Routine inspection device and method for rigid cage guides

一种罐道、刚性的技术,应用在刚性罐道巡检装置领域,能够解决刚罐道安装位置不能保证等距、刚罐道变形等问题,达到避免人工作业误差、安全可靠吸附、提高检测速度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further explained below in conjunction with the accompanying drawings.

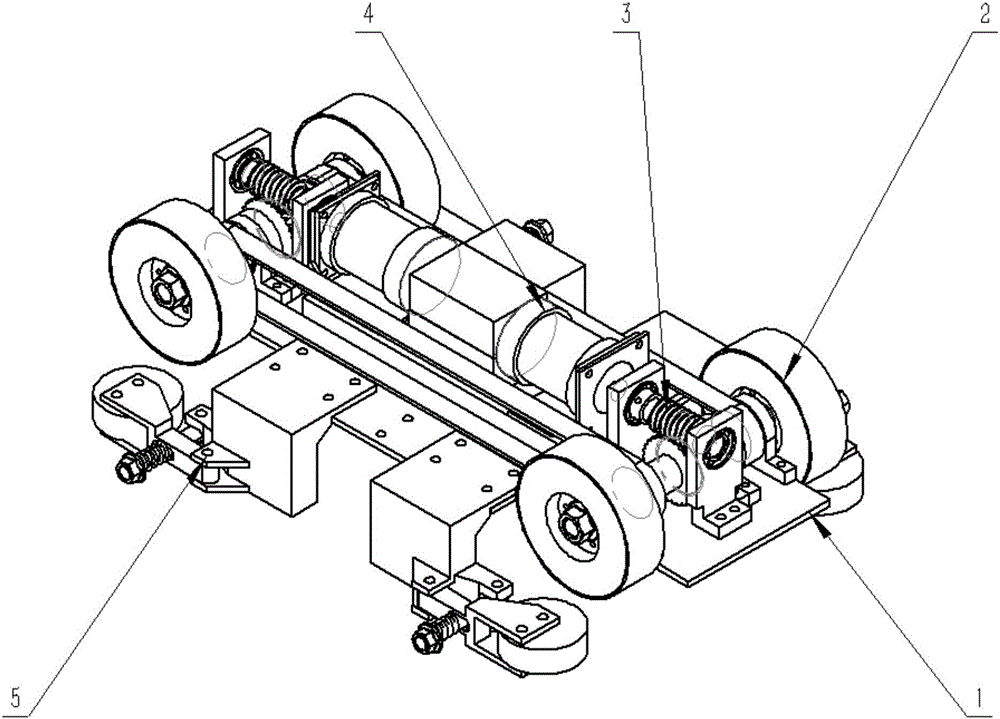

[0051] like figure 1 As shown, a rigid tank road inspection device of the present invention includes a main body bottom plate 1 and a moving part 2 , a transmission part 3 , a driving part 4 , a guide part 5 and a casing 6 arranged on the main body bottom plate 1 .

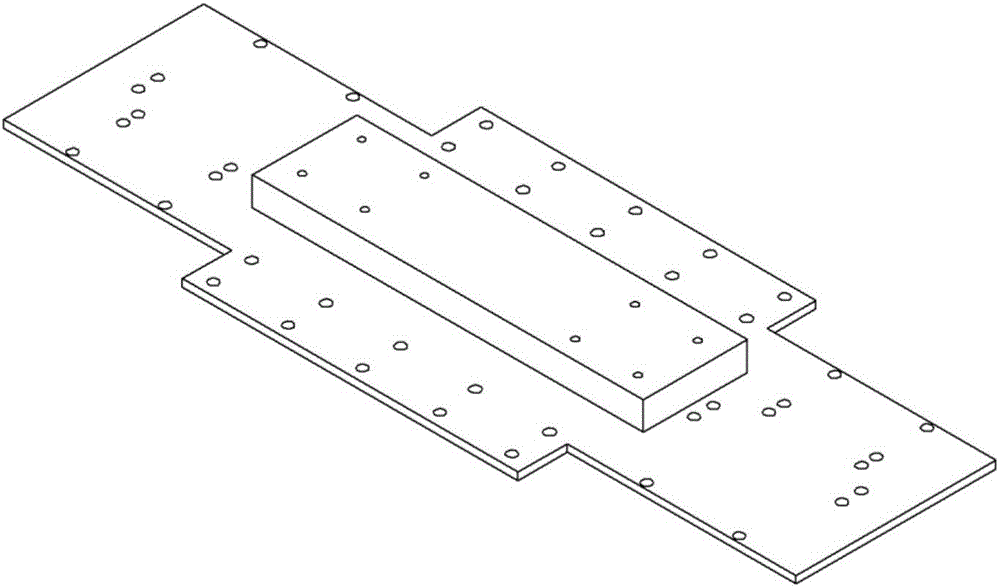

[0052] like figure 2 As shown, a number of assembly holes are opened on the main body bottom plate 1 for realizing bolt connection between various components.

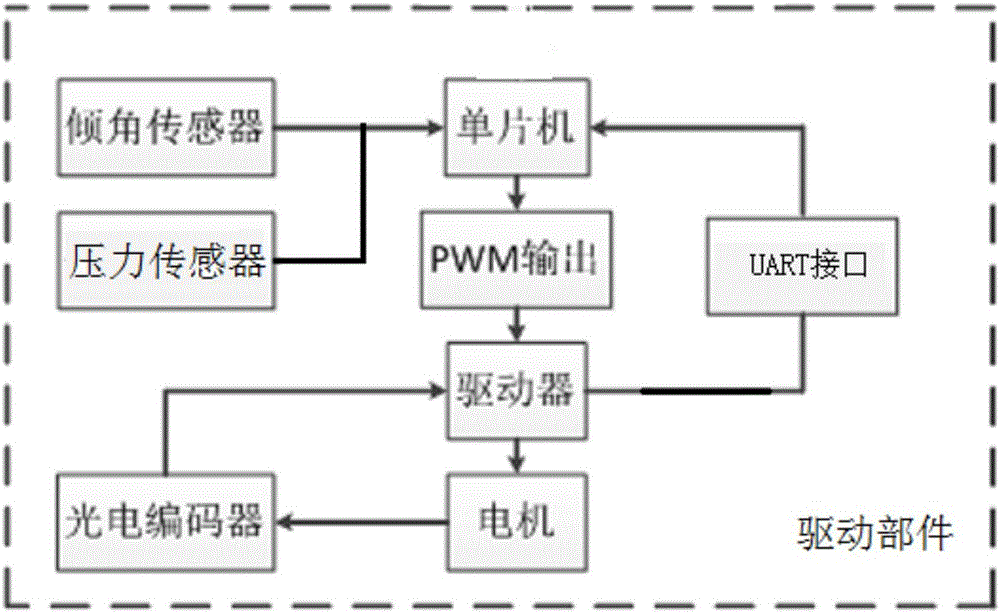

[0053] like image 3 and 4 As shown, the housing 6 is arranged in the middle of the main body bottom plate 1, and the driving part 4 is arranged inside the housing 6. The driving part 4 includes an inclination sensor and a pressure sensor, and the inclination sensor and the pressure sensor are connected to the single-chip microcomputer, and the single-chip microcomputer is connected to the driver 4-3, and the driver 4- 3 Connect the DC brushle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com