the following control method: the flue gas temperature sensing probe can be arranged at the top of the conical baffle and the bottom of both sides, and the temperature threshold T can be set. c , when the temperature at the top of the conical baffle is greater than T c , the conical baffle descends until the temperature measured by the flue gas temperature sensing probe is lower than T c stop. When the temperature at the top of the conical baffle is lower than T c , the conical baffle lifts up until the temperature measured by the flue gas temperature sensing probe is higher than T c stop. When the temperature at the bottom of both sides of the conical baffle is greater than T c , the two splints of the conical baffle are closed inward, and the angle θ between the splints decreases until the temperature measured by the flue gas temperature sensing probe is lower than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com