Ultra-deep vertical shaft guide steel cable tensioning device and tensioning method

A technology of tensioning device and wire rope, which is used in vertical shaft equipment, earth-moving drilling, transportation and packaging, etc., can solve the problem that the tensioning device cannot meet the existing and future needs, the heavy hammer is easy to fall into the bottom hole, hydraulic pressure To solve problems such as large size of the station, to achieve the effect of wide practicability, reliable performance, and reduced requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with the accompanying drawings.

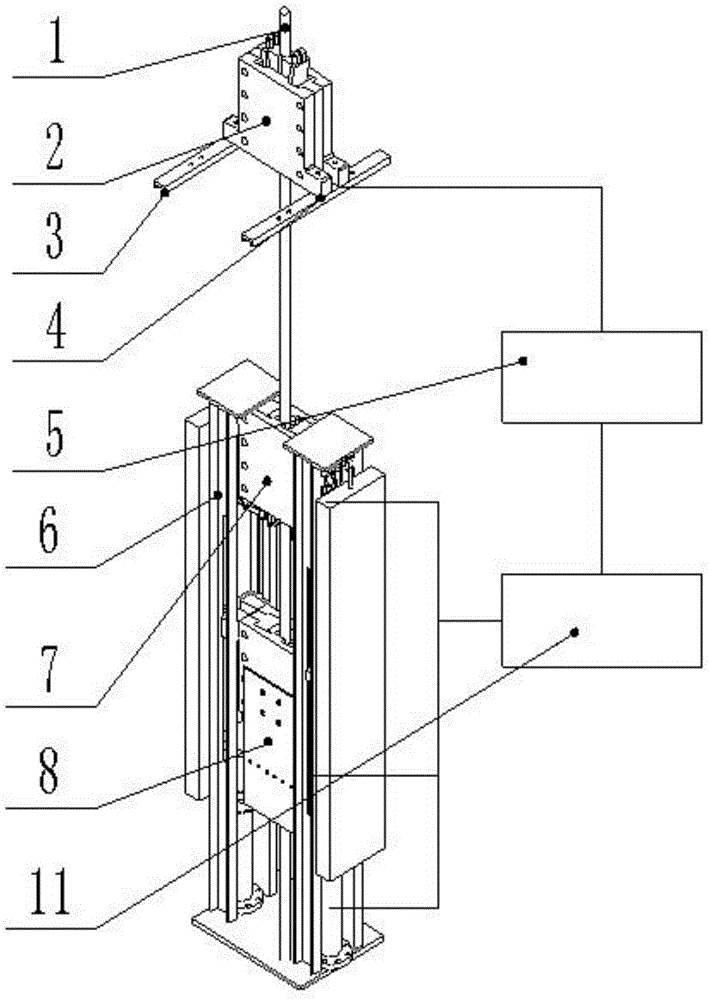

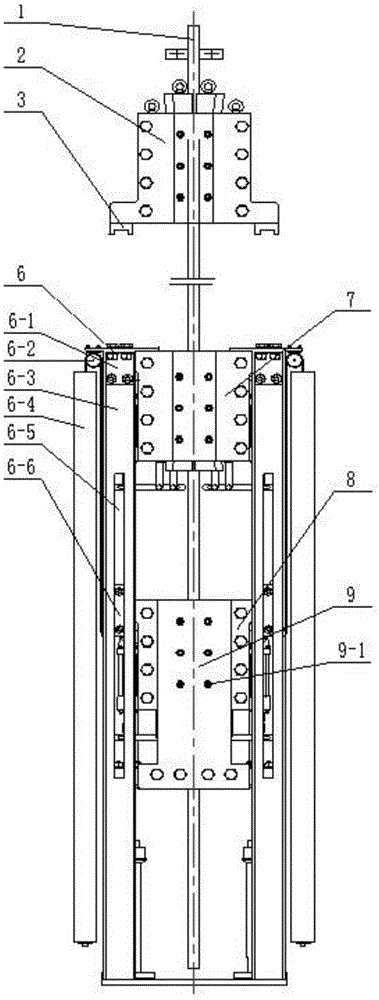

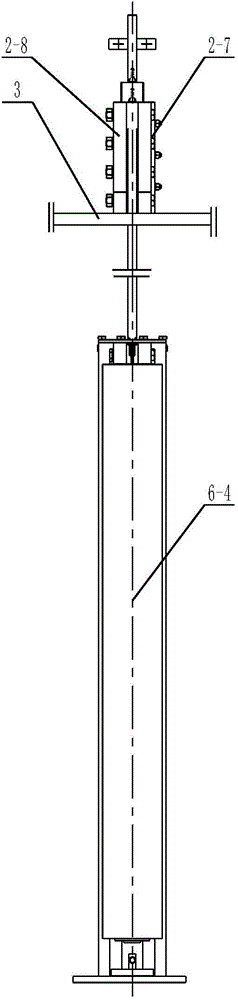

[0021] like Figures 1 to 4 As shown, a steel wire rope tensioning device for an ultra-deep shaft tank road of the present invention includes an upper rope clamping device 2 , a rope adjusting guide frame 6 , a lower hydraulic rope locking device 7 and a lower hydraulic rope adjusting device 8 .

[0022] The upper clamping rope device 2 is fixed on the sky wheel derrick 3 through a symmetrical bolt group 2-5, the upper part of the upper clamping rope device 2 is equipped with a rope clamp 2-1, and the bottom of the upper clamping rope device 2 is provided with a pressure sensor 4, The pressure sensor 4 is connected to the console 5 through a wireless signal transmitting module, and transmits the pressure signal to the console 5 . The rope adjustment guide frame 6 includes a steel frame body 6-3, the upper part of the steel frame body 6-3 is welded with a fixed double ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com